Supplementary Information (docx 349K)

advertisement

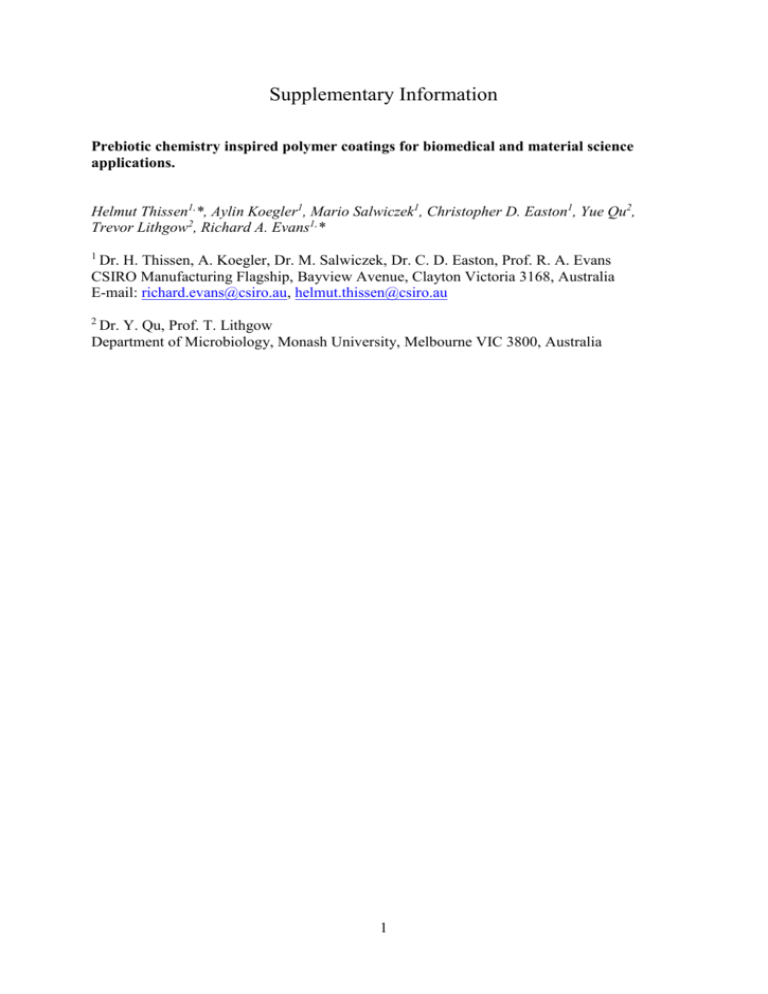

Supplementary Information Prebiotic chemistry inspired polymer coatings for biomedical and material science applications. Helmut Thissen1,*, Aylin Koegler1, Mario Salwiczek1, Christopher D. Easton1, Yue Qu2, Trevor Lithgow2, Richard A. Evans1,* 1 Dr. H. Thissen, A. Koegler, Dr. M. Salwiczek, Dr. C. D. Easton, Prof. R. A. Evans CSIRO Manufacturing Flagship, Bayview Avenue, Clayton Victoria 3168, Australia E-mail: richard.evans@csiro.au, helmut.thissen@csiro.au 2 Dr. Y. Qu, Prof. T. Lithgow Department of Microbiology, Monash University, Melbourne VIC 3800, Australia 1 Structure of HCN derived polymers The precise structure of HCN polymers has yet to be determined despite of many years of investigation. Figure S1 provides an overview of commonly proposed structural features and components. Figure S1 | Origin and components of HCN based polymers. Schematic illustrations of the components of HCN based polymers and the proposed chemistry of their origin. The polymerization mechanism can be a mix of free radical and nucleophilic addition. Partial hydrolysis during aqueous polymerization readily occurs to give peptides and amides from imines and nitriles, respectively. HCN based polymers are highly complex materials with fractions of differing solubility. It has proved very difficult for researchers to directly indentify the precise structure of these polymers. Instead the structure and functionalities of the polymers have been proposed largely based on compounds that have been identified following the complete hydrolysis of the polymers, including amino acids, purines, pyrimidines and pyrimides1-10. The scheme is closely taken from reference 10 and reader is directed to it as a recent article concerning progress in understanding HCN polymer structure. 2 Chemicals and substrate materials Aminomalononitrile p-toluenesulfonate (AMN, 98% purity), trifluoroacetaldehyde ethyl hemiacetal (TFAEH), 2,2,2-triflouroethylamine (TFEA), poly(D,L-lactide), 4-bromobenzyl bromide (BBB) and polyallylamine (PAA) (MW 70,000) were purchased from Sigma-Aldrich and used as received. Potassium cyanide was obtained from Fluka. 1,4-Dibromobenzene (DBB) was obtained from Acros Organics and silver nitrate (AgNO3) was obtained from Chem Supply. Ammonium chloride was purchased from Ajax Finechem. Substrates used for AMN coating deposition experiments included the polymers fluorinated ethylene propylene (FEP), polypropylene (PP), polytetrafluoroethylene (PTFE), polystyrene (PS), polycarbonate (PC), polyethersulfone (PES) and polyethylene terephthalate (PET) as well as the inorganic substrate materials gold (freshly sputter coated onto clean glass slides), glass, silicon wafers and mica (freshly cleaved). Cell culture experiments were carried out on tissue culture polystyrene (TCPS) 24 and 96 well plates obtained from Thermo Scientific (Nunclon™ Delta Surface) as well as 6 well and 96 well Corning® Ultra-Low Attachment (ULA) plates. General method of AMN coating deposition CAUTION: Standard precautions for working with cyanide should be taken. To neutralise any risk of accidental HCN evolution all waste is oxidised using a sodium hypochlorite solution. The coating process has been optimised over the course of this project which was based on our discovery that thickness and morphology are highly dependent on the following factors: 1) concentration of AMN, 2) buffer concentration and 3) temperature. According to our XPS analyses, however, the chemistry of the coating and therefore all subsequent chemical manipulations do not depend on these factors. Initial protocol: Aminomalononitrile p-toluenesulfonate (AMN) was dissolved in phosphate buffered saline (PBS, pH of 7.4) at a concentration of 100 mg/mL. Samples were incubated in this solution for up to 48 hours at ambient temperature after polymerization was induced by 3 adjusting the pH of the solution to 8.5 using 0.1 M sodium hydroxide (NaOH), resulting in a final concentration of approximately 2% (w/v) AMN. Optimised protocol: After the discovery that the buffer concentration has an impact on the morphology and the final thickness of the coating we decided to devise a protocol that ensures 1) a defined final AMN concentration, 2) a defined final buffer concentration and 3) a stable temperature during coating formation. To this end, AMN was dissolved at approximately 25 mg/mL in pH 8.5 buffer (either pure phosphate at a given concentration or PBS). Then, the pH was readjusted to 8.5 using 2 M, 1 M and 0.1 M NaOH solutions containing that specific buffer at the given concentration to ensure that the buffer concentration is kept constant. When the desired final pH was reached the volume of the solution was adjusted in a graduated flask to give the final desired concentration of AMN. The samples were then incubated for the specified amount of time at exactly 25 °C. Washing procedure: After coating, samples were washed five times with MilliQTM water and then incubated overnight in MilliQTM water before being air dried in a laminar flow cabinet. The presence of the adherent coating was indicated by a light brown colour change. To avoid the precipitation of polymer formed in solution, samples were facing downwards during the coating process. Table S1 shows the average water contact angle measurements obtained on different substrate materials before and after coating with the AMN polymer. Even though the water contact angle varied considerably on uncoated samples, similar water contact angles were measured after the coating was applied, indicating that the coating method results in similar physical properties that are independent of the substrate materials. 