Grinnell Mechanical Products Figure 9094 HDPE Flange Coupling

advertisement

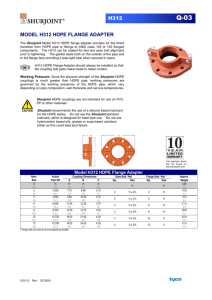

Technical Services: T el: (866) 500-4768 / Fax: (401) 781-7317 www.grinnell.com Grinnell Mechanical Products Figure 9094 HDPE Flange Coupling Installation / Assembly Instructions 1. The following instructions apply to the Grinnell Figure 9094 HDPE Flange Couplings. These couplings are designed to join high-density polyethylene (HDPE) to ANSI class 125 or 150 flanged piping systems. The HDPE pipe is to conform to ASTM D2447, D3000, D3035, or F714 (metric sizes to ISO 161/1, DIN8074, and AS8074), at ambient temperatures with wall thickness from SDR 7.3 to 32.5. The Figure 9094 couplings are not intended for use on anything other than HDPE. Refer to data sheet G584 for more information. 2. NUT GASKET FLANGE HOUSING SEGMENTS GASKET CAVITY 2. MOUNT HOUSING Place the flange housings over HDPE pipe. The flange must be assembled with its machined teeth on the HDPE pipe. The gasket cavity must face the pipe end. Fasten the draw bolts and nuts loosely. ! CAUTION 3. BOLT FIGURE 1: HDPE FLANGE COUPLING (FIGURE 9094) Never remove any piping component nor correct or modify any piping deficiencies without first de-pressurizing and draining the system. Failure to do so may result in serious personal injury, property damage, and/or impaired device performance. It is the Designer’s responsibility to select products suitable for the intended service and to ensure that pressure ratings and performance data are not exceeded. Material and gasket selection should be verified to be compatible for the specific application. Always read and understand the installation instructions. The products described herein must be installed and maintained in compliance with this document, in addition to the standards of any other authorities having jurisdiction. Failure to do so may result in serious personal injury or impair the performance of these devices. The owner is responsible for maintaining their mechanical system and devices in proper operating condition. The installing contractor or device manufacturer should be contacted with any questions. Exercise care when connecting HDPE piping to a steel-pipe system when hydrocarbons (for example, cutting oils) are present. Refer to the HDPE piping manufacturers’ installation instruction for guidance, which may recommend flushing the steel-pipe system prior to connection. To avoid injuries from sharp machined gripping teeth, wear protective gloves when handling couplings. 3. FLUSH FACE The HDPE pipe end must be flush with the flange face. Use a ruler or straight edge to verify. ! WARNING Page 1 of 2 1. SQUARE CUT HDPE PIPE HDPE pipe must be cut square. The maximum allowed tolerances are .125 inch (3.2 mm) on HDPE pipe sizes 2 inch to 4 inch and .156 inch (4.0 mm) on 6 inch and larger sizes. Make sure that the pipe end, within 1 inch from the end, is clean and free from indentations, projections, scratches, or other harmful surface defects such as scale, chips, and grease. 4. 5. October 2009 4. TIGHTEN DRAW BOLTS Tighten the draw bolts and nuts alternately and equally until the housing bolt pads meet forming metal-to-metal contact. Tighten by another 1/4 to 1/2 turn to ensure the nuts and bolts are tight and secure. 5. CHECK GASKET AND LUBRICATE Cover the sealing edges and outer surfaces of the gasket with a fine layer of lubricant. Use a petroleum-free silicone-based lubricant such as Dow Corning® 7 Release Compound. ! CAUTION To avoid injuries from sharp machined gripping teeth, wear protective gloves when handling couplings. G912 G912 Page 2 of 2 To prevent degradation of the polymer, do not use hydrocarbonbased oils, grease, or soap-based solutions. 6. 8. 6. INSTALL GASKET Mount the gasket into the cavity between the pipe OD and flange recess. Make sure that the bottom of the gasket (the marking side) is positioned and seated against the bottom of the flange recess. 7. MATE ADJOINING FLANGE Bring the adjoining flange face to face with the Figure 9094 flange. 7. 9. 