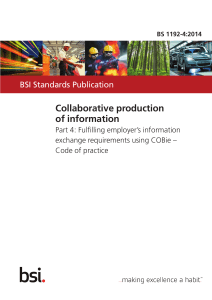

COBie and the common language

advertisement

COBie and the common language (FM3222) Anthony Neal – Autodesk Learning Objectives At the end of this class, you will be able to: Understand the importance of common language classification within BIM to provide earlier and more accurate cost modelling as well as the value in data integration with asset management systems. Understand what COBie is and its value to owner operators. Learn how to output a COBie spreadsheet with a common language classification from Revit. We will also examine the importance of classification for data integration between the building model and asset management systems such as Maximo. About the Speaker Anthony is a solution architect within the Autodesk consulting practice. His background is principally GIS and has been key to the successful delivery of enterprise Infrastructure GIS solutions for the past 17 years within Utilities military and government at Autodesk and GeoVision*. Having worked for most of his career with infrastructure outside the building Anthony has now stepped inside the building with BIM and can see many parallels between the “I” in GIS and the “I” in BIM. Having last year architected a successful BIM/GIS Integration at Heathrow airport is now engaged with one of the world’s largest AEC companies to drive efficiencies into the operate and maintain part of the their business through Autodesk solutions. Introduction With so many nuances and differences within our human language providing a common naming and meaning to the things in our built environment is not straightforward. Even within the same language we have differences, what I call a tap my cousins in America call a Faucet. The advent of BIM and particularly the “I” in BIM has meant if we want to join our Building Information with the rest of our business process and systems we need to be talking a common language classification when referring to the “things” in our buildings. This lecture will examine the Omniclass and Uniclass classification systems and why they are important to owner operators when receiving COBie information at handover. You will also learn about the COBie exchange format and its value to Owner Operators and why a classification system for the assets included in this data rich model are important. Attendees will get to see the latest COBie export tool from Revit. Insert Class Title as per Title Page Common language George Bernard Shaw was an Irish playwright and political activist who interestingly was a cofounder of the London school of Economics. He said England and America are 2 countries separated by a common language. There are several examples of this some which are quite amusing. However one I came across recently was a reference to a Faucet which actually comes from the French and originally Latin. I thought they were most probably referring to a tap but I know that most English speakers outside the US would not have worked this out. So can you see from this extreme example how even with human intelligence there is confusion in our so called common language. One of the benefits of BIM is the ability to make use of the I, analyse it and integrate it with other systems and process to get harness the value from it, if we don’t do this it just remains a pretty 3D graphical model. To get value from the I in BIM it is necessary to have a common language. This common language is required to operate on two levels: a) at a human level and b) at a machine level. Human communication demands a universal language comprising standard naming conventions to facilitate consistency and mitigate against the risk of misinterpretation. In other words no matter who in the design team is defining an asset the same, consistent terminology and unique identifier will be utilized. This strategic approach will have direct benefits for communication between software systems which similarly will require a common file structure to allow data from one system to be read by another. Inconsistent language You can see in figure 1 our humble fan coil unit named in 4 different ways in our asset management system because on each of our projects they were specified in different ways. This problem can also happen within a build where sub contractors haven’t followed the naming specification, one didn’t exist or they ignored it. You may as well be talking about an apple a sheep, Spain and a Tiger as far as the system is concerned. Unless we get into the database and cleanse the data to make it consistent we have no way of grouping the data up so that we can supply performance information. For example what is the failure rate within the first 90 days on our new builds for fan coil units grouped by manufacturer and model. Querying this data becomes more difficult if not impossible because it’s not stored consistently. 2 Insert Class Title as per Title Page Figure 1 Inconsistent Fan Coil Unit The need for classification in the AEC owner operator world Projects need the participants to create, communicate and find relevant information at the appropriate time. The larger the scale of the project, and the greater the number of participants, the more essential it becomes to use methods and systems able to handle the associated complexities of information exchange. Classifying information in a consistent way, agreed by all participants, facilitates clear communication of intent and reduces the incident of misunderstanding, conflict, and wasted resources – this is particularly important in the construction industry because the parties involved usually change from project to project. In essence, classification simply means the grouping together of like things according to some common quality or characteristic. This automatically implies the separation of the unlike. In order to be able to classify a collection of subjects it is at first necessary to define the purpose of the classification. Then the properties of interest to the classification may be