4 Table S1 | Average water contact angle measurements obtained on different substrate materials before and after coating with AMN polymer for 24 hours (n = 10). Substrate material Contact angle before coating Contact angle after coating FEP 114.3° 55.6° PP 100.8° 56.3° PTFE 93.1° 56.9° PS 92.9° 55.5° PC 85.6° 55.6° PES 81.2° 54.3° PET 67.0° 53.1° Gold 17.1° 57.8° Glass 15.6° 55.5° Mica 3.9° 56.3° Table S2 shows X-ray photoelectron spectroscopy (XPS) data collected on different substrate materials before and after coating with AMN. In each case, the XPS results clearly demonstrate the deposition of a coating, with a significant change in the N/C elemental ratio. The similar elemental ratios obtained after deposition of the AMN coating on different substrate materials also suggests that the coating composition is independent of the substrate. Table S2 | Average N/C ratios obtained by XPS on different substrate materials before and after coating with AMN polymer for 24 hours (n = 3). Substrate material N/C before coating N/C after coating FEP 0.000 0.583 PP 0.000 0.558 PTFE 0.000 0.614 PS 0.000 0.576 PC 0.000 0.589 PES 0.000 0.627 PET 0.000 0.637 Gold 0.000 0.608 Glass 0.036 0.600 Mica 0.000 0.618 5 X-ray photoelectron spectroscopy (XPS) XPS analysis was performed using an AXIS HSi and AXIS Ultra DLD spectrometer (Kratos Analytical Inc., Manchester, UK) with a monochromated Al Kα source at a power of 144 W (12 kV 12 mA) and 112 W (8 kV 14 mA) respectively, a hemispherical analyzer operating in the fixed analyser transmission mode and the standard aperture (analysis area: 0.3 mm × 0.7 mm). The total pressure in the main vacuum chamber during analysis was less than 10-8 mbar. Survey spectra were acquired at a pass energy of 160 eV. To obtain more detailed information in regard to the chemical structure, oxidation states etc., high resolution spectra were recorded from individual peaks at 40 eV pass energy (yielding a typical peak width for polymers of 1.0 – 1.1 eV). Each specimen was analyzed at an emission angle of 0° as measured from the surface normal. Assuming typical values for the electron attenuation length of relevant photoelectrons, the XPS analysis depth (from which 95% of the detected signal originates) ranged between 5 and 10 nm. XPS data processing was performed using CasaXPS processing software version 2.3.16 (Casa Software Ltd., Teignmouth, UK). All elements present were identified from survey spectra. The atomic concentrations of the detected elements were calculated using integral peak intensities and the sensitivity factors supplied by the manufacturer. Binding energies were referenced to the aliphatic hydrocarbon peak at 285.0 eV. High resolution C 1s spectra were fitted using standard components based on a GaussianLorentzian function. Labelled components correspond to the following: C1 – C-C and C-H (hydrocarbons), C2 – C-N, C=N, C≡N, and C-O based groups (ethers and alcohols); C3 – (N-)C=O and O-C-O based groups (e.g. aldehydes and ketones); C4 – O-C=O based groups (e.g. acids, esters), C5 – unsaturated/aromatic carbon. The accuracy associated with quantitative XPS is ca. 10% - 15%. Precision (i.e. reproducibility) depends on the signal/noise ratio but is usually much better than 5%. The latter is relevant when comparing similar samples. 6 Atomic force microscopy (AFM) Measuring parameters: A Bruker FastScan atomic force microscope employing an Icon scanner head with NanoScope 9.0 software was used to measure surface topography in tapping mode with ultrasharp silicon tips (TAP150A, Bruker Corporation). The tips used in this study have a typical force constant of 5 N/m and a resonant frequency of 150 kHz. Scans were performed at 0.8 Hz and 512 data points per scan line. All images were processed using NanoScope Analysis 1.5 software. Sample preparation: Silicon wafers (MMRC Pty. Ltd., Malvern, Australia) were cut into 1 cm × 1 cm squares and sonicated in 20 % (v/v) RBS (Pierce RBS 35® Detergent Concentrate) at 50 °C for 30 minutes. The samples were then washed thoroughly with deionised water and dried using a stream of nitrogen. Subsequently, one drop of a 10% (w/v) solution of poly(D,Llactide) in acetone was placed on one corner of each sample and the solvent was allowed to evaporate in a laminar flow cabinet. AMN was dissolved in phosphate buffered saline (PBS, pH 8.5). To induce polymerization, the pH was then adjusted to 8.5 using 0.1 M sodium hydroxide containing the buffer salts to keep the buffer concentration constant. After reaching the desired pH the AMN concentration was adjusted to 2% (w/v) using PBS. The