Biology Department Chemical Hygiene / Lab Safety Program

advertisement

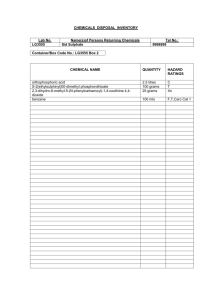

Biology Department Chemical Hygiene / Lab Safety Program The purpose of the Biology Department’s Chemical Hygiene / Lab Safety Program is to provide information and recommendations for recognized work practices to protect students, faculty, staff and visitors from physical and health hazards associated with chemicals in a laboratory setting. The State of Colorado has adopted the federal Occupational Safety and Health Administration’s (OSHA) Laboratory Standard which is applicable to students and employees of Fort Lewis College who work with chemicals. This standard serves as the basis for this program. The program will be reviewed on an annual basis. You may review the program during normal business hours in the Environmental Health & Safety (EH&S) office in room 227 of the Education Business Hall, or view a copy on the EHS web site. The Chemical Hygiene / Lab Safety Program is divided into the following sections: 1. 2. 3. 4. 5. 6. 7. Chemistry and Laboratory Safety; components of the program Physical and health hazards; routes of exposure and control methodologies Basic rules of safe laboratory procedures Personal protective equipment, fume hoods, and chemical handling and storage Training and information Exposure monitoring and medical consultation Emergency planning and response Chemistry and Laboratory Safety A) General Principles for Work with Laboratory Chemicals 1) It is prudent to minimize all chemical exposures. Because few of the chemicals you will use are free of hazards, general precautions for handling all laboratory chemicals must be followed, with specific safeguards followed for more hazardous chemicals. Skin contact with chemicals should be avoided at all times. 2) Avoid underestimation of risk. Always err on the side of caution. You should plan your work based on the assumption that all substances are toxic, and that all substances of unknown toxicity are toxic. Mixture should be considered more toxic than their most toxic component. Chemicals with low toxicity should still be treated in a manner that prevents exposure. Special hazards equal special precautions combined with special handling techniques. 3) Provide adequate ventilation. Always work in a hood when using toxic chemicals, thus minimizing airborne materials escaping into the laboratory. 4) Follow the chemical hygiene / lab safety program. This program is designed to minimize chemical exposure and related laboratory hazards. The purpose is to have students and lab worker follow the recommendations on a day-to-day basis, employing continuous improvement techniques. It is not to be viewed as a shortterm process. 5) Exposure should be limited to levels published by OSHA’s PELs and the American Conference of Governmental Industrial Hygienist’s (ACGIH) TLVs. These levels should not be exceeded in the laboratories at Fort Lewis College if the information in this document is understood and procedures followed as described. B) Chemical Hygiene / Laboratory Safety Responsibilities 1) President of Fort Lewis College. The President has ultimate responsibility for chemical hygiene and laboratory safety at the college and must provide continuing support for the college’s programs. 2) Faculty and the Departmental Chemical Hygiene Officer. These individuals play a crucial role in the support and efficiency of this program. Their responsibilities include the following: a. Work with other administrators and departments to further develop and implement appropriate chemical and laboratory policies and practices b. Supervise procurement, use and disposal of chemicals used in their labs c. Participate in audits and inspections d. Help students develop appropriate behaviors relative to chemical and laboratory safety e. Maintain proficiency in legal requirements regarding regulated substances f. Follow continuous improvement process relative to this program 3) Laboratory Supervisors. Whether student, staff or faculty, has the overall responsibility for chemical safety in the laboratory, including the following; a. Ensure that students and lab workers know and follow the chemical hygiene rules, that protective equipment is available and maintained in good working order and that appropriate training has been provided and documented. b. Provide daily housekeeping inspections including periodic inspection and testing of emergency equipment. c. Provide constant, positive reinforcement of safe chemical and laboratory safety behaviors by students and lab workers. d. Keep current on legal requirements concerning regulated materials e. Determine appropriate type and kind of personal protective equipment (PPE) for general biology needs as well as for more hazardous chemical exposures. Insure PPE training is documented and used by students as required. f. Insure facilities and training for use of any new materials or hazards is adequate. 4) Students and Lab Workers. a. Take responsibility for planning and conducting each task or lab according to the appropriate directions and proper lab safety protocols identified by the laboratory supervisor. b. Learn, develop and put into practices the safe work practices taught in the classroom or laboratory. C) Laboratory Facility 1) Usage. The type of work conducted and its scale must be appropriate to the physical facilities available and to the quality of the ventilation in the lab. Microscale amounts of chemicals should be utilized whenever possible, as should “Green” processes. 