distinguished, and finally the subjects can be sorted into classes with regard to the chosen properties. (Natspec: Information classification systems and the Australian construction industry2008) 3 Insert Class Title as per Title Page Classification systems Coming from the UK the system I am most familiar with is Uniclass, however I will also focus on the Omniclass classification system which is prevalent throughout the US. Figure 2 Omniclass Uniclass Uniclass (UK) The most recent construction information classification system to be implemented in the UK is Uniclass (Unified Classification for the Construction Industry). Uniclass notation consists of a single capital letter followed by zero or more digits, except Tables J and K, which have two initial capital letters to allow the incorporation of the CAWS and CESMM3 codes. Uniclass 1 which was first published in 1997 and incorporates a number of existing systems as follows: • CAWS (Common Arrangement of Work Sections for building works), developed in 1987, was adopted by the National Building Specification (NBS), the Standard Method of Measurement of Building Works (SMM7), and the National Engineering Specification (NES). Until recently CAWS formed the basis of Uniclass Table J Work sections for buildings. • CESMM3 (Civil Engineering Standard Method of Measurement) forms the basis of Uniclass Table K Work sections for civil engineering works. 4 Insert Class Title as per Title Page • EPIC (European Product Information Cooperation) Construction Product Grouping (CPG) – or EPIC for short, a common European classification system for construction products, was first published in 1994. EPIC forms the basis of Uniclass Table L Construction products (Natspec) (Natspec: Information classification systems and the Australian construction industry2008) Issues with existing uniclass Uniclass is currently undergoing a full scale overhaul as a result of a number of short comings in the existing system which will be implemented as Uniclass 2 The scope of work for Uniclass 2 and issues with Uniclass 1 are documented on the CPIC website http://www.cpic.org.uk/en/uniclass/ Scope – some Tables cover architecture (buildings and landscape) and civil and process engineering, but others only deal with one or two of these sectors – Table F only covers architectural spaces for example, and Table K only covers work sections for civil engineering (though some of these overlap with those in Table J). Coding – most Tables use numeric coding below Level 1, but two use alpha-numeric coding (Tables J and K). Most respect the ‘limit of ten’, but some use double figures at some levels on an ad hoc basis (e.g. Tables F and L). Depth – depth of the Tables is not consistent – some Tables comprise seven levels (Tables D, L and M), one (Table K) has just two, for example. Object placement – Tables J and K place the objects they are classifying at the same (lowest) level throughout, but the other Tables may place objects at any of two to five levels. That is, in some Tables a given level may be used both for groups of objects and for individual objects. Granularity – in some Tables the lowest level objects differ markedly in ‘scale’, in others they are more consistent. For example, in Table D oil refineries (D165 3) and signal boxes (D116 1) are classed as ‘facilities’ with no further subdivision. Alignment – the tables do not align completely because they were independently developed. Component products do not clearly map to their elements. http://www.cpic.org.uk/en/uniclass/ Take a look at this lovely visualization to get an understanding of how the new and improved Uniclass 2 will work. http://www.bimgateway.co.uk/uclass2/indent/ Omniclass (US) The most recent construction information classification system to be implemented in North America is Omniclass. A group of volunteers from organisations and firms representing a broad cross - section of the construction industry recognised a need for classifying construction subjects, the increased use of electronic information technology, and the expanding focus on the complete life cycle of construction. The majority of the 15 Omniclass Tables were published in 2006. Omniclass freely adapted and used Uniclass in its development, and therefore shares many of the Uniclass legacy documents – for example, both use EPIC as the basis of their construction product Tables. The most significant points of departure include: 5 Insert Class Title as per Title Page • The adoption of Masterformat as the basis of Omniclass Table 22 Work results. In the same way CAWS is used in the UK, Masterformat is the pre-eminent means of organising commercial and institutional construction specifications, such as Masterspec, in North America. It is published in by the Construction Specifications Institute (CSI) and Construction Specifications Canada (CSC). The most recent edition was published in 2004. • The adoption of Uniformat as the basis of Omniclass Table 21 Elements (including designed elements). Uniformat provides a standard method of arranging construction information, organised around the physical parts of a facility called systems and assemblies. These systems are characterised by their function without identifying the technical or design solutions that may comprise them. It is used for formatting documents on project scope, quality, cost and time, such as cost estimates or reports Omniclass notation consists of numerical codes, generally of six digits. These can be extended by adding more digits after a decimal point. The notation is hierarchical. (Natspec) (Natspec: Information classification systems and the Australian construction industry2008) Consistent language The illustration below shows the common language classification that we should have used for our Fan coil unit. Figure 3 Consistent Fan Coil Unit 6 Insert Class Title as per Title Page COBie The Construction-Operations Building information exchange (COBie) format is the international standard for the exchange of information about managed facility assets. COBie does not add new requirements to contracts; it simply changes the format of existing deliverables from paper documents and proprietary formats, to an open, international standard format. (The COBie Guide: a commentary to the NBIMS-US COBie standard by Dr. Bill East and Mariangelica Carrasquillo-Mangual) The COBie Process The process of creating COBie deliverables follows the same processes used in today’s design and construction. COBie simply transforms the information provided in paper documents into information that can be re-used through the project. The figure below summarizes the COBie process. Figure 4 COBie process During early design, Architects develop the spaces and groups of spaces needed to support the activities required by the owner program brief. This information is delivered through the Schematic Design drawings. COBie delivers the subset of the Schematic Design information related to spaces, zoning, and “room data sheets.” Schematic Design stage COBie information is used to verify that the facility being designed meets the owner’s program brief. Since COBie is an extract from the Schematic Design deliverables, the information in COBie data files must match. the information about spaces and architectural products and schedules found on Schematic Design submittal. 7 Insert Class Title as per Title Page As the design nears completion, Engineers design the systems that deliver the required services, such as electricity, water, appropriate temperature, fire protection, security, etc… to allow the activities to take place. This information is delivered at the Construction Documents design stage. In addition to the updated architectural information, COBie delivers the subset of the Construction Documents information related to the product and equipment assets that will ultimately be managed by the owner. This asset information is found in the design drawing’s equipment and product schedules. Since COBie is an extract from the Construction Documents Design deliverables, the information in COBie should be a perfect match for the printed on the drawings from that deliverable. During construction, the generic asset information found in the Construction Documents stage is filled-in to provide the COBie construction deliverables. A COBie submittal prior to Beneficial Occupancy allows the facility manager to begin efficiently operating their facility upon occupancy. A COBie As-Built submittal is also provided to reflect all final changes and as-built conditions. During construction this information is linked from other sources such as documents containing approved submittals, warranty certificates, etc… As a result construction information may be gleaned directly from electronic submittal records. Other information, documenting the specific installation and testing of equipment, includes some specific information such as serial number and installation dates for every major building asset. The resulting data set is no more, or no less, than a set of Operations and Maintenance Manuals that can actually be used by operations, maintenance, and asset management personnel. Following the delivery of facility asset, maintenance and operations information the owner will load this information directly into their COBie compatible maintenance management system and immediately begin the efficient operation of that facility. Updates to COBie data resulting from work orders should be documented directly in next-generation maintenance management systems. Results of renovations simply update that subset of existing COBie data with the changes coming from the renovation project. (The COBie Guide: a commentary to the NBIMS-US COBie standard by Dr. Bill East and Mariangelica Carrasquillo-Mangual) 8 Insert Class Title as per Title Page COBie deliverables (Drops) COBie deliverables as they are referred to in the US implementation of COBie increase in content over time to reflect the increasing maturation of the design or completion of the construction project. Drop 1 (Concept design /Requirements) Very basic information for example just the functionality of a space. So each space classified by functional type, required performances for finishes, just basic stuff really. Drop 2 (tendering) List of furniture and assets for each space/room. You should be able to generate a schedule at this stage for very approximate costings. Schedule of AHUs which would give us the numbers of AHU’s which would help us derive an approximate cost for operating those pieces of kit even though we don’t have the detail at this stage. Drop 3 (Construction) 70% - 80% complete This will have more info than the previous drop, this would now have more attributive information for each asset class as information and building finishes as well as more detailed information Drop 4 Full O&M This is the golden drop which should have full manufacturer / model information along with detailed operational and functional information. Links to O&M manuals. Warranties, everything complete. 9 Insert Class Title as per Title Page Figure 5 COBie drops/deliverables COBie data structure COBie when materialized as a spreadsheet consists of one worksheet for each informational type as per figure 6. I know spreadsheets are not the best way of transmitting data between systems however you must agree that the coloured coding on individual sheets does get peoples buy in from a human understanding level which you could never do with a boring UML diagram. So don’t think spreadsheet when you think COBie just think of what a great database schema and structure it provides for carrying this information. 