Effects of Rib Turbulator on Distortion Index of a Serpentine Inlet Duct

advertisement

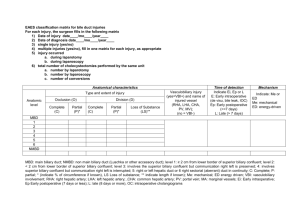

Effects of Rib Turbulator on Distortion Index of a Serpentine Inlet Duct S. Pradeep1, H. K. Narahari2, Shiva Kumar 3 1- (Engg) student, 2-Professor and Dean, 3-Ph.D student (AAE) Aircraft and Automotive Engineering M.S.Ramaiah School of Advanced Studies, Bangalore Abstract Stealth capabilities are a major requirement of modern combat aircraft both manned and unmanned. The major contributor to radar cross section is reflection from the engine face. The fan face can be hidden from radar by developing an inlet duct that is offset so that there is no direct reflection of radar beam from engine face. However, this complex flow path leads to secondary flows in the duct, which in turn affect flow field at engine face. Engine performance is adversely by such heavily distorted flow field. Hence it is essential to understand the flow behaviour and adopt different flow control (active and passive) methods to reduce distortion. Current study investigates the effects of Rib Turbulator inside the Serpentine Duct and their effect on Distortion Index. The computational study has been carried out on baseline serpentine duct to know the flow behaviour and then Rib Turbulator is added to the structure to investigate its effects on the flow behaviour. With the Rib Turbulator installed in the duct, an improvement in static pressure recovery was observed with decreased pressure loss by 21.67% and the reduction in distortion values by 58.69% were observed. Performance at AOA of 2o and 4o are also calculated where pressure loss shows a downtrend by increasing to 265% and 100% respectively and distortion values shows an uptrend by decreasing to 63.58% and 53.56% respectively. Nomenclature Symbol Cp P T Abbreviations AOA CAD CFD Pt, inf Pt,ef qinf P,min 60 60 deg wedge q ef,avg engine face SST UAV VG RT - Description Unit Co-eff of Pressure Pressure Temperature Density -Pa K kg/m3 Angle of Attack Computer Aided Design Computational Fluid Dynamics Total Pressure at the inlet Total Pressure at the engine face Dynamic Pressure entering the duct Min Averaged Total Pressure at any depends on the quality of air delivered by the duct. At higher speeds, it is necessary to deliver the air with minimum pressure loss and less distortion at the engine face and at low velocity and high pressure, for which various types of inlet ducts are available. An important function of inlet duct is to deliver air to compressor in entire flight envelope with minimum amount of pressure drop. The stealth capabilities can be achieved by different methods like shaping the aircraft outer contours, radar absorbing paints, small and canted vertical tail etc. A major contribution to RCS is from reflections coming from engine face. Reduction of this can be achieved by suitably modifying the inlet duct. A ‘serpentine’ inlet duct ensures that radar signals are not reflected back to the source. Area Averaged Dynamic Pressure at Shear stress transport Unmanned Aerial Vehicle Vortex Generators Rib Turbulator 1. INTRODUCTION Inlet duct of the gas turbine engine is one of its main components is normally considered as the part of the airframe. The task of an intake is to transport the air mass flow required by the engine with as little total pressure losses as possible to the engine inlet. They are mainly used to diffuse the flow with less distortion at the engine face. The performance of the engine also 1 . Fig 1.Serpentine Duct [2] Thus the stealth requirements in modern day aircraft and UAVs have led to compact S-shaped inlet ducts commonly called as serpentine ducts [1-7], which often have variations in cross section [8] and curved centrelines, these complex shaped ducts will lead to strong secondary flow structures, which in turn led to the reduced pressure recovery and increased distortion at the engine face. This can mean detrimental effects on the engine performance as well as the engine life. Figure 1 shows a schematic diagram of serpentine duct. The serpentine ducts or S-ducts having complex mean line, offsets the intake plane from the engine face which leads to complex three dimensional flows developed in the duct, such as flow separation and swirl. The secondary flows developed in the duct will adversely affect the performance of aircraft engine and much more critical during different manoeuvres. Therefore the compromise has to be made between the low radar visibility and other performance attributes. Different flow control techniques such as using passive devices like different types of Vortex Generators (VG), Rib Turbulator (RT), or by proper contouring of the duct surface have been explored to minimise the secondary flow. Use of vortex generators, which mix the high energy core flow with the low energy boundary flow, have been studied [6, 7]. However, Vortex Generators showed limited effectiveness, hence in this thesis an attempt has been made to use RT in place of vortex generators and to investigate its effect on the flow and distortion index at the face of engine. RT are protrusions placed in a controlled way along the walls and are commonly used to improve heat transfer in gas turbine engine blades [5]. In a serpentine duct complex shape of mean line generates two counter rotating vortices at engine face and increase the flow distortion with pressure loss. An effort