2) Ventilation. a. The general laboratory heating, ventilation, or air conditioning (HVAC) system should not be relied upon for protection from toxic or hazardous substances released into the air. b. Each hood should be provided with a constant monitoring device that indicates adequate hood performance. Work with substances that are toxic should not be performed unless it is inside a properly operating hood. c. No modifications to the existing hoods or HVAC system should be made unless thorough testing indicates student and lab worker protection from potential airborne will continue to be adequate. Documentation must be completed before work is allowed. d. Fume hood efficiency should be measured and documented at least annually and more frequently as the situation warrants. D) Components of the Chemical Hygiene Plan 1) Chemical Procurement, Distribution and Storage. a. Before a substance is received information on proper handling, storage and disposal should be known to those who will be involved. A material safety data sheet (MSDS) and product specification sheets must be secured and evaluated before the material is purchased. Once delivered, the container must be labeled to adequately identify the contents and hazards. b. Toxic substances must be segregated in well-identified areas and provided with local exhaust ventilation. Highly toxic chemicals should be stored separately and in secondary containers. Stored chemicals should be inventoried on an annual basis and examined for deterioration of the container and chemical. c. Stockrooms should not be used for preparation, repackaging or disposal of chemicals. d. When dispersing or transporting chemicals a secondary container must be used. e. The amount of chemicals to be used should be as small as possible. Storage of chemicals on bench tops or in hoods in not allowed. Avoid exposure of the chemicals to direct heat or sunlight. 2) Environmental Monitoring. In most laboratory situations the need for environmental monitoring is not indicated. Special monitoring may be conducted during hood repairs or if highly toxic chemicals are being used. 3) Housekeeping, Maintenance and Inspections. a. Cleaning of the laboratories should be conducted on a routine basis. Floors should be kept clean and ordinary waste receptacles emptied before they 4) 5) 6) 7) reach capacity. Bench tops and hood surfaces should be cleaned after each laboratory session. b. Inspections should be conducted daily on an informal basis. Formal walk around inspections should be conducted at the beginning and middle of the semester. c. Safety showers should be tested at least monthly and eyewashes should be flushed on a weekly basis. The testing should be documented and kept for at least one year. d. Work areas, hallways and points of egress must be kept clear of obstructions and not used as storage locations. Access to exits, emergency equipment and utility controls must never be blocked. Personal Protective Equipment and Apparel a. Each laboratory must select the type of PPE that protects the students and lab workers. This includes gloves, disposable gloves, aprons, chemical splash goggles, face shields and perhaps disposable coveralls. b. Students and lab workers must be instructed how to operate the eyewash and safety shower. c. Any other protective device or measures deemed necessary by the lab supervisor will be provided and appropriate training provided and documented. Signs and Labels Prominent signs and labels of the following types shall be posted: a. Emergency telephone numbers must be posted, including Fort Lewis Police, Student Health Center, Physical Plant Services, Lab Supervisors and Department emergency contact. b. Identity labels showing contents of containers and appropriate hazards c. Location signs for emergency eyewash and showers, fire extinguishers, first aid equipment (if provided) and where food and beverage are permitted and not allowed. d. Warnings at locations of unusual hazards or equipment. Chemical Spills and Accidents a. A written emergency response plan should be written and reviewed with students at the beginning of each semester. It should include procedures for hood failure, chemical spills – both small and large, evacuation, lock-down, accident reporting, fire emergencies and drills. b. The alarm system should be explained and the required response reviewed and practiced. c. Evacuation routes should be identified, and reassembly points identified. d. All accidents, including near-miss incidents and sharps-related events must be reported to the laboratory supervisor and an accident report completed and forwarded to Human Resources. Information and Training a. The goal is to inform and then train all students and lab workers about the risks and hazards in the laboratory, both from a chemical and physical basis. How to respond to an emergency situation or accident is an essential part of the training. b. Every student and lab worker should know the location and proper use of available protective equipment and apparel. Full time employees should know every procedure applicable in this regard, including how to use a fire extinguisher. First aid training, CPR and AED training is offered and full time employees should avail themselves to attend the training and maintain their certifications. c. Training should be conducted on a regular basis in conjunction with the academic calendar. Training should be part of a continuous effort, and not just an annual or singular event. d. Information on training topics should be readily available to students and lab workers. 