PDF - Semiconductor Industry Association

advertisement

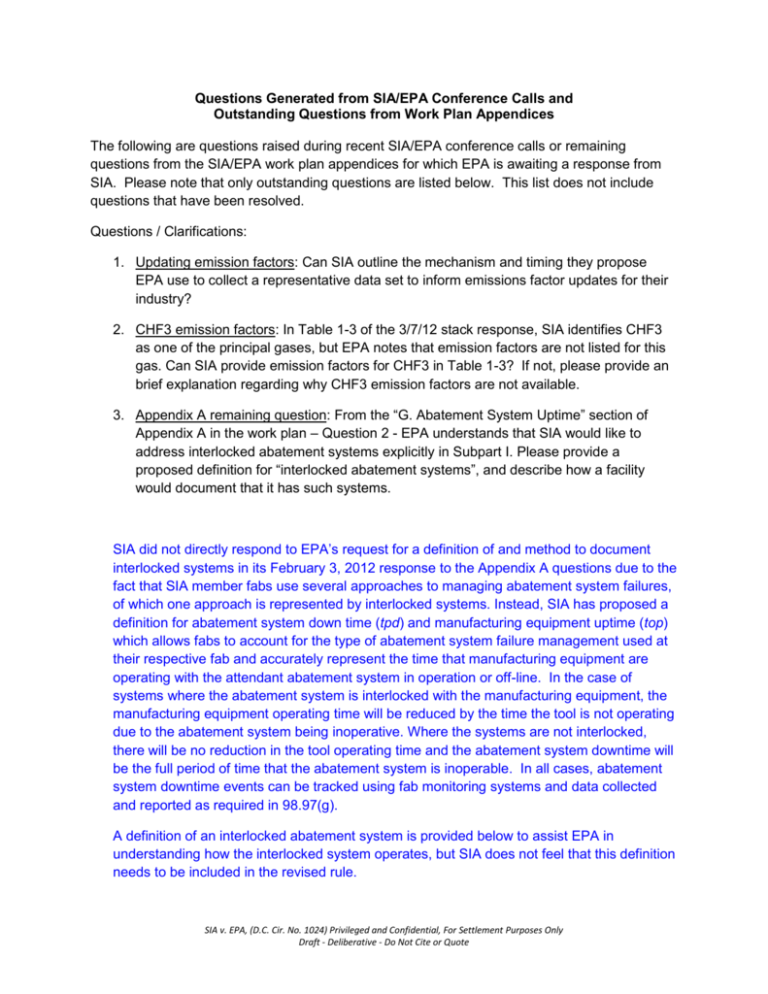

Questions Generated from SIA/EPA Conference Calls and Outstanding Questions from Work Plan Appendices The following are questions raised during recent SIA/EPA conference calls or remaining questions from the SIA/EPA work plan appendices for which EPA is awaiting a response from SIA. Please note that only outstanding questions are listed below. This list does not include questions that have been resolved. Questions / Clarifications: 1. Updating emission factors: Can SIA outline the mechanism and timing they propose EPA use to collect a representative data set to inform emissions factor updates for their industry? 2. CHF3 emission factors: In Table 1-3 of the 3/7/12 stack response, SIA identifies CHF3 as one of the principal gases, but EPA notes that emission factors are not listed for this gas. Can SIA provide emission factors for CHF3 in Table 1-3? If not, please provide an brief explanation regarding why CHF3 emission factors are not available. 3. Appendix A remaining question: From the “G. Abatement System Uptime” section of Appendix A in the work plan – Question 2 - EPA understands that SIA would like to address interlocked abatement systems explicitly in Subpart I. Please provide a proposed definition for “interlocked abatement systems”, and describe how a facility would document that it has such systems. SIA did not directly respond to EPA’s request for a definition of and method to document interlocked systems in its February 3, 2012 response to the Appendix A questions due to the fact that SIA member fabs use several approaches to managing abatement system failures, of which one approach is represented by interlocked systems. Instead, SIA has proposed a definition for abatement system down time (tpd) and manufacturing equipment uptime (top) which allows fabs to account for the type of abatement system failure management used at their respective fab and accurately represent the time that manufacturing equipment are operating with the attendant abatement system in operation or off-line. In the case of systems where the abatement system is interlocked with the manufacturing equipment, the manufacturing equipment operating time will be reduced by the time the tool is not operating due to the abatement system being inoperative. Where the systems are not interlocked, there will be no reduction in the tool operating time and the abatement system downtime will be the full period of time that the abatement system is inoperable. In all cases, abatement system downtime events can be tracked using fab monitoring systems and data collected and reported as required in 98.97(g). A definition of an interlocked abatement system is provided below to assist EPA in understanding how the interlocked system operates, but SIA does not feel that this definition needs to be included in the revised rule. SIA v. EPA, (D.C. Cir. No. 1024) Privileged and Confidential, For Settlement Purposes Only Draft - Deliberative - Do Not Cite or Quote Interlocked Abatement System: An abatement system defined as being “interlocked” with the manufacturing tool or tools that it is abating when a failure of the abatement system causes either immediate cessation of wafer processing on the tool or shutdown of the tool upon completion of the processing of the wafer(s) currently in the chamber. When an Interlocked Abatement System is present, the tool will not be available for processing until the abatement system alarm has been cleared and the abatement system is operational. 4. Appendix C remaining questions: a. Question 1a - Can SIA explain why the CF4 and NF3 DREs were low on the malfunctioning units? To provide some perspective for the answer to this question, SIA wants to reiterate the findings detailed in the abatement briefing paper (120110 SIA abatement briefing paper.pdf) and provide some details on how the tested abatement units in question are configured. Relative to performance, the tested abatement units did perform to the expected DREs for F-gases used in etch, with the exception of CF4, and for the abatement of NF3 from chamber clean processes. For NF3, only three of 36 units had a low DRE, with a significant majority of the units were performing in accordance with the manufacturer’s expected DREs. EXPLANATION OF COMBUSTION SYSTEM OPERATION AT THE TESTING FACILITY In order to understand the analysis of the low DREs, it is helpful to provide a brief explanation on the configuration of the combustion systems on the tested abatement units. Each etch abatement unit can support up to six etch chambers, and each chamber has an individual exhaust line which flows to the abatement unit. The exhaust from each individual chamber is mixed with fuel and O2 and combustion is initiated just prior to the main combustion chamber of the abatement unit. Most abatement units support three or four chambers. Each of the individual chamber exhaust lines feed into the main combustion chamber, which has a burner which receives fuel and combustion air (as opposed to O2) to maintain a combustion flame. Each process chamber has an exhaust gas flow which consists of the process