Output X of the SSFA

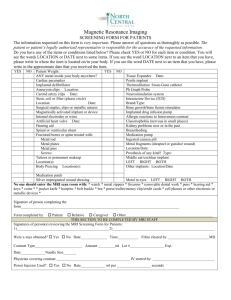

advertisement