150715194701finalabsforchemsuse2015

advertisement

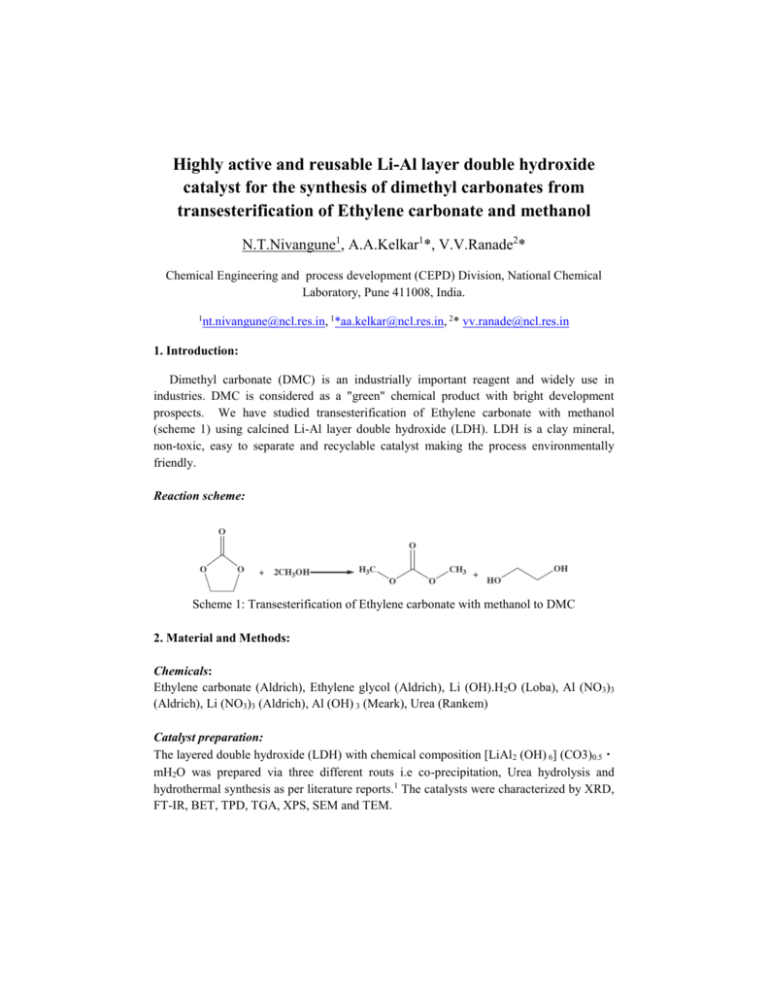

Highly active and reusable Li-Al layer double hydroxide catalyst for the synthesis of dimethyl carbonates from transesterification of Ethylene carbonate and methanol N.T.Nivangune1, A.A.Kelkar1*, V.V.Ranade2* Chemical Engineering and process development (CEPD) Division, National Chemical Laboratory, Pune 411008, India. 1 nt.nivangune@ncl.res.in, 1*aa.kelkar@ncl.res.in, 2* vv.ranade@ncl.res.in 1. Introduction: Dimethyl carbonate (DMC) is an industrially important reagent and widely use in industries. DMC is considered as a "green" chemical product with bright development prospects. We have studied transesterification of Ethylene carbonate with methanol (scheme 1) using calcined Li-Al layer double hydroxide (LDH). LDH is a clay mineral, non-toxic, easy to separate and recyclable catalyst making the process environmentally friendly. Reaction scheme: Scheme 1: Transesterification of Ethylene carbonate with methanol to DMC 2. Material and Methods: Chemicals: Ethylene carbonate (Aldrich), Ethylene glycol (Aldrich), Li (OH).H2O (Loba), Al (NO3)3 (Aldrich), Li (NO3)3 (Aldrich), Al (OH) 3 (Meark), Urea (Rankem) Catalyst preparation: The layered double hydroxide (LDH) with chemical composition [LiAl 2 (OH) 6] (CO3)0.5・ mH2O was prepared via three different routs i.e co-precipitation, Urea hydrolysis and hydrothermal synthesis as per literature reports.1 The catalysts were characterized by XRD, FT-IR, BET, TPD, TGA, XPS, SEM and TEM. Reaction procedure: In a typical experiment, 10 mmol of EC, 100 mmol of methanol and 2.5wt % of catalyst were added into a 50 ml round bottom flask. The resulting mixture was stirred at 70 oC for 1 h at atmospheric pressure. After completion of the reaction the used catalyst was separated by centrifugation, washed with methanol and activate at 450◦C/2h. This recovered catalyst was reused in the next run under the same reaction conditions. The reaction products were quantitatively analyzed by Agilent 6850 GC (FTD detector, HP-Innowax column). 3. Significant Results and Discussion: Li-Al (LDH) was synthesized by co-precipitation method and characterized in detail. XRD analysis (Fig.1) indicates the formation of highly crystalline material with a layered structure. The morphology of catalyst was investigated by TEM (Fig.2) analysis and thin flat (hexagonal) crystals with layered structures are observed. 003 800 Li-Al (HT) 400 110 113 006 Relative intensity 600 015 012 200 0 10 20 30 40 50 60 70 80 2 Theta Figure 1: XRD patterns of LiAl (HT) Figure 2: SEM image of LiAl (HT) The catalyst was found to be highly active and selective for the synthesis of DMC. Effect of reaction time (Fig. 3) and molar ratio of reactants (EC: MeOH) (Fig. 4) were investigated and activity was found to be strongly dependent on the EC:MeOH molar ratio. Conversion\Selectivity (%) Effect of reaction time: 105 95 conv(%) 85 Selectivity(%) 75 65 0.5 1 2 3 5 Reaction time(h) Figure 3: Effect of reaction time on conversion and selectivity Reaction conditions: EC: 10 mmol, Methanol: 100 mmol, Catalyst: 2.5 wt % relative to EC, Temperature: 70˚C. Effect of Molar ratioEC:MeOH: Conversion(%) 100 80 60 1:05 40 1:10 1:15 20 0.5 1 2 3 Reaction time(h) Figure 4: Effect of molar ratio on conversion and selectivity Reaction conditions: EC: 10 mmol, Methanol: 50,100,150 mmol, Catalyst: 2.5 wt % relative to EC, Temperature: 70˚C. ICP analysis indicated that there is no leaching of Li or Al from the catalyst. It shows high activity during recycle experiment indicating good stability of the catalyst. 4. Conclusions: Li-Al (LDH) calcined catalyst exhibited highe activity (Ec conversion 84% and DMC selectivity 100%) in short reaction time (~1h) under mild reaction conditions (reflux temperature of methanol) as compare to other reported catalysts.2, 3 Catalyst was found to be stable during recycle study. References: 1. 2. 3. Vishnu Kamath Inorg. Chem.,50, 2011,5619–5627 1. D. Srinivas , Journal of Molecular Catalysis A: Chemical, 398 ,2015, 42–49. J. Xu et al., Applied Catalysis A: General, 484 ,2014, 1–7