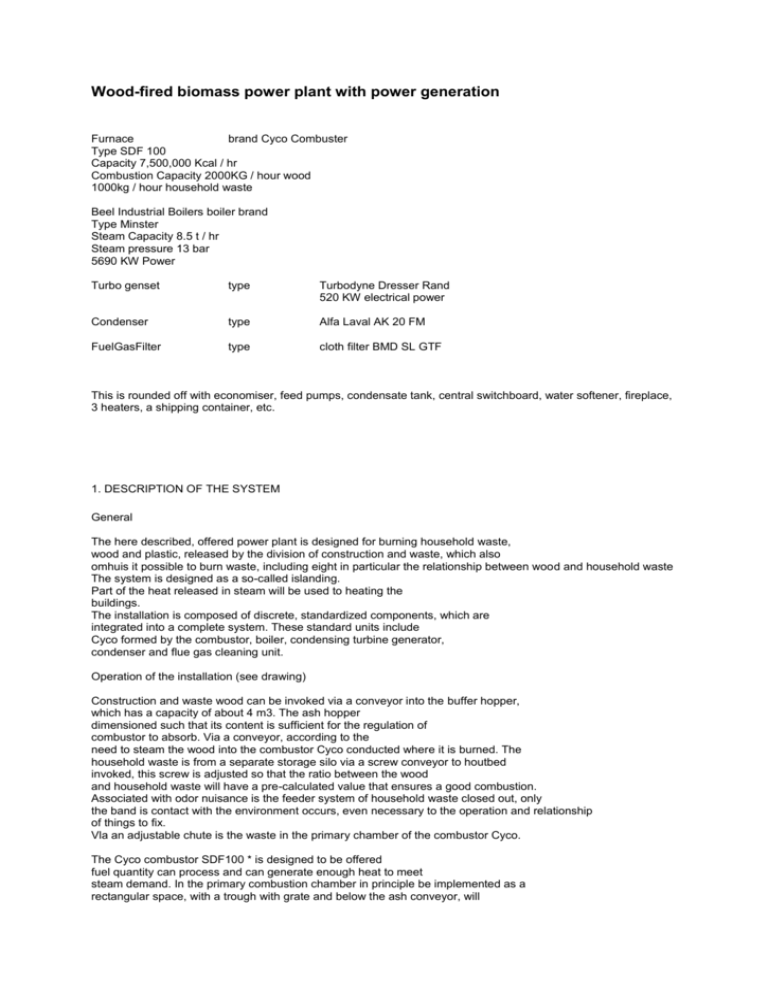

Wood-fired biomass power plant with power generation Furnace

advertisement

Wood-fired biomass power plant with power generation Furnace brand Cyco Combuster Type SDF 100 Capacity 7,500,000 Kcal / hr Combustion Capacity 2000KG / hour wood 1000kg / hour household waste Beel Industrial Boilers boiler brand Type Minster Steam Capacity 8.5 t / hr Steam pressure 13 bar 5690 KW Power Turbo genset type Turbodyne Dresser Rand 520 KW electrical power Condenser type Alfa Laval AK 20 FM FuelGasFilter type cloth filter BMD SL GTF This is rounded off with economiser, feed pumps, condensate tank, central switchboard, water softener, fireplace, 3 heaters, a shipping container, etc. 1. DESCRIPTION OF THE SYSTEM General The here described, offered power plant is designed for burning household waste, wood and plastic, released by the division of construction and waste, which also omhuis it possible to burn waste, including eight in particular the relationship between wood and household waste The system is designed as a so-called islanding. Part of the heat released in steam will be used to heating the buildings. The installation is composed of discrete, standardized components, which are integrated into a complete system. These standard units include Cyco formed by the combustor, boiler, condensing turbine generator, condenser and flue gas cleaning unit. Operation of the installation (see drawing) Construction and waste wood can be invoked via a conveyor into the buffer hopper, which has a capacity of about 4 m3. The ash hopper dimensioned such that its content is sufficient for the regulation of combustor to absorb. Via a conveyor, according to the need to steam the wood into the combustor Cyco conducted where it is burned. The household waste is from a separate storage silo via a screw conveyor to houtbed invoked, this screw is adjusted so that the ratio between the wood and household waste will have a pre-calculated value that ensures a good combustion. Associated with odor nuisance is the feeder system of household waste closed out, only the band is contact with the environment occurs, even necessary to the operation and relationship of things to fix. Vla an adjustable chute is the waste in the primary chamber of the combustor Cyco. The Cyco combustor SDF100 * is designed to be offered fuel quantity can process and can generate enough heat to meet steam demand. In the primary combustion chamber in principle be implemented as a rectangular space, with a trough with grate and below the ash conveyor, will a process of gasification of the fuel site. Injected via a primary air compressor also acts of fluidization the ash bed, making a complete burnout of the waste he maximum retention time is obtained. The gases pass vertically through the ash layer where fuel bed and then subsequently air is supplied again; The gases are mixed with the air and creates a further combustion of these gases. They then enter tangentially into the secondary combustion chamber, where, with the addition of tertiary air completely burn. The shape of the secondary combustion chamber and the method of enter a rotation of the gas flame, it is like a hot cyclone formed hence the name Cyclonic combustor. By mixing air and gas is a complete combustion takes place and maximum combustion temperatures are reached, depending on whose fuel can up to 2000 C. Due to the difference in density between the cold air and hot flue gases, will the outside of the flame (= inner mantle sec. combustion chamber), a cold air skin achieved, in which particles centrifuged cool. Vla