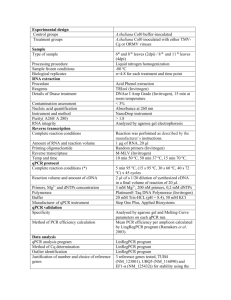

supplementary-material

advertisement

supplementary material Low-temperature synthesis of K0.5FeF3 with tunable exchange bias Qiao-Ru Xu1, Yang Liu1, Yu-Di Zheng1, Wenbing Rui 2, Yan Sheng1, Xuan Shen3, Jun Du2,*, Mingxiang Xu1, Shuai Dong1, Di Wu 3, and Qingyu Xu1,* 1 Department of Physics, Southeast University, Nanjing 211189, & Key Laboratory of MEMS of the Ministry of Education, Southeast University, Nanjing 210096, China 2) National Laboratory of Solid State Microstructures and Department of Physics, Nanjing University, Nanjing 210093, China 3) Department of Materials Science and Engineering, Nanjing University, Nanjing 210008, China * Corresponding author: jdu@nju.edu.cn; xuqingyu@seu.edu.cn 1 1. Confirmation of the reaction at 150 oC To confirm the formation of K0.5FeF3 even at the starting sintering temperature of 150 o C, the XRD patterns of the sample synthesized at 150 oC, and the reagents KF, FeF2 and FeF3 for comparison, are shown in Fig. S1. The main experimental XRD peaks marked by the arrows, cannot be found in the XRD patterns of each reagent, which is a direct proof for the already reaction at sintering temperature as low as 150 oC. Fig. S1 XRD pattern of sample synthesized at 150 oC, and mixed XRD patterns of KF (PDF#36-1458), FeF2 (PDF#45-1062) and FeF3 (PDF#33-0647, 34-1188 and 38-1305). 2. Confirmation of the assistance of crystal water From the basic knowledge of thermodynamics, the diffusion of ions between the particles of reagents depends strongly on the reaction temperature. Thus the formation of K0.5FeF3 at such low temperatures cannot be explained by the mechanism of conventional 2 high temperature solid state reaction. In fact, in the present low temperature synthesis, the crystal water in the reagents is the key factor, which facilitates the interdiffusion of ions through the surface solvent layer during the reaction process and thus effectively decrease the reaction temperature [1]. Here, we prove the crystal water in reagent FeF33H2O have a critical impact on the formation of the K0.5FeF3 phase. An additional experiment was done as the former preparation procedure except for that the crystal water in FeF33H2O was eliminated before the mixing of the reagents and the mixture was grinded in a glovebox filled with pure Ar. Fig. S2 XRD patterns for the samples synthesized at 230 oC with FeF33H2O and FeF3, respectively. The XRD patterns of the sample prepared at 230 oC with and without the crystal water in FeF3 are shown in Fig. S2. Obviously, with dehydrated FeF3, the XRD pattern is quite different from the K0.5FeF3 phase. Therefore, the crystal water in FeF33H2O plays an important role in the reaction. Generally, at low temperature, the interdiffusion of the ions of each reagent is rather limited, leading to the worse reaction between the reagents, as in 3 the case with dehydrated reagents. With the crystal water in the reagents during the grinding and sintering process, a thin solution film might be formed at the surface of the reagents, which will accelerate the reaction and the reaction temperature might be significantly decreased [1-4]. 3. Confirmation of the spin glass behavior by the dc magnetic relaxation measurement The magnetic relaxation behavior has been studied to confirm the spin glass (SG) behavior. The thermo-remnant magnetization (TRM) depending on time was measured at 10 K (shown in Fig. S3) by cooling the sample in a field of 10 kOe from 300 K to the final temperature, decreasing the field to zero and observing the decay of remnant magnetization. By switching off the field, the interface spins will remain in the field direction due to the pinning from the AFM core, and the AFM interfacial coupling forced the spins in SG shell to be aligned antiparallel. It should be noted that as the field cannot be switched off abruptly, the relaxation of the magnetization in the SG shell happened already during the switching off of the field, leading to the negative remnant magnetization. Since the AFM interfacial coupling from the pinning interface spins behaves as an effective magnetic field on the SG spins, we have fitted the time dependent remnant magnetization data with a stretched exponential function 𝑡 1−𝑛 𝑀(𝑡) = 𝑀0 − 𝑀r exp [− (𝜏) ] (1) where M0 the intrinsic ferromagnetic component and Mr the glassy component. The time constant τ and exponent n are related to the relaxation rate of the SG phase. The value of 4 n is 0.61, which is close to 0.5, confirming the SG behavior [5, 6]. In addition, τ is fitted to be 1370 s. Fig. S3 Measured (open symbol) and fitted (solid curve) time dependent remnant magnetization at 10 K. References: [1] X. C. Tang, B. Y. Huang, Y. H. He, and D. Z. Jia, Chin. J. Inorg. Chem. 20, 795 (2004). [2] X. C. Tang, B. Y. Huang, and Y. H. He, Chin. J. Inorg. Chem. 21, 12 (2005). [3] X. C. Tang, D. Z. Jia, C. K. Jiang, L. H. Jiang, and Z. P. Guo, J. Phys. Chem. A 112, 5390 (2008). [4] X. R. Ye, D. Z. Jia, J. Q. Yu, X. Q. Xin, and Z. Xue, Adv. Mater. 11, 941 (1999). [5] A. Maignan, A. Sundaresan, U. V. Varadaraju, and B. Raveau, J. Magn. Magn. Maer. 184, 83 (1998). 5 [6] R. S. Freitas, L. Ghivelder, F. Damay, F. Dias, and L. F. Cohen, Phys. Rev. B 64, 144404 (2001). 6