8) Waste Disposal Program a. The goal of the waste disposal program is to insure that Fort Lewis College follows the Colorado Department of Public Health & Environment’s rules and regulations relative to the handling, storage and disposal of laboratory hazardous wastes. A properly managed program assures minimal harm to students, employees, visitors, the general public and the environment. b. Fort Lewis College has published guidelines and procedures relative to the how hazardous waste should be collected, segregated, stored, and transported. This information is posted on the college’s internet and can be located on the EH&S website. c. Unlabeled containers of chemicals and solutions should be disposed of promptly via our established procedures d. Disposal via floor drains or sinks is strictly prohibited. e. Disposal via hood evaporation is strictly prohibited. f. All chemicals for disposal should be handled by the EH&S department. 9) Records a. Accident reports and near-miss incidents reports should be retained for three years in the department. Copies of each report are required to be on file in Human Resources. b. Assistance with completing an accident report can be coordinated with the EH&S or Human Resources departments. c. Inventory and usage records for high-risk or highly toxic chemicals should be kept as specified by State or federal law. Physical and Health Hazards, Routes of Exposure & Control Methodologies A. Physical Hazards 1) Combustible Liquids – any liquid or mixture with >1% or more of a liquid, with a flashpoint at or above 1000 F but below 2000 F. 2) Compressed Gas – a gas or gas mixture with an absolute pressure exceeding 40 p.s.is at 700 F, or exceeding 104 p.s.i. at 1300 F, or a liquid having a vapor pressure 3) 4) 5) 6) 7) 8) 9) exceeding 40 p.s.i. at 1000 F as determined by the ASTM D-232-72, a standard of the American Society of Testing and Materials. Explosive – a chemical that causes a sudden, almost instantaneous release of gas, pressure, and heat when subjected to sudden shock, high temperature or pressure. Flammable – a. Aerosol – a material that can produce a flame or flashback from a valve opening b. Gas – any gas at ambient conditions that will cause s flammable mixture with air in concentrations below 13% c. Liquid – any liquid, or mixture with 1% or more of a liquid, with a flash point below 1410 F. d. Solid – a material that is liable to cause fire through friction, contact with moisture, spontaneous reaction, or retained heat, or which can be readily ignited and burns with enough persistence or violence to cause a serious health hazard. Organic Peroxides – an organic compound with a bivalent O-O structure, which may be considered a peroxide derivative with one or both of the hydrogen atoms replaced with an organic molecule. They present dangerous fire and explosion risks; many are strong oxidizers. Oxidizer – a chemical that initiates or supports combustion of other materials, causing fire by itself or by the release of oxygen or other gasses. Pyrophoric – a material that will ignite spontaneously in air at or below 1300 F. Unstable – any material which will vigorously decompose, polymerize, condense, or will become self reactive when exposed to conditions of shock, pressure or temperature. Water-reactive - a material which can react with water or steam to produce a gas which is either toxic or flammable. B. Health Hazards 1) Carcinogen – a material which causes or potentially causes cancer according to the International Research on Cancer, or is listed as such in the National toxicology Program Annual Report on carcinogens. 2) Corrosives – chemicals that cause visible destruction of, or irreversible alterations in, living tissue by chemical action at the site of contact. 3) Irritants – chemicals which are not corrosive, but which cause reversible inflammatory effects on living tissue at the site of contact. 4) Mutagen – a material that damages chromosomes. 5) Sensitizer – a chemical, which will cause an allergic reaction in a substantial number of exposed people. 6) Target Organ Effects – consist of the following list of examples: a. Cutaneous hazards: damage the skin b. Eye hazards: damage the eye c. Hematopoetic toxins: damage the blood and/or blood forming organs d. Hepatotoxic: damage the liver e. Nephrotoxic: damage the kidneys f. Pulmonary toxins: damage the lungs g. Reproductive toxins: affect the fetus 7) Teratogen – a material that causes birth defects 8) Toxic – a chemical with an oral lethal dose of 50 – 500 mg/kg, a cutaneous lethal dose of 200 – 1000 mg/kg, or a lethal concentration in air of 200 – 2000 ppm. 9) Highly toxic: a material with an oral lethal dose of <50 mg/kg, a cutaneous lethal dose of <200 mg/kg, or lethal concentration in air at <200 ppm. C. Factors Affecting Toxicity 1) Dose – is the amount of exposure to a chemical. A small dose is usually a lesser concern than a large dose. For most chemicals there is a level of exposure below which no adverse effect is likely to be observed. 