Final Paper - Research - Vanderbilt University

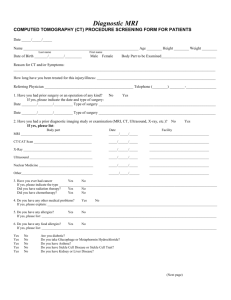

advertisement

Ultrasound Imaging Capability for Surgical Drills Meher Juttukonda, David Morris, Julianna Ianni Advisors: Dr. Jadrien Young, Dr. Paul King _________ BME 273 Senior Design Project _________________ Vanderbilt University School of Engineering Abstract: Lack of safety in surgical settings can be extremely costly to both the patient and hospital, resulting in unnecessary surgeries and malpractice lawsuits. Increasing safety in this surgery is important for ensuring that sensitive structures behind the temporal bone are not damaged. One of the most common otologic procedures is a mastoidectomy. On average there are 30,000 to 60,000 mastoidectomies performed each year within the United States. The mastoid region of the ear contains many vital structures that can cause serious complications if not properly avoided during surgery. These structures include the facial nerve, the ossicles, and the external ear canal. A more effective means of imaging the mastoid region will allow the surgeon to avoid damaging these structures while effectively performing the necessary surgery. The design goal of our project is development of a real-time Ultrasound imaging system that can be attached to an otologic surgical drill in order to allow for the surgeon to perform quick imaging during surgery. The design of the proposed device involves a hollowed-out annular ring transducer, which is be suspended around the drill bit. Analysis to simulate and determine the relative attenuation of ultrasound signal at different frequencies was performed in MATLAB. Proof of concept testing was performed using a tissue analogue and acrylic as an analogue for bone, because bone and acrylic have very similar acoustic properties. Frequency analysis suggested that a transducer frequency between 1 and 8.89 MHz is feasible. Proof of concept testing showed that a range of thicknesses of the acrylic model could be measured to an accuracy of 1 mm for frequencies of 4 MHz and 8 MHz. Since the error is the same for both frequencies and because the signal is higher for 4 MHz, the 4 MHz frequency is the better choice. Further tests need to be done on cadavers in order to more effectively simulate the conditions during surgery. Introduction: Lack of safety in surgical settings can be extremely costly to both the patient and hospital, resulting in unnecessary surgeries and malpractice lawsuits. Otologic surgery takes place on the temporal lobe of the patient, an area that contains many delicate and vital organs that, if damaged, can cause devastating effects to the patient. Increasing safety in this surgery is important for ensuring that these organs go undamaged. New safety precautions must not increase the overall surgical time by a significant amount. Increasing surgical time increases the overall cost of the surgery along with increasing the chances of surgical complications such as infection. One of the most common otologic procedures is a mastoidectomy. On average there are 30,000 to 60,000 mastoidectomies performed each year within the United States (French, 2008). Mastoiditis is an infection of the mastoid region, the portion of the temporal bone found behind the ear which contains air pockets due to the spongy nature of the tissue (Mandell, 2005). The infection typically is caused by a middle ear infection and when antibiotics fail to treat the bacteria the infection can spread to the mastoid bone. Failure to treat the condition can result in destruction of the mastoid bone, dizziness, vertigo, facial paralysis, meningitis, partial or complete hearing loss, and further spread of infection. The surgeon must drill into the mastoid region of the temporal bone and remove the infected regions in order to prevent further damage and ensure the infection does not spread to other regions of the body (Cummings, 2005). The mastoid region of the ear contains many vital structures that can cause serious complications if not properly avoided during surgery. These structures include the facial nerve, the ossicles, and the external ear canal. Damage to the facial nerve can cause facial paralysis and results in permanent damage to the patient. Damage to the facial nerve is usually not noticed until after surgery with the surgeon being unaware that the nerve has been damaged (Green, 1994). A more effective means of imaging the mastoid region will allow for structures to be fully identified and will allow the surgeon to avoid the nerve while effectively