anand resume_1435678060

advertisement

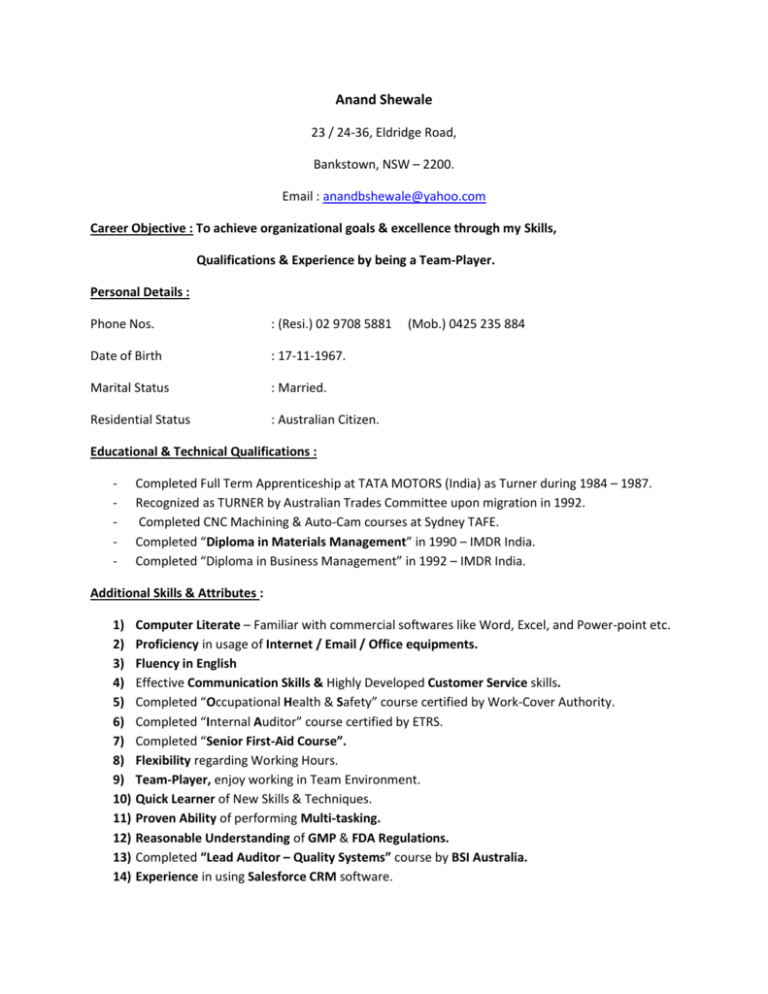

Anand Shewale 23 / 24-36, Eldridge Road, Bankstown, NSW – 2200. Email : anandbshewale@yahoo.com Career Objective : To achieve organizational goals & excellence through my Skills, Qualifications & Experience by being a Team-Player. Personal Details : Phone Nos. : (Resi.) 02 9708 5881 Date of Birth : 17-11-1967. Marital Status : Married. Residential Status : Australian Citizen. (Mob.) 0425 235 884 Educational & Technical Qualifications : - Completed Full Term Apprenticeship at TATA MOTORS (India) as Turner during 1984 – 1987. Recognized as TURNER by Australian Trades Committee upon migration in 1992. Completed CNC Machining & Auto-Cam courses at Sydney TAFE. Completed “Diploma in Materials Management” in 1990 – IMDR India. Completed “Diploma in Business Management” in 1992 – IMDR India. Additional Skills & Attributes : 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) 13) 14) Computer Literate – Familiar with commercial softwares like Word, Excel, and Power-point etc. Proficiency in usage of Internet / Email / Office equipments. Fluency in English Effective Communication Skills & Highly Developed Customer Service skills. Completed “Occupational Health & Safety” course certified by Work-Cover Authority. Completed “Internal Auditor” course certified by ETRS. Completed “Senior First-Aid Course”. Flexibility regarding Working Hours. Team-Player, enjoy working in Team Environment. Quick Learner of New Skills & Techniques. Proven Ability of performing Multi-tasking. Reasonable Understanding of GMP & FDA Regulations. Completed “Lead Auditor – Quality Systems” course by BSI Australia. Experience in using Salesforce CRM software. Experience : Garlock Sealing Technologies – August 2011 till Date – Internal Sales / Business Development. Started as Internal Sales Rep. & gradually been promoted to External sales Role as a Business Development Manager. Primary responsibilities are servicing the existing client base (using monthly Call Cycle) by timely professional service through maintaining & developing relationships & promoting other products & services offered by Garlock with a solution based approach. Also attending to break-downs to provide urgent services & solutions based upgrade suggestions to customer’s on-going problem areas. Using new enquiries & referrals to acquire new accounts to increase the market presence. Compiling & submitting Weekly / Monthly Sales Reports. Also initiating plan / strategy changes when required, by closely monitoring the Budgets Vs Results. Being an integral senior member, I help on new projects / contracts as well as assisting the “Internal Sales Team” with critical / challenging enquiries to ensure timely service delivery. Gantiel Vensott EPS Pty. Ltd. – August 2009 – June 2011 – Internal Sales Rep. Duties involved were processing customer enquiries / orders, assisting external Reps. In converting samples / enquiries into quotes. Processing orders using internal / supplier capabilities. Liasing with overseas suppliers to obtain for specific inventory supplies for unique orders. Following-up on pending quotes to convert into orders. Liaising with customers regarding product-solution, pricing matters etc. SKF Economos Aust. Pty. Ltd. – Dec. 2007 – July 2009 – Technical Sales Rep. Duties involved were working in the sales territory maintaining existing customers & expanding customer base by providing sealing solutions to Hydraulics, Pneumatics, Engineering & Industrial Automation clients including resellers, End-users & OEM’s. Cross-Selling, Up-selling new products to add existing products. Maintaining customer data-base, Monthly sales Reports, Follow-up on pending quotes & follow-through the orders were part of my responsibilities. Due to Global Financial crisis I was offered Redundancy. Hallite Seals Aust. Pty. Ltd. – March 2005 – August 2007 – Internal Sales / Production Manager. Initially started as Internal Sales / stand-by Machinist. Working on the counter supplying sealing solutions, processing enquiries & orders. Also working on the Seal-making m/c in the absence of regular machinist ensuring production targets are met. After 18 months promoted as “Production Manager” looking after planning, scheduling, swapping production plans to accommodate capabilities & urgencies to ensure customer requirements are accommodated for the 2 local & 2 Inter-Branch Machines. Liasing with Internal / External customers, creating & controlling production documentation, Completing QC Documents, Liasing with Purchase on shortages, future requirements. Running Daily Production Reports, Weekly Performance charts etc. Planning scheduled maintenance, Arranging & attending Monthly Safety Meetings, Participating in Production Meetings & providing Feed-back to Production Personnel or Management accordingly whilst continuing to contribute to Internal Sales Function. Bishop Manufacturing Technologies – May 2002 – February 2005 – CNC Machinist. Duties involved were programming, setting & operating CNC Lathe machine to produce High-Quality ToolRoom components whilst ensuring Quality & safety standards. Maintaining the Plant & Machinery by carrying-out preventive maintenance, also filling in the Quality Control Reports etc. Indo Schottle Auto Parts Pvt. Ltd. (India) – October 1999 – April 2002 – Vendor Development Engineer. Indo Schottle is a QS900 Company & a major supplier to Cummins Global, I Was instrumental in managing 21 Vendor companies with a focus on continuous Improvement. Vendor Assessment, ongoing VendorRating, ensuring compliance requirements are constantly met-with & finding long-term solutions in achieving streamlining of supply-chain was part of my routine activities. Other duties involved were planning scheduling purchase of Manufactured Items & Bought-outs by coordinating with Production, Stores & QA Departments. Procurring materials in cost-effective manner to compliment the Production Plans. Being a QS900 company all necessary documentation such as Vendor Registrations, vendor Ratings, Cost Analysis & Updating Vendor QA Systems were part of my job. Crouse Hinds Aust. Pty. Ltd. – March 1993 – March 1999 – CNC Machinist. involved were programming, setting & operating CNC Lathe machine to produce High-Quality Tool-Room components whilst ensuring Quality & safety standards. Maintaining the Plant & Machinery by carryingout preventive maintenance, also filling in the Quality Control Reports etc. Sealol Hindustan Ltd. (India) – November 1987 – July 1992 - Production cum QC Supervisor. Initially started as CNC Machine Operator & gradually got promoted to Supervisor position. Duties involved were co-ordinate production & assembly of Pneumatic Actuators to meet the monthly Sales requirements. Planning, Schedulling, liasing with sales & Stores were my main activities. Monthly Production Reports, QC Documentations & Maintaining Safety were also part of my responsibilities. References : 1) Michael Spain Sales Manager – SKF Economos. Currently working with Parker Hannifin. Phone – 0401 005 302. 2) Dimitri Virski Marketing Director – Gantiel Vensott EPS Pty. Ltd. Phone – 0422 658 004.