silicon wafers were incubated in this solution facing down for different periods of time up to 48 hours. Subsequently, samples were washed five times with MilliQTM water and then incubated overnight in MilliQTM water before being air dried in a laminar flow cabinet. After removing the poly(D,L-lactide) masks to expose the underlying Si surface for coating thickness analysis. The heterogeneous nature of the top surface of the AMN coatings made it difficult to collect AFM data. It was common to experience artefacts during imaging due to loose material on the surface. Two methods were employed within the NanoScope Analysis software to determine coating thickness and thus provide more confidence in the resultant thickness measurement. Section Analysis was employed to measure three line scans per image across the step interface. Particle Analysis was used to generate a histogram of the Z-scale values within an image which 7 resulted in two peaks, the Z-scale heights of the silicon wafer and the top surface of the AMN coating. The distance between the maximum values of the two peaks along the X-axis of the histogram represented the step thickness of the coating. Figure S2 shows the statistical comparison between the results obtained by these two methods. 200 180 160 p = 0.15 5h 20 h 24 h 48 h Step Hight / nm 140 120 p = 0.55 100 p = 0.88 80 60 40 20 p = 0.79 0 Section Anlysis Particle Analysis Figure S2 | AFM analysis of AMN based coatings on silicon wafers. The thickness of the coating was determined by two different methods. A statistical comparison between section analysis (n = 18) and particle analysis (n = 6) for the different time points indicates no differences between the thickness values observed (p ≥ 0.05). Scanning electron microscopy (SEM) analysis For SEM analysis, samples were mounted on an aluminium stub with double-sided conductive carbon tape. These samples were then iridium coated using a Polaron SC5750 sputter coater. The thickness of the iridium coating was approximately 10 nm. Once coated, the samples were placed into a Philips XL30 Field Emission Scanning Electron microscope for imaging. An accelerating voltage of 2 kV was used to obtain images. The image analysis software used was AnalySIS, developed by Olympus Soft-Imaging Solutions. 8 Contact angle measurements Static contact angles were measured using an automated contact angle goniometer (KSV Instruments LTD). A droplet with a volume of approximately 5 μL of ultrapure MilliQTM water was used for the experiments. Average contact angles were calculated from 10 measurements, with each measurement recording the contact angles on both sides of the droplet. Monitoring of coating thickness on transparent substrates using optical density To establish the correlation between coating thickness and optical density for transparent substrates and therewith a quick and easy method to roughly estimate coating thickness and monitor coating quality using UV, coatings were prepared on 2 cm × 2 cm glass disks. A) B) 300 0.2 0.18 Polystyrene 250 0.16 0.14 200 0.12 0.1 D / nm Abs. / a.u. y = 251 ( 23) x - 7 ( 13) 2 adj.R = 0.94 p(slope) = 1.24 · 10-5 p(intecept) = 0.6 Glass 150 0.08 0.06 0.04 100 50 0.02 0 0 300 350 400 450 500 550 600 650 700 λ / nm 0 0.2 0.4 0.6 OD400 / a.u. 0.8 1 Figure S3 | A) Typical UV spectra of a thin coating on glass and untreated polystyrene 96-well plates and B) Correlation of increasing coating thickness with increasing optical density at 400 nm. Confidence bands for the regression are shown as dotted lines. UV spectra (Figure S3A) were measured against a blank using a PowerWaveTM XS Microplate Spectrophotometer (BioTek® Instruments Inc. Winooski VT, USA) scanning wavelengths between 300 and 700 nm at 2 nm intervals. To measure the optical density on glass disks, they were placed into polystyrene 8-well dishes and also measured using the multi-well plate reader. To estimate coating thickness, three scratches were made on each glass sample using a blunt metal tip. Surface profiles were recorded using a Dektak 6M Stylus Profiler 9 (Veeco Instruments, Inc. Plainview NY, USA) applying the following measurement parameters: Stylus radius: 12.5 μm, scan length: 400 μm, Force: 10 mg, Mrange: 65 kÅ. Then the determined thickness was correlated with the optical density at 400 nm. The good correlation (Figure S3B) between estimated coating thickness and optical density at 400 nm justifies using optical density as a relative measure of coating thickness. While the method is certainly not accurate it provides a quick and easy estimate of coating thickness with an error margin of roughly 15%. Reaction with 2,2,2-trifluoroethylamine Labelling with and co-deposition of 2,2,2-trifluoroethylamine (Figure 3A) was carried out on untreated CostarTM flat-bottom 96-well polystyrene plates (Corning) as a substrate. Aminomalononitrile p-toluenesulfonate (AMN) was dissolved in 100 mM phosphate buffer (pH 8.5) at 25 mg/mL. To induce polymerization, the pH was then adjusted to 8.5 using 0.1 M sodium hydroxide and the final AMN concentration was the adjusted to 1% (w/v). Individual wells of 96-well polystyrene plates were incubated with this solution