da Rosa-KY

advertisement

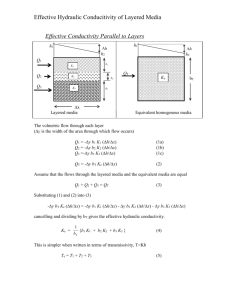

Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 POTENTIAL USE OF WEATHERED SANDSTONES TO CONSTRUCT A LOW PERMEABILITY BARRIER TO ISOLATE PROBLEMATIC COAL MINE SPOILS1 Mariana da Rosa2, Carmen T. Agouridis, and Richard C. Warner Abstract. Specific conductance and selenium (Se) are two water quality parameters of emerging concern in the Appalachian coalfields. Isolation of high specific conductance and Se producing spoils from environmental water flows using a low permeability barrier is one method of minimizing the leaching of these constituents from coal mine spoils. Ideally, the material used to form the barrier should be readily accessible, have low levels of specific conductance and Se, and be capable of achieving a low permeability with the proper moisture adjustment. Brown and gray weathered sandstones are often readily available at mine sites in the Appalachian coalfields. Spoil samples and water quality samples from the University of Kentucky Bent Mountain Research Complex near Pikeville, Kentucky indicated that these spoil types hold promise in meeting the criteria of being a low specific conductance producing material. However, these sandstones tend to have higher sand contents than those typically used in compacted barriers or liners in landfills. The objective of this study was to assess the potential of using brown and/or gray weathered sandstones to create a low permeability barrier. To meet the objective of the study, a total of four spoil samples (identified as M1-M4) were collected in 2012. Each spoil sample was obtained from a different mine in eastern Kentucky. Samples M1 and M2 consisted of brown sandstone; sample M3 was gray sandstone; and sample M4 was a mixture of brown and gray sandstones. Each spoil sample was screened and analyzed for soil texture. Spoil moisture content-density relationships and spoil saturated hydraulic conductivity-moisture content relationships were developed for each sample using double ring permeameters. Maximum saturated hydraulic conductivity values ranged between a low of 5.9 x 10-8 cm s-1 to a high of 3.1 x 10-7 cm s-1 in the laboratory for the <2mm fraction. These saturated hydraulic conductivity values were comparable to soils used to construct liners in landfills, particularly in instances where the percentage of fines in the spoils were about 50% or greater. When in the field, however, it is expected that these saturated hydraulic conductivity values will typically be 1-3 orders of magnitude higher due to rock fragments. These results demonstrate that brown sandstone, with its higher fines content, is likely a more suitable media than gray sandstone for constructing a low permeability barrier to isolate high specific conductance producing and/or Se generating spoils. Based on these laboratory results, field assessments of brown weathered sandstones for this application are recommended. Additional Key Words: Proctor density, hydraulic conductivity, water quality. ___________________ 1 Oral paper presented at the 2013 National Meeting of the American Society of Mining and Reclamation, Laramie, WY Reclamation Across Industries, June 1–6, 2013 and accepted for the online Journal of The American Society of Mining and Reclamation, Volume 2, No. 1, 2013. R.I. Barnhisel (Ed.). Published by ASMR, 3134 Montavesta Rd., Lexington, KY 40502 2 Mariana da Rosa is an Undergraduate Research Assistant in Agricultural Engineering Department, Universidade Federal de Viçosa, Viçosa, Brazil; Carmen T. Agouridis is an Assistant Professor, Biosystems and Agricultural Engineering Department, University of Kentucky, Lexington, KY 40546; and Richard C. Warner is an Extension Professor, Biosystems and Agricultural Engineering Department, University of Kentucky, Lexington, KY 40546. 49 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 Introduction Surface mining practices such as contour and area mining have been linked to elevated levels of specific conductance and selenium (Se) (Fritz et al., 2010; Lindberg et al., 2011), which are two constituents of emerging concern in the Appalachian coalfields. During the mining process, consolidated rock above the coal seams are subjected to blasting resulting in many smaller more weatherable particles, some of which are high in sulfur and/or Se (Vesper et al., 2008; Barton, 2011). Research has shown that high specific conductance and Se levels in mine drainage waters negatively impact aquatic communities. Pond et al. (2008) found notably fewer Ephemeroptera taxa in streams in the Appalachian coalfields when specific conductance levels were above 500 μS cm-1. Selenium, while an essential trace element, is toxic to fish at high levels (Janz, 2012). Chronic exposure to elevated levels of Se, particularly in the early stages of life, can result in fish deformities or death (Hamilton, 2004; Janz, 2012). In response to such findings regarding specific conductance, the U.S. Environmental Protection