2) Toxicity – chemicals vary widely in how toxic or poisonous they are. Exposure to small amounts of highly toxic materials can be a greater danger than exposure to large amounts or less toxic chemicals. 3) Duration and frequency – One-time exposures of short duration are of less concern that multiple exposures of long duration. 4) Synergistic effects – when two or more chemicals present an exposure the result may be more hazardous than adding the two effects together. 5) Acute and chronic effects – acute exposure may result in an immediate response, such as spilling a caustic on the skin. Chronic effects result from long term exposure which may span years. D. Routes of Exposure 1) Inhalation - is the most common route of entry into the body. Materials inhaled can include gases, vapors, mists, sprays, dust particles and fibers. 2) Skin contact – chemicals can injure the skin by direct contact or can be absorbed through the skin to cause systemic effects. 3) Ingestion – usually occurs via contaminated hands. Washing prior to eating, drinking, applying cosmetics or smoking will reduce the possibility of contamination. 4) Injection – occurs during accidental contact with sharps or broken glassware. A secondary source of injection is compressed air or high pressure liquid or gases. E. Control Methodologies 1) Engineering controls – reduce or eliminate hazards through methods of isolating the hazard, work practice changes, substitution of less hazardous materials and redesign of a process. Using a chemical fume hood or glove box are examples of engineering control. 2) Administrative controls – are actions taken to reduce exposure via personnel actions. Examples include posting of warning signs, restricting access to authorized personnel, working off-shifts to reduce exposure, job rotation and job sharing. 3) Personal protective equipment (PPE) – is considered the last line of defense to chemical exposure. Examples of PPE include splash goggles, hearing protection, gloves, aprons and respiratory protection. Basic Rules of Safe Laboratory Procedures Accident reporting – all accidents and near miss events must be reported to the laboratory supervisor. Investigation and reporting information can be found on the EH&S website. Call 911 or 9-911 from a campus phone in emergency situation. Avoidance of exposure – learn, develop and practice safe lab habits, and always avoid unnecessary exposure to chemicals by any route. Do not smell or taste chemicals. Always open containers of volatile chemicals inside a working chemical fume hood. Chemical spills – if a chemical is spilled on the skin, flush the area for at least 15 minutes. Call 911 or 9-911 from a campus phone if the spill is large, or if assistance is needed. Small spills may be cleaned up using the laboratory spill kit. Large spills necessitate evacuation of the lab and perhaps the building. Children in labs – children should not be in laboratories where hazardous materials or equipment are in use. Disposal of chemicals – contact the laboratory director to arrange for disposal of chemical collection containers through EH&S. Eating, drinking, smoking, applying cosmetics – is prohibited in laboratories. Always wash hands before (and after) these activities. Do not consume, handle or store food or water in lab operation areas. Emergency eyewash and safety showers – must be properly maintained. Protective caps must be kept on the eyewash. Miscellaneous items are not to be kept in the eyewash. The eyewash and safety shower must be readily accessible; do not store anything in front of them. Signage may be needed to indicate the location of the eyewash/shower. Eyewashes and showers should be flushed on a regular basis – weekly for eyewashes and monthly for showers. Testing should be documented. Equipment and glassware - handle glassware carefully to avoid damage to it and injury to you. Use caution when handling Dewer flasks or other evacuated glass apparatus. Use equipment only for its designed purpose. Exits – Keep exits clear of storage and insure the access to the exit is kept clear, as well. Extension cords – should only be plugged into ground fault circuit interrupters (GFCI) and be visible while in use. Cords should be inspected on a regular basis. Damaged cords should be immediately removed from service. Use appropriate length cords – do not coil cords as significant heat can build up when used. Do not run cords through doors, window, in aisles, under rugs or above drop ceilings. Do not wrap them around fixtures, pipes, lights or ductwork. Fire Alarms – know what the alarm sounds like and where to evacuate in case of an emergency. Always evacuate the lab as if there were a working fire in progress. Never use an elevator during an evacuation. Do not reenter the building until the alarm is turned off and it is safe to do so. Fire Extinguishers - locate the fire extinguisher in the lab and insure access to it is not blocked. Do not use an extinguisher unless you have been trained, it is appropriate for the fire and you have a clear escape path. Horseplay – is strictly forbidden. Any behavior that could confuse, startle or distract another student or worker is forbidden. Housekeeping – keep the work area clean and uncluttered. Chemicals must be properly labeled, handled and stored. The lab work areas should be cleaned at the end of the class or the end of the day. Do not use floors for storage. Do not dispose of broken glass or sharps in the trash removed by our custodial staff. Utilize the designated broken glass containers at all time. Mouth pipetting – never pipette by mouth. Personal apparel – confine hair and loose clothing. The legs should be fully covered – no shorts or skirts. No open toed shoes or sandals in the lab. If warranted, wear a lab coat or disposable aprons or coveralls. Personal Protective Equipment, Fume Hoods, and Chemical Handling and Storage A. Personal Protective Equipment (PPE) – appropriate PPE must be worn by all students, lab workers and visitors whenever chemicals are handled. 