Web page: home page intro

advertisement

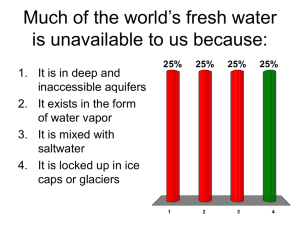

Brian Kirke’s web page summary: 1 Oct 2014. Why a web page? I have a lot of ideas about meeting basic human material needs: water, food, sustainable energy, environmental issues - too many for me to develop in one lifetime. Some may prove to be impractical but others may turn out to be worth developing further. Thanks to my good friends Leo Lazauskas and Kitty Davis, who have put some of my ideas on their web page in the past and have agreed to add some more, I hope that I can link up with other interested people and organizations with skills that complement mine, to evaluate these ideas and develop some of the more promising ones. Or failing that, in the hope that someone, somewhere, will get some value from them one day. Some of these overlap and if I ever get smart at web design I'll develop links. What ideas? 1. Geomimicry: mimicking natural processes, not just the physical forms of living organisms as in “biomimicry.” 1.1 Improved soil fertility and agricultural productivity 1.2 Using natural flow to clear blocked river mouths 2. Water supply: 2.1 subsea stormwater storage 2.2 reducing evaporation and seepage losses in irrigation channels using low cost, thin-walled plastic pipes 2.3 wind and wave-powered reverse osmosis 2.4 deep sea reverse osmosis 2.5 towing icebergs 2.6 inter-basin water transfer from North Queensland or northern NSW to the Murray-Darling 2.7 water transfer from Tasmania to the mainland via an undersea pipe 2.8 Point Lowly desal plant 3. Water quality: 3.1 circulation in potable storages to reduce cyanobacteria and Mn, Fe and P in solution 3.2 suction dredging of dams to remove nutrient-rich bottom sediments, restore lost storage capacity and restore function of bottom scour valves and intakes which have become covered with silt in old dams 3.3 cleaning up Torrens Lake in Adelaide, West Lake on the Gold Coast and other stagnant water bodies by circulation and filtration 4. Renewable Energy: 4.1 direct mechanical application of wind power, especially for pumping (including reverse osmosis, pumped hydro energy storage, liquid air energy storage, sand pumping and artificial upwelling) 4.2 Renewable Energy: from tidal and river currents using HKTs 4.3 Renewable Energy: from waves, especially direct mechanical applications such as upwelling, sand pumping, pumped storage and RO 4.4 Geothermal 5. Energy storage: 5.1 pumped hydro 5.2 liquid air storage 5.3 rust belt flow batteries 6. Food: 6.1 enhancing fish stocks by artificial upwelling using wind, tidal or wave energy 1 6.2 saline irrigation 6.3 Water requirements to produce 1 kg beef 6.4 Low energy circulation and aeration in intensive pond aquaculture, e.g. prawns (shrimps) 7. Environmental: reducing coral bleaching on the Barrier Reef by artificial upwelling of cool deep ocean water, using wind, tidal or wave energy 8. Algae for biofuels, wastewater treatment and CO2 bio-sequestration. Why not publish in refereed journals? I do, when practicable, but I have lots of ideas that do not fit the mould or are not well enough established to be acceptable to most journals. And there are some disadvantages to publishing: Delays: it can take months or years to go through the process of submission, review, rejection, revision, resubmission etc., especially if you are exploring innovative ideas which don’t fit easily into an established category, or ideas that span two or more traditional disciplines. Busy referees who have risen in a narrow discipline may not have the time to think deeply and understand what you have written and may therefore reject it. By the time it is published – if at all - the content may be obsolete. Trivial publications. Most journal articles and conference papers are written by aspiring academics who have to accumulate publications in order to climb the rungs of academe. Applicants for academic positions are commonly screened by eliminating those without enough weighty-looking publications. Although lip service is paid to quality of publications, this is much harder to quantify than just the number of publications, so the overworked people who sit on academic promotion committees usually just count the number. So the imperative for the aspiring academic is to notch up as many papers as possible. Often papers have multiple authors so they can all score a publication, and basically the same information often appears in 2 or 3 places with only slightly modified content. The result: 90% of what gets published is mediocre stuff, making minute and insignificant contributions to knowledge. Much better to publish on a website where any interested person can read and respond immediately and there is no need to conform slavishly to the required format for a particular target journal. Of course a lot of garbage gets on the internet, and we all have to use some critical judgement to assess what is believable. What ideas? More about each of the ideas listed above: why is it important? What am I doing about it? Priorities, roadblocks. 1. Geomimicry: mimicking natural processes, not just the physical forms of living organisms as in “biomimicry.” Geomimicry is a term I use for processes of mimicking natural systems or processes to achieve desirable outcomes such as improved soil fertility, agricultural productivity, water quality, increased fish stocks, etc. 1.1 Improved soil fertility and agricultural productivity The term geomimicry could be used for such well-known processes as spreading manure and/or biochar on agricultural land to enhance fertility. Another agricultural example is the use of pulverised natural minerals to correct deficiencies and imbalances in the chemical composition of soils to mimic the composition of soils known to be highly fertile and productive. This was done by Bob Hill, who ran a company called Mineral Fertilizers in the early 1970s. Yet another example, pioneered by Roger Groocock of Clendon Farm near Bordertown and others, is "delving" and "claying," in which the fertility of a sandy soil overlying heavy clay is enhanced by digging up some of the clay and