View

advertisement

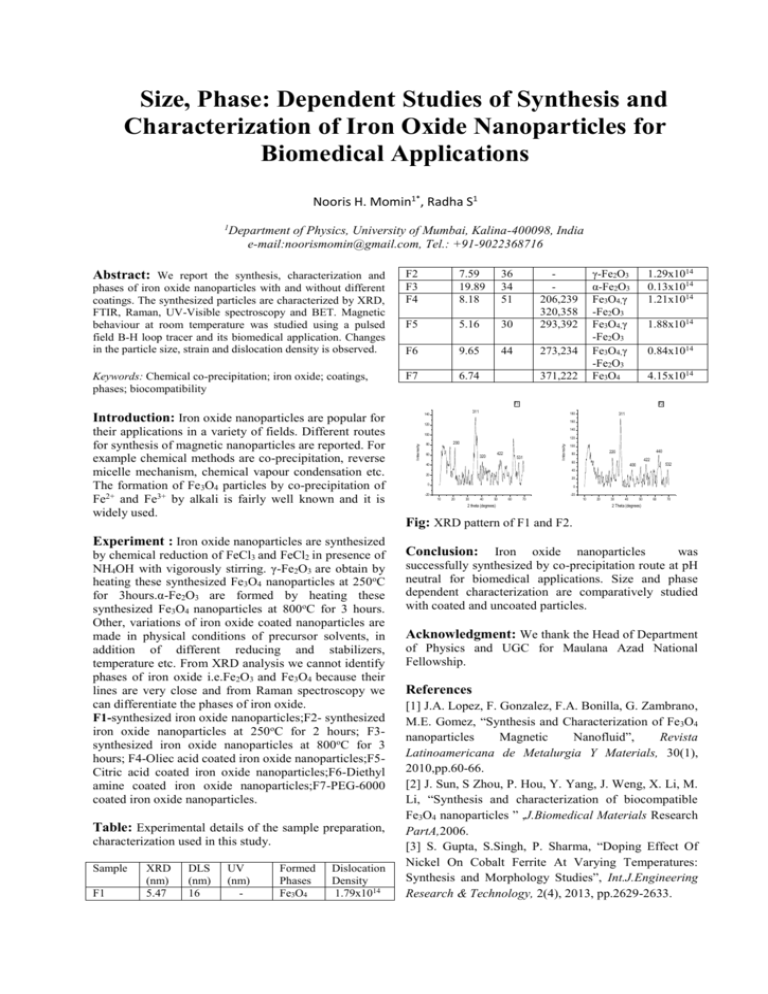

Size, Phase: Dependent Studies of Synthesis and Characterization of Iron Oxide Nanoparticles for Biomedical Applications Nooris H. Momin1*, Radha S1 1 Department of Physics, University of Mumbai, Kalina-400098, India e-mail:noorismomin@gmail.com, Tel.: +91-9022368716 Abstract: We report the synthesis, characterization and phases of iron oxide nanoparticles with and without different coatings. The synthesized particles are characterized by XRD, FTIR, Raman, UV-Visible spectroscopy and BET. Magnetic behaviour at room temperature was studied using a pulsed field B-H loop tracer and its biomedical application. Changes in the particle size, strain and dislocation density is observed. Keywords: Chemical co-precipitation; iron oxide; coatings, phases; biocompatibility F2 F3 F4 7.59 19.89 8.18 36 34 51 F5 5.16 30 206,239 320,358 293,392 F6 9.65 44 273,234 F7 6.74 γ-Fe2O3 α-Fe2O3 Fe3O4,γ -Fe2O3 Fe3O4,γ -Fe2O3 Fe3O4,γ -Fe2O3 Fe3O4 371,222 1.29x1014 0.13x1014 1.21x1014 1.88x1014 0.84x1014 4.15x1014 F1 Introduction: Iron oxide nanoparticles are popular for Experiment : Iron oxide nanoparticles are synthesized by chemical reduction of FeCl3 and FeCl2 in presence of NH4OH with vigorously stirring. γ-Fe2O3 are obtain by heating these synthesized Fe3O4 nanoparticles at 250oC for 3hours.α-Fe2O3 are formed by heating these synthesized Fe3O4 nanoparticles at 800oC for 3 hours. Other, variations of iron oxide coated nanoparticles are made in physical conditions of precursor solvents, in addition of different reducing and stabilizers, temperature etc. From XRD analysis we cannot identify phases of iron oxide i.e.Fe2O3 and Fe3O4 because their lines are very close and from Raman spectroscopy we can differentiate the phases of iron oxide. F1-synthesized iron oxide nanoparticles;F2- synthesized iron oxide nanoparticles at 250oC for 2 hours; F3synthesized iron oxide nanoparticles at 800oC for 3 hours; F4-Oliec acid coated iron oxide nanoparticles;F5Citric acid coated iron oxide nanoparticles;F6-Diethyl amine coated iron oxide nanoparticles;F7-PEG-6000 coated iron oxide nanoparticles. Table: Experimental details of the sample preparation, characterization used in this study. Sample F1 XRD (nm) 5.47 DLS (nm) 16 UV (nm) - Formed Phases Fe3O4 Dislocation Density 1.79x1014 180 311 160 120 140 100 120 200 80 60 422 320 531 Intensity Intensity their applications in a variety of fields. Different routes for synthesis of magnetic nanoparticles are reported. For example chemical methods are co-precipitation, reverse micelle mechanism, chemical vapour condensation etc. The formation of Fe3O4 particles by co-precipitation of Fe2+ and Fe3+ by alkali is fairly well known and it is widely used. F2 311 140 100 440 220 80 422 60 40 532 400 40 20 20 0 0 -20 -20 10 20 30 40 50 60 70 2 theta (degrees) 10 20 30 40 50 60 70 2 Theta (degrees) Fig: XRD pattern of F1 and F2. Conclusion: Iron oxide nanoparticles was successfully synthesized by co-precipitation route at pH neutral for biomedical applications. Size and phase dependent characterization are comparatively studied with coated and uncoated particles. Acknowledgment: We thank the Head of Department of Physics and UGC for Maulana Azad National Fellowship. References [1] J.A. Lopez, F. Gonzalez, F.A. Bonilla, G. Zambrano, M.E. Gomez, “Synthesis and Characterization of Fe3O4 nanoparticles Magnetic Nanofluid”, Revista Latinoamericana de Metalurgia Y Materials, 30(1), 2010,pp.60-66. [2] J. Sun, S Zhou, P. Hou, Y. Yang, J. Weng, X. Li, M. Li, “Synthesis and characterization of biocompatible Fe3O4 nanoparticles ” ,J.Biomedical Materials Research PartA,2006. [3] S. Gupta, S.Singh, P. Sharma, “Doping Effect Of Nickel On Cobalt Ferrite At Varying Temperatures: Synthesis and Morphology Studies”, Int.J.Engineering Research & Technology, 2(4), 2013, pp.2629-2633.