Fe-Y2O3_SM

advertisement

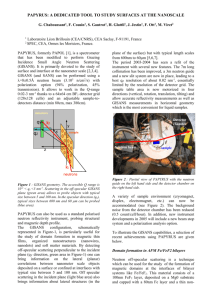

Supplementary Materials for Characterization of a Fe/Y2O3 metal/oxide interface using neutron and x-ray scattering E. B. Watkins1, #, A. Kashinath2, 3 #, P. Wang1, 4, J. K. Baldwin5, J. Majewski1,*, and M. J. Demkowicz2, * 1 Lujan Neutron Scattering Center, Los Alamos National Laboratory, Los Alamos, NM 87545, USA 2 Department of Materials Science and Engineering, Massachusetts Institute of Technology, Cambridge, MA 02139, USA 3 Computational Modeling Technology, Aramco Research Center—Boston, Cambridge MA 02139, USA 4 Intel Corporation, Hillsboro, OR, 97006, USA 5 Center for Integrated Nanotechnologies, Los Alamos National Laboratory, Los Alamos, NM 87545, USA *Corresponding authors: jarek@lanl.gov, demkowicz@mit.edu # These authors participated equally to the work. Magnetic neutron scattering To fit the NR data, the magnetic component of neutron scattering in the Fe layer must be taken into account. The magnetic scattering length density of iron is 𝛽𝑚 = ± 𝑚𝑛 𝜇𝑛 2𝜋ℏ2 𝜇0 𝑁𝜇𝐹𝑒 = ±5.09 × 10−6 Å−2 , where 𝜇0 is the vacuum permeability, N is the number density of iron, 𝑚𝑛 is the neutron mass, 𝜇𝑛 is the neutron magnetic moment, and the magnetic moment of iron is 𝜇𝐹𝑒 =2.219 Bohr magnetons1. Using software developed by the authors, the unpolarized NR data is fitted by calculating the incoherent addition of the spin-up and spin-down reflectivites. The fitting procedure converges to a value of βm = ±5.3x10-6Å for the magnetic SLD of the Fe layer, close to the theoretically predicted value for bulk iron. This result indicates 1 that the Fe film is magnetically saturated with the magnetic field direction in the plane of the layer. Reflectivity fitting strategy In fitting the NR data, we apply the simplest possible model capable of reproducing the measured reflectivity. A series of models with increasing complexity is created to approximate the structure of the metal/oxide interface and their 2 goodness-of-fit values are compared (Fig. S1). A two-layer model describing the Fe and Y2O3 materials cannot reproduce the NR measurement. By comparison, a three-layer model incorporating a distinct interfacial region significantly improves the match between the measured and calculated reflectivities. While adding a fourth layer to describe two distinct interfacial structures leads to a further decrease in the χ2 value, the addition of a fifth layer does not result in significant improvement of the fit. Thus, the four-layer model is applied to describe the metal/oxide interface and to fit both the NR and XR data. To further reduce the risk of over-parameterization, several of the fitting parameters are constrained or fixed to physically motivated values. For example, the SLDs of the Fe and Y2O3 layers are fixed to literature values and the roughness of all interfaces are constrained to be equal to each other. Since the maximum momentum transfer vectors Qz for the NR and XR experiments are the same, the roughness parameters in XR are fixed to the values obtained from NR. The real and imaginary x-ray SLDs of the Fe and the Y2O3 layer are allowed to vary ±5% from the theoretical values and the SLDs of the interfacial layers are allowed to vary ±10% from the values obtained from the NR fit. The thicknesses of all layers in XR are allowed to vary around the values obtained from NR. 1 in Modern Techniques for Characterizing Magnetic Materials, edited by Yimei Zhu (Springer US, 2005), pp. 107. Supplementary Figure: 2 Fig. S1. (left) NR data from the Fe/Y2O3 bilayer sample (symbols with error bars) and fitted curves (solid lines) corresponding to three different 2-, 3-, and 4-box SLD profiles (right). The χ2 goodness-of-fit values of these models are listed in the legend in (left). The 4-box model provides the best fit to the data without over-parameterizing. 3