section 1 * chemical product and company identification

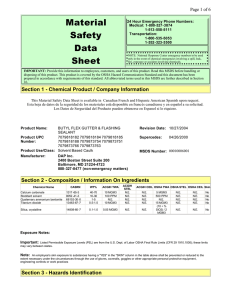

advertisement

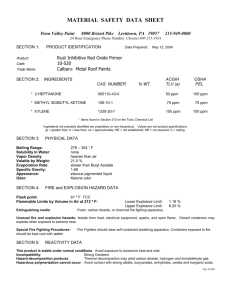

Vanberg Specialized Coatings Material Safety Data Sheet SECTION 1 – CHEMICAL PRODUCT AND COMPANY IDENTIFICATION PRODUCT NAME: IDENTIFICATION NUMBER: SUPPLIER/MANUFACTURER: EPO-KOTE RESIN PART A ES046-125, ES046-5, ES045-125, ES045-5 VANBERG SPECIALIZED COATINGS 10705 COTTONWOOD ST LENEXA, KS 66215-2032 CHEMTREC: PREPARER: PHONE: PREPARE DATE: 800-424-9300; 24 HOURS VSC 913-599-5939 AUGUST, 23 2006 SECTION 2 – COMPOSITION/INFORMATION OF INGREDIENTS HAZARDOUS COMPONENTS None CAS NUMBER N/A OSHA PEL NE AGCIH TLV NE OSHA STEL NE WT/WT % 100 NE – Not Established SECTION 3 – HAZARDS IDENTIFICATION Effects of overexposure—eyes May cause irritation. Effects of overexposure—skin Can be absorbed through the skin. Effects of overexposure—inhalation Harmful if inhaled. May affedt the brain, nervous system or respiratory system causing dizziness, headache, nausea or respiratory irritation. Effects of overexposure—ingestion No hazard in normal industrial use. Effects of overexposure—chronic and acute hazards Reports have associated repeated and prolonged occupational overexposure to solvents with permanent brain and nervous system damage. Intentional misuse by deliberately concentrating and inhaling the contents may be harmful or fatal. Contains ingredients which may cause liver damage, kidney damage, mucous membrane irritation. Primary Routes of Entry Skin contact; inhalation; ingestion, eye contact SECTION 4 – FIRST AID MEASURES Eye Contact Flush eyes immediately with plenty of water for at least 15 minutes and get medical attention. Skin Contact Wash thoroughly with soap and water. Inhalation If affected by inhalation of vapor or spray mist, remove to fresh air. Ingestion If swallowed, seek immediate medical attention. Epo-Kote Resin Part A Page 1 of 3 SECTION 5 – FIRE FIGHTING MEASURES Flash Point >250º F Method used Setaflash Flammable Limits In Air By Volume Lower: 25.00 Upper: 16.00 Extinguishing Media CO2, dry chemical, foam and/or water fog Unusual Fire and Explosion Hazards None Special Fire fighting Procedures Fire fighters must wear self contained breathing apparatus or air masks. Containers exposed to fire should be kept cool with water spray. Do not spray fire directly. A solid stream of water directed into the hot burning liquid could cause frothing. SECTION 6 – ACCIDENTAL RELEASE MEASURES Steps to be Taken in Case Material is Released or Spilled Ventilate area. Avoid breathing of vapors. Use self-contained breathing apparatus or air mask for large spills in a confined area. Eliminate ignition sources. Remove with inert absorbent and non-sparking tools. Avoid contact with eyes. SECTION 7 – HANDLING AND STORAGE Precautions to be Taken in Handling and Storing Containers should be grounded/bonded when pouring. Avoid free fall of liquid in excess of a few inches. Keep away from heat, sparks and open flames. Keep containers closed when not in use. Do not store above 120ºF. Based on the product flash point and vapor pressure, suitable storage should be provided in accordance with OSHA regulations 1910.106. Empty containers may contain product residue, including flammable or explosive vapors. Do not cut, puncture, or weld on or near container. All label warnings must be observed until the container has been professionally cleaned or reconditioned. SECTION 8 – EXPOSURE CONTROLS/PERSONAL PROTECTION Engineering Controls Good general ventilation should be sufficient to control airborne levels. Respiratory Protection Wear appropriate, properly fitted respirator (NIOSH/MSHA approved) during and after application unless air monitoring vapor/mist levels are below applicable limits. Follow respirator manufacturer’s directions for respirator use. Skin Protection Where contact is likely, wear chemical resistant gloves, rubber boots, and chemical safety goggles. Eye Protection Wear chemical safety glasses with side shields or goggles. Other Protective Equipment Nitrile rubber gloves Hygienic Practices Wash hands before eating. Remove contaminated clothing and wash before reuse. Follow all MSDS/label precautions even after container is emptied because they may retain product residues. Avoid prolonged or repeated contact with skin. Avoid contact with eyes, skin, and clothing. SECTION 9 – PHYSICAL AND CHEMICAL PROPERTIES Boiling Range >212º F Vapor Density Approx. .569 (Air = 1) Vapor Pressure 29.33 mm Hg @ 68º F Epo-Kote Resin Part A Page 2 of 3 VOC 0.00 Solubility in Water Very slight Appearance & Odor Milky clear liquid with a mild, ammonia odor Specific Gravity (H20=1) 1.05 Evaporation Rate .38 (Butyl acetate=1) SECTION 10 – STABILITY AND REACTIVITY Conditions to Avoid None Incompatibility None Hazardous Decomposition Products By fire: CO2, CO, and other aliphatic fragments Hazardous Polymerization None Stability Stable SECTION 11 – HMIS RATINGS Health Flammability Reactivity 1 0 0 SECTION 12 – ECOLOGICAL INFORMATION Exotoxicity NE Environmental Fate NE SECTION 13 – DISPOSAL CONSIDERATIONS Comply with all Federal, State and Local Regulations. SECTION 14 – TRANPORTATION INFORMATION DOT Proper Shipping Name: DOT Technical Name: DOT Hazard Class: DOT UN/NA Number Packing Group: RQ (Reportable Quantity): POLYESTER RESIN DISPERSION RESIN COMPOUND, NOT REGULATED. Not regulated by DOT, IMO, or ICAO N/A N/A N/A SECTION 15 – REGULATORY INFORMATION This product contains no hazardous ingredients as defined under the criteria of the Federal OSHA Hazard Communication Standard 29 CFR 1910.1200 SECTION 16 – OTHER INFORMATION The information accumulated herein is believed to be accurate but is not warranted to be whether originating with the company or not. Recipients are advised to confirm in advance of need that the information is current, applicable, and suitable to their circumstances. Epo-Kote Resin Part A Page 3 of 3