Perchloric Acid SOP

advertisement

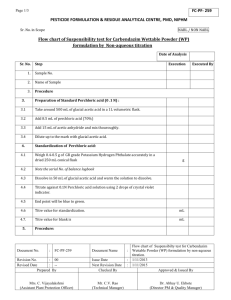

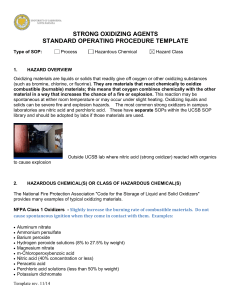

Standard Operating Procedures Laboratory Specific Chemical: Strong Oxidizing Agent - Perchloric acid Please fill out the form completely. Print a copy and insert into your Laboratory Safety Manual and Chemical Hygiene Plan. Refer to instructions for assistance. _____________________________________________________________________________ Department:_Chemistry______________ Date when SOP was written:_11/11/12 Date when SOP was approved by the lab supervisor: __1/13/2013_________________ Principal Investigator:__Richmond Sarpong_______________________________________ Internal Laboratory Safety Coordinator/Lab Manager:__Rebecca Murphy________________ Laboratory Phone:____510-643-2485___ Office Phone:__510-643-6312_________ Emergency Contact:___Richmond Sarpong 626-644-2407_____________________ (Name and Phone Number) Location(s) covered by this SOP:____Latimer 834, 836, 837, 838, 839, 842, 844, 847, 849, 907 (Building/Room Number) _____________________________________________________________________________ Type of SOP: Process Hazardous Chemical Hazardous Class Purpose Perchloric acid is the inorganic compound with the formula HClO4. Usually encountered as an aqueous solution, this colorless compound is a strong acid comparable in strength to sulfuric acid and nitric acid. It is a powerful oxidizer, but its aqueous solutions up to 70% are remarkably inert, only showing strong acid properties and no other oxidizing properties. Above concentrations of approx. 70% the speed of oxidizing reactions rapidly increases with increasing acid concentration. The oxidizing power also greatly increases as the temperature is increased It is useful for preparing perchlorate salts, especially ammonium perchlorate, an important rocket fuel. Perchloric acid is also dangerously corrosive and readily forms explosive mixtures. Perchloric acid is mainly produced as a precursor to ammonium perchlorate, which is used as rocket fuel. The growth in rocketry has led to increased production of perchloric acid. Several million kilograms are produced annually. It is one of the strongest Brønsted-Lowry acids. Despite hazards associated with the explosiveness of its salts, the acid is often preferred in certain syntheses. SOP – Perchloric Acid 1/10/2013 1 Physical & Chemical Properties/Definition of Chemical Group CAS#: 7601-90-3 Class: Produces explosive salts, crystals and perchlorate residues Molecular formula: HClO4 Boiling Point: 203 oC/ 397.4 oF @ 760 mm Hg Melting Point: -18 oC/ -.04 oF Decomposition Temperature: Not available Potential Hazards/Toxicity EMERGENCY OVERVIEW: Appearance: clear, colorless liquid. Causes digestive and respiratory tract burns. Causes eye and skin burns. Strong oxidizer. Contact with other material may cause a fire. Heating may cause an explosion. Contact with other material may cause explosion. Corrosive to metal. Highly important danger information! In addition to being a corrosive liquid, while not combustible, under some circumstances perchloric acid may act as an oxidizer and/or present an explosion hazard. Perchloric crystals, or perchloric acid in crystalline form, is an extremely dangerous inorganic compound. The crystals are sometimes formed due to condensation inside of ventilation hoods in chemical labs or in bottles stored for extended periods in the lab. Among the principle hazards are that the perchlorite crystals are subject to exploding on impact. Perchlorate salts are shock sensitive. Organic materials are especially susceptible to spontaneous combustion if mixed or contacted with perchloric acid. Under some circumstances, perchloric acid vapors form perchlorates in duct work, which are shock sensitive. Target Organs: Eyes, thyroid, skin, mucous membranes. Potential Health Effects: Eye: Causes eye burns. Skin: Causes skin burns. Ingestion: Harmful if swallowed. Causes gastrointestinal tract burns. SOP – Perchloric Acid 1/10/2013 2 Inhalation: Causes severe respiratory tract irritation with possible burns. Chronic: Prolonged or repeated skin contact may cause dermatitis. Personal Protective Equipment (PPE) Eyes: Wear chemical goggles and face shield. Use chemical splash and impact-rated goggles. Use face shield (8-inch minimum) when appropriate (not protected by fume hood sash for example). Use equipment for eye protection tested and approved under appropriate government standards such as NIOSH (US) or EN 166(EU) or ANSI Z87.1. Hand Protection: Handle with gloves. Gloves must be inspected prior to use. Use proper glove removal technique (without touching glove's outer surface) to avoid skin contact with this product. Dispose of contaminated gloves after use in accordance with applicable laws and good laboratory practices. Wash and dry hands. For glove selection, go to: http://ehs.berkeley.edu/hs/63-laboratory-safety/94-glove-selection-andusage.html Skin and Body Protection: Long pants, closed-toed and closed-heeled shoes, cottonbased clothing/attire, and lab coat must be worn for protecting against chemical hazards. Respiratory protection: NOTE: Lab personnel intending to use/wear a respirator mask must be trained and fit-tested by EH&S. This is a regulatory requirement. Respirators should be used only under any of the following circumstances: As a last line of defense (i.e., after engineering and administrative controls have been exhausted). When Permissible Exposure