Agency (USEPA) issued guidance in 2011 stating that waters discharged from mined lands in this region should have specific conductance levels no greater than 300-500 μS cm-1 (USEPA, 2011b). USEPA (2011a) recommended the lower limit of 300 μS cm-1 as this was the level at which “5% of native macroinvertebrate genera are extirpated,” which is the endpoint typically used when establishing a numeric criteria for protecting aquatic life, while the upper limit of 500 μS cm-1 was based upon the findings of Pond et al. (2008). This guidance was struck down by the U.S. District Court for the District of Columbia on July 2012 for violating rulemaking procedures outlined in the Administrative Procedure Act (National Mining Association v. Jackson, D.D.C., No. 1:10-cv1220, 7/31/12) (Kovski, 2012). However, on May 7, 2013, the USEPA was delivered a formal petition requesting that they begin the rule-making process to establish a specific conductance standard for streams affected by mountaintop mining (Ward, 2013) meaning that the issues surrounding specific conductance and coal mining are not yet resolved. As for Se, the USEPA has a freshwater chronic water quality guideline of 5 μg L-1. It is theorized that reclamation techniques, such as the Forestry Reclamation Approach (FRA) which promotes the creation of a suitable root medium for good tree growth (e.g. topsoil, weathered sandstone, and/or the best available material) and hence reforestation, will help mitigate the impacts of surface mining on water quality (Burger et al., 2005; Zipper et al., 2011; Agouridis et al., 2012). Specific conductance levels in grab samples collected from test plots of 50 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 brown weathered sandstone, gray unweathered sandstone, and a mixture of the two and shale were below 500 μS cm-1 after three years (Agouridis et al., 2012) which is a relatively short time period considering that Fritz et al. (2010) measured specific conductance values between 2,000 and 3,000 μS cm-1 down-gradient of valley fills older than 10 years. While Agouridis et al. (2012) showed that a reduction in the specific conductance levels of waters discharged from spoil placed in accordance with the FRA occurred, the cause of this reduction is not certain. It is possible that the thickness of the spoil (approximately 2.5 m) influenced specific conductance levels as salts were flushed from the spoil over the study period. Less thick spoils may flush salts more quickly while a longer period of time may be required to reach the same specific conductance levels for thicker spoils. To date, the FRA has not been evaluated as a mechanism to reduce Se concentrations in mine discharged waters. While it is important to note the mitigating effects of the FRA, it is also important to note the timeline in which these effects are realized. As noted by Barton (2011), one significant challenge is maintaining water quality standards during the active mining practice. Warner and Agouridis (2010) recommended the use of source reduction techniques whereby highconductivity and high-Se producing materials are isolated from infiltrating waters through the use of a low permeability barrier. The technique of isolating materials with such a barrier is common in landfill operations (Goldman et al., 1988) and in coal mining operations which encounter acid-forming strata (Skousen et al., 2000; Johnson and Hallberg, 2005). However, in landfill operations, the barrier is typically created using clay which is difficult to locate in the sandstone geology of the Appalachian coalfields. While the literature is plentiful regarding the saturated hydraulic conductivity of clayey soils (e.g. Olson and Daniel, 1981; Goldman et al., 1988; Kang and Shackelford, 2010), a void exists regarding materials with higher sand contents such as weathered sandstone spoils. The question remains regarding whether or not these weathered brown and gray sandstone spoils, which have high sand contents (Emerson et al., 2009; Agouridis et al., 2012), have a sufficient percentage of fines (e.g. silt and clay) in the overall rock content to create a low permeability barrier when compacted or if an amendment or alternate material is needed. The objective of this study was to measure maximum density and saturated hydraulic conductivity of brown, gray, and a combination of brown and gray weathered sandstones to assess their potential for use in constructing a low permeability barrier to isolate problematic spoils. 