performing the necessary surgery. Currently computed tomography (CT) is the primary means of imaging the surgical region. Images are taken in order to give the surgeon a visual representation of where he/she will be drilling. One drawback to this method includes exposing the patient to large amounts of radiation (Smith-Bindman, 2009). These images also need to be taken several days before the surgery is performed meaning that if any small changes occurred within the region they could result in the surgeon drilling too far and damaging the patient. A real time imaging system would provide a means of ensuring accurate measurements along with decreasing the chances of the surgeon making a mistake based on inaccurate information. Ultrasound technology works by using sound waves to image the region of interest in real time. This would prevent the patient from being exposed to radiation along with ensuring accurate images are being used to perform surgery. The design goal of our project is development of a real time imaging system that can be attached to an otologic surgical drill in order to allow for the surgeon to perform quick imaging during surgery. The device will use ultrasound technology in order to perform real time images that can be used to determine how far the surgeon has drilled along with revealing any key structure that may be nearby. The device must be able to be used quickly by the surgeon while not hindering the surgeon’s performance and not increasing the overall time of surgery by a significant margin. The device must also be able to be sterilized and usable within a surgical setting. The device should also be able to be removed from the drill when it is not longer needed during surgery. The device should also calculate the remaining thickness of the mastoid bone. The device should increase the overall safety of surgery without hindering the ability of the surgeon to effectively operate. Methods: Frequency Simulation: Analysis to simulate and determine the relative attenuation of ultrasound signal at different frequencies was performed in MATLAB. The assumptions of this model include the uniformity of each material layer—bone, air—and negligible scattering of signal. The frequencies studied were 1MHz, 4MHz, and 8.89MHz. To determine the amount of attenuation through each layer, the equation for attenuation was used: 𝐴 = 𝐴0 𝑒 −𝛼𝜈𝑙 where A is the final ultrasound signal amplitude, A0 is the initial signal amplitude, α is the material attenuation coefficient in dB/(m MHz), 𝑙 is the thickness of the layer in meters, and 𝜈 is the frequency of the ultrasound waves in MHz. The attenuation coefficients used for bone and soft tissue were 2000dB/(m*MHz) and 63dB/(m*MHz), respectively, which were within the ranges of normal values given by Bushberg. (Bushberg, 2002) The thickness of the mastoid bone modeled was 0.002m. The amount of signal reflected at each interface was calculated as 𝐴= 𝐴0 (𝑧2 − 𝑧1 ) 𝑧2 + 𝑧1 where 𝑧2 is the acoustic impedance of the more proximal layer in kg/(m2s) and 𝑧1 is the acoustic impedance of the more distal layer. The acoustic impedances of bone, soft tissue, and air are 7.8 kg/(m2s), 1.35 kg/(m2s), and 0.0004 kg/(m2s), respectively. (Bushberg, 2002) To determine the amount of time required to receive the echoes back from each interface, the following equation was used: 𝑐 = 2𝑙/𝑡 where c is the speed of sound in the layer, and t is times. The speed of sound used for skull bone was c=2921m/s, and for soft tissue and air, 1540m/s and 330m/s, respectively. (Plinkert, 2009), (Bushberg, 2002). By calculating the signal after attenuation and then the signal after reflection in each layer the signal ultimately received was calculated and plotted versus the time required to receive the signal reflection. Design: The design of the ultrasound device originally planned to use an existing intravascular ultrasound catheter (IVUS), which has a diameter on the order of 1mm. This initial design involved hollowing out an otologic drill bit (~5mm diameter) and threading the catheter through the center of this drill bit. This design was altered in order to arrive at a design that was less difficult to manufacture. The new design involved a hollowed-out annular ring transducer, which would be suspended around the otologic drill bit. This design was developed in Solidworks [3], and a piezoelectric company, Noliac, was contacted to manufacture the transducer for this design. Proof of Concept: Proof of concept testing was performed using a tissue analogue and acrylic as an analogue