Manual_for_QCRF4Photo

advertisement

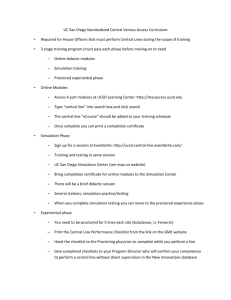

Photovoltaics QCRF-FDTD Simulator Manual 1.1 10/8/2015 Jacob Duritsch, Haejun Chung, Peter Bermel Overall Information The Photovoltaics QCRF-FDTD simulation tool is designed to simulate user-defined solar cells through the means use of Finite Difference Time Domain and Quadratic Complex Rational Function methods. The tool allows for a wide range of inputs and customizable features that will be discussed in greater detail down below. The Finite Difference Time Domain method is used for simulation for a variety of reasons [1-4]. By utilizing this method, a single simulation run is required to gain the frequency response for a given range (for this simulation, the range is 400 to 1100 nm wavelengths). Another feature gained by using this method is the accuracy (or definition) of small objects within the simulation area. This is required for simulating photovoltaic layer texturing that have fine peaks and features. However, a major drawback of this method is the time required to complete a single run. While smaller grid size or lower dimensions provide reasonable simulation time, larger grids defined as three-dimensional can take hours upon days. The Quadratic Complex Rational Function [3-4] is used to model dispersive materials. Studies [3-4] have shown that this method for modeling dispersive materials is more accurate for photovoltaic materials compared to the Lorentz, Drude, or Debye models(add reference). The models uses a five-coefficient equation to model materials as a function of wavelength: 𝜀𝑟 (𝜔) = 𝐴0 + 𝐴1 (𝑗𝜔) + 𝐴2 (𝑗𝜔)2 1 + 𝐵1 (𝑗𝜔) + 𝐵2 (𝑗𝜔)2 Where A0, A1, A2, B1, and B2 are found through experimental data. With this model being relatively new, defined coefficients are limited which proves to be the only major drawback of using the QCRF model. In addition to dispersive materials, non-dispersive materials are easily modeled with the commonly-found refractive index and K values. Assumptions: Calculating the Jsc, Voc, FF, and efficiency can change between simulations. Therefore, the method that this simulation uses is presented below to inform the user. First, the Jsc, Voc, and ideality factor (n) is collected through measurement data. Using this information from the measurement data, Jsc and Jdark are calculated using: 𝜆1 𝐽𝑠𝑐 = ∫ 𝐴𝑀1.5(𝜆) ∗ 𝐴(𝜆) ∗ 𝐼𝑄𝐸(𝜆) ∗ 𝜆2 𝐽𝑑𝑎𝑟𝑘 = 𝐽𝑠𝑐 exp (− 𝑞𝑉𝑜𝑐 ). 𝑛𝑘𝑇 𝑒∗𝜆 𝑑𝜆. ℎ𝑐 Using the simulated Jsc and measured Jdark, Voc and Zoc is calculated using: 𝑉𝑜𝑐 = 𝑛𝑘𝑇 𝐽𝑠𝑐 ln ( ) 𝑞 𝐽𝑑𝑎𝑟𝑘 And 𝑍𝑜𝑐 = 𝑉𝑜𝑐1 𝑉𝑜𝑐2 + 𝑛𝐾𝑇 𝑛𝑘𝑇 𝑞 𝑞 [5]. Using Zoc, the fill factor can be calculated: 𝐹𝐹 = 𝑍𝑜𝑐 − ln(𝑍𝑜𝑐 + 0.72) [5]. 𝑍𝑜𝑐 + 1 Using the Voc, the Isc, FF, and input power, the overall efficiency of the photovoltaic cell can be calculated: 𝐸𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 = 𝑉𝑜𝑐 𝐼𝑠𝑐 𝐹𝐹 . 𝑃𝑖𝑛 Comparison with S4 To determine accuracy of the results within this simulator, the results are compared with results from S4 for a given structured. Below are different structures’ results with this simulator being on the right and S4 being in the left. 300 nm dielectric slab of c- Si 300 nm of c-Si / 100 nm of a-Si 300 nm dielectric slab of silver Within the overlapping wavelengths of the two simulators, the only major difference are the dips in of absorption for silver. Reasoning behind this is differences in measurements of silver samples between the separate simulations’ groups. Introduction Page The welcome page serves to provide the user with basic information about how the simulation to decrease the need to refer to a separate manual. It details what is to be expected out of the GUI, which includes the absorption, reflection, and transmission curves along with the shortcircuit current density (Jsc), open-circuit voltage (Voc), the fill factor (FF), efficiency, and a two/three-dimensional mesh of the randomly generated surface. Simulation Options Page The simulation options page is the first page that allows for user input to customize the photovoltaic cell. The first option, denoted as “Simulation Option” allows the user to define whether a single junction or tandem junction photovoltaic cell will be created. By selecting the single junction, the program will expect the user to enter a photovoltaic cell with only one active junction. Tandem junctions currently allow the user to enter two active junctions. The next feature is the ability to select simulation in one, two, or three dimensions. This keeps the trade-offs in the user’s control. Three dimension simulation will provide the most accurate results while one dimension will provide a quicker simulation time and two dimensions is somewhere in between. As a higher dimension is selected, more of the grayed cell sizes on a future page will become available. Note: When one-dimension simulation is selected, texturing features for individual layers are removed due to simulation constraints. Next is the options to enter the x-grid size and y-grid size. These items are grayed out dependent on the value chosen for the dimensions. Two-dimensions incorporates the x-grid and three-dimensions includes both the x-grid and the y-grid. Finally is a set of tabs that allows the user to define the thickness and material properties of the layers. The number of tabs is dependent on “Simulation Options”. There will be a tab for each individual layer where single junction provides four tabs and tandem junction provides eight tabs. Each tab has a pre-defined modeling for the material (refractive index or Quadratic Complex Rational Function). Active absorbing materials and metallic