1) Colorado state law specifies that eye protection be worn by students, staff or visitors in labs whenever a hazardous condition exists. Safety glasses or chemical splash goggles are the preferred types of protection. Contact lenses should not be worn in labs. 2) Faces shields should be worn if the hazard warrants additional protection to the face and/or body. 3) Gloves must be worn when hazardous materials or toxic compounds are handled. Insure the gloves offer appropriate resistance to the chemical being handled. 4) Chemical resistant aprons or lab coats should be worn depending on the chemicals in use. B. Fume Hoods 1) Chemical fume hoods are designed to protect the user when operating with a sash air velocity of 100 (+/- 10 %) fpm at the appropriate sash height. 2) Fume hoods may not capture fumes emitted from a container located within six inches of the sash. All vapor sources should be located at least six inches deep into the hood. 3) Since the sash is designed to be used as a safety shield, work with it as low as is comfortably possible and always set at or below the sash stop. This will provide maximum air flow and maximum protection for your face and body. 4) The laminar flow that captures the heavier-than-air vapors is disrupted by large objects both in and immediately outside of the hood, including the operator and passers-by. 5) Close the sash when you are not working in the fume hood. 6) Do not store chemicals or flammable solvents in the fume hood. C. Chemical Handling and Storage 1) Do not underestimate risk. Assume that any mixture will be more toxic than its most toxic component and that all substances of unknown toxicity are toxic. 2) When undertaking chemical work, seek information and advice about hazards and plan appropriate protective procedures. Allow adequate time and attention for careful work. 3) Minimize exposures to all laboratory chemicals, including exposures to vapors, dusts and via skin contact. 4) Minimize vapor exposures by working in a fume hood and by keeping containers tightly closed whenever possible. Remain aware of the presence of odor in the workplace as a warning about exposure. If exposure symptoms appear (nausea, lightheadedness, headache, breathing difficulty, etc), immediately leave the area and seek help. 5) Use equipment only for its designed purpose. 6) Keep the work area clean and uncluttered, with chemicals and equipment being properly labeled and stored; clean up the work area before leaving. 7) Do not use compressed air or gases until you have completed training in safe cylinder handling and have documented your proficiency to the lab supervisor. 8) Insure all containers and secondary containers are in good shape. Make sure that the container is compatible with the chemical it holds. Any deficiency in containers must be brought to the attention of the lab supervisor. 9) Make sure all labels are legible, containing the chemical name and appropriate health and fire hazards. 10) When handling chemicals be sure to: use a secondary container when needed; keep caps tightly closed; never add water to concentrated acid; wear PPE as needed and work inside of the hood. 11) Store chemicals by hazard class, and do not store incompatible chemicals adjacent to one another. Store volatile chemicals in special ventilated storage cabinets. Store chemicals with ergonomics in mind – no liquids at eye height and heavier containers between knee and waist height. 12) Follow lab policy in disposing of waste chemicals – nothing down the drain unless specifically identified and approved. Inform lab supervisor when the designated waste container is to the fill line. D. Working with chemicals of Highly Acute or Moderate Chronic toxicity 1) Always minimize exposure to these materials by any route using all reasonable precautions. 2) Use and store these materials only in areas of restricted access with special warning signs posted. 3) Always work in a chemical fume hood. 4) Always wear appropriate PPE. Avoid skin contact by wearing long sleeves and gloves. Wash gloves, remove and dispose, then thoroughly wash hands and arms. 5) Maintain records of the amounts of these materials ordered, used, and disposed. Record the names of all students and lab workers exposed to these materials. 6) Prepare ahead and have appropriate spill materials selected and on-hand. 7) Store materials in secondary containers that are chemically compatible with the materials. 