for bone, because bone and acrylic have very similar acoustic properties. To make the tissue analogue, a 7% Weight/Volume suspension of hydrolyzed polyvinyl alcohol powder in cold water was mixed. The suspension was then heated to 80 °C. Following the addition of 10% by volume glycerol, the container was covered tightly and allowed to cool to room temperature while being agitated on magnetic stir plate. The tissue was then poured into a clay mold using filter paper to remove undissolved polyvinyl alcohol powder. The phantom was then placed in a -37 °C freezer for 12 hours. This sample was then removed and allowed to thaw naturally at room temperature for approximately 12 hours. The tissue analogue was allowed to set within a clay frame on top of a sheet of acrylic 2.03mm thick. Ultrasound imaging was performed on a Siemens system provided Dr. Michael Miga. Ultrasound images were acquired by applying gel to the acrylic, and capturing images through both the acrylic-tissue interface and through the acrylic-air interface. This process was repeated for both 4MHz and 8.89MHz frequencies, with a linear array transducer in A-mode. Three more layers of acrylic, of the same thickness, were then added, one at a time, applying gel between each layer, with the imaging process above repeated after each addition. Additionally, a sheet of acrylic of thickness 0.1905m was measured using ultrasound at 4MHz and 8.89MHz, with an air interface behind the acrylic and no tissue analogue. These results were analyzed using MATLAB. The images from the ultrasound were imported into MATLAB, and the gradient of the reflected signal in the vertical (y- or depth-) direction was calculated. The depth scale of the ultrasound was converted by scaling the image to cm. The ultrasound machine used calculated the depth of the image assuming that tissue was being imaged, which has a different speed of sound than acrylic. Therefore, the depth scale had to be recalculated using the equation: 𝑑𝑛𝑒𝑤 = 𝑑0 ∗ 𝑐𝑎𝑐𝑟𝑦𝑙𝑖𝑐 𝑐𝑡𝑖𝑠𝑠𝑢𝑒 where dnew is the recalculated thickness, dnew is the original thickness scale, and cacrylic and ctissue are the speeds of sound in acrylic and tissue respectively. The average gradient of the signal acquired versus recalculated depth was plotted in order to determine where the greatest peak in the gradient occurred, that being where most stark changes in ultrasound signal occurred. The peaks therefore indicate the depths of tissue from which the most reflections were received, indicating an edge. This method of gradient edge detection was compared results from using MATLAB’s built in Roberts edge-detection function and averaging the signal acquired from that along the horizontal axis of the image. Results Frequency Optimization The first step of the project was to determine the specifications for the annular transducer to be used, the most important of which is the frequency. Code was written in MATLAB to analyze the signal attenuation at three frequencies: 1 MHz, 4 MHz, and 8.89 MHz. The results of the study are summarized in Figure 1. Since the acoustic attenuation increases with frequency, there exists a trade-off between resolution (which increases with frequency) and depth penetration (which decreases with frequency). As seen in Figure 1, the fraction of the input amplitude that returns to the transducer when the frequency is set to 1 MHz from the distal edge of the bone is 1.62 x 10-8. As expected, the fractions that were calculated for frequencies of 4 MHz and 8.89 MHz are significantly lower than for a frequency of 1 MHz: 1.70 x 10-20 and 5.03 x 10-40 respectively. 1 MHz 1 However, this trend of lower 0.9 0.8 frequencies yielding higher continue very much lower than 1 Fractional Amplitude fractional amplitudes does not 0.7 0.6 0.5 0.4 0.3 MHz. Also, it is not clinically feasible to choose a frequency 0.2 0.1 0 0 0.2 below 1 MHz. Therefore, 1 MHz is the lowest frequency that was considered. The upper 0.4 0.6 0.8 1 Time (s) 1.2 1.4 1.6 1.8 -5 x 10 Figure 1. This is a plot of fractional amplitude of the simulated ultrasound signal versus time. The point where the line starts its descent is the proximal edge of the bone, while the point with the lowest amplitude is the distal edge. bound of the range (8.89 MHz) of frequencies was limited both by availability of transducers for testing and by significant loss in fractional amplitude if a higher frequency is used. Proof of Concept The next step, after narrowing the range of frequencies, was to test the hypothesis the project using the model described in the