StiffDriveRes_APL_SuppMat_final

advertisement

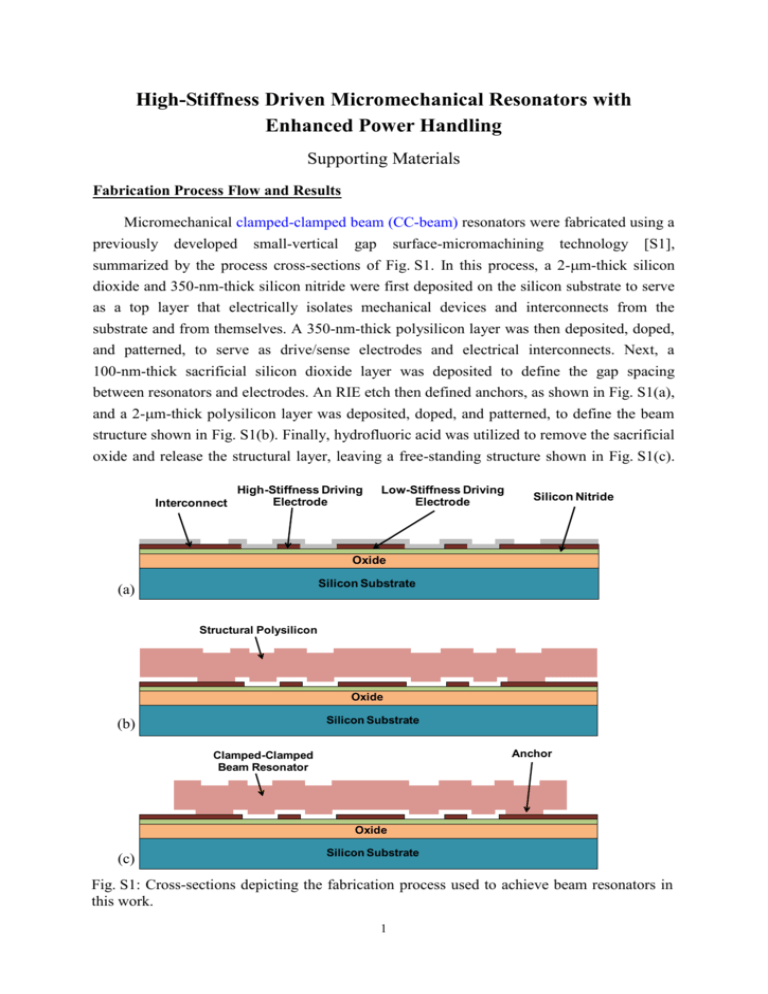

High-Stiffness Driven Micromechanical Resonators with Enhanced Power Handling Supporting Materials Fabrication Process Flow and Results Micromechanical clamped-clamped beam (CC-beam) resonators were fabricated using a previously developed small-vertical gap surface-micromachining technology [S1], summarized by the process cross-sections of Fig. S1. In this process, a 2-m-thick silicon dioxide and 350-nm-thick silicon nitride were first deposited on the silicon substrate to serve as a top layer that electrically isolates mechanical devices and interconnects from the substrate and from themselves. A 350-nm-thick polysilicon layer was then deposited, doped, and patterned, to serve as drive/sense electrodes and electrical interconnects. Next, a 100-nm-thick sacrificial silicon dioxide layer was deposited to define the gap spacing between resonators and electrodes. An RIE etch then defined anchors, as shown in Fig. S1(a), and a 2-m-thick polysilicon layer was deposited, doped, and patterned, to define the beam structure shown in Fig. S1(b). Finally, hydrofluoric acid was utilized to remove the sacrificial oxide and release the structural layer, leaving a free-standing structure shown in Fig. S1(c). Interconnect High-Stiffness Driving Electrode Low-Stiffness Driving Electrode Silicon Nitride Oxide Silicon Substrate (a) Structural Polysilicon Oxide Silicon Substrate (b) Anchor Clamped-Clamped Beam Resonator Oxide (c) Silicon Substrate Fig. S1: Cross-sections depicting the fabrication process used to achieve beam resonators in this work. 1 Driving Electrode Clamped-Clamped Beam Resonator Clamped-Clamped Beam Resonator 50μm 40μm 2μm DC Bias VP Sensing Electrode 100nm Gap (a) (b) Fig. S2: (a) Global and (b) zoom-in SEM views of a fabricated 50m-wide clamped-clamped beam resonator. Fig. S2(a) presents a global SEM (scanning electron microscope) view for a fabricated 50m-wide CC-beam resonator, identifying its driving, sensing, and dc-bias ports; and Fig. S2(b) further shows the resonator zoom-in view with detail dimensions and its 100-nm gap spacing. Modeling and Simulation Results To model the high-stiffness driven resonator, the governing equations of a clamped-clamped beam resonator from [S1] are utilized. As shown in Fig. S3 which identifies key features for the resonator modeling and equation derivation, the mode shape of the resonator is governed by 𝑋𝑚𝑜𝑑𝑒 𝑦 = 𝜁 𝑐𝑜𝑠𝑘𝑦 − 𝑐𝑜𝑠ℎ𝑘𝑦 + 𝑠𝑖𝑛𝑘𝑦 − 𝑠𝑖𝑛ℎ𝑘𝑦 (S1) Referring to [S1] by using the relationship between the kinetic energy and velocity, the equations for equivalent mass, damping factor, and stiffness are presented in (S2), (S3), and (S4). 