A. Standard Terms and Conditions - Ohio Environmental Protection

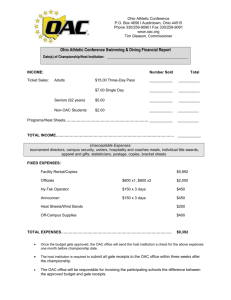

advertisement