gases, the purge nitrogen and eventually, the added fuel and O2 flows. This total flow in each individual chamber line, of which there can be a total of six, is the V(in) discussed below. Additional flow is generated in the combustion chamber through the addition of the fuel and combustion air in the burner. The sum of the V(in) of the chamber lines and the fuel and combustion air flow to the combustion chamber burner constitute V(out). SIA v. EPA, (D.C. Cir. No. 1024) Privileged and Confidential, For Settlement Purposes Only Draft - Deliberative - Do Not Cite or Quote This description is specific to the configuration of the abatement systems installed at the testing facility. Other facilities may use this configuration where abatement units support multiple chambers, but a facility may also use a different configuration which supports a single process chamber. Other manufacturer’s equipment may only support a single chamber or use a different system configuration to support multiple chambers. There are also abatement units which use plasma technology, which will have different flows and a different set of control parameters. As such, it is not possible to extrapolate the specifics of the corrective action analysis below to the full inventory of abatement systems installed at US fabs. CORRECTIVE ACTION ANALYSIS As discussed in the March 5, 2012 document submitted to EPA, the low DREs in the abatement units at the one testing facility were primarily the result of high inlet and/or outlet flow at the abatement unit. High inlet flows are typically caused by incorrectly set vacuum pump purge flows, while a high V(out) can result from several high inlet flows or from high fuel/combustion air flows to the combustion burner. For the abatement units used at the testing facility, both for NF3 and etch gases, the problems were corrected by setting the various flows and/or pressures to the manufacturer’s recommended settings. Specifically where low DRE was found for NF3, the primary cause was high inlet flows in the individual chamber lines into the abatement unit. For CF4 units, in addition to the impacts of the high inlet and outlet flows, it was also determined that manufacturer recommended set points for flowrate and/or pressure for fuel, oxygen and air need to be verified during set-up and ongoing maintenance to assure that the unit operates at the expected DRE for CF4. For the abatement units that had tested CF4 DREs at or above the manufacturer’s expected performance of 90% destruction, the corrective action investigation found that the flow, fuel and O2 settings were properly set and the flow out of the abatement unit was within the required range. After a full assessment of the results of the abatement testing, it was determined that modifications were required in the maintenance procedures to validate that the fuel, O2, and combustion air flows and/or pressure settings were in accordance with the manufacturer’s recommended requirements. Maintenance checklists and the training for technicians servicing the units have been improved to more clearly define set-up requirements that apply at the completion of initial system installation and to the regular maintenance checks. The equipment maintenance contractor for this facility is now able to certify that all units will perform to specification, as required under 98.96(q)(1) and 98.97(d) of the subpart I rule, based on the implementation of the revised procedures. SIA v. EPA, (D.C. Cir. No. 1024) Privileged and Confidential, For Settlement Purposes Only Draft - Deliberative - Do Not Cite or Quote It is important to note that the testing facility was in the process of performing DRE testing and validation of the maintenance procedures to enable the facility to use site specific DREs for emissions reporting and to be in a position to certify the performance of the abatement units as required in the Subpart I regulations. Prior to this testing, these abatement units were not covered by a specific set of regulatory requirements. b. Question 1b - Can SIA indicate whether there are any general criteria that could be applied to ascertain whether a unit is under performing or needs service without having to measure the abatement system DRE? After discussions and evaluation of available information from fabs with abatement units and abatement unit equipment manufacturers, SIA has determined that there are not any general criteria that can be applied to validate that abatement units made by different manufacturers or based on different technologies are performing to their expected DRE. As discussed in 7a, systems using the same technology but manufactured by different companies will have different control indicators based on how the system technology and their set-up requirements. The common denominator amongst these different systems is that the manufacturers of the equipment have established set-up and maintenance procedures to maintain system operation at their expected DREs as required by Subpart I certification requirements under 98.96(q)(1) and 96.97(d)(1). The installation and maintenance of the abatement units, performed in accordance with the manufacturer’s recommended