Combined Pre-Treatment Unit type CC/Q

advertisement

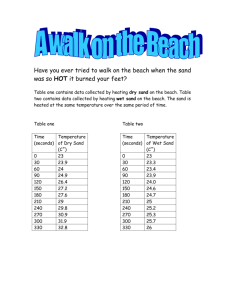

Combined Pre-Treatment Unit type CC/Q 1. Technological Purpose Combined Pre-Treatment Unit type CC/Q consists of a screw screen, a decanting tank, a sand extracting screw and a grease scraper. Sewage from civil or industrial waste water treatment plants has to be pre-treated before being transferred to any purification system. The CC/Q carries out different processes: dewatering and compacting of screened solid waste in the screen compactor, separation of sand by the sand classifier and removal of floating, greasy matter by air / mechanical removal system. During the process solids, sand/grit and greasy matter present in the sewage are removed in order to avoid overloading of the downstream treatment system. Waste water enters the unit and is processed by means of separation by screw screen. The separated debris are de-watered and compacted by the screen compactor. Subsequently, a sedimentation process and the extraction of the sand or grit takes place. In the CC/Q 20model and above, an additional degreasing device works to remove fats and suspended solids using an aeration system and a special mechanical scraper. 1 - Inlet Camera; 2 - Fine screw screen; 3 - Tank; 4 - Horizontal screw conveyor ; 5 - Sand extraction screw conveyor; 6 - Motor Gear of Fine Screen (MG 2); 7 - Motor Gear of Sand extraction screw conveyor (MG 3); 8 - Motor Gear of Horizontal screw conveyor (MG 1); 9 - Motor Gear of Grease / oil removal (MG4) 2. Design Parameters Design Parameters Model CC/Q 10 CC/Q 30 CC/Q 60 CC/Q 100 CC/Q 150 Q L/s A mm B mm C mm D mm E mm F mm G mm H mm I mm J mm K 10 ≈ 4200 * ≈ 2300 ≈ 3100 ≈ 3000 ≈ 1200 ≈ 1700 DN 200 DN 200 ≈ 1085 ≈ 885 ≈ 1500 30 ≈ 4800 * ≈ 2300 ≈ 3100 ≈ 3600 ≈ 1200 ≈ 1700 DN 200 DN 200 ≈ 1500 ≈ 1300 ≈ 1500 60 ≈ 5200 * ≈ 2300 ≈ 3100 ≈ 4000 ≈ 1850 ≈ 1700 DN 250 DN 250 ≈ 1500 ≈ 1300 ≈ 1500 100 ≈ 5700 * ≈ 2300 ≈ 3100 ≈ 4500 ≈ 1850 ≈ 1700 DN 350 DN 350 ≈ 1900 ≈ 1700 ≈ 1700 150 ≈ 6200 * ≈ 2300 ≈ 3100 ≈ 5000 ≈ 2200 ≈ 1700 DN 500 DN 500 ≈ 2050 ≈ 1885 ≈ 1700 Q - Capacity; A - Max. Length; B - Max. Width; C - Max. Height; D - Length; E - Width; F - Height; G - Inlet Dimension; H - Outlet Dimenson; I - Height Inlet; J - Height Outlet; K - Height Discharge. * - all units have corps modular construction. It can by elongated by modules for better settlement of the sand acc. customer requirements. mm 3. Functional Parameters Model CC/Q10 Flow rate – 10 L/s ; Inlet screen mesh – 0.5 ~ 5 mm ; Sand separation – 70% particle size ≥ 200 μm ; Grease removal – No ; Solids volume reduction – Up to 10% ; Modular design – Yes. Model CC/Q30 Flow rate – 30 L/s ; Inlet screen mesh – 0.5 ~ 6 mm ; Sand separation – 80% particle size ≥ 200 μm ; Grease removal – No ; Solids volume reduction – Up to 20%; Modular design – Yes. Model CC/Q60 Flow rate – 60 L/s ; Inlet screen mesh – 0.5 ~ 10 mm ; Sand separation – 90% particle size ≥ 200 μm ; Grease removal – Yes ; Solids volume reduction – Up to 30% ; Modular design – Yes. Model CC/Q100 Flow rate – 100 L/s ; Inlet screen mesh – 0.5 ~ 10 mm ; Sand separation – 90% particle size ≥ 150 μm ; Grease removal – Yes ; Solids volume reduction – Up to 35% ; Modular design – Yes. Model CC/Q150 Flow rate – 150 L/s ; Inlet screen mesh – 0.5 ~ 10 mm ; Sand separation – 90% particle size ≥ 150 μm ; Grease removal – Yes ; Solids volume reduction – Up to 35% ; Modular design – Yes. 4. Construction External structure: Stainless steel AISI304L Tanks: Stainless steel AISI304L Shaft less spirals: High carbon steel painted RAL Bolts: A2 Anti-wear material: Bolted plates in stainless steel AISI304L Inlet / outlet flage: AISI 304 L Screw screen: Loading basket diameter: 300 - 700 mm Screw diameter for transport / compaction: Ø150 - 250 mm Filtration type: Rounded holes Dimension: Ø0.5 - 10 mm Inclination: 35° Squared outlet spout for screening discharge Basket cleaning through nylon bolted brushes Motor brand Simotop, 400V – 50Hz – 3 phases, 4 poles, IP55, F class Gear reducer: brand MOTOVARIO, parallel shafts Horizontal screw conveyor and sand transport mod. SCH-T……. Shaft less screw diameter: Ø150 – 280 mm High carbon steel single profile, pitch 1/1, th. 20 mm. With mechanical water tight group. Motor brand: Simotop, 400V – 50Hz – 3 phases, 4 poles, IP55, F class Gear reducer: brand MOTOVARIO, parallel shafts Sand extraction screw conveyor mod. SCH-T……. Shaft less screw diameter: Ø150 – 280 mm High carbon steel single profile, pitch 1/1, th. 20 mm. With mechanical water tight group. Motor brand: Simotop, 0,25 kW, 400V – 50Hz – 3 phases, 4 poles, IP55, F class Gear reducer: brand MOTOVARIO, parallel shafts Grease / oil removal “go & back carriage” Motor: brand Simotop, 0,25 kW, 400V – 50Hz – 3 phases, 4 poles, IP55, F class Blower Flow rate: 57 Nm3/h Pressure: 60 kPa Motor: 2.2 kW 400/50/3, IP55, F class Side installation: With stainless steel hoses Retention valve Suction filter Pressure valve The machine not included: Control panel & wiring connection Electrical air blower Hydraulic connections Potential scaffolding