9. TIGHTEN NUTS Tighten all nuts evenly as with a regular flange assembly, until faces contact firmly. Apply the recommended flange joint torque evenly to all the bolts. Mating Bolts and Nuts are not supplied. Flange mating bolts must be at least SAE J429 Grade 5 or stronger. It is the responsibility of the purchaser to verify correct length for the intended application. See Table 1 for mating bolt recommendations. 8. ADD BOLTS Add flange bolts and hand-tighten nuts. All the bolts shall be inserted from the same direction. Make sure that the oval neck of the bolt engages into the bolt hole of the housing. Nominal Pipe Size ANSI Inches / DN Mating Bolts ‡ O.D. Inches / (mm) Quantity Bolt Size Inches Recommended bolt-torque ft.lbs. 4 / DN100 4.500 / (114,3) 8 5/8 x 3-1/4 110 - 140 6 / DN150 6.625 / (168,3) 8 3/4 x 3-1/2 220 - 230 8 / DN200 8.625 / (219,1) 8 3/4 x 3-3/4 220 - 250 ‡ Mating Bolts and Nuts are not supplied. Flange Mating Bolts must be at least SAE J429 Grade 5 or stronger. Responsibility lies with the purchaser to verify correct length for the intended application. TABLE 1 FIGURE 9094 MATING BOLT RECOMMENDATIONS Pipe Wall Thickness and Standard Dimension Ratio Nominal Pipe Size ANSI O.D. Inches Inches DN (mm) Tol. +/Inches (mm) Max. Pipe Ovality +/Inches (mm) SDR 7.3 SDR 9 SDR 11 SDR 15.5 SDR 17 SDR 21 SDR 32.5 Inches (mm) 2 DN50 2.375 (60,3) 0.006 (0.15) 0.035 (0.89) 0.325 0.264 0.216 0.153 0.140 0.113 (8.3) (6.7) (5.5) (3.9) (3.6) (2.9) 3 DN80 3.500 (88,9) 0.016 (0.41) 0.040 (1.02) 0.479 0.389 0.318 0.226 0.206 0.167 0.108 (12.2) (9.9) (8.1) (5.7) (5.2) (4.2) (2.7) 4 DN100 4.500 (114,3) 0.020 (0.51) 0.040 (1.02) 0.616 0.500 0.409 0.290 0.265 0.214 0.138 (15.6) (12.7) (10.4) (7.4) (6.7) (5.4) (3.5) 6 DN150 6.625 (168,3) 0.030 (0.76) 0.050 (1.27) 0.908 0.736 0.602 0.427 0.327 0.265 0.204 (23.1) (18.7) (15.3) (10.8) (8.3) (6.7) (5.2) 8 DN200 8.625 (219,1) 0.039 (0.99) 0.075 (1.91) 1.182 0.958 0.784 0.556 0.507 0.340 0.265 (30.0) (24.3) (19.9) (14.1) (12.9) (8.6) (6.7) 10 DN250 10.750 (273,0) 0.048 (1.22) 0.075 (1.91) 1.473 1.194 0.977 0.694 0.632 0.512 0.331 (37.4) (30.3) (24.8) (17.6) (16.1) (13.0) (8.4) 12 DN300 12.750 (323,9) 0.057 (1.45) 0.075 (1.91) 1.747 1.417 1.159 0.823 0.750 0.607 0.392 (44.4) (36.0) (29.4) (20.9) (19.1) (15.4) (10.0) Per Specification for Polyethylene (P.E.) Plastic Pipe ASTM F714, D2447, D3035 - Limited Warranty Products manufactured by Tyco Fire Suppression & Building Products (TFSBP) are warranted solely to the original Buyer for ten (10) years against defects in material and workmanship when paid for and properly installed and maintained under normal use and service. This warranty will expire ten (10) years from date of shipment by TFSBP. No warranty is given for products or components manufactured by companies not affiliated by ownership with TFSBP or for products and components which have been subject to misuse, improper installation or maintenance, corrosion, or other external sources of damage. Materials found by TFSBP to be defective shall be either repaired or replaced, at TFSBP’s sole option. TFSBP neither assumes, nor authorizes any person to assume for it, any other obligation in connection with the sale of products or parts of products. TFSBP shall not be responsible for system design errors or inaccurate or incomplete information supplied by Buyer or Buyer’s representatives. In no event shall TFSBP be liable, in contract, tort, strict liability or under any other legal theory, for incidental, indirect, special or consequential damages, including but not limited to labor charges, regardless of whether TFSBP was informed about the possibility of such damages, and in no event shall TFSBP’s liability exceed an amount equal to the sales price. The foregoing warranty is made in lieu of any and all other warranties, express or implied, including warranties of merchantability and fitness for a particular purpose. This limited warranty sets forth the exclusive remedy for claims based on failure of or defect in products, materials or components, whether the claim is made in contract, tort, strict liability or any other legal theory. This warranty will apply to the full extent permitted by law. The invalidity, in whole or part, of any portion of this warranty will not affect the remainder. TABLE 2 HDPE PIPE DIMENSIONAL SPECIFICATIONS © 2009 T YCO FIRE SUPPRESSION & BUILDING PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446 Certified Company