51 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 Methods Study Sites Spoil samples were collected in August 2012 from four surface mines located in the Appalachian coalfields of eastern Kentucky (Fig. 1). Because of confidentiality agreements, we are not permitted to reveal the exact locations of the mines. All of the surface mines are located in the Cumberland Plateau Physiographic region, which is a predominately forested region in eastern Kentucky. The climate in this region is humid and temperate. Based on the National Oceanic and Atmospheric Administration (NOAA) weather station located in Jackson, Kentucky, which is central to three of the four mines, average annual rainfall is 125 cm. Temperatures range from a low of -4°C in the winter months to a high of 32°C in the summer months. The geologic unit of all four mines was the Lower and Middle Pennsylvanian Breathitt formation. One sandstone sample was collected at each of the mines, which are referred to as Mine 1 (M1), Mine 2 (M2), Mine 3 (M3), and Mine 4 (M4) (Table 1) in this paper. The sample from M1 was associated with the Lower Richardson coal seam, and it consisted of 100% brown sandstone that was collected from the top 2 m below a shallow soil layer. The sample from M2 was associated with the Middle Peach Orchard coal seam, and it consisted of 100% brown sandstone that was collected from the top 1.2 m below a shallow soil layer. The samples from M3 and M4 were associated with the Hazard 7, 8, and 9 coal seams. Sample M3 consisted of 100% gray sandstone located immediately below a brown sandstone layer while sample M4 is 50% brown sandstone and 50% gray sandstone (visual approximation made by personnel in the Virginia Tech University Department of Crop and Soil Environmental Sciences). The mixture of brown and gray sandstones (M4) was tested as this represents the condition in which the mine operator acquires spoil at a greater depth below the surface (e.g. 1-4 m). Spoil samples were placed in 19 L buckets and sealed for transport to the University of Kentucky Biosystems and Agricultural Engineering Department for analysis. Spoil Characterization Three subsamples of each spoil (M1, M2, M3, and M4) were taken to the University of Kentucky Regulatory Services (UKRS) and analyzed for percent sand, silt and clay using the micro-pipette method (Miller and Miller, 1987; Burt et al., 1993). For this analysis, subsamples 52 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 Figure 1. Approximate locations of the surface mines sampled in eastern Kentucky. Numbers 1, 2, 3, and 4 correspond to the mine codes (and sample codes) Mine 1 (M1), Mine 2 (M2), Mine 3 (M3), and Mine 4 (M4). Table 1. Coal seams associations and spoil types for each sample. Sample M1 M2 M3 M4 Coal Seam Lower Richardson Middle Peach Orchard Hazard 7, 8 and 9 Hazard 7, 8 and 9 Spoil Type 100% brown sandstone 100% brown sandstone 100% gray sandstone 50% brown sandstone and 50% gray sandstone1 1 Visual assessment performed by personnel in the Virginia Tech University Department of Crop and Soil Environmental Sciences. were classified using the United States Department of Agriculture (USDA) textural triangle (USDA-NRCS, 2012) and compared using a completely randomized design (PROC GLM) in SAS (SAS Institute, 2008). The liquid limit, plastic limit, and plasticity were each ground and passed through a 2 mm sieve by UKRS. Any fragments >2 mm were discarded. Spoils were classified using the United States Department of Agriculture index by using a second subsample of each spoil using ASTM D4318-10 (ASTM International, 2010). 53 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 To determine electrical conductivity, a modification of a U.S. Geological Survey (USGS) field leach test was performed using a third subsample of each spoil (Hageman, 2007). The modification involved the addition of 3% H2O2 to the sample in addition to distilled water (9:1 distilled water-to- H2O2 ratio) to promote the oxidation of minerals in the rocks and thus increase the rate of dissolution (Skousen et al., 1997; Fallavena et al., 2012). Electrical conductivity of the leachate was then determined using a multiparameter meter (HI991300; Hanna Instruments, Woonsocket, RI). Selenium concentrations were not measured since only sandstones not adjacent (>2 m) to the coal seams were used. According to Vesper et al. (2008), sandstones generally contain the lowest concentrations of Se with the exception of those adjacent to coal beds. The authors found that Se concentrations were generally highest in sandstones within 0.5 m of the coal seam though in 10 samples, Se concentrations >2 mg L-1 were found more than 2 m from the coal seam. Vesper et al. (2008) noted that these higher Se concentration samples were most often associated with a carbolith layer (e.g. either comprised of or immediately below a high-Se carbolith layer). This trend was confirmed according to unpublished data collected by R. Warner who in sampling two drill cores (33 m and 106 m) in West Virginia, found that the lowest Se levels were associated with sandstones while the highest levels were found in the shales, fire clays, and those sandstones adjacent to the coal seams. Spoil Compaction and Permeability To evaluate spoil compaction and permeability characteristics, a fourth subsample from each spoil type was air dried and then ground (<2 mm) using a Thomas Wiley Laboratory Mill Model 4 (Thomas Scientific, Swedesboro, NJ) in the Biosystems and Agricultural Engineering Department. For each ground spoil sample, the Standard Proctor test (ASTM D698) was used to determine the maximum achievable level of compaction (𝜌𝑚𝑎𝑥 ) for the optimum moisture content (MC) (ASTM International, 2012). Moisture contents (gravimetric) ranged from 10 to 18% (IDT, 2013) and were assessed following the determination of 𝜌𝑚𝑎𝑥 . Because of this, not all spoils were tested at the exact same MCs. Following the Standard Proctor test (i.e. determination of 𝜌𝑚𝑎𝑥 and MC values), a rigid wall double-ring permeameter, which was constructed in the Biosystems and Agricultural Engineering Department, was used to determine the saturated hydraulic conductivity (ℎ𝑠𝑎𝑡 ) of each spoil sample (Goldman et al., 1988). 