an inspection / cleaning hatch these particles are periodically removed. The Cyco combustor is controlled by sensors and a PLC unit. The supply of primary, secondary and tertiary combustion air is regulated with respect to the fuel supply, so that (Preset) maximum, optimal combustion conditions are maintained. The fuel is set to a signal from the boiler system and is carried out through a signaling to the infeed conveyor. The hot flue gases from the combustion are then placed in the furnace of a 3-pass boiler sucked. In this boiler the flue gases cool off in the furnace, second and third Pull Pipes, giving off heat to the water in the boiler, whereby the steam generated. The steam leaves the boiler through the main valve to the steam turbine; condensate / feedwater custard a boiler feed pump pressure on the boiler fed. The three-component system controls the boiler water level in the boiler relative steam and water supply and drainage: the power to regulate. By increasing the steam-pressure steam will decrease and this signal serves as power signal for the combustor / power band. The boiler, sufficient to meet the test the Stoomwezen is equipped with the necessary accessories, such as sight glasses, purge and vent valves, main steam valve, safety valves and level control for the electrodes and security. Through bolted inspection doors is cleaning the interior of the pipe bundles possible. Of the turbine / condenser returning condensate via a buffer (Hot-well) to the boiler pumped back to the extent necessary to make up water treatment (Softening). The steam through a pipe from the boiler to the turbine. This single stage turbine expands steam from a higher to a lower pressure release of energy. The turbine drives through a transmission, the generator, where the electrical energy generated. The turbine is equipped with a TG 13 Governor for speed control and security. The bearings are a sealed lubrication system, equipped with water cooling. The turbine [s designed for outdoor use, and consists essentially of: - The turbine housing 4 "inlet and 12" outlet flange, divided horizontally; - Curtis the single stage turbine rotor blades mounted on two points; - The TG 13 Governor, overspeed and local beveillging triphef tree; - Bearings with oil lubrication and coolers and seal. The driven generator is a 4-pole induction generator, 50 Hz, 380 V, 1500 rpm, 630 kVA for islanding. Between the turbine and generator is a high revving gearbox with forced oil cooling / lubrication, so the turbine speed down to 1500 rpm. An oil lubrication system completes this turbine generator, which is in a frame assembled into a complete unit. The cooled flue gases leave the boiler in an off-gas purified, to ensure that environmental requirements in the permit are met. Dust is trapped in a so-called vibrating vane electrostatic filter, with a spraying device to the plates clean. When gaseous pollutants are the molecules are electrically charged, "the structure of the molecule is changed so that to meet emission standards (NOx and SOx breakup) and also enter a improvement by washing with chemicals. The spray water is recirculated, and pH controlled, solid particles are trapped in a sieve. Through a 15 meters (above surface) high chimney flue gases leaving the Plant, which chimney provide a measure of: performing emission measurements by third parties. Moreover, Some instruments placed out in the framework of the permit prescribed. The low pressure stream which leaves the turbine is fed to a condenser where the heat is released to the cooling water. For heating, the heat free as