Press text (English)

advertisement

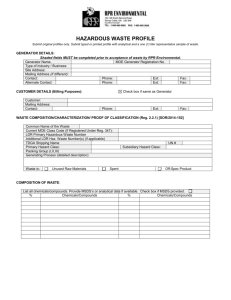

Practically Limitless Possibilities Press release PI 1888 Page 1 of 3 New functions for the JUMO mTRON T measuring, control, and automation system With the mTRON T, JUMO GmbH & Co. KG is increasingly evolving into a system supplier instead of just a supplier of components. The measuring, control, and automation system has been introduced to the market with great success and is already represented in a highly-diverse range of sectors. The range of functions on the mTRON T is being consistently expanded to meet customer needs. A program generator with procedural steps, an optimized user management system, and an extended process screen editor are now available as updates. As an option in the mTRON T central processing unit, a program generator is available especially for thermal treatments or thermal procedures. Up to nine asynchronous program generators can be activated. This standard program generator type allows setpoint value profiles to be specified. A setpoint value profile forms a program, together with the conditions of the control contacts. A special program generator type is required for curing, cooking, and smoking chambers or for heating cabinets, cold chambers, and test chambers. In these areas, procedural steps are defined by the plant manufacturer (e.g. as a PLC application). Here, the user has no access, as special knowledge of plant operation is required. During program entry in the JUMO setup program, the user completes the procedural steps with the setpoint values for the program sections that have been defined by the plant manufacturer. Examples of the setpoint values include the chamber temperature or humidity, the core temperature, or the intensity of the smoke generator. The processing of the program sections is then defined as a program by the user. In addition, various functions are extended in the system when the new program generator type is implemented and summarized as a new stage of expansion. This includes additions to the user management system and amendments to the process screen editor. Editorial information: Michael Brosig, Press Office Phone: +49 661 6003-238 Fax: +49 661 6003-881238 Email: michael.brosig@jumo.net Technical information: Thomas Diel, Product Manager Phone: +49 661 6003-648 Fax: +49 661 6003-881648 E-mail: andre.berning@jumo.net JUMO GmbH & Co. KG Moritz-Juchheim-Straße 1 36039 Fulda, Germany Phone: +49 661 6003-0 Fax: +49 661 6003-500 Email: mail@jumo.net Website: www.jumo.net Press release Users in a variety of industries have expressed the wish to configure the display and operation options according to the user who is signed in. As a result, up to 50 users – each with ID, name, and password – could be managed by the system in the future. The special feature here is that new users can be defined in the JUMO setup program or installed directly in the JUMO mTRON T multifunction panel. The option of defining up to 16 user groups in the JUMO setup program with individual rights is available. Currently, up to 18 individual process screens can be shown in the JUMO mTRON T multifunction panel. The process screens are created in the JUMO setup program using the process screen editor. In the future, the option of defining up to 16 levels in each process screen will be available. When a process screen is created, the individual process screen objects are assigned to the corresponding level. The visibility and editability of each process screen level can be influenced by the soft PLC and the aforementioned user groups. In addition, the process screen object types are extended to include points such as program selection and batch reporting. Image 1: The measuring, control, and automation system JUMO mTRON T has been introduced to the market with great success Page 2 of 3 Press release Page 3 of 3 Image 2: schematic diagram of the new program generator type Image 3: the new user group management system Image 4: the extended process screen editor The JUMO business group, headquartered in Fulda, employs more than 2,100 people worldwide and is one of the leading manufacturers in the field of industrial sensor and automation technology. The innovative range of products encompasses the entire measuring chain from sensors through to automated solutions for the measurands temperature, pressure, liquid analysis, flow, filling level, and humidity. The business group consists of five branches in Germany, 24 subsidiaries abroad, and more than 40 agencies around the world. In 2013 turnover was 218 million euro.