spreading it on the surface, where it gradually breaks down and mixes with the sand, improving 2 texture, mineral content, moisture holding capacity and hence drought resistance. It has also been shown to improve non-wetting soils and frost resistance. P.A. Yeomans developed the keyline farming concept in which runoff is trapped by furrows and dams as high up on a property as practicable so that flood irrigation can be carried out. He also promoted chisel ploughing to increase the depth of biologically active soil. According to http://www.keyline.com.au, Yeomans exploded the myth that it takes 1,000 years to produce an inch of topsoil. Yeomans pioneered, among other things, the use of on farm irrigation dams in Australian, as well as chisel plows and subsoil aerating rippers. Yeomans perfected a system of amplified contour ripping that controlled rainfall run off and enabled the fast flood irrigation of undulating land without the need for terracing....he proposed the use of Keyline methods to create City Forests for sewage effluent utilisation. Peter Andrews is the inventor of the Natural Sequence Farming method. He is acknowledged as having converted his degraded high-salinity land at Tarwyn Park into a fertile, drought-resistant estate. His techniques run counter to prevailing accepted practices. Peter Andrews is also the author of a best selling book on his methods, entitled Back from the Brink: How Australia's Landscape can be Saved. He also has written a book called "Beyond the Brink" that further explains his theories about water movement in the Australian landscape with the additional subjects of global warming and GMO usage and how this affects soil and the environment. This is a pragmatic book. Permaculture is a branch of ecological design, ecological engineering, environmental design, construction and integrated water resources management that develops sustainable architecture, regenerative and self-maintained habitat and agricultural systems modeled from natural ecosystems.[1][2] The term permaculture (as a systematic method) was first coined byAustralians Bill Mollison and David Holmgren in 1978. The word permaculture originally referred to "permanent agriculture" [3] but was expanded to stand also for "permanent culture," as it was seen that social aspects were integral to a truly sustainable system as inspired by Masanobu Fukuoka's natural farming philosophy. Permaculture is a philosophy of working with, rather than against nature; of protracted and thoughtful observation rather than protracted and thoughtless labor; and of looking at plants and animals in all their functions, rather than treating any area as a single product system. http://en.wikipedia.org/wiki/Permaculture 1.2 Using natural flow to clear blocked river mouths. Rather than using an expensive, dieselguzzling dredge in a futile battle to keep ahead of siltation at the mouth of the River Murray, Dean Thomas of Mount Compass and Ric Capaldo of Port Elliott investigated the use of the energy in the outgoing tide to keep the mouth clear. They demonstrated a device which increases the flow velocity at a point on the bottom, resuspending sand and creating helical vortices which carry the resuspended sand up towards the top of the water column where the current can carry it back out through the mouth. But the authorities are not interested. 2. Water supply 2.1 Subsea stormwater storage Stormwater pipes could feed into a large subsurface “umbrella” made of flexible material, anchored to the bottom, deep enough to be out of the way of boats and not too much disturbed by wave action. Being less dense than sea water, the low salinity stormwater would be buoyant and would rise until held by the “umbrella,” so a complete bag would not be necessary. 2.2 Water supply: reducing evaporation and seepage losses in dams and irrigation channels using low cost, thin-walled plastic sheet 3 Although most of us live in the suburbs and there is a need to improve water use efficiency in the suburbs, most of the water in the Murray-Darling system is used for irrigation. A small percentage reduction in water wastage in irrigation could save more water than millions of people “watching every drop” in the suburbs. One big area of wastage is evaporation and seepage loss from irrigation channels. According to http://www.theage.com.au/articles/2003/05/22/1053196672927.html (accessed 30/09/2013), in January 2002 Richard Pratt committed $100 million towards a national scheme to save the estimated 40 to 50% of water now lost to evaporation and seepage in uncovered and unsealed irrigation channels by financing on-farm efficiencies and, more ambitiously, replacing the channels with a huge network of pipes. Pratt's family investment arm had a 13.11 per cent interest in Gale Pacific, an Australian specialist in dam covers and liners and collapsible pipes. "I've found we can create a pipe that is similar in appearance and texture to a fire hose but a metre, or a metre-and-a-half across," he says. "A partly woven laminate of different substrates that collapses flat when empty, kilometres of the fluming could be carried in the back of a truck to be unreeled when needed. And, he says, at a cost of $10 a metre.. " In early 2004, Gale Pacific of Melbourne was conducting trials on a very thin walled pipe at Griffith. I looked at this pipe in Feb 2004, and it appeared to be leaking. I was concerned that this particular trial could be a failure and could lead to the conclusion that “it doesn’t work.” At the time I had discussions with retired chemical engineer Rob Downing of Ashmore, Qld., about an alternative material for this purpose which would be far stronger and more robust. There seems a strong case for trials of alternative materials. Ribloc in Adelaide make large diameter pipes which may be suitable. David Eccles has contacts with a Finnish company that can produce light polyethylene pipes up to 3 m diameter on site. I couldn’t find any reference to these pipes on Gale Pacific’s website in Sept 2013, but it appears that they make polypropylene dam liners and shade sails. According to