10 Insert Class Title as per Title Page Figure 6 COBie spreadsheet COBie to asset management The key to BIM is not the graphical model, but the database of information that sits behind it. This enables different organisations working on the same project but using different software to store and retrieve information in a consistent, shareable format. Good database design needs to look at the output first and reverse engineer in order to provide all the required fields for FM and asset management. Understand what you need in your FM asset management world and specify it in your protocols, BIM execution plans, contracts, QA/QC procedures. This video is somewhat close to the Nirvana we are trying to achieve. http://labs.autodesk.com/utilities/revit_maximo The video (produced by Autodesk Labs as a Maximo Integration for Autodesk Revit) details the process of exporting data from a Revit model to Maximo. Richly attributed data about building assets, that are developed in Revit during the building design and construction phases, can be published directly into Maximo during commissioning or at building "handover," thus supporting more immediate and efficient use of Maximo once the building is occupied. The Revit asset data can be exported in the COBie data specification, if desired. In addition, the BIM/3D asset data can be viewed inside Maximo, in context with Maximo applications and processes. 11 Insert Class Title as per Title Page The benefits include smoother building handover with the automated data transfer and linking into Maximo. In addition, by having more accurate asset and location data within the Maximo database and providing access to the visual BIM model while processing work orders within Maximo, the amount of time planning and executing work may be reduced and real cost This integration only works if the Building information transitioning into asset management is consistent every time. Common language classification and naming is the essential building block for this to happen. BIM faces the same cultural, organisational and technological hurdles to those that often hamper the introduction of collaborative approaches. Owners, designers, contractors and supply chains need to be committed to the idea from the outset, and they need the appropriate knowledge, processes, tools and infrastructure to help them collaborate electronically. To be enable to realise the full benefits of BIM, a ‘Common Language’ is needed for all to understand and to follow in order that the information in the database can be stored, retrieved and used successfully. The value of common language Consistency Interoperability (Between systems) Because the input data is in a consistent format and the output format is also consistent it we can automate BIM into other business systems. The data model is consistent and how we refer to an object in one system is the same way we refer to it in another. The Space/Room in my BIM model has the same classification, naming and numbering as I use in my lease management system. So when a new retail space is at as-built on a specific floor with a specific classified usage type, when the data is translated it slots straights into my lease management system without any data munging/fixing because the common language naming convention has been established between both systems. Performance information feedback With this linkage between the information model of the building with its operational model within the asset management system we can then start to provide feedback to the building modelers/designer as to performance. For example as an MEP designers I need to place a number of “Direct Expansion Air Handling units that are split cooling that we are potentially operating and maintaining for 30 years once built. The Omniclass code for that rather excitingly 12 Insert Class Title as per Title Page is 23-33 17 13 11 Air source split system heat pumps. Wouldn’t it be great if I could easily mine my asset management system to give me performance information on the heat pumps we currently have in commision at all our other facilities. This is not a pipe dream, because as long as our systems (Our building models and our asset management system have the same consistent numbering naming then it’s just a case of data linkage to provide that report) Long lead Identifying long lead items especially for the untrained eye is critical. The definition of a "Long Lead" item is any piece of kit that is required to be engaged in the project with a procurement time that is likely to affect the completion date. Getting visibility on these long lead items as early in the project as possible is important. We don’t know the manufacturer of our Chiller or even what type but if we have a basic classification at the early stage (COBie drop 1 or 2) we some visibility of cost. If we can’t consistently identify or more importantly our systems can’t identify what that thing is with a consistent naming convention then we are shooting in the dark. Planned maintenance regimes can be costed earlier in the lifecycle if we know what these objects are consistently. Consistently identify assets With classification even if you have no clue what the object is by looking at the Omniclass/Uniclass code will give you that consistent definition and naming of that building object. More importantly a system process can now link the consistent name of that component with its consistent name in the asset management system and for that matter any other system. Further with older more experienced employees retiring and outsourced work force it’s important for a human to be able to easily identify an object without ambiguity. Data “Munging” Munging is my term for “converting”. Munging is what we do when we take some data from an outside source and try to make it fit our data schema; normally this takes the form of converting from one format to another. But in our case its more than that because we have to maybe infer some of the information values are infer what some of the objects are. The quality of this data at the end could be suspect as we have had to make assumptions. Munging data like this for every project is also a cost that really multiplies up over multiple projects. So demand a common language from the supply chain (Using a standard such as OmniClass UniClass or Natspec) and demand a common schema from the supply chain which is COBie. 13