Aerosol Review Manuscript_TARA

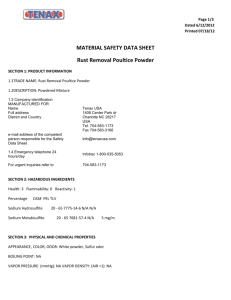

advertisement