http://specialtyfabricsreview.com/articles/0111_f3_water_conservation.html (accessed 30/09/2013), Gale Pacific Ltd. provided advanced polymer shade fabric in 2011 for a dam cover trial project, also makes dam liners, tank liners, water bladders and irrigation flumes. Darling Downs Tarps have developed a method of joining plastic sheet on the surface of dams. 2.3 Water supply: wind or wave-powered reverse osmosis It makes sense to use the water already available on land as efficiently as we can by catching and recycling roof rainwater and urban stormwater, and by using aquifer storage and recovery, before going to energy-intensive methods of producing fresh water from seawater. However the limitless quantity of water in the ocean is attractive as a "droughtproof" water supply if we can desalinate it economically without wasting a lot of fossil energy in the process. As Technical Director of Seadov P/L (www.seadov.com) I have costed a floating desal plant powered by wind and wave energy and it appears to be competitive with the large shore-based desal plants. The most energy-efficient, well established desal method at present is reverse osmosis (RO), which according to www.Affordabledesalination.com in 2006 (this website has now disappeared), can use as little as 2 kWh/kL, but this is probably for just pumping through the membranes without including pumping feedwater to the site. According to suppliers of RO plant it currently requires at least 3 kWh per kL. For comparison, in Adelaide in 2013 we pay about 30 c per kWh for electrical power, and about $3 per kL for water. So the cost of energy to desalinate seawater is less than the retail cost of water, but the cost of infrastructure trebles the cost of fresh water “manufactured” by reverse osmosis. xxxx But if wave energy could be used directly to power desalination of seawater, this would be a lot better than using electricity generated from coal or natural gas. In principle RO is just very high pressure pumping. It needs about 26 bar to overcome the osmotic pressure before any flow occurs, then 4 typically another 30 bar or so to produce a reasonable flow rate through the membrane, so about 56 bar in total. Carnegie Wave Energy Limited (http://www.carnegiewave.com) has developed the CETO system to do this, and is building their 5th prototype at Garden Island off Perth. In normal RO plants there are other operations involved, like circulation of feedwater, rejection of concentrated brine and recovery of the energy in the high pressure brine. These all add to the cost and the complexity of the operation, but the technology is well established and these need not be problems: the main problem is the energy cost. Wind and waves produce very large forces, which can be used to drive piston pumps much more easily than to generate electricity. The energy in storm winds and waves can be used when available, and desalinated water can be stored for still periods. 2.4 Deep sea reverse osmosis A novel concept is to sink a pipe into the ocean with an RO module on the end, and pump the water out of the pipe so the external hydrostatic pressure forces fresh water into the pipe. To get the initial 26 Bar to overcome the osmotic pressure, a depth of 260 m would be needed. 500-600 m would be ideal. There should be no problem with concentration polarisation as the whole ocean is the feedwater. There is no need for energy recovery from the pressurised concentrate, and there may be no need for pretreatment. Heitmann (1990) “The risk of colloidal fouling is best assessed by determining the silt density index (SDI) of the raw water…The SDI of surface water may range between 4 and the limit value of 6.7, depending on how far the intake system is situated from the shore. If water is drawn from larger depths, a value of 1 can sometimes be found.” (Heitmann, H-G (1990) (Ed), Saline Water Processing, VCH). Using this process could halve the energy requirement and simplify the process greatly. 2.5 towing icebergs Icebergs breaking off glaciers in Antarctica are typically about 250 m thick (deep) and may be several sq km in area. One of these would contain more than enough fresh water for Adelaide for a year. The possibility of towing icebergs from Antarctica to the south coast of Australia was seriously considered in the 1970s and several papers were written on the topic, including one by Professor Schwertfeger, formerly of Flinders University, in which he estimated the cost of water delivered to the south coast at 0.1 to 3.5 c/kL. The official estimate is currently $19 per kL and “towing icebergs” is mentioned with a derisive smirk by the experts. I have a few ideas that could reduce costs and make this option more feasible, but I would not regard it as a high priority – more a fun idea to play around with at present. I'm not really serious about iceberg towing. I heard that it would take all the tugs in the world to move a decent sized iceberg fast enough to get to where it was needed before it melted. But I thought the air force could have some fun shooting or bombing an iceberg to break it up into manageable sized pieces which could be enclosed in a low drag vessel like a giant canoe with sails, that opens at the front to "gobble up" the ice blocks, then sails north through the roaring 40s to Adelaide or Perth. The hydrodynamic drag of the vessel would be way lower than a bluff shaped iceberg so it would require a lot less power to move it, and if insulated it would protect the ice from contact with the warmer ocean on the voyage so it wouldn't melt so fast. At its destination the fresh melt water could be drawn off as it melts, and could be bottled and sold at stupid prices as pure, pristine Antarctic water. Rich people could commission their own vessels and race to bring the first iceblocks of the season, like the old tea clippers. This could develop into an annual event like the solar car race. 2.6 inter-basin water transfer from NQ to Murray-Darling: see my detailed report prepared for Grundfos in 2011, and various proposals by Terry Bowring. 