54 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 Results and Discussion Spoil Characterization Table 2 contains the results of the USDA textural classification of the spoil samples. Samples M1, M2, and M4, all of which contained brown sandstone, were classified as having a loam texture while sample M3, which was gray sandstone, was classified as a sandy loam. All spoil samples differed significantly from each other with respect to the percent of fines (silt and clay) (p<0.001). Sample M1 had the largest percentage of fines at 62% followed by M4 at 53%, M2 at 48%, and M3 at 27%. With the exception of M3, the percentage of fines in these samples is higher than those measured by Agouridis et al. (2012) who found mean fines of 38% in the brown sandstone samples and 24% in the gray sandstone samples. Miller et al. (2012) found even lower percentages of fines in brown and gray sandstones at 22 and 21%, respectively. Note that both Agouridis et al. (2012) and Miller et al. (2012) used the same procedure and laboratory as used in this study. The results from this study coupled with those of Agouridis et al. (2012) and Miller et al. (2012) show that the percentage of fines can vary considerably for the brown and gray sandstones, but that the brown sandstones often have a greater percentage of fines than the gray sandstones. Table 3 contains the values for liquid limit, plastic limit, and plasticity index for the four spoils. Both M1 and M4 were classified as ML according to the Universal Soil Classification System (USCS) while M2 was close to this designation (ASTM International, 2006). M3 was classified as an SM according to the USCS. It is expected that a low permeability liner constructed of these ML spoils would not experience significant shrinking and swelling as long as they were not subjected to large changes in moisture contents (e.g. below 2 m or more of spoil). As soils have very little tensile strength (Kim et al., 2012), they tend to crack when subjected to differential settling, which can occur in valley fills. However, low permeability liners have been successfully constructed in landfills using ML soils (R. Warner, personal communication). The Pennsylvania Department of Environmental Protection (PDEP) (2011) lists ML and SM soils as recommended types for use in dam embankment construction for oil and gas wells. 55 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 Table 2. Means and standard deviations of spoil texture values. Texture Spoil Sample1 M2 M3 M1 Percent Sand A2 B C Mean ± Std. Dev. Percent Silt A B C Mean ± Std. Dev. Percent Clay A B C Mean ± Std. Dev. USDA Textural Classification3 A B C M4 40.5 37.2 37.4 38.4 ± 1.9 52.3 54.0 50.8 52.4 ± 1.6 73.5 72.9 72.4 72.9 ± 0.5 48.5 45.0 46.8 46.8 ± 1.7 41.7 39.5 45.4 42.2 ± 3.0 33.9 31.9 34.7 33.5 ± 1.5 16.5 17.2 17.4 17.0 ± 0.5 35.0 37.6 35.9 36.2 ± 1.3 17.8 23.4 17.3 19.5 ± 3.4 13.8 14.2 14.5 14.2 ± 0.3 10.1 9.9 10.2 10.1 ± 0.2 16.5 17.4 17.3 17.1 ± 0.5 loam loam loam loam sandy loam loam sandy loam sandy loam sandy loam loam loam loam 1 M1 is100% brown sandstone, M2 is 100% brown sandstone, M3 is 100% gray sandstone, and M4 is 50% brown sandstone and 50% gray sandstone. 2 A, B, and C refer to subsamples. 3 Source: USDA-NRCS (2012). Table 3. Liquid limit, plastic limit, and plasticity index for each spoil sample. Spoil Sample1 M1 M2 M3 M4 Liquid Limit (%) 31 25 17 27 Plastic Limit (%) 31 25 --2 24 Plasticity Index (%) 0 0 -3 1 M1 is100% brown sandstone, M2 is 100% brown sandstone, M3 is 100% gray sandstone, and M4 is 50% brown sandstone and 50% gray sandstone. 