water of approximately C go through a pump to transport the convection heating in buildings. The cooled water is returned to the system. The tension cables of the generator are fed to a central Control box / panel. It is also the scheme for voltage and frequency, this according to the attached schedule. D [t switch panel will be linked the main distribution of the PEN, so that power available for starting of the installation. The ash (slag) from the primary combustion chamber of the combustor, condoned, by a Screw conveyor fed from the combustor. From this point, over half outflow This screw conveyor shaft in a single container to be conducted. The amount will depend on the ash content: the fuel. The whole system is shown on the attached diagram Fig 1 and consists basically of The following standard 7 main components: 1. Cyco combustor system (A) 2. Boiler unit (B) 3. Steam turbine generator (C) 4. Condenser (D) 5. Central control panel and main distribution (E) 6. Flue gas treatment unit (F) The generation capacity of 520 kW is achieved at an incineration capacity of approximately 2000 kg / hour of wood and 1000 kg / hour household waste. The plant is designed for continuous operation at full load and 98% of full load. For 1 hour is an overload of 10% (= 570 kW). The frequency Rules on voltage is + / - 2 Hz to 50 Hz and full load it + or - 5 Hz at 10% overload. The average settlement during normal operation is continuous or - 2 Hz. The installation is suitable for outdoor setting at temperatures from - 15 C to + 45 C and protected again performed. 2. General The plant is supplied as a modular package and consists of six 'modules' and a 'package' general components, and working along the following description: 2.1 Module 1: Cyco combustor 2.1.1 One (1) Cyco combustor type SDF 100 This according to sketch. The combustor consists of the primary combustion chamber, rectangular in shape, with a grid including a astrechter, all made of 304 stainless steel, the addition cylindrical secondary combustion chamber and the connecting channel between the two combustion chambers, also made of steel 304. Both combustion chambers are mounted in a casing humps made of normal carbon steel. 2.1.2 The air supply system comprising a primary air fan drive, the piping and nozzles supply air into the combustion chamber, the air valves secondary and tertiary air actuators. 2.1.3 The automatic ash discharge conveyor chain comprising a solid, top In the primary combustion chamber, with drive and output tray. 2.1.4 The induced draft fan motor. 2.1.5 The feed belt drive motor and with filler, including support. 2.1.6 The thermal insulation of the whole combustor with exterior siding. 2.2 Module 2: Steam Boiler Unit One (1) 'Minster' boiler 8.5 t / h steam, 12 bar, complete with boiler feed pump, boiler accessories, high and low water protection, as required by the Stoomwezen. 2.3 Module 3: turbo genset One (1) reciprocally complete turbine generator set, equipped with a pressure steam turbine type 701 T (Dresser-Rand), speed reduction drive, and an oil lubrication system Newage International, generator, type B 364 W Vibration Fri mounted on a frame. 2.4 Module 4: Condenser One (1) Alfa Laval Ak-20-FM with steam heat exchangers, condensate and process connections. 2.5 Module S: Regulation One (1) detached single interface with entertainment and power connections Power distribution, phase, steam-, voltage and frequency identification and kwh meter. Designed as a dual circuit system with automatic secure "Fall Safe" control. This panel also housed the damper system, the sensor converters for Cyco combustor and the boiler system, PLC controlled. 