2.7 water transfer from Tasmania to mainland via undersea pipe: see my detailed report prepared for Ray Pank in 2012, and various articles by, or about, Geoff Croker (who originally proposed the idea), and John Martin of Docklands Science Park who are backing it. 5 2.8 Point Lowly desal plant There was much controversy over BHP's proposal to put a desalination plant at Point Lowly near Whyalla to provide fresh water for the Olympic Dam mine expansion and possible harm to the giant cuttlefish that breed in the area due to increased salinity. Although the controversy has died down since the mine expansion was deferred, it may come up again. I offer 3 possible solutions: (i) a large diameter, thin walled flexi pipe in deepest part of gulf to carry the reject "brine" (6% salt compared to 3% in sea water) further south. Spencer Gulf presumably gets deeper as you go south, so the more dense brine would flow south naturally and could be discharged gradually through diffusers. (ii) Given the rate of evaporation in upper Spencer Gulf, I suspect the effect of the desal plant would be negligible anyway, so we should do the sums and if this true, relax. (iii) Build the plant at Ceduna and power it with wind and wave energy. The distance from Ceduna to Olympic Dam is about 330 km, 10% further than from Pt Lowly, and although there is some high ground on the way, much of the energy needed to pump the water up to the watershed would be offset by gravity flow on the other side. 3 Water quality 3.1 circulation to reduce cyanobacteria and Mn, Fe and P in solution This was one of my main interests from about 1995 to 2003, and I have written several articles on the topic: see my CV and pdfs. 3.2 Water quality: suction dredging of dams to remove nutrient-rich bottom sediments, restore lost storage capacity and restore function of bottom scour valves and intakes which have become covered with silt in old dams Although there is evidence that circulation can improve water quality (see above), ultimately this is only a temporary solution. As long as there are nutrient-rich sediments at the bottom of a dam these will tend to be released into the water column and will feed algal blooms. It should be feasible to suck these sediments out using a “vacuum cleaner” suction dredge that does not resuspend sediments but removes them and makes them available for use as topdressing, after removal of heavy metals of necessary. Some dams have been frequently and heavily dosed with copper sulphate for so long that it may be economic to recover the copper! Besides reducing the nutrient loading and therefore the potential for algal blooms, removal of bottom sediments would have 2 side benefits: (i) restoration of lost storage capacity and (ii) restoration of function of bottom scour valves and intakes which have become covered with silt in old dams. 3.3 cleaning up Torrens Lake and other long, narrow stagnant water bodies by circulation and filtration Torrens lake capacity: needs 570ML to refill, according to a news item dated Feb 09 when the weir was left open due to an electrical fault. The problem: nutrient inflow with stormwater, recycling of accumulated nutrients in bottom sediments, and lack of flushing leads to blooms of cyanobacteria (blue green algae). Ways to reduce blooms of cyanobacteria. These have been reviewed in Justin Brookes’s PhD thesis (1998). Among the most effective measures appear to be: 1. Light deprivation 2. Turbulence, which mixes nutrients through the water column so they are more readily available to harmless green algae which can then out-compete cyanobacteria for available nutrients 3. Reduction in available nutrients. I counted 9 fountains in the 3 km stretch from the zoo to the weir, plus several areas of turbulence apparently caused by subsurface devices, which appeared to be bringing bottom water to the surface. Although these fountains etc produce some local turbulence, circulation and aeration, they probably have little effect on most of the lake, apart from bringing nutrients to the surface which is 6 counterproductive. Aeration per se does not affect cyanobacteria except by oxidising phosphorus to insoluble forms which go out of solution, thereby reducing nutrient availability. Of course it is desirable to minimise the inflow of nutrients by means of public education, and by placing gross pollutant traps on stormwater drains, but it will never be possible to eliminate nutrient inflow to the point where there are insufficient nutrients for a cyanobacteria to bloom in a stagnant pond in the middle of a city. Wherever there are nutrients, water and sunlight, something will grow, so it makes sense to create an environment in which desirable species will out-compete the undesirable species such as cyanobacteria. My proposal is to circulate the water through one or more large diameter, thin walled plastic pipes located along the bed of the river. One or more high flow, low head axial flow pumps would draw in water near the Weir and pump it through physical and biological filters (see below) to take out cyanobacteria, turbidity and nutrients, and thence via the pipes to a point somewhere near the Zoo Bridge. Water would then flow back down the river to the weir and continue to circulate, passing through the filters each time. This would achieve the following 6 objectives: - deprivation of light while cyanobacteria are in the black plastic pipes, which will disrupt their metabolism - continuous removal of cyanobacteria before they can bloom - continuous removal of the nutrients on which they depend - some turbulence, which gives a competitive advantage to non-toxic green algae over potentially toxic cyanobacteria, so that the green algae “grab” the available nutrients - reduction in turbidity - a continuous apparent flow downstream instead of the present stagnant pond, making the Torrens look more like a real, flowing river. Biological filters: I do not claim any expertise in this field, but I understand that some species of shellfish and water weed are used to polish nutrients from water recirculated in prawn ponds. Freshwater mussels grow in some inland waters – perhaps they would grow in a cleaner Torrens. It seems to me it needs 3 steps: 1. Remove many years’ accumulation of nutrient-rich bottom sediments by suction dredging (see http://www.pneuma.it/reference.html ). Phoslock (http://www.phoslock.com.au/) was being toted at one time as a means to immobilise nutrient-rich bottom sediments but I’m told it doesn’t work Unless this is done there will always be a reservoir of nutrients which are endlessly recycled through algal blooms which die and sink, thereby replenishing the nutrients, no matter how many fountains they put in. 2. Minimize further nutrient inflow by any practicable means. It can never be totally eliminated but perhaps it can be further reduced. 