2 Sample was too sandy to perform test. Specific conductance values for all spoil samples were below 25 μS cm-1 except for the M2 spoil sample which was 46 μS cm-1 (Table 4). Miller et al. (2012) found average specific conductivities of 80 and 90 μS cm-1 for brown and gray sandstones, respectively, at Bent Mountain in Kentucky. Agouridis et al. (2012) measured higher specific conductance values for brown (165 μS cm-1) and gray (147 μS cm-1) sandstones at the same mine as that in Miller et al. (2012), using the same technique, but for different spoils. Emerson et al. (2009) measured 56 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 Table 4. Specific Conductance values for each spoil sample. Specific Conductance (μS cm-1) 24 46 23 24 Spoil Sample1 M1 M2 M3 M4 1 M1 is100% brown sandstone, M2 is 100% brown sandstone, M3 is 100% gray sandstone, and M4 is 50% brown sandstone and 50% gray sandstone. specific conductance values between 270 and 440 μS cm-1 for brown sandstones and 240 to 250 μS cm-1 for gray sandstones in West Virginia. The higher specific conductance values reported by Emerson et al. (2009) may be due to the methodology employed as the authors used a 1:2 spoil:water mixture while Agouridis et al. (2012) and Miller et al. (2012) used a 1:3 spoil:water mixture. While the procedure for measuring specific conductance used in this study was not identical to the methodology used by Emerson et al. (2009), Agouridis et al. (2012), and Miller et al. (2012) and hence is not directly comparable, these studies show a trend that specific conductance values for brown sandstones and gray sandstones are generally lower than 300 μS cm-1.While the purpose of the liner is to restrict the movement of water through problematic spoils, and hence it could be argued that the quality (e.g. specific conductance) of the spoil used to comprise the liner is of lesser importance, we recommend the use of higher quality (e.g. low specific conductance, low Se producing) spoils. The reason is that water will still flow along the upper boundary of the liner. If the liner is comprised of poorer quality spoils, then the effectiveness of the liner at preventing water quality impairments will likely be reduced. The spoils tested in this study were well below the 300-500 μS cm-1 threshold designated by the USEPA. Though this one-time test was not sufficient to predict long-term mine drainage quality, the low specific conductance levels measured for all the spoils were promising. Prior research has shown that column tests have successfully predicted mine drainage quality (Bradham and Carrucio, 1990; Stewart et al., 2001). Presently, a study is underway to compare the modified USGS field leach or static test used in this paper to column testing (Daniels et al., 2013). Considering only the specific conductance levels of the spoils from the static test, all samples would be deemed acceptable for use in a low permeability barrier for isolating problematic spoils. When compared to other specific conductance data presented in the literature, these results point to the importance of testing individual strata rather than assuming a particular spoil 57 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 type, such as brown or gray sandstone, will produce low specific conductance values. In Agouridis et al. (2012), for example, it was noted that one test plot of brown weathered spoil produced higher specific conductance values than the other. Spoil Compaction and Permeability Table 5 contains the maximum density and maximum saturated hydraulic conductivity values for the tested spoils. Note that the extrapolated values were used in some cases; however, this does not affect the interpretation of the results as the order of magnitude, which is of primary interest, does not change. Maximum density was highest for M3 and M4 at about 2,500 kg m -3 followed by M2 at 2,400 kg m-3, and M1 at 2,200 kg m-3. Samples M3 and M4 both contained gray sandstone at 100% and 50%, respectively. As seen in Fig. 2-5 and Table 5, the moisture contents required to reach these maximum densities were between about 12 and 14% for all samples except M1 which required a moisture content of about 17%. Table 5. Maximum density and saturated hydraulic conductivity values for the sampled spoils. 1 Spoil Sample1 𝜌𝑚𝑎𝑥 (kg m-3) M1 M2 M3 M4 2,200 2,400 2,500 2,500 Moisture Content (%) 17 14 12 13 ℎ𝑠𝑎𝑡 (cm s-1) 6x10-8 1x10-7 3x10-7 3x10-7 Moisture Content (%) 17 14 11 13 M1 is100% brown sandstone, M2 is 100% brown sandstone, M3 is 100% gray sandstone, and M4 is 50% brown sandstone and 50% gray sandstone. Figures 2-5 and Table 5 show that the saturated hydraulic conductivity was highest for M3 followed by M4, M2, and M1 (note that lower saturated hydraulic conductivity values are desired for liners or barriers). With the exception of M1, these saturated hydraulic conductivity values were above the maximum level (1 x 10-7 cm s-1) required for soil (e.g. clay) liners used in waste management facilities as outlined in Part 258, Subpart D of the Code of Federal Regulations (Goldman et al., 1988). Sample M2 was relatively close to the 1 x 10-7 cm s-1 level. Thus, M1 and M2, which contained 100% brown sandstone, had the lowest saturated hydraulic conductivities. Sample M3 and M4, which contained gray sandstone, had slightly higher values for saturated hydraulic conductivities. These results suggest that brown sandstone may be a more suitable media for constructing a low permeability barrier than gray sandstone. Additionally, Miller et al. (2012) found that brown weathered sandstone was less durable than gray unweathered sandstone suggesting that, in the field, it will be easier to crush the brown 58 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 