for 24 hours. Subsequently, samples were washed five times with MilliQTM water and then incubated overnight in MilliQTM water before being air dried in a laminar flow cabinet. The presence of the coating was indicated by a light brown colour change. During the coating process samples were facing downwards to avoid the precipitation of polymer from solution. For the labelling experiments, a 1 M stock solution of the amine in 100 mM phosphate buffer at pH 8.5 was prepared. Then, a ten-fold serial dilution (6 steps) was prepared to provide 7 concentrations ranging from 1 μM to 1 M. Using these solutions and pure buffer as a control, 8 wells per concentration were incubated for 24 hours. The wells were then washed three times with MilliQTM water by pipetting and soaked in water for an additional 24 hours before drying. For co-deposition, a 2 M solution of the amine was prepared and diluted to give 7 concentrations between 2 μM and 2 M with a pH of 8.5. Simultaneously, a 2% (w/v) solution 10 of AMN was prepared as described above and mixed in a ratio 1:1 with the different amine concentrations to give a final concentration of 1% AMN. These solutions were then used to coat 8 wells per concentration applying the coating and washing process as described above. While the coating worked for all concentrations, visual and UV analysis (Figure S4) reveal that the coating thickness decreases as the amine concentration present during coating formation increases such that at the highest concentration for the amine (1 M) no uniform coating is formed. 0.6 0.55 OD400 / a.u. 0.5 0.45 0.4 0.35 0.3 1.E-06 1.E-04 1.E-02 1.E+00 c(CF3CH2NH2) used for co-deposition / M Figure S4 | Coating thickness as a function of the concentration of 2,2,2-trifuoroethylamine present as a co-monomer during coating formation. For XPS analysis, three samples per concentration were analyzed. In these experiments, a trace amount of fluorine was observed on the control surface which can be explained by spill over during pipetting and washing. Under the assumption that the spill over is equal throughout the plate, a background correction (suing the blank surface value) was performed for all other concentrations. The uncorrected values are listed in Table S3. The successful incorporation of the TFAE label in the coating both during coating formation and by reaction after AMN coating deposition demonstrates that amines can be incorporated into the coating using both routes. 11 Table S3 | Average measured F/C ratios ± standard deviation obtained by XPS on AMN coatings labelled or co-deposited with different concentrations of 2,2,2-trifluoroethylamine (n = 3). F/C labelling F/C co-deposition 0 0.002 ± 0.001 0.005 ± 0.001 10-6 0.003 ± 0.001 0.0032 ± 0.0003 10-5 0.003 ± 0.001 0.0066 ± 0.0004 10-4 0.005 ± 0.001 0.009 ± 0.001 10-3 0.007 ± 0.001 0.010 ± 0.001 10-2 0.008 ± 0.002 0.017 ± 0.002 10-1 0.015 ± 0.001 0.018 ± 0.002 1 0.037 ± 0.002 c / mol × l-1 Possible mechanism of reaction of exogenous amines during or after polymerization of AMN: AMN possesses a primary amine group, an active methlyene and two activated nitrile groups. Although the mechanism polymerization and indeed the structure of the HCN polymers is ambiguous (as described earlier) is it highly likely that the nucleophilic primary amine attacks the nitrile of another AMN molecule and so on to make an initial polymer (Figure S5). Depending on pH the active methylene may also participate. Thus for every AMN amine reacting with a nitrile, there is an unreacted nitrile. This unreacted nitrile would be formally available for reaction with an exogenous amine. 12 Figure S5 | The proposed reaction of amines with AMN polymers. There is indirect support for this from a report by Raulin et al. that thiol nucleophiles will readily attack the activated nitriles of malononitrile to give an iminothioester (Figure S6)11. Amines being stronger nucleophiles than thiols could be expected to also undergo an analogous reaction. Figure S6 | The reaction of ethane thiol with malononitrile11. Reaction with trifluoroacetaldehyde ethyl hemiacetal Labelling with and co-deposition of trifluoroacetaldehyde ethyl hemiacetal (TFAEH) (Figure 3B) was carried out on untreated CostarTM flat-bottom 96-well polystyrene plates (Corning) as a substrate. The experimental procedures for labelling and co-deposition of TFAEH are identical to the ones described above for 2,2,2-trifluoroethylamine. Note that when dissolving the high concentrations of the hemiacteal, the solutions are initially cloudy but then quickly form clear transparent solutions indicating hydrolysis of the hemiacetal. Also note that the trend of decreasing coating thickness as a function of co-monomer concentration is less pronounced as compared to the amine (Figure S7). Equivalent to the amine labelling a spill over to the control surface was observed an a background correction was performed. The uncorrected values are listed in Table S4. 