8) Store wastes in chemical compatible container and in a separate, secure location. E. Working with chemicals of High Chronic toxicity 1) The work rules listed above are to be followed, as well as the following: a) All work and handling must be in a controlled area with a restricted access fume hood or lab space designed for work with high chronic toxicity materials, and insure all students and lab workers are aware of the hazards of the materials in use. b) Prepare a plan for use and disposal of these materials and have it approved by the laboratory supervisor prior to beginning work. c) Upon completion of work decontaminate the work surfaces. d) Insure the controlled area is conspicuously marked with warning signs and restricted access signs. e) Insure all containers are labeled and include warning labels. f) Whenever possible use chemical decontamination and ensure the containers of wastes are transferred in secondary containment to the disposal site. Training and Information Students and lab workers must be trained on the OSHA laboratory standard. A copy of the standard is available for all students and employees to review at their convenience. This document provides an overview of the standard. Topics covered in training include the information in this document and any specific hazards associated with non-routine work. Faculty and staff should train students and lab workers when any new chemical hazard is introduced into the laboratory or before any new procedure is introduced. Some of the best information on chemical hazards is found in the manufacturer’s or supplier’s material safety data sheets (MSDSs). Most MSDSs can be located on-line via web searches or at MSDS repository sites. Each lab should have a copy of a MSDS for each chemical. Check with the laboratory director if the MSDS is not in the lab. It is important to note that each business or organization can design their MSDS according to their preferred format. Not all MSDS are created equally. All MSDSs must contain the following information: Name, address and phone number of the manufacturer, supplier or importer Chemical name, synonyms and Chemical Abstracts (CAD) Number Physical properties List of chemical constituents for mixtures with corresponding exposure criteria defined by either the American Conference of Governmental Industrial Hygienists (ACGIH) listed as the Threshold Limit Value (TLV) or the Occupational Safety and Health Administration (OSHA) Permissible Exposure Limit (PEL). Health hazard information First aid measures Fire fighting methods Handling and storage precautions PPE recommendations Exposure controls Stability and reactivity Newer versions of MSDSs will contain additional information listed below: Toxicological data Ecological data Disposal information based on Environmental Protection Agency (EPA) requirements Transportation information Various regulatory information Any other information considered important by the authors Manufacturers, suppliers and importers must make the MSDS information readily available when requested; supply a copy the first time the product is sold to a new customer; update the MSDS at least every three years; and provide trade secret information during a medical emergency. A PowerPoint presentation on Chemical Hygiene and Laboratory Safety is available for use by students, lab workers and faculty to assist in training. Exposure Monitoring and Medical Consultation Limiting exposure to chemicals used in the laboratories is one of the main objectives of the Chemical Hygiene / Lab Safety Program. Fort Lewis College requires that chemical exposures be maintained below OSHA’s PELs and any applicable Action Levels. Certain chemicals have Action Levels that are lower than the PELs and which require certain actions be taken, such as medical surveillance and workplace monitoring. Lab supervisors will be expected to use professional judgment when assessing the nature of chemical exposure resulting from a lab procedure and prescribe engineering controls and/or personal protective equipment to be used during the procedure. If the supervisor, students or lab workers have a question regarding exposure, air monitoring will conducted. The supervisor will contact EH&S who will arrange for the monitoring. The results of the monitoring will be shared with the individual wearing the monitoring equipment and laboratory supervisor. EH&S will maintain all air monitoring records. Employees are asked to contact their immediate supervisor if they suspect exposure levels above allowable concentrations. When exposure exceeds either the action level or PEL, an appropriate type of control measure will be selected and implemented. Control measures are classified as: Engineering Controls Standard Operating Procedures Personal Protective Equipment Implementation of specific measures will be carried out on a case-by-case basis, following established risk management techniques and nationally recognized best practices. Laboratory workers exposed to hazardous chemicals may receive medical examinations and necessary follow-up examinations by a physician when: An employee develops symptoms associated with a hazardous chemical to which the employee may have been exposed in the lab When exposure monitoring reveals airborne chemical levels routinely exceed the Action Level or PEL for a regulated substance Whenever an event such as a spill, leak or explosion occurs that results in exposure The laboratory supervisor will be responsible for contacting EH&S regarding the potential exposure. The responsibility for coordinating appropriate medical examination rests with the lab supervisor, department chair and/or dean, EH&S and Human Resources. Fort Lewis College will provide for all medical examinations, follow-ups and consultations as directed by the attending physician. Employees will be