weathered sandstone with a dozer or other such mine equipment. Part of the reason may be related to the percentage of fines in the samples (Fig. 6). As the percentage of fines increased, saturated hydraulic conductivity tended to decrease. Goldman et al. (1988) showed that the percent fines in clay liners is typically 50% or greater. With the exception of M3, which was the one sample containing only gray sandstone, the other samples met or nearly met this criterion. At this time, it is important to note that no maximum saturated hydraulic conductivity guideline has been established for low permeability barriers used to isolate problematic spoils. It is possible that a maximum saturated hydraulic conductivity value higher than the one required for waste management facilities (e.g. greater than 1 x 10-7 cm s-1) would prevent or limit the leaching of constituents from problematic spoils. 2250 1.2x10-6 -3 Density (kg m ) 10-6 2200 8.0x10-7 2150 6.0x10-7 2100 4.0x10-7 2050 2000 10 2.0x10-7 12 14 16 18 -1 Density Saturated Hydraulic Conductivity Saturated hydraulic conductivity (cm s ) 1.4x10-6 2300 20 Moisture Content (%) Figure 2. Maximum density and saturated hydraulic conductivity results for sample M1 (100% brown sandstone). Dashed vertical line represents the minimum saturated hydraulic conductivity. 59 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 -1 Density Saturated Hydraulic Conductivity 2380 8x10-7 -3 Density (kg m ) 2360 2340 6x10-7 2320 2300 4x10-7 2280 2260 2x10-7 2240 2220 10 12 14 16 18 Saturated Hydraulic Conductivity (cm s ) 10-6 2400 20 Moisture Content (%) Figure 3. Maximum density and saturated hydraulic conductivity results for sample M2 (100% brown sandstone). Dashed vertical line represents the minimum saturated hydraulic conductivity. -3 Density (kg m ) -1 Density Saturated Hydraulic Conductivity 2480 2.5x10-6 2460 2.0x10-6 2440 1.5x10-6 2420 10-6 2400 5.0x10-7 2380 10 12 14 16 18 Saturated Hydraulic Conductivity (cm s ) 3.0x10-6 2500 20 Moisture Content (%) Figure 4. Maximum density and saturated hydraulic conductivity results for sample M3 (100% gray sandstone). Dashed vertical line represents the minimum saturated hydraulic conductivity. 60 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 -3 Density Saturated Hydraulic Conductivity 5.0x10-7 2440 4.5x10-7 -3 Density (kg m ) Saturated Hydraulic Conductivity (g cm ) 5.5x10-7 2460 2420 4.0x10-7 2400 3.5x10-7 2380 3.0x10-7 2.5x10-7 2360 10 12 14 16 18 20 Moisture Content (%) Figure 5. Maximum density and saturated hydraulic conductivity results for sample M4 (50% brown sandstone and 50% gray sandstone). Dashed vertical line represents the minimum saturated hydraulic conductivity. R2=0.55 -1 Saturated Hydraulic Conductivity (cm s ) 3.5e-7 3.0e-7 2.5e-7 2.0e-7 1.5e-7 1.0e-7 5.0e-8 0.0 30 40 50 60 Fines (%) Figure 6. Saturated hydraulic conductivity versus the percentage of fines (silt and clay) in the spoil sample. 61 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 In all cases, the maximum saturated hydraulic conductivity occurred at a moisture content at or nearly at proctor (i.e. maximum density). This moisture content finding is in the lower range of those presented by Goldman et al. (1988). For the lowest saturated hydraulic conductivity, the authors reported moisture content values that were typically 2% above the moisture content required for proctor. Conclusions Isolating high specific conductance and Se producing spoils using a low permeability barrier (i.e. source reduction) is one possible method to help mitigate the impacts of mining operations on headwater streams. Such barriers or liners are commonly employed in landfills and in active coal mining operations where acid-forming strata are encountered. However, landfill liners are constructed of clay which is a material of limited quantities in the Appalachian coalfields. Furthermore, the shales and fire clays found in this region are often unacceptable due to elevated specific conductance and/or Se levels as these shales and clays are found adjacent to the coal seams. Sandstones on the other hand are abundant in the Appalachian coalfields and typically have low specific conductance and Se levels. The results of this laboratory study demonstrate that brown sandstones are a promising material for use in construction of a low permeability barrier to isolate problematic spoils provided that the sandstones used have low levels of specific conductance and leachable Se. The two brown sandstone spoils tested met or exceeded the recommended saturated hydraulic conductivity threshold of 1 x 10-7 cm s-1 for waste management facilities while the samples containing gray sandstone had higher values (e.g. were more permeable). As noted by Olson and Daniel (1981), saturated hydraulic conductivity values recorded in the laboratory are almost always lower than those recorded in the field. This difference is due to factors such as the screening of laboratory samples to remove gravels, roots, and