13 0.8 0.7 0.6 OD400 / a.u. 0.5 0.4 0.3 0.2 0.1 0 0.000001 0.0001 0.01 c(TFAEH) used for co-deposition / M 1 Figure S7 | Coating thickness as a function of the concentration of TFAEH present as a comonomer during coating formation. The data point at 0.01 M appears to be an outlier from the trend. Table S4 | Average measured F/C ratios ± standard deviation obtained by XPS on AMN coatings labelled or co-deposited with different concentrations of TFAEH (n = 3). c(TFAEH) / mol × l-1 F/C labelling F/C co-deposition 0 0.0040 ± 0.0004 0.0067 ± 0.0003 10-6 0.0030 ± 0.0001 0.006 ± 0.001 10-5 0.003 ± 0.001 0.0048 ± 0.0007 10-4 0.003 ± 0.002 0.0066 ± 0.0004 10-3 0.005 ± 0.001 0.008 ± 0.001 10-2 0.005 ± 0.001 0.035 ± 0.001 10-1 0.023 ± 0.002 0.160 ± 0.001 1 0.022 ± 0.004 0.205 ± 0.001 Possible mechanisms of reaction of exogenous aldehydes during or after polymerization of AMN: There are at least 2 possible mechanisms of reaction of aldehydes with HCN polymers: (1) Amine groups available in HCN polymers can be expected to react with aldehydes to form imines and (2) Aldehydes could also be incorporated by nucleophilic reaction of the active methyl hydrogen in aminomalonontrile and the polymer (Figure S8A) which would be analogous the reported reaction of acrylonitrile with the AMN polymer (Figure S8B). 14 Figure S8 | (a) The proposed base catalysed reaction of aldehydes with active methylene groups on the backbone of a HCN polymer. (b) The reported reaction of acrylonitrile with AMN polymer. The reactivity of the in-chain methylene group was established by Minard and McGowan when evidence for base catalysed reaction of acrylontrile with polyaminomalononitrile was reported12. Surface modification with 4-bromobenzyl bromide Aminomalononitrile p-toluenesulfonate (AMN) was dissolved in phosphate buffered saline (PBS) with a pH of 7.4. To induce polymerization, the pH was then adjusted to 8.5 using 0.1 M sodium hydroxide, resulting in a final AMN concentration of 2% (w/v). Glass cover slip samples were incubated in this solution for 24 hours. Subsequently, samples were washed five times with MilliQTM water and then incubated overnight in MilliQTM water before being air dried in a laminar flow cabinet. The presence of the coating was indicated by a light brown colour change. During the coating process samples were facing downwards to avoid the precipitation of polymer from solution. Subsequently the freshly prepared samples were incubated over 16 hours in a solution of 100 mg 4-bromobenzyl bromide (BBB) and 200 µL 0.1 M triethylamine (TEA) in 5 mL acetonitrile at 37 °C, followed by extensive repeated washing in acetonitrile and subsequently MilliQ™ water and drying in a laminar flow cabinet. Control samples were analogously prepared under identical conditions using 100 mg 1,4dibromobenzene (DBB) instead of BBB. The detection of bromine by XPS after reaction with BBB demonstrates the reactivity of the AMN surface with benzyl bromide containing 15 compounds and their covalent immobilization (Figure 3C). Furthermore, the fact that no bromine was detected after reaction with DBB demonstrates that bromobenzene functional groups do not react with the AMN surface. In addition, the control experiment demonstrates that the washing procedures were sufficient to achieve the complete removal of non-covalently bound BBB and DBB, respectively. Metallization of AMN coatings Incorporation of silver was achieved by incubating coated surfaces in the dark with aqueous solutions of silver nitrate (Chem-Supply Pty Ltd, Gillman SA, Australia), which were prepared from a fresh 100 mM stock in deionised water by 10-fold serial dilution to give a range of concentrations between 10-9 M and 0.1 M. A surface incubated with pure water served as a control. After 24 hours the solutions were removed and each well washed three times with water using a pipette. The wells were then completely filled with water and left to soak for another 24 hours. After drying in a laminar flow chamber, samples for XPS were taken. Prior to biological evaluations the plates were double sealed in plastic bags and γ-sterilised (25 kGy, Steritech Pty Ltd, Dandenong VIC, Australia). At higher silver concentrations, coated samples showed a visible grey colour change, suggesting the deposition of metallic silver. This observation was confirmed by XPS experiments which revealed an average Ag/C ratio of 0.205 and the presence of Ag(0) and Ag(+) (Table S5 and Figure 4B). 16 Table S5 | XPS and ICP-OES results obtained on AMN coated polystyrene substrates before and after incubation with AgNO3. c(AgNO3) / mol × l-1 Ag/C ratio a Ag surface concentration / μg × cm-2 b 0 N.D. N.D. 10-9 N.D. N.D. 10-8 N.D. N.D. 10-7 N.D. N.D. 10-6 N.D. 0.035 ± 0.001 10-5 0.00128 ± 0.00001 0.039 ± 0.000 10-4 0.0217 ± 0.0009 2.15 ± 0.02 10-3 0.0569 ± 0.0009 3.57 ± 0.02 10-2 0.0883 ± 0.0009 4.92 ± 0.07 10-1 0.180 ± 0.001 13.8 ± 0.2 a b XPS ICP-OES Deposition of coatings using potassium cyanide Equimolar amounts of potassium cyanide (65.1 mg, KCN) (caution) and ammonium chloride (53.5 mg) were dissolved in 2 mL of MilliQTM water. Glass samples were incubated in this solution at room temperature for 7 days. Subsequently, samples were washed five times with MilliQTM water and then incubated overnight in MilliQTM water before being air dried in a laminar flow cabinet. The presence of the coating was indicated by a