is also made to understand the flow details at different angles in order to look for any adverse effect of RTs. 2. GEOMETRIC MODEL The entire geometry as shown in figure 2 was reconstructed in CATIA V5 R14 software as shown in Fig.3 and the geometric specifications are mentioned in the Table 1. The flow path of interest in this study is an ultracompact serpentine inlet duct designed by Lockheed Martin Aeronautics Company. The inlet is identical to the test article of the research conducted by [1, 4]. The duct features a length-to diameter ratio of 2.5 and consists of a 4:1 aspect ratio, bi-convex entrance section followed by a dual-turn offset section and a diffusing, elliptical-to-circular exit section and a length of 63.5 cm and an exit diameter of 25.4 cm. 2 Fig 2. Three views of the Inlet duct Specifications Length Inlet Minor Diameter Inlet Major Diameter Outlet diameter 0.63 m 0.124 m 0.49 m 0.254 m Table 1. Geometric Details of the Serpentine Inlet Duct Fig 3. CAD model of Serpentine Inlet Duct RTs were modelled inside the duct at a distance of one radii of the minor axis of the inlet from the flow separation point, the minor axis radius is used for the height ratio of the RT. Fig 4. Rib Turbulator modelling in the Serpentine Duct Specifications Rib width Rib Thickness 0.096 m 0.0186 m Table 2. Geometric Details of the Serpentine Inlet Duct 2.1 Discretization of the Model A multi block grid was created by ANSYS ICEM CFD Software. Figure 5 shows the discretised model of the serpentine duct, the mesh was kept fine at the first and 2nd bend and near the walls regions which were the critical regions were the study of boundary layer separation and generation of vortices was of the main interest. The inlet duct with the RT was also discretised in the same manner as of the baseline duct, but the block was split near each of the RT to have a grid control on the RT. This SST k– ω turbulence model is a two-equation eddy-viscosity model. The use of a k-ω formulation in the inner parts of the boundary layer makes the model directly usable all the way down to the wall through the viscous sub-layer, hence the SST k-ω model can be used as a Low-Re turbulence model without any extra damping functions. The SST formulation also switches to a k-ε behaviour in the free-stream and thereby avoids the common k-ω problem that the model is too sensitive to the inlet free-stream turbulence properties. In addition, SST k-ω model often shows good behaviour in adverse pressure gradients and separating flow [9]. Table 3 shows the parameters at the boundary conditions. Parameters Inlet Total Pressure, Pa Inlet Static Pressure, Pa Inlet Total Temperature, K Exit Static Pressure, Pa Exit Static Temperature, K Value 99991.78 97313.02 298.15 97889.49 296.37 Table 3. Parameters at Boundary Conditions and their values 3. GRID INDEPENDENCE STUDY Fig 5. Discretized model of a Serpentine Inlet Duct 2.2 Boundary Conditions The SST k– ω turbulence model was used along with the boundary conditions shown in figure 6. Also a stationary no-slip wall is considered for calculations. The results from numerical analysis are sensitive to number of grid points, so great care needs to be taken in preventing the results dependent on number of grids. For the current problem, initially a coarse mesh with 1032952 cells was used to do the flow analysis. The cell size was subsequently increased to 1491658 and 2024365 cells. Figure 7 shows the grid independence with respect to Cp loss. Figure 6 shows different part of the duct where boundary conditions are applied. Fig 7. Grid independence study The distortion value and the pressure loss values for 1491658 and 2024365 did not differ significantly, so considering the available resources with the accuracy of the results required, the G2 grid is considered as final mesh for the further computations. To ensure the results grid independence study has been carried out for the duct with RT. Fig 6. Different part of duct where Boundary Conditions are applied 3 Fig 9. Contours of Velocity near 1st and 2nd Separation Point and at Rib Turbulators Fig 8. Comparison of Cp contours obtained on three grids G1, G2 and G3 Where in the duct with the RT, there are no reverse flows either near the first bend or at the second bend, indicating that there are no flow separations inside the duct. Figure 8 shows the Cp Loss comparison. From the comparison we can find that the counter rotating vortices have almost disappeared in all 3 grids and the incorporation of RT successfully managed to suppress the counter rotating vortices at the engine inlet. 4. RESULTS AND DISCUSSIONS 4. 