scheduled for examinations during their regular working hours, without loss of pay. Emergency treatment will follow these standard procedures: Fort Lewis College will furnish the following information to the physician: The identity of the hazardous chemical A description of the conditions under which the exposure occurred, with quantitative exposure data provided, if available A description of signs and symptoms expected or realized by the employee The physician will provide a report to Fort Lewis College that includes the following: Recommendations for further follow-up Results of the medical examination and associated tests Any medical condition which may put the employee at increase risk of result of exposure to the hazardous chemical A statement that the employee has been informed by the physician of the results of the examination and if further medical treatment is needed The written opinion(s) will not reveal any information unrelated to the occupational exposure. Emergency Planning and Response A. Planning for spills 1) Before working with chemicals determine what could go wrong and how you would respond to it. This process should be documented and approved by the laboratory supervisor. This process should then be communicated to all in the lab. 2) Spill kits should be available in the lab, and contain appropriate clean up materials and tools. Each student and lab worker should be informed of the contents of the kits. Kits should be checked periodically to ensure the contents listed are present. 3) Materials presenting the greatest hazard include: air or water reactive, flammables, corrosives and highly toxic items. Based on your hazard analysis you should pre-select PPE, appropriate clean up materials and define basic first aid procedures. B. Small Spills (Less than 3 ft2 or 3 ft. in diameter) Alert people in the immediate area, especially the lab instructor. Stop the source of the spill if possible. Avoid breathing vapors from the spill. Increase ventilation in area of spill (open windows, turn on hoods). If the vapors are flammable, turn off any potential heat or sparking source. If the spill site appears unsafe, evacuate the area, close the door and call 911 or 9-911 from a campus phone. Remain in the vicinity to provide the emergency responders pertinent information about the nature of the spilled materials. Keep others out of the spill area. If you are trained in spill cleanup and can safely do so, clean up the spill, wear protective equipment, including safety goggles, gloves, etc., as needed. Do not work alone during a spill cleanup. If the workplace is equipped with a Spill Cleanup Kit (available from EH&S) use the adsorbant materials for liquids. Prevent the spread of the material. Thoroughly clean the spill area with a suitable cleaning agent. If the spilled material is a hazardous chemical consider all residual chemical and cleanup materials (adsorbent, gloves, etc.) as hazardous waste. Place these materials in a plastic bag or container with lid, label the container and contact EH&S for disposal instructions and pickup. Restock the spill kit and any emergency supplies and equipment. Assess the incident and revise plans and lab procedures accordingly. Share the information with others in your department. C. Large Spills (Greater than 3 ft2 or 3 ft. in diameter) If the spill is a large spill, call 911 or 9-911 from a campus phone immediately Alert people in the immediate area, especially the lab instructor. Avoid breathing vapors from spill. Increase ventilation in area of spill (open windows, turn on hoods). If the vapors are flammable, turn off any potential heat or sparking source. Be ready to evacuate the building, if needed. When calling 911 or 9-911 from a campus phone indicate it is a major hazardous material spill. Be ready to identify the spilled material, if known. Remain in the vicinity to provide the emergency responders pertinent information about the nature of the spilled materials. Keep others from entering the spill area. Be ready to supply the following information: location of spill including building, floor, room number; potential fire hazard: what has been spilled and if contained or continuing; is the material a gas, liquid, solid; if the spilled material could travel to another location. Do not attempt to clean up the spill unless you are trained as an emergency responder. After the spill is cleaned up, thoroughly reclean the spill area with a suitable cleaning agent. Place all spill related cleanup materials in a plastic bag or container with lid, label the container and contact EH&S for disposal instructions and pickup. Restock the spill kit and any emergency supplies and equipment. Assess the incident and revise plans and lab procedures accordingly. Share the information with others in your department. D. Injuries Do not move an injured person unless they are in further danger (from inhalation or skin exposure). Call 911 or 9-911 from a campus phone in an emergency. Student Health Center and Mercy Medical Emergency Room personnel have direct access to MSDS and emergency treatment information if provided with the chemical name. You can also check on-line at the EH&S web site. Each department should have a current copy of the MSDS for each product in use. Complete an accident report for any incident requiring assisted cleanup or medical assistance. File the report with EH&S and Human Resources.