Microstructure and texture evolution of an ultrafine grained Ti-6Al

advertisement

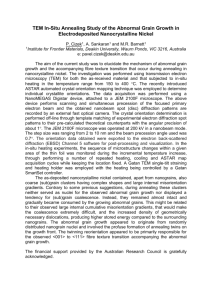

Microstructure and texture evolution of an ultrafine grained Ti-6Al4V alloy during post-deformation annealing Q. Chao1, P.D. Hodgson1 and H. Beladi1 1Institute for Frontier Materials, Deakin University, Geelong, VIC 3216, Australia qchao@deakin.edu.au, peter.hodgson@deakin.edu.au and hossein.beladi@deakin.edu.au Fabrication of an ultrafine grained (UFG) microstructure in titanium and its alloys is a promising route to enhance the strength and ductility simultaneously and widen their application. Recently several successful trials have been reported in the Ti-6Al4V alloy through different approaches [1-3]. Thereby, it becomes imperative to understand the thermal stability of the UFG structure at elevated temperatures, where superplastic deformation or interpass holding of the material for multipass hot working are typically conducted. In the current study, the post-deformation annealing behaviour of an ultrafine grained Ti-6Al-4V alloy was studied throughout the thickness of as-rolled sheet. The evolution of hardness, microstructure and texture over the annealing cycle were investigated for the surface and interior layers which had different starting microstructures (i.e. fully and partially UFG). Upon annealing, the surface layer revealed more significant softening than the interior layer and the material softening rate at 800°C was ~50 times quicker than that at 700°C. The microstructure evolution in the surface layer comprised of concurrent grain growth of alpha and beta precipitation, whereas the interior layer also revealed the replacement of partially fragmented alpha lath by equiaxed grains most likely through static recrystallization. Despite the presence of relatively high dislocation density, the continuous precipitation of beta on alpha grain boundaries significantly retards the alpha grain growth through a pinning effect. The overall texture was mostly preserved for both surface and interior layers throughout the post-deformation annealing treatment. However, slight changes appeared in the surface layer texture with holding time, mainly showing a gradual strengthening of the (0°, 0°, 30°) component at the expense of the (0°, 0°, 0°) and (0°, 90°, 0°) components. The changes were mainly attributed to preferred grain growth of specific orientations. References [1] S.V. Zherebtsov, G.A. Salishchev, R.M. Galeyev, O.R. Valiakhmetov, S.Y. Mironov and S.L. Semiatin, Scr. Mater. 51 1147 (2004). [2] C.H. Park, J.H. Kim, J.-T. Yeom, C.-S. Oh, S.L. Semiatin and C.S. Lee, Scr. Mater. 68 996 (2013). [3] Q. Chao, P.D. Hodgson and H. Beladi, Metall. Mater. Trans. A 45 2659 (2014).