3. Continuously circulate all of the water in Torrens Lake through physical and/or biological filters (possibly a wetland) near the weir, thence via a large diameter, low pressure pipe in the river bed, probably to the Zoo Bridge. Clean filtered water would then flow back downstream, giving the impression that the river flows. There’s about 570 ML in Torrens Lake, so a high flow, ultra-low head Flygt or equivalent pump of a few kW capacity could pump say 500 L/s at low velocity through a 1 m diameter thin walled plastic pipe with a friction head of only about 1¼ m (H = fLv2/(2gd) = 0.02x3000x(0.636)2/(2x9.8x1) = 1.24m. Power P = Qgh = 0.5x1000x9.8x1.24 Watta = 6 kW). The pipe could be made by solvent welding PVC or heat welding polyethylene sheet – 1mm thick would be adequate, costing about $4.20/sq.m or say $15/m incl welding = $45,000 for 3 km of river. This would circulate the whole contents of Torrens lake through the filtration system about once per month. Like a swimming pool filter, but more effective because it’s a long thin water body so it’s relatively easy to draw the water into one end of a pipe with minimal dead spots. At the Zoo Bridge the river is only about 20m wide. If it’s 1 m deep on average, the return flow velocity would be Q/A = 0.5/20 m/s = 2.5 7 cm/sec average, which doesn’t sound like much, but it would be non-uniform and would be noticeable and would make the river look less like a stagnant duckpond. If successful, the same scheme could be duplicated in other stretches of the river. I’d welcome any feedback on this proposal. 4. Renewable Energy 4.1 direct mechanical application of wind power, especially for pumping (including RO, pumped storage, sand pumping and upwelling) Aerodynamic forces in wind energy are converted first to mechanical shaft power, which can then be used to drive a generator or a pump or any other load. In recent years interest has focussed on electrical energy because of its versatility, and wind-electric technology is now the fastest growing source of electricity. While wind energy has been progressing in leaps and bounds, I was told in about 1995 by a representative of Southern Cross, once Australia’s market leader in windmills (i.e. wind turbines driving pumps) that windmills were a “post-mature technology,” i.e. they were old hat, and not worth bothering with (a few years earlier I had been told proudly by another Southern Cross rep that their windmill design had been the same since 1930: apparently it was so good it didn’t need to be improved, and now it is defunct). This is a striking example of compartmentalised thinking: windmills are old hat, but wind turbines are the latest thing. But in fact they are the same thing: both convert kinetic energy in the wind to mechanical shaft power and only the load differs. If modern low solidity wind turbine design is applied to driving pumps directly, the cost of the electrical generators and motors is eliminated for applications like RO, sand pumping, artificial upwelling and pumped storage of seawater, all of which happen at windy coastal or ocean sites. Positive displacement pumps can be highly efficient: they are used in fluid power applications all the time. All that is needed is a bit of attention to matching load to power source: a load disengaging device to allow the low solidity wind turbine to get started, and possibly 2 or more pumps with a range of power requirements, that can be brought on line according to the available wind energy. My 1995 article and Ch 8 of my PhD thesis explore these issues in some detail. 4.2 Renewable Energy: from tidal or river currents Tidal, river and other water currents can be harnessed using similar design principles to wind energy conversion. With Tidal Energy P/L of Currumbin, Qld, I started investigating a diffuser-augmented tidal turbine (HKT or hydro-kinetic turbine) in 1999. In 2003 we demonstrated that the diffuser can increase the power output of a given turbine by a factor of 3. I worked with a Canadian company on this project from 2006-2010, and am now working with a UK company on tidal turbines and with a colleague at Uni Malaysia on small river turbines for power supply to remote villages. I have published several articles on HKT design. 4.3 Renewable Energy: from waves, especially direct mechanical applications such as upwelling, sand pumping, pumped storage and RO In principle it seems simple to harness wave forces to drive turbines and generators, or alternatively reciprocating pumps directly, with several possible applications. SEADOV (www.seadov.com) is a visionary proposal developed by myself and 2 partners starting in 2005 to convert a recycled oil tanker hull into a floating offshore platform housing OWC (oscillating water column) wave energy converters, wind turbines and possibly tidal turbines at suitable sites, either to supply electrical power or to drive RO desalination plant on board. Using wave or wind power to pump sand to prevent the formation of sandbars across river mouths. An array of simple bellows pumps driven by wave or wind action could draw in a sand-water slurry and pump it along one or more delivery pipes in the same way that the jet pumps at the Gold Coast Seaway and the Tweed River mouth do. The principle has been demonstrated by Griffith University Gold Coast School of Engineering student Ivan Mircev using a model in 2003-4. There is a 8 need for sand pumping at the mouth of Currumbin Creek and this may be a good site to explore further. A Pelamis-type float (two or more long cylinders hinged end to end) would probably be the easiest to deploy as it needs only a slack mooring to prevent it from drifting. The bellows pumps could be made from old car tyres or aircraft tyres. 