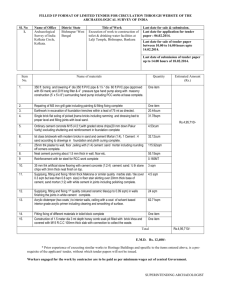

Improvement Development of Dispensary Seelampur market [-

advertisement

Improvement Development of Dispensary Seelampur market [--] by pdg.0 from in Jafrabad in Ward No.250 Shah(N) Zone. Item No. Description Quantity Rate Unit Amount 51.15 kg 3162.60 51.20 kg 2560.00 2592.70 sqm 12600.52 694.40 sqm 1475.60 676.75 sqm 84.59 556.60 sqm 40910.10 63.00 sqm 3279.78 220.85 sqm 11497.45 108.00 each 216.00 163.40 metre 3268.00 96.90 each 969.00 77.55 62.15 21.40 sqm sqm sqm 10791.08 3402.09 176.44 r.No 1 10.13 2 10.25.2 3 10.3 4 11.26.1 5 11.27 6 11.36 7 12.15.1 8 12.16.1 9 12.22 10 12.41.2 11 12.43.2 12 13 14 13.1.1 13.16.1 13.18 10.13 Providing and fixing T-iron frames for doors, windows and ventilators of mild steel Tee-sections, joints mitred and welded with 15x3 mm lugs 10cm long embedded in cement concrete blocks 15x10x10 cm of 1:3:6 (1 cement : 3 coarse sand : 6 graded stone 61.83 aggregate 20 mm nominal size) or with wooden plugs and screws or rawl plugs and screws or with dash fastener or with fixing clips or with bolts and nuts as required including fixing of necessary butt hinges and screws and applying a priming coat of approved steel primer. 10.25 Steel work welded in built up sections/ framed work including cutting, hoisting, fixing in position and applying a priming coat of approved steel primer using structural steel etc. as required. 10.25.2 In 50.00 gratings, frames, guard bar, ladder, railings, brackets, gates and similar works. 10.3 Providing and fixing in position collapsible steel shutters with vertical channels 20x10x2mm and braced with flat iron diagonals 20x5mm size with top and bottom rail of T-iron 40x40x6mm with 40mm 4.86 dia, steel pulleys complete with bolts, nuts, locking arrangement, stoppers, handles, including applying a priming coat of approved steel primer. 11.26 Kota stone slab flooring over 20 mm (average) thick base laid over and jointed with grey cement slurry mixed with pigment to match the shade of the slab including rubbing and polishing complete with 2.13 base of cement mortar 1 : 4 (1 cement : 4 coarse sand) : 11.26.1 25 mm thick. 11.27 Kota stone slabs 25 mm thick in risers of steps, skirting, dado and pillars laid on 12 mm (average) thick cement mortar 1:3 (1 cement 3 coarse sand) and jointed with grey cement slurry mixed with .13 pigment to match the shade of the slabs, including rubbing and polishing complete. 11.36 Providing and fixing Ist quality ceramic glazed wall tiles conforming to IS : 15622 (thickness to be specified by the manufacturer ) of approved make in all colours, shades except burgundy, bottle green, black of any size as approved by Engineer-in73.50 Charge in skirting, risers of steps and dados over 12 mm thick bed of cement Mortar 1:3 (1 cement : 3 coarse sand) and jointing with grey cement slurry at the rate 3.3kg per sqm including pointing in white cement mixed with pigment of matching shade complete. 12.15 Painting top of roofs with bitumen of approved quality at 17kg per 10 sqm impregnated with a coat of coarse sand at 60 cu dm per 10sqm including cleaning the slab surface with brushes and finally 52.06 with a piece of cloth lightly soaked in kerosene oil complete : 12.15.1 With residual type petroleum bitumen of penetration 80/100 12.16 10 cm thick (average) mud phaska of damped brick earth on roofs laid to slope consolidated and plastered with 25 mm thick mud mortar mixed with bhusa at 35 kg per cum of earth and gobri leaping with mix 1:1 (1 clay : 1 cow dung) and covered with flat tile bricks of 52.06 class designation 100 grouted with cement mortar 1:3 (1 cement : 3 fine sand) mixed with 2 percentage of integral water proofing compound by weight of cement and finished neat : 12.16.1 With F.P.S. brick tiles 12.22 Making khurras 45x45 cm with average minimum thickness of 5 cm cement concrete 1:2:4 (1 cement : 2 coarse sand : 4 graded stone aggregate of 20 mm nominal size) over P.V.C. sheet 2.00 1mx1mx400micron, finished with 12mm cement plaster 1:3 (1 cement : 3 coarse sand) and a coat of neat cement rounding the edge sand making and finishing the outlet complete. 