requirements, coupled with the certification mandated in the two sections of Subpart I, provide a repeatable, robust process for validating that the abatement units should be operating to the expected DREs. As discussed above, with the exception of the CF4 DRE, the tested units operated at the expected DREs for abatement of NF3 from in-situ and remote plasma cleans and all of the tested F-gases used in etch over a range of abatement unit types. These results indicate that installing and maintaining the units in accordance with the manufacturer’s recommended procedures provides an effective means to validate that the abatement units are performing to the expected DREs for the gases being treated. The test data indicated that CF4 abatement systems at this one facility required a more detailed maintenance procedure than the current one being executed at the facility prior to testing. The need for more precise procedures is driven by the fact that CF4 is difficult to breakdown, as exhibited by the low process utilization rates for CF4. As discussed in the answer to 7a, supplier recommended modifications have been made to the procedures and are being implemented at the facility. SIA v. EPA, (D.C. Cir. No. 1024) Privileged and Confidential, For Settlement Purposes Only Draft - Deliberative - Do Not Cite or Quote SIA recommends that the manufacturer’s recommended installation and maintenance procedures serve as the generic criteria to validate that the abatement units are performing at the expected DREs. ENDING OPTION #1 The subpart I requirements can be strengthened by adding a section between 98.97(c) and 98.97(d) that requires the facility to establish and maintain a maintenance plan for the abatement units, which includes a defined preventive maintenance process and checklist (built on the manufacturer’s recommended maintenance program) and a corrective action process to follow whenever an abatement unit is found to not be operating properly. Recommended Language: 98.97( ): The facility will establish and maintain an abatement unit maintenance and corrective action plan which will define the required maintenance procedure for each type of abatement units in use at the facility and a corrective action process that will be followed whenever an abatement unit is found to not be operating properly. This language would provide clarity to the requirements behind the certification. This will enable a facility to set the maintenance procedures appropriate to its inventory of abatement systems and will be an underpinning to the certification requirement in 98.96(q)(1) and 98.97(d)(1). 5. Additional abatement / DRE submission: SIA references additional information / responses on abatement and DRE that will be submitted in March in the recent 3/6/12 submission to EPA. One SIA member company intends to complete DRE testing of 20% of their installed abatement units used for the removal of C2F6 and C3F8 from 200 mm chamber clean processes in accordance with the requirements of the Subpart I rule. This represents approximately 8 abatement units for C2F6 and 3 abatement units for C3F8. Because they are still arranging scheduling with the testing firm and the fab, we expect that DRE data will not be available for submittal to EPA until July or August of 2012. In addition, there may be additional, limited DRE testing for 200 mm CVD C2F6 abatement from another SIA member company. If done, these results should be available in April. It is SIA’s intent to collect and analyze the results of this testing utilizing the same methodology used to analyze the 300 mm NF3 CVD abatement and 300 mm etch abatement data and propose an industry level DREs for abatement of 200 mm C2F6 and C3F8 CVD clean processes. Our intent is to have the industry level DRE results available for incorporation into the re-proposed rule. If that is not possible, we intend to SIA v. EPA, (D.C. Cir. No. 1024) Privileged and Confidential, For Settlement Purposes Only Draft - Deliberative - Do Not Cite or Quote submit the data and associated statistical analysis for consideration as part of our comments on the re-proposed Subpart I rule. 6. Gas consumption over time data: SIA has presented comparisons of short- and longterm consumption rates for two gases, NF3 (“SIA response to EPA stack Questions feb 2012”) and c-C4F8 (“Response to EPA’s Stack Test Question 1”). Can SIA provide equivalent data for several other gases? 7. Threshold for infrequently used gases: EPA is considering setting a consumption limit for gases that are used during the reporting period but not included (i.e. flowing) during a stack test. If a gas goes over that limit, it would trigger a retest. Can SIA suggest a threshold and metric (i.e. % estimated CO2e, kg/yr) for this limit? 8. Use of different methods at the same facility: Would SIA prefer to be able to choose a method (i.e. etch or stack) per fab, as opposed to per facility? For facilities that have gas cylinders/tanks feeding more than one fab, is this option possible or would those facilities need to use one method for all fabs? SIA v. EPA, (D.C. Cir. No. 1024) Privileged and Confidential, For Settlement Purposes Only Draft - Deliberative - Do Not Cite or Quote