4.4 Geothermal In the early 2000s, geothermal power was being touted as the new baseload energy source that would solve all our energy needs for the foreseeable future, but 10 years on in 2013, the outlook is less bright. It costs some $20 million to drill a hole 5 km into the rock, and if a drill bit breaks that hole has to be abandoned. And it turns out that the rock a depth is less permeable than that near the surface due to the weight of overburden (with hindsight this should have been predicted), so the water doesn’t percolate through from one hole to the other as well as expected. So we should keep pressing on with other energy sources. 5. Energy storage In South Australia we have the most peaky energy demand of any Australian state, with peak demand around 3 GW, about double the average, occurring only a few days per year, adding greatly to the capital cost of generating and reticulation capacity. Some reduction in this peak demand could be achieved by better passive solar design of residential and commercial buildings, and since the introduction of generous feed-in tariffs for residential solar PV systems and the recent drastic drop in PV prices, the corresponding surge in residential systems is reducing the peak demand on the centralised generating and distribution systems, since they produce on sunny afternoons when demand peaks. We have plenty of existing and proposed wind power capacity, and potentially plenty of solar and wave power potential, but these are intermittent and until or unless geothermal becomes a reality, we need either storage or a stronger interconnector with the eastern states. While an interconnector gives added flexibility, it is expensive, there are line losses, and Victoria tends to get the same cycles of windy and calm weather as SA, albeit a day or so later, so when we have surplus energy from wind, solar or waves, so do they. Although gas turbines can be, and are, used when wind falls short, they are still using fossil fuel and pumping CO2 into the atmosphere. So energy storage should be an important part of our energy supply system if we are to move towards more renewables. 5.1 Pumped hydro energy storage Although better batteries, flywheels and supercapacitors are all being developed, none can so far compete on a large scale with pumped hydro. There is a need for energy sources that can be brought on line quickly to meet peak demand, especially on hot days when people turn on their air conditioners. Hydro power is good for peak power as it can be brought on line relatively quickly whenever required. Although there is not a lot of potential for hydro power as a primary energy source in South Australia, there may be significant potential for pumped storage, a process in which water is pumped from a low storage to a high storage at off peak periods when surplus generating capacity is available, and then runs back down through turbines to generate power at peak periods. This is being done at Wivenhoe Dam west of Brisbane, with 500 MW capacity, and could in principle be done on a modest scale at several sites in SA, notably on the Fleurieu Peninsula, where there are numerous steep valleys which could be dammed, providing storage at various elevations. Myponga River below the existing dam is a good example. A small storage could also be built at Paracombe above Kangaroo Creek dam and another above Baroota Reservoir near Pt Pirie. A further possibility would be to pump seawater up to an elevated storage using wind, wave or tidal power, and run it back through turbines. This could be done on the West Coast, on Kangaroo Island and on the Fleurieu Peninsula. Where there is concern about seepage into aquifers the storage could be 9 lined with dam liner material. There is a need for a geologist to identify sites where permeable strata dip towards the sea so seepage would simply drain back to sea, to save the extra cost of dam liners. The CETO wave powered pump could be used, and an off the shelf turbine designed for salt water. Such turbines must exist in tidal barrage installations, although these would be low head. 5.2 Energy storage as liquid air CAES or compressed air energy storage seems to be taken seriously in some quarters, but it requires a huge airtight underground cavern to provide useful amounts of storage capacity, and a source of waste heat to replace the losses in adiabatic expansion. I have heard of only 2 places worldwide where it has been demonstrated. These are places where there is a large cavern created by coal mining and a thermal power station. Undersea compressed air storage has also been proposed, but the huge buoyancy forces would require a very strong storage vessel and huge weights. I doubt if this would be viable. But interest has grown recently in liquid air. Just as phase change materials can provide greater thermal energy density than sensible heat storage, a working fluid that evaporates and condenses as it is expanded and compressed can provide more energy density than a gas that is simply expanded and compressed without a phase change. One problem is where to put the vapour or gas phase. If we could use air as the working fluid, that presents no problem – there is plenty of it, but it requires extremely low temperatures to condense. Nitrogen makes up 78% of the atmosphere and has a critical point of 125K or -148C, at a pressure of 32 Bar. Oxygen, which makes up 21%, i.e. most of the remainder, has a critical point of 154K or -119C at 51 Bar, but condenses at 15 Bar at 125K. Liquid nitrogen is stored in insulated Dewar (thermos) flasks in laboratories at atmospheric pressure. It gradually evaporates but can be stored for useful periods this way. So a chamber with a refrigeration plant to make up for heat gain could store liquid air (nitrogen and oxygen) at 125K and 32 Bar, or at near atmospheric pressure at a lower temperature. The energy density