other large items; the use of different compaction devices in the laboratory and the field; the presence of macro-pores, cracks or other preferential flow paths in larger field samples (Daniel, 1984; Stewart and T.W. Nolan 1987); and the challenges associated with achieving the optimal moisture content in the field. As such, it is expected that the achievable field saturated hydraulic conductivity values for the spoils examined in this study will be higher than the laboratory values measured. However, this does not mean that a low permeability barrier with saturated hydraulic conductivity value > 1 x 10- 62 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 7 cm s-1 is not acceptable when isolating problematic spoils. A higher value may provide the needed water quality protection. Acknowledgements The authors would like to thank Alex Fogle and Lloyd Dunn for their invaluable assistance in conducting this study. The authors would also like to thank the anonymous reviewers for their comments. This study was sponsored by the Appalachian Research Initiative for Environmental Science (ARIES). The views, opinions and recommendations expressed herein are solely those of the authors and do not imply any endorsement by ARIES employees, other ARIES-affiliated researchers, or industrial members. Information about ARIES can be found at http://www.energy.vt.edu/ARIES . Literature Cited Agouridis, C.T., P.N. Angel, T.J. Taylor, C.D. Barton, R.C. Warner, X. Yu, and C. Wood. 2012. Water quality characteristics of discharge from reforested loose-dumped mine spoil in eastern Kentucky. Journal of Environmental Quality 41: 454-468. [ASTM International] American Society for Testing and Materials International. 2006. D248706 Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). West Conshohocken, PA. [ASTM International] American Society for Testing and Materials International. 2010. D431810. Standard test methods for liquid limit, plastic limit, and plasticity index of soils. West Conshohocken, PA. [ASTM International] American Society for Testing and Materials International. 2012. D69812. Standard test methods for laboratory compaction characteristics of soils using standard effort (12 400 ft-lbf/ft3 (600 kN-m/m3)). West Conshohocken, PA. Barton, C.D. 2011. Coal mining versus water quality: An electrifying topic. American Water Resources Association Water Resources Impact 13: 23-24. Bradham, W.S., and F.T. Carrucio. 1990. A comparative study of tailings analysis using acid/base accounting, cells, columns, and soxhlets. p. 19-25. In Skousen et al. (ed.), Proceedings of the 1990 Mining and Reclamation Conference and Exhibition, Charleston, WV. 23-26 April 1990. American Society for Surface Mining and Reclamation. 63 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 Burger, J., D. Graves, P. Angel, V. Davis, and C. Zipper. 2005. The forestry reclamation approach. Appalachian Regional Reforestation Initiative, Office of Surface Mining. Forestry Reclamation Advisory Number 2. Burt, R., T.G. Reinsch, and W.P. Miller. 1993. A micro-pipette method for water dispersible clay. Communications in Soil Science and Plant Analysis 24: 2531-2544. Daniel, D.E. 1984. Predicting hydraulic conductivity of clay liners. Journal of Geotechnical Engineering 110: 285-300. Daniels, W.L, Z. Orndorff, M. Eick, and C. Zipper. 2013. Predicting TDS release from Appalachian Mine Spoils. p. 275-285. In J.R. Craynon (ed.). Environmental Considerations for Energy Production, Society of Mining, Metallurgy, and Exploration, Inc. Emerson, P. J. Skousen, and P. Ziemkiewicz. 2009. Survival and growth of hardwoods in brown versus gray sandstone on a surface mine in West Virginia. Journal of Environmental Quality 38: 1821-1829. Fallavena, V.L.V., T.D. Inácia, C.S. de Abreu, C.M.N. Azevedo, and M. Pires. 2012. Acidic peroxidation of Brazilian coal: desulfurization and estimation of the forms of sulfur. Energy and Fuels 26: 1135-1143. Fritz, K.M., S. Fulton, B.R. Johnson, C.D. Barton, J.D. Jack, D.A. Word, and R.A. Burke. 2010. Structural and functional characteristics of natural and constructed channels draining a reclaimed mountaintop removal and valley fill coal mine. Journal of the North American Benthological Society 29: 673-689. Goldman, L.J., L.I. Greenfield, A.S. Damle, and G.L. Kingsbury. 1988. Design, construction, and evaluation of clay liners for waste management facilities. EPA/530/SW-86/007F. U.S. Environmental Protection Agency, Office of Solid Waste and Emergency Response, Washington, D.C. Hageman, P.L. 2007. U.S. Geological Survey field leach test for assessing water reactivity and leaching potential of mine wastes, soils, and other geologic and environmental materials. U.S. Geological Survey Techniques and Methods, book 5, chapter D3. Hamilton, S.J. 2004. Review of selenium toxicity in the aquatic food chain. Science of the Total Environment 326: 1-31. 64 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 [IDT] Iowa Department of Transportation. 