light brown colour change. XPS data collected before and after coating clearly demonstrate the deposition of a coating, with a significant change in the elemental ratios (Table S6). The most significant changes observed were an increase in the N/C ratio from 0.000 to 0.645 and a decrease in the Si/C ratio from 1.538 to 0.072. The latter reflects the almost complete attenuation of the Si signal from the underlying substrate material and a coating thickness close to the sampling depth of XPS. 17 Table S6 | XPS results obtained on glass substrates before and after coating with a solution containing equimolar amounts of potassium cyanide (KCN) and ammonium chloride. The average atomic ratios ± standard variation observed are presented (n = 3). Substrate O/C N/C Si/C Glass 2.961±0.072 - 1.538±0.047 Glass-KCN 0.231±0.007 0.645±0.003 0.072±0.004 Evaluation of cell attachment Aminomalononitrile p-toluenesulfonate (AMN) (Aldrich) was dissolved in phosphate buffered saline (PBS) with a pH of 7.4. To induce polymerization, the pH was then adjusted to 8.5 using 0.1 M sodium hydroxide, resulting in a final AMN concentration of 2% (w/v). Individual wells of Corning® Ultra-Low Attachment (ULA) plates were incubated with this solution for 24 h. Subsequently, samples were washed five times with MilliQTM water and then incubated overnight in MilliQTM water before being air dried in a laminar flow cabinet. The presence of the coating was indicated by a light brown colour change. During the coating process samples were facing downwards to avoid the precipitation of polymer from solution. L929 mouse fibroblasts (cell line ATCC-CCL-1, Rockville, USA, recently authenticated and tested for mycoplasma contamination by PCR assay at the Victorian Infectious Diseases Reference Laboratory, VIDREL) were used to investigate the cellular response to modified surfaces. Cells were cultured in minimum essential medium (MEM) containing 10% foetal bovine serum and 1% non-essential amino acids (Invitrogen, USA). After cell seeding on tissue culture polystyrene (TCPS) 96 well plates (Nunclon™ Delta Surface), Corning® Ultra-Low Attachment (ULA) 96 well plates and AMN coated ULA 96 well plates (ULA-AMN) at a density of 2.5 × 104 cells/cm2, samples were incubated for 24 hours at 37 °C in humidified air containing 5% CO2. Subsequently substrates were washed once with minimum essential medium (MEM) before a solution consisting of 100 µL phenazine methosulfate (PMS) solution (0.92 mg/mL in DPBS), 2 mL 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide 18 (MTS) solution (2 mg/mL in DPBS), and 10 mL MEM was added. The substrates were incubated for 3 hours at 37 °C in humidified air containing 5% CO2 before a colorimetric readout was performed at 490 nm and 655 nm. Table S7 shows the colorimetric assay results obtained on the different coatings. Cell attachment was reduced to 2.6% on the ULA coating relative to the tissue culture polystyrene (TCPS) surface. On the other hand, cell attachment increased to almost 130% (Table S6) on the AMN coated ULA coating relative to TCPS. No cytotoxic effect originating from the coating was observed during cell culture experiments. The cell culture results clearly demonstrate that AMN coatings lead to high cell attachment and are suitable for the culture of cells in serum containing media. The high cell attachment is thought to be related to the adsorption of proteins from the cell culture medium. The cell culture results obtained on the ULA and the ULA-AMN surface also demonstrate that the AMN coating is able to mask the properties of the underlying substrate material effectively. Table S7 | Cell attachment results obtained from colorimetric test performed on 96 well plates relative to TCPS in % (n = 8). Sample Cell attachment ± SD relative to TCPS (%) TCPS 100 ± 13 ULA 3±2 ULA-AMN 127 ± 5 Cytotoxicity evaluation of AMN coatings Aminomalononitrile p-tolunesulfonate (AMN) (Aldrich) was dissolved in phosphate buffered saline (PBS) with a pH of 7.4. To induce polymerization, the pH was then adjusted to 8.5 using 0.1 M sodium hydroxide, resulting in a final AMN concentration of 2% (w/v). Individual wells of tissue culture polystyrene (TCPS) 24 well plates (Nunclon™ Delta Surface) were coated with this solution for 24 hours. During the incubation period, samples were facing downwards 19 to avoid the precipitation of polymer from solution. Subsequently, samples were washed five times with MilliQTM water and then incubated overnight in MilliQTM water before being air dried in a laminar flow cabinet. The presence of the coating was indicated by a light brown colour change. Cytotoxicity testing was performed using these samples according to the international standard ISO10993-5 (Biological evaluation of medical devices - Part 5: Tests for in vitro cytotoxicity and Part 12: Sample preparation and reference materials). The volume of the extraction solution was determined by the surface area of the base and side wall of the well (0.8 mL per well), giving a depth of 6 mm for the extraction fluid. The extraction solution was serum free medium (SFM). The extraction solvent was incubated on the samples for 66 hours at 