12.41 Providing and fixing on wall face un plasticised Rigid PVC rain water pipes conforming to IS : 13592 Type A including jointing with 20.00 seal ring conforming to IS : 5382 leaving 10 mm gap for thermal expansion.(i) Single socketed pipes. 12.41.2 110 mm diameter 12.43 Providing and fixing unplasticised -PVC pipe clips of approved design to unplasticised - PVC rain water pipes by means of 50x50x50mm hard wood plugs, screwed with M.S. screws of required 10.00 length including cutting brick work and fixing in cement mortar 1:4 (1 cement : 4 coarse sand) and making good the wall etc. complete. 12.43.2 110 mm 13.1 12 mm cement plaster of mix : 13.1.1 1:4 (1 cement: 4 fine sand) 139.15 13.16 6 mm cement plaster of mix : 13.16.1 1:3 (1 cement: 3 fine sand) 54.74 13.18 Neat cement punning 8.25 15 13.37.1 16 13.45.1 17 13.61.1 18 15.2.1 19 15.23.1 20 15.27 21 15.56 22 17.1.1 23 17.28.2.1 24 17.7.4 25 18.17.1 26 18.48 27 18.54.1 28 18.55.1 29 18.56.1 30 18.7.2 31 18.7.3 32 19.21.2 33 19.27.1 13.37 White washing with lime to give an even shade: 13.37.1 New 54.74 work (three or more coats) 13.45 Finishing walls with textured exterior paint of required shade : 13.45.1 New work (Two or more coats applied at the rate 3.28 ltr/10 10.00 sqm) over and including base coat of water proofing cement paint applied at the rate 2.20kg/10 sqm. 13.61 Painting with synthetic enamel paint of approved brand and manufacture to give an even shade : 13.61.1 Two or more coats on 4.86 new work 15.2 Demolishing cement concrete manually/ by mechanical means including disposal of material within 50 metres lead as per direction of 2.43 Engineer - in - charge. 15.2.1 1:3:6 or richer mix 15.23 Dismantling tile work in floors and roofs laid in cement mortar including stacking material within 50 metres lead. 15.23.1 For 73.50 thickness of tiles 10 mm to 25 mm 15.27 Demolishing mud phaska in terracing and disposal of material 3.86 within 50 metres lead. 15.56 Dismantling old plaster or skirting raking out joints and cleaning the surface for plaster including disposal of rubbish to the dumping 176.72 ground within 50 metres lead. 17.1 Providing and fixing water closet squatting pan (Indian type W.C. pan ) with 100mm sand cast Iron P or S trap, 10 litre low level white P.V.C. flushing cistern with manually controlled device (handle lever) conforming to IS : 7231, with all fittings and fixtures complete 1.00 including cutting and making good the walls and floors wherever required : 17.1.1 White Vitreous china Orissa pattern W.C. pan of size 580x440mm with integral type foot rests. 17.28 Providing and fixing P.V.C. waste pipe for sink or wash basin including P.V.C. waste fittings complete. 17.28.2 Flexible pipe 17.28.2.1 1.00 32 mm dia 17.7 Providing and fixing wash basin with C.I. brackets, 15 mm C.P. brass pillar taps,32 mm C.P. brass waste of standard pattern, including painting of fittings and brackets, cutting and making good 1.00 the walls wherever require : 17.7.4 White Vitreous China Flat back wash basin size 550x400 mm with single 15 mm C.P. brass pillar tap. 18.17 Providing and fixing gun metal gate valve with C.I. wheel of 1.00 approved quality (screwed end) : 18.17.1 25 mm nominal bore 18.48 Providing and placing on terrace (at all floor levels) polyethylene water storage tank ISI : 12701 marked with cover and suitable locking 1000.00 arrangement and making necessary holes for inlet, outlet and overflow pipes but without fittings and the base support for tank 18.54 Providing and fixing PTMT bib cock of approved quality and colour. 