reflectors are represented with the QCRF modeling while the front coating, anti-reflection material, and transparent conductive oxide (TCO) are represented with a refractive index. In each tab, the first prompted input is for the base thickness of the layer (subjected to change slightly with texturing turned on). For nondispersive materials, input are available for the refractive index and K value. For QCRF modeling, the five coefficients of the QCRF model equation become available for input (A 0, A1, A2, B1, and B2). Above the inputs for the QCRF coefficients or the non-dispersive inputs is a simple drop-down menu with pre-defined materials available. The first option for both situations is denoted as “user-defined” which gives the user to enter their personal inputs for the selected layer. However, the other options will gray-out (prevent) the user from entering their own inputs and use a pre-defined material that is stored within the background code. For QCRF modelling, predefined materials include crystalline silicon, doped crystalline silicon, amorphous silicon, silver, and non-abs silver. For non-dispersive materials, pre-defined materials include air, zinc oxide, silicon dioxide (glass), and Indium Tin Oxide. Texturing Parameters Page The primary focus of the texturing parameters page is to focus on the necessary inputs to adjust randomly correlated texture surfaces. Reasoning for including texturing capabilities is to allow user to determine light-trapping abilities of photovoltaic cells when a roughed surface is applied. The first of two options is the correlation factor. The user has the ability to enter a number on the range from zero to negative infinity. As the number approaches negative infinity, the surface will become increasingly flatter (smoother). Likewise, as the number approaches zero, the surface becomes increasingly “roughed” and random. The equation that creates the randomly generated surface requires a correlation factor of zero to one where zero is random and one is flat. To convert the scale presented to the user to the scale used by the equation, a separate equation is used: 𝑓 = 1 − 10(𝑐𝑜𝑟𝑟𝑒𝑙𝑎𝑡𝑖𝑜𝑛 𝑓𝑎𝑐𝑡𝑜𝑟) . This provides and exponential relationship between the user-defined correlation factor and the factor used by the simulation. The equation that defines the surface is randomly correlated double-sided surface function shown below: 𝑍𝑛+1 = 𝑤(𝑛, 𝑁) ∗ 𝑍𝑛 + (𝑓 − 𝑤(𝑛, 𝑁)) ∗ 𝑍𝑁−𝑛−1 + (1 + 𝑓 2 )0.5 ∗ 𝑟𝑛 , Where N is the maximum index of the 1-D structure and w() denotes a one dimensional weighting function: 𝑤(𝑛, 𝑁) = 𝑓 − 𝑓 ∗ 𝑒 −(𝑁−2∗𝑛+2) . 2 This function creates an array of grid size i x j points with values at each location being the height of the structure. With this information, the simulation is able to create the designated surface on the individual layers of the photovoltaic cell with the purpose to increase light trapping abilities. Besides the correlation factor, there is an option to control the aspect ratio which limits the depth that the randomly correlated surface will affect the individual layers. An aspect ratio of 1 gives the maximum texturing height of 1*periodicity of the cell. At 0, the texturing height would be zero. The periodicity is based upon the inputs for the x-grid and y-grid. The overall function of texturing height is as follow: 𝑇𝑒𝑥𝑡𝑢𝑟𝑒 𝐻𝑒𝑖𝑔ℎ𝑡 = 𝐴𝑠𝑝𝑒𝑐𝑡 𝑅𝑎𝑡𝑖𝑜 ∗ 𝑃𝑒𝑟𝑖𝑜𝑑𝑖𝑐𝑖𝑡𝑦. Simulate Page Simulation time can take between a minute to a couple days dependent on the features that the user selected. Once simulation is complete, the finished page will look as depicted above. There will be a drop down menu to view the different outputs of the simulation with the default output being a set of curves. The set of curves will display the amount (percentage) of the waves at each wavelength that was either absorbed, transmitted, or reflected due to the photovoltaic cell. These curves demonstrate the optical performance of the photovoltaic cell and is useful for analyzing and creating new cells. There are two options for the curves: one that displays a single absorption curve for the single junction cell and one that displays two curves of absorption for the tandem junction cell. One curve represents the upper cell absorption and the other represents the bottom cell absorption. Four addition outputs that are numbers include the Jsc, Voc, FF, and efficiency. These numbers are all represented as a single point on a plot where the y-axis is the value and the x-axis is the simulation run. If multiple simulations are ran, the values for these outputs can be compared between simulations. The final output is a mesh that displays the surface texture of the layers based upon the correlation factor, texturing height, and the dimensions. This is provided to give users a view of the texture used within the photovoltaic cell. References [1] D. Griffiths. “Introduction to Electrodynamics,” Prentice Hall, Upper Saddle River, NJ (1999). [2] J. Schneider, “Understanding the Finite-Difference Time-Domain Method,” School of electrical engineering and computer science Washington State University (2010). http://www.EEcs.Wsu.Edu/~schneidj/ufdtd/. [3] H. Chung, K-Y. Jung, X.T. Tee, and P. Bermel, “Time domain simulation of tandem silicon solar cells with optimal textured light trapping enabled by the quadratic complex rational function,” Optics Express 22, A818-A832 (2014). [4] H. Chung, J. Cho, S-G. Ha, S. Ju, and K-Y. Jung, “Accurate FDTD dispersive modeling for concrete materials,” ETRI Journal 35, 915-918 (2013). [5] C. Honsberg and S. Bowden, “PVCDROM,” Stuart, (2014). http://pveducation.org/pvcdrom.