1 Effect of RT The computational results obtained for the duct with RT is compared with the baseline results to know the effects of RT on the flow structure. Figure 9 shows the comparison for velocity along the axial direction. In the figure 9 the flow separation near the second bend can be seen for the baseline duct, where there are reverse flows leading to flow separation which are shown as the path lines in the Figure 9(a). Fig 10. Contours of Vorticity Magnitude for Baseline, and with the RT Figure 10 compares Vorticity magnitude of Baseline duct and duct with RT Figure 11 shows the contour plots of pressure loss at the engine face, in figure 11 (a) pair of large counter rotating vortices can be seen at the top of the duct indicating the flow separation, whereas in figure 11 (b) 4 the duct with RT does not show any such vortices, which is a clear indication that there is no flow separation in the duct, the vortices which were generated in the duct because of the bend are counter acted by the RT and the reduction in Cp loss and distortion values at the engine face in terms of percentage compared to baseline are listed below. Fig 12. Static Pressure Plots for Baseline, and with the RT for Lower and upper points Table 4. Listing of the Reduction in the Cp and Distortion Compared to Baseline 4.2 Performance Comparisons at different Angle of Attack A well designed inlet duct straightens the flow at the engine face irrespective of angle of attack of the aircraft. Computations were done at moderate angles of attack in order to verify if RT had any adverse effect. AOA values chosen are 2o and 4o. Simulations are carried out for these cases by incorporating changes in velocity components due to different AOA. AOA = 2o Fig 11. Pressure Loss Contours at the Engine Face The performance of the duct was compared in terms of Cp loss, distortion and static pressure plots which are defined as follows. Cp loss = ((Pt,inf - pt, ef)/qinf)*100 Distortion (DC60) = DC 60 =((Pt,ef - Pmin 60,avg)/qef,avg)*100 Figure 12 shows static pressure plots on chosen lower and upper points. Here plots of baseline duct and duct with RT are compared. We can observe that there are fluctuations in pressure value near the placement of Ribs for duct with RT. Figure 13 shows comparison of Total Pressure at Engine Face for Baseline duct and Duct with RT at angle of attack 2deg. It can be seen that there is a very good decrease in the distortion values in case of Duct with RT. Fig 13. Total Pressure at Engine Face, AOA=2o For angle of attack of 2deg, the distortion value at Engine Face in percentage are 70.24 and 25.58 for Baseline duct and Duct with RT respectively. Thus the net improvement calculated is 63.58%. AOA = 4o Figure 14 shows comparison of Total Pressure at Engine Face for Baseline duct and Duct with RT at angle of attack 4deg. It can be seen that there is a very good decrease in the distortion values in case of Duct with RT. 5 Fig 14. Total Pressure at Engine Face, AOA=4deg Fig 16. Static Pressure Comparison for Baseline and with RT at different AOA (Upper Points) 5. CONCLUSIONS The RT were incorporated in the duct to know its effect on the flow properties such as distortion,,Cp loss and at various angles of attack. The baseline results for distortion and Cp loss show the same trend as of the experimental results and results obtained from literature as shown in Table 4. However, there were some differences in the Cp Loss and distortion index values as compared to experimental results The RT were effective in preventing the flow separation. They were effective in controlling the pressure distortion, a 58.69% reduction at engine face is observed with the RT installed with no AOA. They were also effective in controlling the pressure loss at the engine face, about 21.67% of reduction in Cp pressure loss was observed with the RT installed with no AOA. It was observed that the RT installations tend to distribute the low energy flow uniformly around the inside periphery of the engine face, leaving a high energy core flow. It can be seen that RT have negligible effect on distortion at engine face at small AOA of 2deg and 4deg. Fig 15. Static Pressure Comparison for Baseline and with RT at different AOA (Lower Points) Figures 15and 16 shows static pressure plots on chosen lower and upper points. Here plots of baseline duct at AOA=0o, 2o, 4o and duct with RT at AOA=2o, 4o are compared. We can observe that these plots closely match for all chosen AOA. REFERENCES [1] Aaron Michael Kirk, B.S. (2006) ‘Active Flow Control in an Advanced Serpentine Jet Engine Inlet Duct’. Texas A&M University [2] Kirk, Aaron M., Gargoloff, Joaquin I., Rediniotis, Othon K. and Cizmas, Paul G.A. (2009) 'Numerical and experimental investigation of a serpentine inlet duct'. International Journal of Computational Fluid Dynamics, 23: 3, 245— 258, 2009 6 [3] Angela C. Rabe (2003) ”Effectiveness of a Serpentine Inlet Duct Flow Control Scheme at Design and Off-Design Simulated Flight Conditions” Virginia Polytechnic Institute and State University, Blacksburg, Virginia, August 2003 [4] J.W. Hamstra, D.N. Miller, P.P. Truax, B.A. Anderson, and B.J. Wendt. (2000) ‘Active inlet flow control technology Demonstration’. ICAS 2000 CONGRESS, Published by the International Council of the Aeronautical Sciences. [5] Aravind Rohan Sampath. (2006) “Effect OfRT On Heat Transfer Performance In Stationary Ribbed Channels”. Cleveland State University, MS Project Thesis. [6] Bernhard H. Anderson and James Gibb. (1996) ‘Vortex Generator Installation Studies on Steady State and Dynamic Inlet Distortion’. 32nd Joint Propulsion Conference cosponsored by AIAA, ASME, SAE, and ASEE Lake Buena Vista, Florida. [7] Vikas K. T. (2013) ‘Numerical Investigation of Aircraft Serpentine Engine Inlet Duct to Improve the Flow Performance’. MSRSAS, MSc [Engg] Project Thesis,FT-12. [8] Ritesh Gaur, Vimala Narayanan and Kishore Kumar S. (2012) ‘Influence of Area Distribution with fixed Trajectory on Serpentine Intake Duct Performance’ ASME-2012 Gas Turbine India Conference, GT India 2012-9625 [9] CFD Online (28 February 2011, at 21.36). SST k-omega model. Retrieved on June 12, 2015, from <http://www.cfd-online.com/Wiki/SST_komega_model> 7 8