18.54.1 15mm nominal bore, 86 mm long. Weighing not less 2.00 than 88 gms. 18.55 Providing and fixing PTMT stop cock of approved quality and colour. 18.55.1 15 mm nominal bore,86mm long. Weighing not less 1.00 than 88 gms. 18.56 Providing and fixing PTMT pillar cock of approved quality and colour . 18.56.1 15mm nominal bore, 107mm long. Weighing not less 1.00 than 110 gms. 18.7 Providing and fixing Chlorinated Polyvinyl Chloride (CPVC) pipes, having thermal stability for hot and cold water supply including all CPVC plain and brass threaded fittings including fixing the pipe with clamps at 1.00 m spacing. This includes jointing of pipes and fittings 15.00 with one step CPVC solvent cement and testing of joints complete as per direction of Engineer in Charge Internal work - Exposed on wall: 18.7.2 20 mm nominal outer dia .Pipes. 18.7 Providing and fixing Chlorinated Polyvinyl Chloride (CPVC) pipes, having thermal stability for hot and cold water supply including all CPVC plain and brass threaded fittings including fixing the pipe with clamps at 1.00 m spacing. This includes jointing of pipes and fittings 15.00 with one step CPVC solvent cement and testing of joints complete as per direction of Engineer in Charge Internal work - Exposed on wall: 18.7.3 25 mm nominal outer dia .Pipes. 19.21 Making connection of drain or sewer line with existing manhole including breaking into and making good the walls, floors with cement concrete 1:2:4 mix (1 cement : 2 coarse sand : 4 graded stone aggregate 20 mm nominal size) cement plastered on both sides with 1.00 cement mortar 1:3 (1 cement : 3 coarse sand) finished with a floating coat of neat cement and making necessary channels for the drain etc. complete : 19.21.2 For pipes 250 to 300 mm diameter 19.27 Constructing brick masonry road gully chamber 50x45x60 cm with bricks of class designation 75 in cement mortar 1:4 (1 cement : 4 coarse sand) including 500x450 mm pre-cast R.C.C. horizontal grating 1.00 with frame complete as per standard design : 19.27.1 With F.P.S. bricks 6.75 sqm 369.50 96.25 sqm 962.50 35.35 sqm 171.80 368.45 cum 894.30 10.90 sqm 801.14 137.90 cum 532.76 8.20 sqm 1449.07 2304.65 each 2304.65 46.80 each 46.80 1044.90 each 1044.90 285.50 each 285.50 5.25 per litre 5250.00 120.85 each 241.70 120.85 each 120.85 185.25 each 185.25 115.65 metre 1734.75 150.40 metre 2256.00 205.40 each 205.40 2248.35 each 2248.35 34 19.9.1.1 35 4.1.3 36 5.22.6 37 5.3 38 5.9.3 39 9.120.1 40 9.63.1 41 9.66.1 42 9.96.1 43 mcd16.a 19.9 Constructing brick masonry circular type manhole 0.91m internal dia at bottom and 0.56m dia at top in cement mortar 1:4 (1 cement :4 coarse sand), in side cement plaster 12 mm thick with cement mortar 1:3 (1 cement : 3 coarse sand) finished with a floating coat of neat cement, foundation concrete 1:3:6 mix (1 cement : 3 coarse sand : 6 graded stone aggregate 40mm nominal size), and making necessary channel in cement concrete 1:2:4 (1 cement : 2 coarse sand : 4 graded stone aggregate 20mm nominal size) finished with a floating coat of neat cement all complete as per standard design : 19.9.1 0.91 m deep with S.F.R.C. cover and frame (heavy duty, HD-20 grade designation) 560mm internal diameter conforming to I.S. 12592, total weight of cover and frame to be not less than 182kg., fixed in cement concrete 1:2:4 (1 cement : 2 coarse sand : 4 graded stone aggregate 20 mm nominal size) including centering shuttering all complete. (Excavation, foot rests and 12mm thick cement plaster at the external surface shall be paid for separately) : 19.9.1.1 With F.P.S. bricks class designation 75 4.1 Providing and laying in position cement concrete of specified grade excluding the cost of centering and shuttering - All work up to plinth level : 4.1.3 1:2:4 (1 cement :2 coarse sand : 4 graded stone aggregate 20 mm nominal size) 5.22 Reinforcement for R.C.C. work including straightening, cutting, bending, placing in position and binding all complete upto plinth level. 