would be PV = 3.2E6 N/m2 per m3 = 3.2MJ/m3 = 0.888 MWh/1000 m3if constant pressure could be maintained during charge and discharge. Thus a chamber 100x100x100m would theoretically store 888 MWh – say 700MWh allowing for losses, similar to the capacity of a pumped hydro installation with 1GL upper and lower storage, operating at 320m head. If storage is worth say $20/MWh (i.e. the value of being able to store renewable energy at off peak and deliver at peak demand times) then this is $14000 per cycle. If we get one cycle per day, then the value is $5 million p.a. The pressure could be maintained in a chamber under the ocean at a depth of 320m, or less if the temperature is lower. It would not need to be a high strength pressure vessel as long as the internal and external pressures were maintained equal, i.e. as long as there was some liquid and some gaseous phase in equilibrium inside the vessel. A pipe containing a compressor/expander would connect the subsea chamber to the atmosphere. It could be driven in compressor mode by wind or wave power to store surplus energy, as could the refrigeration plant, and energy could be recovered in calm weather by running in reverse as an expander. The latent heat of vaporisation/condensation is 214 kJ/kg (188 MJ/m3) for liquid Oxygen 199 kJ/kg (161 MJ/m3 or 44.7 kWh/m3) for liquid nitrogen, i.e. ~ 50 times the pressure energy stored. Thus a big heat exchanger would be needed to ensure essentially isothermal conditions. The ocean surrounding the pipe and the ice that would form around it would have plenty of thermal capacity – the challenges would be getting the heat in and out. Ice on the chamber would provide additional insulation. In fact it may be possible to form a very large chamber almost entirely of ice, thereby eliminating most of the capital cost of materials for construction. This might be done using some sort of slip form construction similar to that used for reinforced concrete towers. The ice would be buoyant and so would the contents (specific gravity of liquid nitrogen = 0.808, oxygen 1.14, so average SG = 0.88 approx. SG of ice = 0.92). 10 According to http://www.gi.alaska.edu/~eicken/he_teach/GEOS615icenom/struc/strength.htm, ice has a uniaxial compressive strength of about 9-11MPa, so a thick- walled cylinder of ice should have plenty of strength. This would need to be assessed economically, but it appears to be an environmentally friendly, technically feasible alternative to building dams for pumped hydro, with virtually limitless potential capacity. Imagine one cylinder of ice 100m in diameter and 1 km long: energy storage capacity ~ 5000 MWh, or 1GW for 5 hours, the typical period required for daily demand fluctuations. This is double the capacity of the Wivenhoe installation west of Brisbane. I wrote the above before finding out that this technology is now being seriously considered: see for example http://www.highview-power.com: Highview Power Storage is a designer and developer of large-scale energy storage solutions for utility and distributed power systems. Using liquid air as the storage medium, Highview can design bespoke Liquid Air Energy Storage (LAES) plants, that can deliver around 5MW/15MWh – to significantly more than 50MW/200MWh to service a growing multi billion dollar energy storage market. The principles are explained at http://en.wikipedia.org/wiki/Cryocooler. 5.3 Rustbelt Flow Battery - Iron Based Energy Storage System by Energy Matters According to http://www.energymatters.com.au/index.php?main_page=news_article&article_id=1537, “Researchers at Case Western Reserve University are utilizing iron to create a flow battery; a scalable energy storage system that can service a single home or an entire community. We've reported on flow battery technology in the past - it refers to a form of battery in which all electroactive components are dissolved in the electrolyte, rather than using solid electrodes that are consumed over time as part of the fuel, such as in the case of a normal deep cycle battery. In a flow battery, the chemical solutions are stored in two tanks and the electrodes in a separate chamber. The solutions are pumped one direction through the chamber to charge the battery and the other direction to discharge it. "The researchers' goal is to create an economic and efficient battery system that could be used to store surplus energy created by wind turbines and solar panels, for use in conditions when electricity is not being produced. Robert Savinell, professor of chemical engineering at Case Western Reserve, refers to their project as the "rustbelt battery". Our previous story was on a vanadium based flow battery - but iron is as little as 1% of the cost of vanadium. The researchers estimate because of the low cost of components, the iron-based battery would cost USD$30 per kilowatt-hour; well below a $100 per kilowatt goal set by Sandia National Laboratories." See also http://blog.case.edu/think/2011/05/27/from_the_rustbelt_an_ironbased_flow_battery . 6 Food 6.1 Enhancing fish stocks by artificial upwelling using wind, tidal or wave energy The richest ocean fishing grounds occur where there is natural upwelling of nutrient-rich deep ocean water due to a combination of ocean currents and prevailing winds, typically on west-facing coasts. It may be possible to produce the same effect on a small scale by pumping, using renewable energy. See pdf of my 2003 article in Ocean and Coastal Management. 6.2 Saline Irrigation. Hugo and Elisabeth Boyko pioneered the technique of saline and marine agriculture at Eilat in Israel in the 1950s. Eilat has an extremely arid climate with an annual average rainfall of 28 mm (just over an inch). Some of the species grown successfully with seawater irrigation in the Desert Garden at Eilat are shown in the table below. 