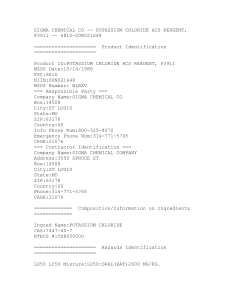

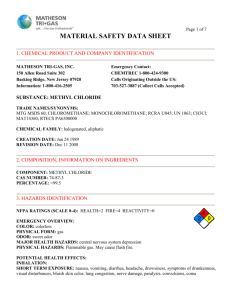

2. Components and Hazard Classification

advertisement

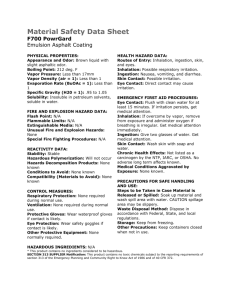

MATERIAL SAFETY DATA SHEET 1. Production & Company Identification Manufacturer: PT Sinar Cemerlang Alamindo Address: Jalan Parengan KM12, Kecamatan Jetis, Mojokerto, Indonesia Telephone: (0321) 363233 FAX: (0321) 363233 Product Name: Wood Polyvinyl Chloride Composite Chemical Name: Mixture CAS-Number: Mixture 2. Components and Hazard Classification Weight % CAS Number PVC Resin 50-95% 9002-86-2 Polyvinyl Chloride Polymer Wood Fiber 30-60% N/A Teak Wood Filler 0-30% 1317-65-3 Calcium Carbonate Heat Stabilizer 0-3% Mixture Organic Compounds 1072-35-1 Lead Stearate Mixture Acrylic Polymers Lubricants Process Aids 0-5% 0-3% 3. Hazards Identification Emergency Overview These materials have not been evaluated as a whole for health effects. Information provided on health effects of these products are based on individual components. See sections 3 and f11 for additional details. This product may contain residual vinyl chloride monomer (VCM, CAS number 75-01-4) below 1ppm (0.0001%). OSHA considers VCM a suspect carcinogen and regulates it under 29 CFR 1910.1017. It is unlikely, under normal working conditions with adequate ventilation, that the OSHA action level and the OSHA exposure limits will be exceeded for residual VCM. However, the user should take the necessary precautions (e.g. mechanical ventilation, local exhaust ventilation, air- monitoring, respiratory protection, etc.) to ensure airborne levels of any vapors including VCM or dusts that may be released during heating or processing are below regulated levels. Potential Health Effects - - Routes of exposure o Inhalation, Ingestion, Skin Contact Acute exposure o Inhalation Resin particles, like other materials, can be mechanically irritating to respiratory system. o Ingestion Maybe harmful if swallowed o Eyes Resin particles, like other inert materials, are mechanically irritating to eyes o Skin Exposure has shown no unusual dermatitis hazard from routine handling. Medical conditions Aggravated by exposure o None known 4. First Aid Measures - - - - Inhalation o Move to fresh air in case of accidental inhalation of fumes from overheating or combustion. When symptoms persist or in all cases of doubt see medical advice. Ingestion o Do not induce vomiting without medical advice. Whey symptoms persist or in all cases of doubt seek medical advice. Eyes o Rinse immediately with plenty of water, also under the eyelids, for at least 15 minutes. If eye irritation persists, seek medical attention. Skin o Wash off with soap and plenty of water. If skin irritation persists, seek medical attention. 5. Fire Fighting Measures - - Flash Point o 684 degree F Method Used o ASTM 1929 Ignition Temperature o 761 degree F Extinguish Media o Water spray or CO2 Special Fire Fighting Procedures o In the event of a fire, wear NIOSH approved, positive pressure, self-contained breathing apparatus (SCBA) and full protective clothing. Evacuate all personnel from danger area. Use dry chemical, foam, water or carbon dioxide to extinguish fire. Unusual Fire and Explosion Hazards o This product is nonflammable and non-explosive under normal conditions of use. It will not continue to burn after ignition without an external fire source. When forced to burn, the major gaseous products of the combustion of PVC are carbon monoxide, carbon dioxide, and hydrogen chloride. 6. Accidental Release Measures - - - Personal precautions o Wear appropriate personal protection during clean up, such as impervious gloves, boots, and coveralls. Environmental precautions o Should not be released into the environment. The product should not be allowed to enter drains, watercourses, or the soil. Methods for cleaning up o Clean up promptly by sweeping or vacuum. Package all material in plastic, cardboard, or metal containers for disposal. Refer to Section 13 of this MSDS for proper disposal methods. 7. Handling and Storage - Handling o Use with adequate ventilation. Avoid inhalation, and contact with eyes or skins Storage o Store in a well-ventilated dry place 8. Stability and Reactivity - - - Stability o Stable at room temperatures less than 212°F Hazardous polymerization o Will not occur Conditions to avoid o Keep away from oxidizing agents and open flame. Do not overheat to avoid thermal decomposition (usually above 392°F for more than 10 minutes) Incompatible materials o Strong acids and oxidizing agents. Avoid mixing or contacting acetyl polymers and acetyl copolymers during processing. Hazardous decomposition products o Carbon dioxide (CO2), Carbon Monoxide (CO), oxides of nitrogen (NOX) o Other hazardous materials, and smoke are all possible. Prolonged heating (>30 minutes or more) above 392°F(200°C) or short term heating at 482°F(250°C) may result in product decomposition and evolution of carbon monoxide and hydrogen chloride.