Limit (PEL) has exceeded or when there is a possibility that PEL will be exceeded. Regulations require the use of a respirator. An employer requires the use of a respirator. There is potential for harmful exposure due to an atmospheric contaminant (in the absence of PEL) As PPE in the event of a chemical spill clean-up process Hygiene Measures: Handle in accordance with good industrial hygiene and safety practice. Wash hands before breaks and at the end of workday. Engineering Controls NOTE: Lab-specific information on engineering controls may be included in the Protocol/Procedure section. Facilities storing or utilizing this material should be equipped with an eyewash facility and a safety shower. Any procedure involving heating of perchloric acid must be conducted in a perchloric acid fume hood, with the sash down. No organic materials should be stored in the perchloric acid hood. SOP – Perchloric Acid 1/10/2013 3 First Aid Procedures Notify supervisor and EH&S immediately. Follow up with a call to 510-642-9090 to report the incident. Eyes: In case of contact, immediately flush eyes with plenty of water for at least 15 minutes. Get medical aid immediately. Skin: Destroy contaminated shoes. In case of contact, immediately flush skin with plenty of water for at least 15 minutes while removing contaminated clothing and shoes. Get medical aid immediately. Wash clothing before reuse. Ingestion: If swallowed, do NOT induce vomiting. Call the poison control center at 1-800-2221222. Get medical aid immediately. If victim is fully conscious, give a cupful of water. Never give anything by mouth to an unconscious person. Inhalation: If inhaled, remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Get medical aid. Notes to Physician: Treat symptomatically and supportively. Special Handling and Storage Requirements NOTE: Lab-specific information on handling and storage may be included in the Protocol/Procedure section. Handling: Wash thoroughly after handling. Remove contaminated clothing and wash before reuse. Use spark-proof tools and explosion proof equipment. Avoid contact with clothing and other combustible materials. Do not get on skin or in eyes. Do not ingest or inhale. Use only with adequate ventilation. Do not allow perchloric acid to come into contact with strong dehydrating agents (concentrated sulfuric acid, anhydrous phosphorous pentoxide, etc.). Keep the quantities of perchloric acid handled at the bare minimum for safety. Perchloric acid should be handled in a masonry building with concrete or tile floors. Handling acid on wooden floors is dangerous, especially after the acid has dried. The wooden floor will then become sensitive to ignition by friction. Perchloric acid mist and vapor can condense in ventilation systems to form metallic perchlorates, which can be explosive. Inform laundry personnel of contaminant's hazards. Storage: Do not store near combustible materials. Store in a tightly closed container. Keep container closed when not in use. Store in a cool, dry, well-ventilated area away from incompatible substances (e.g. strong dehydrating agents). Avoid storage on wood floors. Perchloric acid should be stored segregated from all other chemicals & inside secondary containment (such as pyrex baking dish). It must not be stored near organic acids, near bases, or near other organic or flammable material. Shelves and floor material should be non-combustible and acid-resistant. Protect from freezing. Do not store for long periods of time or allow solids to form (water to evaporate). Working alone: Certain extremely hazardous operations should not be performed if the PI or Lab Safety Contact(s) are not present. Never work alone with extremely hazardous materials/operations. See the Protocol/Procedure section below for specific prohibitions (if any) on working alone. SOP – Perchloric Acid 1/10/2013 4 Spill and Accident Procedure Chemical Spill Dial 911 Spill – Assess the extent of danger. Clean up perchloric acid spills immediately, observing precautions in the Protective Equipment section. Remove all sources of ignition. Absorb spill using an absorbent, non-combustible material such as earth, sand, or vermiculite. Do not use combustible materials such as sawdust. Flush spill area with water. Wet area to prevent drying out. Provide ventilation. Keep combustibles (wood, paper, oil, etc.,) away from spilled material. Keep unnecessary and unprotected personnel away. Use only non-sparking tools and equipment. Spill may be carefully neutralized with soda ash (sodium carbonate). Small (<1 L) – If you have training, you may assist in the clean-up effort. Use appropriate personal protective equipment and clean-up material for chemical spilled. Double bag spill waste in clear plastic bags, label and take to the next chemical waste pick-up. Large (>1 L) – Dial 911 and 510-642-9090 for assistance. Chemical Spill on Body or Clothes – Remove clothing and rinse body thoroughly in emergency shower for at least 15 minutes. Seek medical attention. Notify supervisor and EH&S immediately. Follow up with a call to 510-642-9090 to report the incident. Chemical Splash Into Eyes – Immediately rinse eyeball and inner surface of eyelid with water for 15 minutes by forcibly holding the eye open. Seek medical attention. Notify supervisor and EH&S immediately. Follow up with a call to 510-642-9090 to report the incident. Medical Emergency Dial 911 Life Threatening Emergency, After Hours, Weekends And Holidays – Dial 911 or