Investigating the `crisis`: production workers` literacy and numeracy

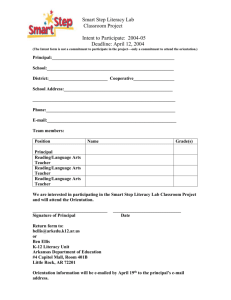

advertisement