Flange Joint & Management: Assembly, Torque, Tension

advertisement

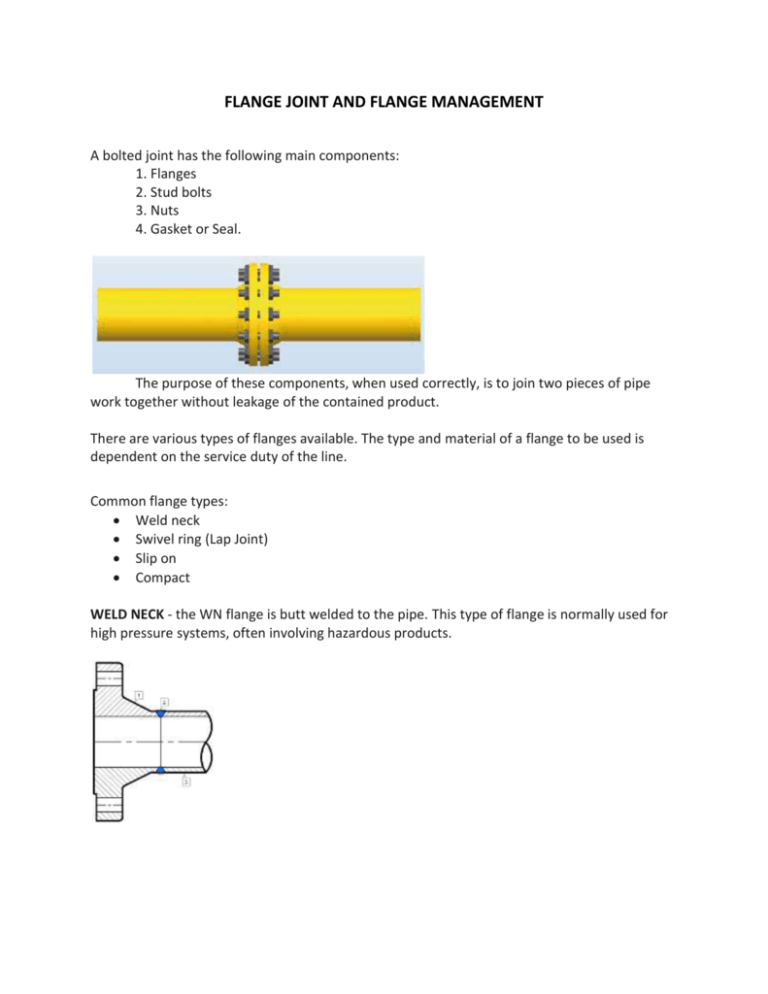

FLANGE JOINT AND FLANGE MANAGEMENT A bolted joint has the following main components: 1. Flanges 2. Stud bolts 3. Nuts 4. Gasket or Seal. The purpose of these components, when used correctly, is to join two pieces of pipe work together without leakage of the contained product. There are various types of flanges available. The type and material of a flange to be used is dependent on the service duty of the line. Common flange types: Weld neck Swivel ring (Lap Joint) Slip on Compact WELD NECK - the WN flange is butt welded to the pipe. This type of flange is normally used for high pressure systems, often involving hazardous products. SWIVEL RING - as with the WN, a butt will be welded. A swivel ring sits over the hub and allows the pipe flanges to be bolted together. This type of flange is normally found on sub-sea applications where the swivel ring aids flange alignment. SLIP-ON flanges are designed to slide over the outside diameter of the pipe to which it will be welded. These flanges are attached to the pipe by fillet welding at the hub and at the end of the pipe inside the flange. Common Flange Facings COMPACT FLANGE (Norsok L005) • No corrosion/erosion problems on flange faces • Smaller and lighter alternative to conventional ANSI flanges • Bolts of smaller diameter/tool fit issues • Easy, quick and reliable make-up • Suitable for high pressure or extreme temperature requirements • Re-useable metal seal rings Behaviour of Nuts and Bolts Acts like a spring Hookes’ law Stress is directly proportional to strain Example of Bolt Materials: • B7 – General Usage bolt • L7 – Low temperature • B7M & L7M • B8M Class 2 – Stainless Steel (Based on Project Requirement), For Example: All Stud Bolts Are To Be Lubricated with JetLube 550 (K Factor = 0.12). All B8M Class 2 Bolts will be Torque Tightened Common Gasket Types • SPIRAL WOUND GASKET (SWG) • RING TYPE JOINT (RTJ) • SOFT CUT TYPE GASKETS (C.N.A.F) • INSULATING GASKET SETS • TANGED GRAPHITE • KAMMPROFILE FLANGE SURFACE FINISH Managing the Installation of Gaskets is a key element of Integrity Correct surface finish No flange surface damage or corrosion Ensure flange flatness Ensure it is the correct gasket and correct material Ensure the gasket is not damaged Do not force the gasket into position Do not use any grease. Do not use compounds - unless specified Flange Assembly Definition: The main purpose of the bolt and nut is to apply bolt load to the flange which maintains sufficient stress to the gasket to maintain the joint leak free in all conditions. Too high bolt loads causes: Excessive stress in bolts, joint members, and gaskets. High stress can damage components, create leak paths, and encourage stress corrosion cracking or fatigue failure. Overstressed gaskets can lose their elasticity and become unable to adapt to changes in load, creating a leak path when the system is pressurized. Insufficient bolt loads can result in: Lack of joint strength or rigidity. Bolt loosening due to vibration, thermal cycles, or other in-operational conditions. Joint slip and wear on the gasket Leakage due to insufficient gasket stress. Fatigue failure under cyclic loads Flange Assembly Checks Check that