on the influence of the sample preparation and analysis method of

advertisement

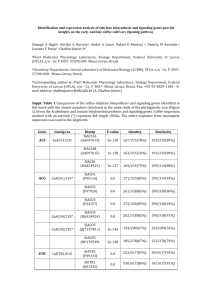

ON THE INFLUENCE OF THE SAMPLE PREPARATION AND ANALYSIS METHOD OF TEM BISMUTH TELLURIDE Milagres T.1, Balzuweit K.1,2, Nascimento V. B.1, Ladeira L. O.1, Soares E. A.1, Carvalho V. E.1 1 (1) Physics Department of the Federal University of Minas Gerais (UFMG), 2(2) Center of Microscopy of the Federal University of Minas Gerais (CM-UFMG) Email of the presenting author: thaismilagres20@gmail.com Bismuth Telluride is a very well know thermoelectric material [1] with relatively high coefficients at room temperature. Recently, interest in bismuth telluride has been renewed as scientists measured it as a 3D topological insulator [2,3]. Bismuth telluride is a relatively easy material to obtain and different compositions are being studied both as bulk material and thin films [4]. The main aim of the study is to compare the structure of bulk and surface of Bridgman grown crystals using both transmission electron microscopy (TEM and HRTEM) and surface characterization techniques as Low Energy Electron Diffraction (LEED). Crystals of Bi2Te3 were Bridgman grown in a sealed quartz ampoule in a directional resistance oven at a temperature of 600 °C. The crystals were slowly cooled down to room temperature and quartz ampoule broken to retrieve the grown crystal. Conventional X-ray diffraction showed patterns compatible with a single crystal along the sample except for the starting point, which was discarded. LEED measurements were performed and also showed patterns compatible with a single crystalline sample. The grown crystals were cleaved and fixed on a substrate for LEED. The samples for TEM were prepared in two ways: cleaved pieces were crushed on a mortar and deposited directly onto a holey carbon cooper grid. Thin cleaved slices were chosen and mounted directly onto a sample holder and cut into thin slices with a Leica UC6 Ultramicrotome with a diamond knife into water. The thin slices were fished out and deposited onto a holey carbon coated TEM grid. A second ultramicromtome sample with a thinner cut was also made. The samples are analyzed at a 200 kV transmission electron microscope (Tecnai G2-20 from FEI). The LEED samples were cleaved then sputtered with 0.5 keV Ar+, annealed for 60 minutes at 473 K and cooled down to 223K before measurements. The four diffraction patterns show a quite distinct behavior of the different preparation methods and analysis. [1] H. Julian Goldsmid, Materials, Volume 7, 2577, 2014. [2] Y.L. Chen, Science, Volume 325, 178, 2009. [3] D. O. Scanlon, Adv. Mater., Volume 24, 2154, 2012. [4] D. Teweldebrhan, Nano Lett., Volume 10, 1209, 2010. Acknowledgment: The authors would like to acknowledge the Center of Microscopy at the Federal University of Minas Gerais (www.microscopia.ufmg.br) for providing the equipment and technical support for experiments involving electron microscopy, and FAPEMIG, CNPq and CAPES for financial support. Figures: