INDIVIDUAL ASSIGNMENT – Danial Hafiz

advertisement

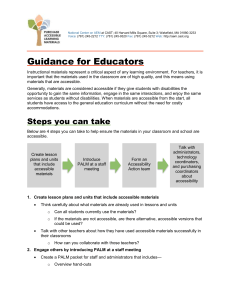

INDIVIDUAL ASSIGNMENT ANIMAL NUTRITION DVT 1084 MUHAMMAD DANIAL HAFIZ BIN MOHD SUADI NATA D11A017 DR. WAN ZAHARI BIN MOHAMED 7 MAC 2012 Palm Kernel Expeller (PKE) WHAT IS THE PALM KERNEL EXPELLER ( PKE ) ? Palm Kernel Expeller meal (PKE), is a by-product of the palm oil industry in South East Asia, mainly from Malaysia. It is a by-product of the crushing and physical expelling of oil from the kernel of the fruit of the oil palm tree (Elaeis guineensis). The outer fleshy fruit of the palm fruit is removed and extracted to produce palm oil leaving the kernel. After removing the shell, the kernels are also crushed to release Palm Kernel Oil and Palm Kernel Expeller. PKE combines mid to high energy levels (around 8 percent fat and 65 percent NDF) with moderate protein levels. WHAT IS THE NUTRITIVE VALUE OF PKE For the nutritive value of the Palm Kernel Expeller, it is protein feed and with its high fibre content it is often considered as suitable for feeding of ruminants. Palm Kernel Expeller was ranked a little higher than copra expeller but lower than fish meal and groundnut expeller especially in its protein value (Devendra, 1977). The nutrient composition of Palm Kernel Expeller is presented in Table 1. Main difference between the palm kernel extraction meal and the expeller pressed type is in the ether extract or oil content. The oil content of the former is low, around 0.5 to 3%, while that in the latter is higher and ranges between 5 to 12%, depending on the extent of oil extraction. No difference can be found in the crude protein contents between the two types, which range from 14.6 to 16.0% on dry matter basis. Solvent extracted Expeller pressed 1 2 3 1 2 3 Dry matter (%) 89 91 91 92 93 89 Crude protein (%) 15 15 15 14 14 16 Crude fibre (%) 14 16 16 12 16 17 Acid detergent fibre (%) 46 46 40 42 44 40 Neutral detergent fibre (%) 66.7 - - 66.4 - - Ether extract (%) 3 2 1 9 10 11 Ash (%) 4 4 4 4 4 4 Nitrogen free extract (%) 63 63 65 60 56 53 Total digestible nutrient, TDN (calculated,%) 75 70 75 72 67 70 Metabolisable energy (cattle, MJ/kg) 13 12 13 13 12 12 Calcium (%) 0.2 0.3 - 0.2 0.2 - Phosphorus (%) 0.5 0.5 - 0.5 0.3 - Magnesium (%) - 0.16 - - - - Copper (ppm) 34 29 - 18 - - Ferrous (mg/kg) - 4 - - - - Manganese (mg/kg) - 225 - - - - Zinc (mg/kg) - 77 - - - - TABLE 1 Nutritional specifications : Dry matter - Typically 90% DM. Crude Protein - Typically in the range of 16-18% so is a medium level protein feed. In comparison to leafy pasture the protein in PKE is slower to be digested, 60% rumen degradable and only 13% soluble, thus complementing quality pasture. Energy - At 10.5-12.5 MJ/kg DM PKE is comparable to energy in cereal grains. However with very little starch (3%) or sugar (4%) PKE is ideally suited to be fed in conjunction with a starch or sugar source like cereal grain or maize silage or molasses. Fibre - Laboratory tests show that PKE has a high fibre content testing 60-65% NDF. What many of the laboratory tests do not describe, however, is that a large portion of the fibre in PKE is highly digestible (60% of NDF is digested in 30 hours). Unlike many feeds with high NDF values the fibre component of PKE does not take up a lot of rumen space and contributes considerably to the energy content. Oil - Being mechanically extracted, PKE contains higher oil (8-10%) content than many of the solvent extracted oilseed meals. Palm Oil is a saturated fat that is largely rumen stable, and does not interfere with rumen function. Palm oil is used to manufacture many of the high value bypass fats fed to cows to improve condition score and fertility. This is a considerable source of energy for the cow. Minerals - Calcium 0.45% (average), Phosphorus 0.6% (good), Magnesium 0.3% (adequate) Sulphur 0.2% (low). NB very low in salt, Sodium 0.009%. Copper 24ppm (high) from field liver testing this seems to be relatively available. Zinc 42ppm (average), Manganese 224ppm (high), Molybdenum 0.3ppm (average), Cobalt nil (very low). Starch - PKE contains virtually no starch and as such is an ideal feed when energy intake is inadequate but grain or maize feeding is at its limit, or when protein is lacking. FUNCTION OF THE PKE Lower palatability of PKE will affect voluntary intake levels during the first period after introduction. It is best introduced mixed with more palatable inputs like molasses or silage. After about 10 days cows will consume it straight. Highly contain of fibre that suitable for ruminant animal such as cattle and goat. PKE is very low in starch and sugars (most of the energy coming from oil and NDF) and does not cause any risk of developing acidosis and few rumen health issues are likely to be caused. The NDF in PKE has a small particle size and is low in effective fibre. PKE should be fed with a long (effective) fibre source to establish sufficient rumination. The calcium to phosphorous ratio of PKE is low as is sodium, calcium and sodium may need to be supplemented if PKE is fed at high levels. The high fermentable NDF level in Palm Kernel Expeller is a substrate for acetic and butyric acid production which will aid the production of milk fat and stimulates cow condition and milk fat levels. PKE's moderately fast fermentable NDF and higher protein levels makes it ideally suitable to be fed in conjunction with high starch low protein supplements like maize silage or tapioca. Safe, non-acid producing foodstuff (low levels of starch and sugar) Excellent source of oil and rumen fermentable fibre which usually improves fat test Although high in Acid Detergent Fibre (ADF) and Neutral Detergent Fibre (NDF) it does not substitute for grass intake (i.e. increases total DM intake) Good source of minerals especially phosphorus, copper, zinc and manganese HOW TO PRODUCE AND STORAGE The process of palm kernel oil extraction existed since early human civilization. In ancient times, palm oil extraction process merely involves the cleaning of palm kernels and grinded with the use of grinders or stone mills. In modern times, with the advancement of science and technology, screw presses and palm kernel expellers are introduced, which offer a much efficient solution in extracting palm oil. Today, oil expellers play a vital role in the palm oil industry in Malaysia. As we all know, palm kernels contain some amount of oil in them, which can be extracted by crushing them. A palm kernel screw press is a mechanical machine that is used to extract palm oil by applying intense pressure to palm kernels. During earlier times, traditional methods of grinding were used as a method of palm oil extraction, but these methods did not produce as effective results as the modern oil expellers do. MBL is a designer and manufacturer of oil seed expellers primarily for palm kernel oil. The oil seed expellers comprise primarily of pressing stations, coupling, gearbox, pulley and belt, and a motor. The palm kernel oil expeller is designed with the main shaft directly driven by a coupling affixed to the gearbox. Thus, it has a simple structure by eliminating the extra gear set needed. This EK series design of palm kernel oil expeller reduces maintenance costs and time. MBL are also manufacturers of automated oil seed expellers, better known as the EK (Automated) series. The automated oil seed expellers are designed to protect the gearbox from breaking or the main shaft or bearing from malfunctioning. Thus, our palm kernel expellers are well known for being the most efficient and cost effective in the industry STORAGE: Like all feedstuffs, PKE should be stored dry, in bulk bins or placed on cement slabs (away from vermin and covered and protected from the weather accordingly). If stored in a silo, the sides should be smooth, the bottom cone steep and, preferably, a wide opening to allow free flow of the PKE. Pre-blending with grain will allow for a better flow ability. INCLUSION LEVELS Animal Inclusion Level (%) Calves Inclusion (%) 10 Beef Cattle Inclusion (%) 25 Lamb Inclusion (%) 20 Sheep Inclusion (%) 30 Broiler Inclusion (%) 10 Layer Inclusion (%) 15 Starter Pig Inclusion (%) 5 Finisher Pig Inclusion (%) 10 Sow Inclusion (%) 15 REFERENCES i. ii. iii. Source: Mustaffa et al. (1987), Chin (1991) Department of Veterinary Services Malaysia Malaysian Agricultural Research and Development Institute, MARDI Universiti Putra Malaysia, UPM Online supplements. Animal feed supplies. Royston Newman, Commodities Broker. http://www.chgs.com.my