joint faces are clean and free from cuts, indentations and other marks. Note particularly the presence of radial marks crossing the joint face. For RTJ flanges careful inspection of the groove is important. The surface finish should be within the specified range. Check that flange faces are parallel, or that the pipe work is flexible to allow the flanges to be pulled parallel and concentric without undue bolt loads. No Paint on Nut bearing areas on back of Flange Preservation and Cleanliness Flange faces to be clean undamaged & corrosion free. All preservations substances removed. No grease or bolt lubricant on any gasket or flange face including grooves of ring type joints Correct Gasket Compression, Uniform Gasket Compression Flange faces shall be aligned within 0.5 m/m in 200 m/m measured across any diameter. Ref : ASME Piping Code B31.3 Torque Tightening What is torque? Hand and Hydraulic Torque APPLIED TORQUE- FRICTIONAL LOSSES = RESIDUAL BOLT LOAD There are 3 main factors to take into account in order that the bolt forces determined are produced by the torque applied to the nut or bolt: 1. Torque to stretch the bolt 2. Torque to overcome friction at the bolt threads 3. Torque to overcome friction at the nut spot face All Stud Bolts are to be lubricated with Jet Lube 550 only! Including Teflon coated and Stainless Note: All studs [Torque & Tension] to be lubricated! Hand torque wrench operation Pull the torque wrench steadily using its handgrip. An uncontrolled pull may result in a false reading/ torque being produced. As soon as your wrench indicates that the pre determined torque has been achieved by for example ‘clicking’ or ‘breaking’ stop pulling immediately. Continuing to pull past this indicated point may cause a higher than required torque to be applied, and may over stress the components of the joint. Always wind the torque wrench setting back to lowest value on the scale failure to do so will eventually cause damage to the internal spring A hand torque wrench should be kept clean, and handled with care. If it is dropped or knocked then calibration of the wrench should be carried out. Advantages / Disadvantages of Torque Tightening Advantages One wrench + range of sockets /cassettes can cover a number of bolt sizes Standard bolt/stud bolt length Simple to operate Tool cost Low profile tooling overcomes restricted access Disadvantages Control of lubrication critical Time consuming Uneven gasket load Torsional stresses developed Reaction point is required Hydraulic Bolt Tensioners When to Torque or Tension The principles are as follows: All B8M Class 2 bolts to be Torque Tightened. Flanges with stud bolts 2” and above will be tensioned. ANSI 1500# with bolt size 1.5” and above will be tensioned. Flanges with stud bolts below above mentioned sizes can be hand or hydraulic torqued depending on the torque value. What is bolt tensioning? Areas of load loss/transfer when tensioning When applying a Bolt Load with a Tensioning Device the Applied Load (Gross Load) must be higher than the required residual load to allow for relaxation once the tool pressure is removed. Bolt Tensioning The resultant Bolt Load is known as Residual Load. The difference between Gross Load and Residual Load in 100% cover is known as the Tool Load Loss Factor -TLLF