2.6 Module 6: Flue gas cleaning plant 2.6.1 One (1) AES 2000 vibrating vane type of emission control system, comprising an electrostatic filter for removing dust and heavy metals, see attached general description. 2.6.2 One (1) electronic gas and vapor filter for the removal of gaseous Contamination 2.6.3 One (1) circulating wash system with pH control and sedimentation tanks 2.6.4 Temperature - / gas equipment Item 1 1 (a) pieces 02 and CO analyzer Manufacturer:. Ametek ThermoX Instruments Inc.. Model: WDG-HPIIC Power supply: 220Vac / 50Hz Range: 0-20% 02 0-2000 ppm combustibles (CO + H2) Alarms: February 2 combustibles and two alarms Output: 4-20 mA (2x) Maximum flue gas temp.: 704 C with 316 SS probe 1020 C with 253 mA probe 02 Combustibles -------------------------------------------------- ----------------- Accuracy + / -2% + / - 5% Repeatability + / - 0.2% + / -2% Response time 16 sec. 25 sec. The system consists of: A) A sensor unit suitable for mounting directly on the stack. The sensor is mounted in a heated and insulated stainless steel cabinet in which all the flue gas in contact with parts above 225 C heated. The filter probe the convection loop to make the system suitable for incinerator exhaust gases from a timber. Probe material: 316 SS or 253 mA. b) A transmitter unit suitable for wall or panel mounting. Ambient temperature: - 18 to 49 C. Item 2 1 (a) pieces Miniature Hybrid Recorder Manufacturer: Tracor Westronics Model: 1560 * For 4 channels (max 6) - 2 channel thermocouple (type J, K, T, etc.) - 2 channel 4-20 mA dc Print alarms, date and time along with writing the channels plain paper. Paper Width: 100 mm Paper Speed: 1910 to 1200 mm / hr Power supply: 220 VAC/50 Hz DIN dimensions: 144 x 144 mm 2.6.5 An induced draft fan motor. 2.6.6 One (1) chimney, getuid, up to 15 meters to the surface courts, with a blunt receivers for measuring emission measurements. 2.7 Not included in delivery - Reduction Installation and storage respectively. flow to the combustor of the waste - Disposal of ash from the combustor. - Supply of water, power. - Drain to grid, distribution and linking to decreasing machinery. - Civil works, - Emission measurements for County (license verification), except for the first measurements. - Depiction of installation. 3. TECHNICAL SPECIFICATIONS 3.1 Module 1: Cyco combustor. Type SDF 100 Cont. Capacity 7,500,000 Kcal / hr Fuel wood, board, chipboard Incineration 2000Kg / hr wood 1000kg/hr household waste Timber supply operation manual / automatic Ash removal method of automatic / electric Combustor operation automatically Electric included Power 2.9 KW at full load 3.2 Module 2: Steam Boiler Unit Steam Capacity 8.5 t / h C. Steam pressure 12 bar Manufacturer Beel industrial boilers PLC Type Minster 5690 KW Power Length 7040mm. Width 3590mm. Height Max. weight, filled with Water 40730 KG Transport weight 21815 KG 3.3 Module 3: Turbo-qenset 520 kW electrical power Steam Consumption 8.5 t / h Steam pressure 12 bar entrance Taxable 98% continuous full load Overload protection automatically switch off after 1 hour Frequency Control average 1%, 3% overload Voltage 380 Volts Phase 3 + + Ground Zero 3.4 Module 4: Condenser Manufacturer Alfa - Laval Type AK 20 - FM, plate capacitor Continuous load 3.5 Module 5: Central Control Manufacturer AES Type A-501-M Capacity of 520 KW Voltage 380 Volts Frequency 50 Hz 24 volt control voltage is equal Response to signals from 0.25 to 1.5 seconden Double safety / fail system Overload 570 KW Overload Protection 0.5 KW to 570 KW