methods section. Figure 2 shows an example of one of the Ultrasound images that were acquired during the test. This image was for a slab of acrylic 1.91 cm thick that was imaged using a frequency of 8.89 MHz. This image alone does not provide very much relevant information. Analysis was performed on the images using code in MATLAB and the results are documented in Figure 3. The gradient plots for model with the acrylic-air interface are generally less noisy than the ones for the acrylic-gel interface. As can be seen in subsets e) and f), there is very little noise in the 8.89 MHz image immediately before and after the edge peak at 1.9 cm. In the 4 MHz image, however, there is much more noise. Also, the amplitudes are generally higher for the 4 MHz scans than for the 8.89 MHz scans. This can also be observed in subsets e) and f). The amplitude for the edge peak in the 4 MHz image is about 15, whereas this amplitude is less than 5 in the 8.89 MHz image. Therefore, a trade-off exists between resolution and signal amplitude. Figure 3. This is an ultrasound image acquired on an acrylic model with a thickness of 1.91 cm and with a transducer frequency of 8.89 MHz. The accuracy of the measurements made using Ultrasound was also analyzed and is summarized in Table 1. The most important thing to note Figure 4. These are plots of the gradient of the echo magnitudes vs. depth. For (a), (b), (c), and (d), the thickness of the acrylic was 0.2 cm. For (e) and (f), the thickness of the acrylic was 1.91 cm. For (a), (b), and (e), the transducer frequency was 4 MHz. For (c), (d), and (f), the transducer frequency was 8.89 MHz. For (a) and (c), the interface was acrylic-gel. For (b), (d), (e), and (f), the interface was acrylic-air. from this table is that the percent error does not increase as the thickness of the measured object increases. This indicates that the absolute error of the measurements stays the same within the range of thicknesses measured in the study. The error does not seem to be correlated with the frequency. Therefore, since the peaks can be distinguished well by both the frequencies and because the 4 MHz frequency has higher signal amplitude, the 4 MHz frequency is the better choice. Table 1: Error in Measurements Frequency Thickness Measured Image (MHz) (cm) (cm) a 4.00 0.203 0.228 b 4.00 0.203 0.240 c 8.89 0.203 0.216 d 8.89 0.203 0.227 e 4.00 1.905 1.849 f 8.89 1.905 1.827 Error (cm) 0.024 0.037 0.013 0.024 -0.056 -0.078 Percent Error 11.959 18.012 6.496 11.811 -2.940 -4.094 Safety Ultrasound is considered an extremely safe imaging modality because it uses sound waves, as opposed to ionizing radiation, to collect its images. The prototype was also designed with safety in mind. The transducer can slide into and out of place as needed by the surgeon. When out of place, it is well out of the field of surgery and does not interfere with the surgeon's ability to maneuver the region. Due to the real-time nature of Ultrasound, this device actually improves patient safety. It allows the surgeon to know when the thickness of the remaining bone is small and to be careful when this situation arises. Economics The target market for this product is the otologic surgeon community who perform mastoidectomies. This product will be a valuable asset to them because it will provide safe, non-invasive, and real-time imaging capability to the surgeons. The safety aspect of the product is seen in the lowering the need for delivering ionizing radiation to a patient through a CT scan. The real-time imaging is also a cause of this improved safety. This improved safety for the patient will also result in less malpractice cases against the surgeons due accidental damage to the patient. This product will also result in saved time as the surgeons no longer have to perform secondary tasks in order to obtain image guidance. This allows them to perform more procedures per day, resulting in higher income. Further, this technology can be adapted to other types of surgery that use drill bits, not just otologic surgery. All of these reasons are what make this product highly marketable. The design of the prototype was sent to an external company Noliac to be built. The unit cost of a transducer was between $20 and $33. Since most hospitals already have Ultrasound systems available, the marginal cost of adding this product is only the cost of the transducer. With the cost of each transducer being relatively low, there is no reason for surgeons not to employ this technology if it is shown to be successful in its goals. FDA