5.22.6 Thermo-Mechanically Treated bars. 5.3 Reinforced cement concrete work in beams, suspended floors, roofs having slope up to 15 landings, balconies, shelves, chajjas, lintels, bands, plain window sills, staircases and spiral stair cases up to floor five level excluding the cost of centering, shuttering, finishing and reinforcement with 1:2:4 (1 cement : 2 coarse sand : 4 graded stone aggregate 20 mm nominal size). 5.9 Centering and shuttering including strutting, propping etc. and removal of form for : 5.9.3 Suspended floors, roofs, landings, balconies and access platform. 9.120 Providing and fixing to existing door frames. 9.120.1 30mm thick factory made panel PVC door shutter consisting of frame made out of M.S. tubes of 19 gauge thickness and size of 19mm x 19mm for styles and 15x15mm for top and bottom rails. M.S. frame shall have a coat of steel primers of approved make and manufacture . M.S. frame covered with 5mm thick heat moulded PVC C channel of size 30mm thickness, 70mm width out of which 50mm shall be flat and 20mm shall be tapered in 45degree angle on either side forming styles; and 5mm thick, 95mm wide PVC sheet out of which 75mm shall be flat and 20mm shall be tapered in 45 degree on the inner side to form top and bottom rail and 115mm wide PVC sheet out of which 75mm shall be flat and 20mm shall be tapered on both sides to form lock rail. Top, bottom and lock rails shall be provided either side of the panel. 10mm (5mm x 2 ) thick, 20mm wide cross PVC sheet be provided as gap insert for top rail and bottom rail. paneling of 5mm thick both side PVC sheet to be fitted in the M.S. frame welded/ sealed to the styles and rails with 7mm (5mm+2mm) thick x 15mm wide PVC sheet beading on inner side, and joined together with solvent cement adhesive. An additional 5mm thick PVC strip of 20mm width is to be stuck on the interior side of the C Channel using PVC solvent adhesive etc. complete as per direction of Engineer-in-charge. Manufacturers specification and drawing (for W.C. and bathroom door shutter). 9.63 Providing and fixing ISI marked oxidised M.S. tower bolt black finish, (Barrel type) with necessary screws etc. complete : 9.63.1 250x10 mm 9.66 Providing and fixing ISI marked oxidised M.S. handles conforming to IS:4992 with necessary screws etc. complete : 9.66.1 125 mm 9.96 Providing and fixing aluminium sliding door bolts ISI marked anodised (anodic coating not less than grade AC 10 as per IS : 1868) transparent or dyed to required colour or shade with nuts and screws etc. complete : 9.96.1 300x16 mm mcd16 24mm thick washed marble chips plaster on exterior walls of height upto 10 m above groung level in two layers under layer 12 mm cement plaster 1:4 (1 cement: 4 coarse sand) furrowing the under layer with scratching tool, applying cement slurry on the under layer at the rate 2 kg of cement/sqm, top layer 12mm thick cement marble chips plaster 4:7 (4cement : 7marble chips 4mm size) in panel with grooves all around as per approved pattern including scrubbing and washing the top layer with brushes and water to expose the marble chips complete as per specifications and directions of Engineer in charge [payment for providing groove shall be made for seperately]. mcd16.a Using ordinary cement in top layer. 1.00 4933.50 each 4933.50 3.03 3257.45 cum 9883.10 98.40 42.70 kg 4201.68 .82 3673.85 cum 3029.09 10.34 187.35 sqm 1936.27 5.67 2109.95 sqm 11963.42 2.00 33.90 each 67.80 2.00 10.20 each 20.40 2.00 158.50 each 317.00 23.97 230.85 sqm 5534.63 Sub Total 157385.36