go the nearest Occupational Health Center or emergency room if it is after hours. Note: All serious injuries must be reported to EH&S within 8 hours. Follow up with a call to 510-642-9090 to report the incident. Non-Life Threatening Emergency– Go to the nearest Occupational Health Center or emergency room if it is after hours. Note: All serious injuries must be reported to EH&S within 8 hours. Follow up with a call to 510-642-9090 to report the incident. Needle stick/puncture exposure (as applicable to chemical handling procedure)– Wash the affected area with antiseptic soap and warm water for 15 minutes. For mucous membrane exposure, flush the affected area for 15 minutes using an eyewash station. Page the needle stick nurse and then enter your extension or go the nearest Occupational Health Center or emergency room if it is after hours . Note: All needle stick/puncture exposures must be reported to EH&S within 8 hours. Follow up with a call to 510-642-9090 to report the incident. Decontamination/Waste Disposal Procedure NOTE: Lab-specific information on decontamination/waste disposal may be included in the Protocol/Procedure section. SOP – Perchloric Acid 1/10/2013 5 Waste disposal procedures General hazardous waste disposing guidelines: Labeling Requirements for Hazardous Waste Containers: Perchloric acid waste should be placed in a chemically compatible container with a sealed lid and clearly labeled. Label all containers with the label provided at http://ehs.berkeley.edu/hm/279-new-hazardous-waste-program-hwp.html. See the EH&S Fact Sheet, “Hazardous Waste Management” for general instructions on procedures for disposing of hazardous waste. Hazardous Waste Storage: Waste containers must be in secondary containment at all times to adequately contain the contents of the container/spilled materials. Do not mix with other waste or incompatibles Hazardous waste must always be appropriately labeled with a waste tag at all times. Containers must be closed when not in use. Storage of hazardous waste in fume hoods or under sinks is not recommended. Report damaged containers to EH&S. EH&S can provide assistance to transfer the contents to an appropriate container. Containers should be inspected weekly for signs of leaks, corrosion, or deterioration. Hazardous Waste Disposal: Don't dispose of chemicals down the drain. Don't dispose of chemicals via trashcans. Transport the hazardous waste to your designated pick-up location using a sturdy cart and secondary containment. Dispose of regularly generated chemical waste within 6 months Call EH&S for questions Material Safety Data Sheet (MSDS) Location An SDS can be accessed online at http://ucmsds.com SOP – Perchloric Acid 1/10/2013 6 Protocol/Procedure CAS#: 7601-90-3 Eliminate incompatible materials from potential spill area. Preparation Know the location of the nearest fire extinguisher, eyewash, and safety shower before beginning work. Never work alone. Make sure there is another worker present who is also trained in the perchlorid acid SOP. Lab-specific Information Use spark-proof and explosion proof equipment Do not heat perchloric acid, as any procedure involving heating of perchloric acid must be conducted in a special perchloric acid fume hood. Procedure/ Use Scale Engineering Controls/Equipment PPE (eye, face, gloves, clothing) Procedure Steps and Precautions Preparation of dilute solutions (typically <60%) Up to 10 mL concentrated perchloric acid per dilution All work using Perchloric acid must be performed in a ventilated fume hood with a chemical resistant surface. Eye protection: Wear tight-fitting safety goggles or safety glasses with side shields. Always add acid slowly to the bulk water component. Do not add the water to the acid. Never heat perchloric acid in a standard hood. If heating is necessary, it must be in a hood designed for perchloric acid use. Face protection: Wear a face shield when not protected by a lab hood sash. Gloves: Natural Rubber, Natural Rubber, PVC, SOP – Perchloric Acid 1/10/2013 7 Avoid contact with strong dehydrating agents (sulfuric acid, phosphorous pentoxide etc) Avoid contact with organic materials (wood, cotton, paper) could result in fire or explosion. Nitrile or Viton gloves must be worn while handling perchloric acid. Remove gloves as soon as contaminated. Wash down hood and work area after use Do not touch bottles that have turned brown or contain solids (pose explosion hazard) Clothing: Wear lab coat, Determine volume of solution you need full length pants or before dispensing acid. equivalent; and close-toed closed heeled shoes. Wear acid resistant apron when pouring concentrated perchloric acid. Note: Any deviation from this SOP requires written approval from PI. SOP – Perchloric Acid 1/10/2013 8 Documentation of Training (signature of all users is required) Prior to conducting any work with perchloric acid, designated personnel must provide training to his/her laboratory personnel specific to the hazards involved in working with the substance(s), work area decontamination, and emergency procedures. The Principal Investigator must provide his/her laboratory personnel with a copy of this SOP and a copy of the SDS provided by the manufacturer. I have read and understand the content of this SOP: Name Signature Initials Click here to enter text. Identification Date Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter a date. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. SOP – Perchloric Acid 1/10/2013 9