Since this device would be classified by the FDA as a medical device, it would need to receive FDA approval before use. Conclusion Custom transducers were made with a range of frequencies with a hollowed opening for the drill bit. The groundwork of frequency analysis and proof of concept simulation has been laid out so that the advantages of each frequency range can be clearly seen, and proof of concept is indicative of the feasibility of this design for measuring mastoid bone thickness during otologic surgery. The advantage of low frequency is low signal attenuation, and the advantage of higher frequency is slightly better resolution. The advantages of this design are that it does not require surgeon to change technique and it is a real-time imaging method as opposed to computed tomography, which has been previously explored for imaging otologic surgery. In addition, this ultrasound design would be able to attach to existing drill bits and drills, and therefore is a very flexible design. Recommendations: Further tests need to be done on cadavers in order to more effectively simulate the conditions during surgery. This will allow for more effective calibration of the signal processing and analysis necessary to calculate the remaining thickness found in the mastoid bone. Without more tests inaccurate calculations of the speed of sound in bone may result in inaccurate measurements of the remaining thickness which could result in the surgeon drilling too far accidentally damaging the patient. Otologic surgeons also need to be consulted in order to determine whether the device can be used effectively during surgery without hindering the ability of the surgeon to operate. If the device increases the overall length of surgery by a significant amount then the added degree of safety will be disproportionate to the cost. Effective testing in a simulated surgical setting on a practice bone will be able to determine if the device can properly serve its desired function. Other means of attaching the ultrasound transducer to the drill could also be tested in order to determine the most effective way to attach the transducer. The transducer should be able to be moved into and out of place quickly in order to allow for the surgeon to perform quick measurements without having to switch to a new instrument. The attachment should also not be bulky and have no chance of moving out of place and affecting the surgeon’s ability to operate. Any wires that are loose should be pinned down in order to make the drill and transducer system easy to manage. The system should in no way prevent the surgeon effectively operating and thus not decrease the overall safety of the surgery. When used properly the device should effectively increase the overall safety and efficiency of otologic surgeries by allowing the surgeon to drill using real time images of the surgical region. The device should not increase the overall time of surgery because it allows the surgeon to quickly switch between imaging and drilling. The device adds a large degree of safety to otologic surgery while adding no additional risk to the patient and not hindering the ability of the surgeon to effectively operate. If the device is properly sterilized before entering the surgical field any risk of infection from the device should be eliminated. Safety is a huge concern in all operations and the added degree of safety afforded by our device should be welcomed by both patients and surgeons. References: 1. French, LC et al. “An estimate of the number of mastoidectomy procedures performed annually in the United States”. Ear Nose Throat J. 2008 May; 87(5): 267-70. 2. Mandell GL, Bennett JE, Dolin R. “Principles and Practice of Infectious Diseases”. 6th ed. London: Churchill Livingstone; 2005:771. 3. Cummings CW, Flint PW, Haughey BH, et al. “Otolaryngology: Head & Neck Surgery”. 4th ed. St Louis, Mo; Mosby; 2005:3019-3020. 4. Green, J. D., Shelton, C. and Brackmann, D. E. (1994), “Iatrogenic facial nerve injury during otologic surgery”. The Laryngoscope, 104: 922–926. 5. Smith-Bindman R, Lipson J, Marcus R, et al. (December 2009). "Radiation dose associated with common computed tomography examinations and the associated lifetime attributable risk of cancer". 6. J.T. Bushberg, The essential physics of medical imaging.: Lippincott Williams & Wilkins, 2002. 7. P.K. Plinkert, P.A. Federspil S. H. Tretbar, "Accuracy of Ultrasound Measurements for Skull Bone Thickness Using Coded Signals," IEEE Transactions on Biomedical Engineering, vol. 56, no. 3, pp. 733-739, 2009.