2013. Construction inspector’s course manual: Soils compaction and testing. Technical Training and Certification Program. Available at: http://www.iowadot.gov/training/ttcp/training_manuals/Soils.pdf. Janz, D.M. 2012. Selenium. pp. 327-374. In C.M. Wood, A.P. Farrell, and C.J. Brauner (eds.). Fish Physiology: Homeostasis and Toxicology of Essential Metals 31A. Johnson, D.B., and K.B. Hallberg. 2005. Acid mine drainage remediation options: a review. Science of the Total Environment 338: 3-14. Kang, J.B., and C.D. Shackelford. 2010. Membrane behavior of compacted clay liners. Journal of Geotechnical and Geoenvironmental Engineering 136: 1368-1382. Kim, T.H., T.H. Kim, G.C. Kang, and L. Ge. 2012. Factors influencing crack-induced tensile strength of compacted soil. Journal of Materials in Civil Engineering 24: 315-320. Kovski, A. 2012. Court rules EPA erred in using guidance to impose conductivity test on coal mines. Bloomberg Daily Environmental Report. August 1. Available at: http://www.bna.com/court-rules-epa-n12884910920/ . Lindberg, T.T., E.S. Barnhardt, R. Bier, A.M. Helton, R.B. Merola, A. Vengosh, and R.T. Di Giulio. 2011. Cumulative impacts of mountaintop mining on an Appalachian watershed. Proc Natl Acad Sci ;108(52):20929-34 Miller, J., C.D. Barton, C. Agouridis, A. Fogle, T. Dowdy, and P. Angel. 2012. Evaluating soil genesis and reforestation success on a surface coal mine in Appalachia. Soil Science Society of America Journal 76: 950-960. Miller, W.P., and D.M. Miller. 1987. A micropipette method for soil mechanical analysis. Communications in Soil Science and Plant Analysis 18: 1-15. Olson, R.E., and D.E. Daniel. 1981. Measurement of the hydraulic conductivity of fine-grained soils. pp. 18-64. In T.F. Zimmie and C.E. Riggs (eds.). Permeability and Groundwater Contaminant Transport, ASTM STP 746. American Society for Testing and Materials. [PDEP] Pennsylvania Department of Environmental Protection. 2011. Design, construction and maintenance standards for dam embankments associated with impoundments for oil and gas wells. 5500-PM-OG-0085 Rev. 1/2011. Commonwealth of Pennsylvania, Department of 65 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 Environmental Protection, Bureau of Waterways Engineering, Bureau of Oil and Gas Management. Pond, G.J., M.E. Passmore, F.A. Borsuk, L. Reynolds, and C.J. Rose. 2008. Downstream effects of mountaintop coal mining: Comparing biological conditions using family- and genus-level macroinvertebrate bioassessment tools. Journal of the North American Benthological Society 27: 717-737. SAS Institute. 2008. SAS user’s guide. Version 9. SAS Institute, Cary, NC. Skousen, J.G., A. Sexstone, and P.F. Ziemkiewicz. 2000. Acid mine drainage control and treatment. pp. 131-168. In F. Schaller (ed.). Reclamation of Drastically Disturbed Lands. American Society of Agronomy and American Society for Surface Mining and Reclamation, Agronomy No. 41. Skousen, J., J. Renton, H. Brown, P. Evans, B. Leavitt, K. Brady, L. Cohen, and P. Ziemkiewicz. 1997. Neutralization potential of overburden samples containing siderite. Journal of Environmental Quality 26: 673-681. Stewart, B.R., W.L. Daniels, L.W. Zelazny, and M.L. Jackson. 2001. Evaluation of leachates from coal refuse blended with fly ash at different rates. Journal of Environmental Quality 30: 1382-1391. Stewart, J.P., and T.W. Nolan. 1987. Infiltration testing for hydraulic conductivity of soil liners. Geotechnical Testing Journal 10: 41-50. [USDA-NRCS,] U.S. Department of Agriculture-Natural Resource Conservation Service. 2012. Soil Texture Calculator. Available at: http://soils.usda.gov/technical/aids/investigations/texture/. [USEPA] U.S. Environmental Protection Agency. 2011a. A field based aquatic life benchmark for conductivity in central Appalachian streams. Office of Research and Development. National Center for Environmental Assessment, Washington, D.C. EPA/600/R-10/023F. [USEPA] U.S. Environmental Protection Agency. 2011b. Memorandum, improving EPA review of Appalachian surface coal mining operations under the Clean Water Act, National Environmental Policy Act, and the Environmental Justice Executive Order. 66 Journal American Society of Mining and Reclamation, 2013 Volume 2, Issue 1 Vesper, D.J., M. Roy, and C. J. Rhoads. 2008. Selenium distribution and mode of occurrence in the Kanawha Formation, southern West Virginia, USA. International Journal of Coal Geology 73: 237-249. Ward, K. 2013. Groups seek EPA mountaintop removal rule. The Charleston Gazette. May 7. Available at: http://www.wvgazette.com/News/201305070218?page=2&build=cache . Warner, R.C. and C.T. Agouridis. 2010. Enhanced environmental protection through new valley fill design techniques. Presented at the 23rd Annual Kentucky Professional Engineers in Mining Seminar, Lexington, Kentucky, August 20th. Zipper, C., J. Burger, J. Skousen, P. Angel. C. Barton, V. Davis, and J. Franklin. 2011. Restoring forests and associated ecosystem services on Appalachian coal surface mines. Environmental Management 47 751-765. 67