37 C with agitation on a rocking platform set to 20 rpm. Subsequently the extraction solutions from each well were brought to room temperature and the extraction fluid from each well separately serially diluted 1 in 2 using SFM as the diluent to give a range of test solutions from 100%, 50% etc. to 0.39% of the original extraction solution. Standard control solutions included SFM alone, SFM containing 5% PBS, and SFM containing 5% DMSO. All solutions were prepared in sterile 96 well plates (Nunclon™ Delta Surface) in quadruplicate. In parallel, L929 mouse fibroblast cells were seeded at a density of 2x104 cells/well into 96 well plates (NunclonTM Delta Surface) in 100 µL of freshly prepared serum containing medium. The cells were incubated for 24 hours at 37 C in humidified air containing 5% CO2. Following removal of the serum containing medium from all of the wells, these were washed twice with 150 µL of SFM after which 100 µL of test solution (100%, 50% etc. to 0.39%. of the original extraction solution) or control solution (SFM, SFM containing 5% PBS or SFM containing 5% DMSO) was added to individual wells. The plates were then incubated for a further 20 hours at 37 °C. To quantify the number of metabolically active cells, a colorimetric MTS assay was performed using 3-(4,5-dimethylthiazol-2-yl)-5(3-carboxymethoxphenyl)-2-(4-sulphophenyl)-2Htetrazolium (Promega). At 20 hours, a fresh working solution of MTS reagent was prepared as per the manufacturer’s instructions. The test and control solutions were removed from the plates 20 and 100 µL of MTS solution added. The plates were then incubated for 3 hours at 37 °C. Subsequently the plates were read using an ELISA plate reader (BioTek, USA). The quantitative evaluation of cytotoxicity using the MTS assay with serial dilutions (100% to 0.39%) of SFM-based extraction solutions originated from 4 different samples, each of which were investigated in multiple replicates. The MTS assay was also carried out on the same overall number of replicates using SFM, SFM containing 5% PBS and SFM containing 5% DMSO. Qualitative evaluation of the plates by visual inspection showed that none of the wells containing SFM and 5% PBS showed any reactivity to the solution with all cells having an attached, flattened healthy appearance. Also none of the test solutions showed any reactivity at any dilution with all cells having an attached, flattened healthy appearance (Grade 0). In comparison, wells containing 5% DMSO showed a mild reaction with approximately 25% of cells having a rounded appearance (Grade 2). The quantitative evaluation of cytotoxicity based on MTS assay results (Figure 6F) showed no cytotoxic effect for any of the dilutions investigated in this experiment, while the control solutions (5% PBS buffer and 5% DMSO) showed the desired non-toxic and toxic response, respectively. The lack of cytotoxicity underlines the suitability of AMN coatings for a broad range of biomedical applications. Spatial control over the biological response using AMN coatings Samples with a size of approximately 4 cm2 were cut out of 6 well Corning® Ultra-Low Attachment (ULA) plates and served as a substrate for this experiment. Aminomalononitrile p-toluenesulfonate (AMN) (Aldrich) was dissolved in phosphate buffered saline (PBS) with a pH of 7.4. To induce polymerization, the pH was then adjusted to 8.5 using 0.1 M sodium hydroxide, resulting in a final AMN concentration of 2% (w/v). After 30 minutes incubation, 100 μL of this solution was transferred to individual wells of a 96 well plate, which was used as a source plate in a microarray printer (NanoPrint LM60 microarrayer, ArrayIt, USA). After contact printing of the solution onto the ULA coated samples in an array pattern 21 using pins with a diameter of 375 μm, samples were air dried in a laminar flow cabinet over 48 hours. Subsequently, samples were washed three times with MilliQTM water before again being air dried in a laminar flow cabinet. Prior to cell seeding, samples were subjected to sterilization at a dose of 15 kGy (Steritech, Australia). L929 mouse fibroblasts (cell line ATCCCCL-1, Rockville, USA) were used to investigate the cellular response to the patterned surface chemistry. Cells were cultured in minimum essential medium (MEM) containing 10% foetal bovine serum and 1% non-essential amino acids (Invitrogen, USA). After cell seeding at a density of 2.5 × 104 cells/cm2, samples were incubated for 16 hours at 37 °C in humidified air containing 5% CO2. After washing samples with medium, a Molecular Probes live/dead assay was performed, which resulted in live, attached cells being stained green and dead, attached cells being stained red. Samples were then imaged using a Nikon TE 2000 Fluorescent Microscope. The cell attachment pattern observed (Figure 6E) demonstrates that cells were only able to attach to areas where the AMN coating is present, while cell attachment was prevented on the ULA background material. Cell attachment exactly followed the pattern provided by the microarray printing process. Furthermore, all cells attached to the AMN coated areas showed green fluorescence, indicating live cells and