11 Excellent Natal plum Water melon Sugar melon Carob Tomato Okra Date Pomegranate Many timber tree species Good Fig Asparagus Mulberry Olive Eggplant Spinach Many fodder & timber species According to Hugo and Elisabeth Boyko “we were not the first to grow plants with seawater. Old documents prove it for a sand island near Bilboa more than 250 years ago and good harvests were recorded during a period of famine..” Bilboa has a dry summer with less than 10 mm average rainfall in July and about 15 mm in August. Esteban-Gomez reported that maize, beans, potatoes (30 tonnes/Ha), lettuce, tomatoes (30 tonnes/Ha), beets, radishes, alfalfa and barley were successfully grown with seawater irrigation on the beach at Orinon in northern Spain. However Orinon is not in an arid area and gets on average over 50 mm rainfall per month, even in summer, so this success cannot be attributed solely to seawater irrigation. See also http://www.seawaterfoundation.org/toc.htm . 6.3 Water requirements for 1 kg beef. According to ABC TV program Landline on Sunday 16th August 2009, "The Water Footprint Network in the Netherlands has come up with water usage figures for a series of foods and drinks, and claims 1 kilogram of rice takes an astounding 3,400 litres to produce. One kilogram of cheese around 5,000 litres, the glass of wine one might have with that cheese took 120 litres of water, mostly in the growing of the grapes. A cup of coffee requires 140 litres of water. Tea is a little less thirsty, 30 litres for every cup. But this is perhaps the most contentious statistic published by the Water Footprint Network - a kilogram of beef allegedly requires a water input of more than 15,000 litres. Australian researcher, Brad Ridoutt, harbours grave concerns with the methodology used to calculate these numbers. BRAD RIDOUT: You have to question those figures that I have seen in the media, ranging from 15 to even 100,000 litres per kilogram of Australian beef. I think it's potential is very high for that information to be misunderstood and to be confusing because if Australian consumers, or dare say consumers in the UK, get the sense that if they avoid eating a kilogram of Australian beef, they'll return 100,000 litres of water to a river system that's in need of extra water resources for its health, I think that's very misleading. DAVID INALL, CATTLE COUNCIL OF AUSTRALIA: Yes, our immediate thought is that we are concerned at those figures coming up as you just indicated. PRUE ADAMS: The Cattle Council's David Inall maintains most Australian beef is grown out in the range lands where the cattle feed on vegetation, surviving on rainfall alone, not on irrigated pasture. DAVID INALL: Those types of figures assume that all of the rain fall that falls onto cattle properties, are consumed by the cattle to produce the product. That's clearly not the case. The figures that we have seen indicate 18 to 540 litres of water are used to produce a kilo of beef. 12 PRUE ADAMS: The CSIRO agrees with the beef industry, that where the water comes from does make a difference. Brad Ridoutt is helping to put together a revised water footprinting methodology that looks at impact of water use rather than volume. Not all water is created equal. He says there are three types of water - green water is the rainwater that hydrates food crops. Blue water comes from surface or underground resources. It's the rivers and reservoirs on which the irrigated regions rely and there is the more esoteric grey water, which could be called diluted water, it's the amount needed to dilute waste water from industry and crops. BRAD RIDOUT: One of the questions we ask is "in the absence of production, to what extent would that water be available for the environment?" or, "to what extent would that water be available for other users?" 6.4 Low energy circulation and aeration in intensive pond aquaculture, e.g. prawns (shrimps) In about 2000, Conrad Gaudin was planning to grow prawns as they are known in Australia (shrimps in USA) in New Caledonia, at a site with no mains power. He wanted a low energy circulation and aeration system and approached Steve Elliott of WEARS to design a system. Steve and I came up with a 1 Ha racetrack shaped pond for uniform flow with a single paddle wheel drawing 300 Watts that circulated the water adequately, compared with 9-13 kW used in conventional ponds. This was very pleasing but didn't add enough oxygen to the water, so I started to research the mechanism of atmospheric oxygen transfer into the water. I became clear that the trick is to replace the thin oxygensaturated surface layer of water as often as possible, and the slow turnover of the water column would carry the oxygen down to the bottom. In 2008 UniSA engineering student Sean Chan tested a concept involving reciprocating strings across the water surface, with promising results. In 2012 another group of UniSA students tested another concept using small axial flow impellers in the hope of producing helical vortices, but without success. I still believe this could be a good solution and UniSA lecturer James Ward and I have discussed possibilities but I haven't had the time or energy to continue the experiments. 7 Environmental: reducing coral bleaching on the Barrier Reef by artificial upwelling of cool deep ocean water, using wind, tidal or wave energy See my 2003 article in Ocean and Coastal Management. 8. Algae for biofuels, wastewater treatment and CO2 bio-sequestration. This appears to be a promising field – in 2006 I got quite interested in the apparent win-win-win prospect of (i) using nutrients from sewage (ii) using CO2, and (iii) producing biofuel. But when you do the numbers the amount of CO2 absorbed would be insignificant, and according to expert John Benemann, Manager, International Network on Biofixation of CO2 and Greenhouse Gas Abatement with Microalgae, the only way it can be economically viable is if it’s primarily seen as a wastewater treatment method, with biofuels and CO2 absorption as byproducts. It seems that algae need to be genetically engineered to both (i) grow fast enough and (ii) have high enough hydrocarbon content, to be viable. Open ponds are low capital cost but tend to get contaminated by less productive wild species, while closed vessels exclude unwanted species but have high capital cost. It’s way out of my areas of expertise, so like battery research I just watch developments and hope for the best. 13