𝑚𝑟 𝑦 = 𝜌𝑊𝑟 ℎ 𝑊𝑟 [𝑋𝑚𝑜𝑑𝑒 0 (𝑦′)]2 𝑑(𝑦 ′ ) [𝑋𝑚𝑜𝑑𝑒 (𝑦)]2 = 𝐾𝐸𝑡𝑜𝑡 1 𝑣(𝑦)2 2 𝑘𝑚 𝑦 𝑚𝑟 (𝑦) 𝜔𝑛𝑜𝑚 𝑚𝑟 (𝑦) k m (y) = = 𝑄𝑛𝑜𝑚 𝑄𝑛𝑜𝑚 𝜔𝑛𝑜𝑚 𝑄𝑛𝑜𝑚 𝑐𝑟𝑒 𝑦 = 2 2 𝑘𝑟𝑒 𝑦 = 𝜔 × 𝑚𝑟𝑒 𝑦 = 𝜔 × 2 𝜌𝑊𝑟 ℎ 𝑊𝑟 [𝑋𝑚𝑜𝑑𝑒 0 (S2) (S3) (𝑦′)]2 𝑑(𝑦 ′ ) [𝑋𝑚𝑜𝑑𝑒 (𝑦)]2 (S4) Mode Shape Clamped-Clamped Beam Lr y h Wed Led1 d(y) Wed (b) Wes Led2 Les1 Les2 Fig. S3: Resonator cross-sectional schematic for theoretical derivation. Therefore, the effective stiffness kre in (S4) is location dependent (inversely proportional 2 to [𝑋𝑚𝑜𝑑𝑒 (𝑦)] ) due to the beam-vibrating mode shape where high-stiffness and low-stiffness locations correspond to low-velocity (close to the anchors) and high-velocity (at the middle of the beam) positions, respectively. With that, MATLAB simulation based on (S1)-(S4) was utilized to generate Table I and Fig. 3(b). As shown in Table I, the use of high-stiffness driving approach demonstrates 16.9X power handling enhancement based on simulation as compared to its low-stiffness counterpart. From the simulation of Fig. 3(b), the effective stiffness near the anchors is much larger than that at the center of the beam. The power handling of the beam resonator is governed by [S2] Pomax o Q k r ( yd )a 2 d o2 (S5) where a (= 0.56 at resonance) is the fraction of the electrode-to-resonator gap beyond which the onset of strong nonlinearities ensue and where kr (yd) is the effective stiffness of the resonator at its driving location yd. From (S5), the maximum handling power of the resonator before entering strong Duffing nonlinearity is proportional to the equivalent stiffness of the resonator. As a result, the higher the stiffness, the better the power handling capability (or linearity). Table I: Resonator Data Summary Driven at high-stiffness Driven at low-stiffness (low-velocity) location (high-velocity) location 50μm-Wide CC-Beam Parameters Units Young’s Modulus, E 150 GPa Density, ρ 2,300 kg/m3 3 Beam Length Lr = 40 Beam Width Wr = 50 Beam Thickness h = 2 Driving Location yd = 6 & Dimensions (see Fig. S3) Driving Location yd = 20 yd = 34 μm Driving Electrode Width Driving Electrode Width Wd = 4 Wd = 20 Sensing Location ys = 6 & Sensing Location ys = 20 ys = 34 Sensing Electrode Width Sensing Electrode Width Ws = 20 Ws = 4 Electrode-to-Resonator Gap, do 100 nm DC-Bias Voltage, VP 9 V 9.54 MHz 610 ― Measured Resonance Frequency, fo (at Low Input Power) Measured Quality Factor, Q (at Low Input Power) Effective Mass, mreff (at Driving Port) Effective Stiffness, kreff (at Driving Port) 6.15×10-11 3.65×10-12 kg 1.94×105 1.15×104 N/m -10 (98.93W) -22.3 (5.87W) dBm Calculated Resonator Power Handling, Pomax References [S1] F. D. Bannon III, J. R. Clark, and C. T.-C. Nguyen, “High-Q HF micro-electromechanical filters,” IEEE Journal of Solid-State Circuits, vol. 35, no. 4, pp. 512-526, April 2000. [S2] S. Lee and C. T.-C. Nguyen, “Influence of automatic level control on micromechanical resonator oscillator phase noise,” Proceedings, 2003 IEEE Int. Frequency Control Symposium, Tampa, Florida, May 5-8, 2003, pp. 341-349. 4