therefore negligible cytotoxicity. These results demonstrate that spatial control over biological responses such as cell attachment can be achieved using AMN coating deposition. Inductively coupled plasma optical emission spectrometry (ICP-OES) To determine the absolute amount of silver incorporated, all silver including the coating was dissolved by treating the wells of the coated 12-well plates with 5.5 mL 35% (w/w) nitric acid prepared form a 70% (w/w) stock (ChemSupply Pty. Ltd., Gillman SA, Australia) for 24 hours. The solution was removed and transferred to a 25 mL graduated flask. The surfaces were washed three times with 5.5 mL water (MilliQTM grade) and the washing solution transferred 22 to the same flask. The volume was then adjusted to 25 mL giving a final nitric acid concentration of ~ 8% (w/w). A silver free coating treated equally served as the background. ICP-OES measurements were carried out on a Varian 730 ES Axial ICP-OES using a standard quartz torch and spray chamber fitted with a “OneNeb” nebuliser (Power: 1.0 kW, Argon plasma flow: 15 L/min, Argon auxiliary flow: 1.5 L/min, Argon nebuliser flow: 0.75 L/min, Sample pump speed: 15 rpm, Stabilisation delay: 15 s). All experiments were run in triplicate. Silver nitrate calibration standards were prepared in 8% (w/w) nitric acid to match the sample background. The calibration and accuracy of the method were validated using certified multielement solutions. The amount of silver in mg/mL was normalised to surface area (A) calculated as 2πrh + πr2 based on the dimensions of the wells (r = 0.525 cm, h = 1.7 cm) that were completely coated including the walls. To evaluate the relationship between silver content and thickness, coatings of different thickness including an uncoated control surface were incubated with 100 mM silver nitrate solutions following the metallization protocol described above. Figure S9 shows the observed correlation between coating thickness (expressed as optical density at 400 nm) and the absolute amount of silver incorporated into these coatings. 23 Ag-content from ICP-OES / μg cm-2 25.0 y = 55 ( 6) x + 1 ( 1) 2 adj.R = 0.96 p(slope) = 0.002 p(intercept) = 0.34 22.5 20.0 17.5 15.0 12.5 10.0 7.5 5.0 2.5 0.0 0 0.05 0.1 0.15 0.2 0.25 OD400 / a.u. 0.3 0.35 Figure S9 | Analysis of the correlation between coating thickness (expressed as optical density at 400 nm) and silver content determined by ICP-OES (95% confidence bands are shown as dotted lines). The analysis reveals a good linear correlation with and adjusted correlation coefficient of 0.96. The intercept has not been set to zero but its p-value being much greater than 0.05 indicates that it, expectedly, is not significantly different from zero. Data Analysis: Statistical analyses were performed in Microsoft Excel. Depending on the data set, One-Way or Two-Way Anova analyses and correlation/regression analyses were performed at the 95% confidence level with p-values of less than 0.05 indicating statistical significance (rejection of the “null hypothesis”) using the following increments of increasing significance: p > 0.05 (ns, not significant); p ≤ 0.05 (*), p ≤ 0.01 (**), p ≤ 0.001 (***) and p ≤ 0.0001 (****). Error bars in Figures 1d, 1e, 3c, 6d, S2 and Tables S2-6 represent the standard deviation from the mean. References 1. Matthews C.N., Minard R.D. Hydrogen cyanide polymers connect cosmochemistry and biochemistry. Proc. Internatl. Astronom. Union 4, 453-458 (2008). 2. Ferris J.P., Hagan Jr. W.J. HCN and chemical evolution: The possible role of cyano compounds in prebiotic synthesis. Tetrahedron 40, 1093-1120 (1984). 3. Moser R.E., Claggett A.R., Matthews C.N. Peptide formation from aminomalononitrile (HCN trimer). Tetrahedron Lett. 9, 1605-1608 (1968). 24 4. Matthews C.N. The HCN world: Establishing protein nucleic acid life via hydrogen cyanide polymers. In: Origins: Genesis, evolution and diversity of life (ed. Seckbach J.). Kluver Academic Publishers (2004). 5. Mamajanov I., Herzfeld J. HCN polymers characterized by solid state NMR: Chains and sheets formed in the neat liquid. J. Chem. Phys. 130, 134503 (2009). 6. Umemoto K., Takahasi M., Yokota K. Studies on the structure of HCN oligomers. Orig. Life Evol. Biosph. 17, 283-293 (1987). 7. Oró J., Kamat S.S. Amino-acid synthesis from hydrogen cyanide under possible primitive earth conditions. Nature 190, 442-443 (1961). 8. Menor-Salván C., Marín-Yaseli M.R. Prebiotic chemistry in eutectic solutions at the water-ice matrix. Chem. Soc. Rev. 41, 5404-5415 (2012). 9. Ruiz-Bermejo M., Zorzano M.-P., Osuna-Esteban S. Simple organics and biomonomers identified in HCN polymers: An overview. Life 3, 421-448 (2013). 10. De la Fuente J.L., Ruiz-Bermejo M., Nna-Mvondo D., Minard R.D. Further Progress into the thermal characterization of HCN polymers. Polym. Degrad. Stab. 110, 241-251 (2014) 11. Raulin F., Lussiana J.-P. Prebiotic formation of iminothioesters. II: Addition of thiophenols to malonic nitriles. Orig. Life Evol. Biosph. 14, 157-162 (1984). 12. Minard R.D., McGowan B. A test for polyaminomalononitrile as an intermediate in HCN polymerization. In: NASA Astrobiology Institute General Meeting 2003 (2002). 25