Problem Statement

advertisement

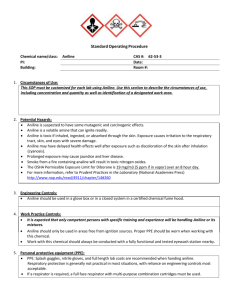

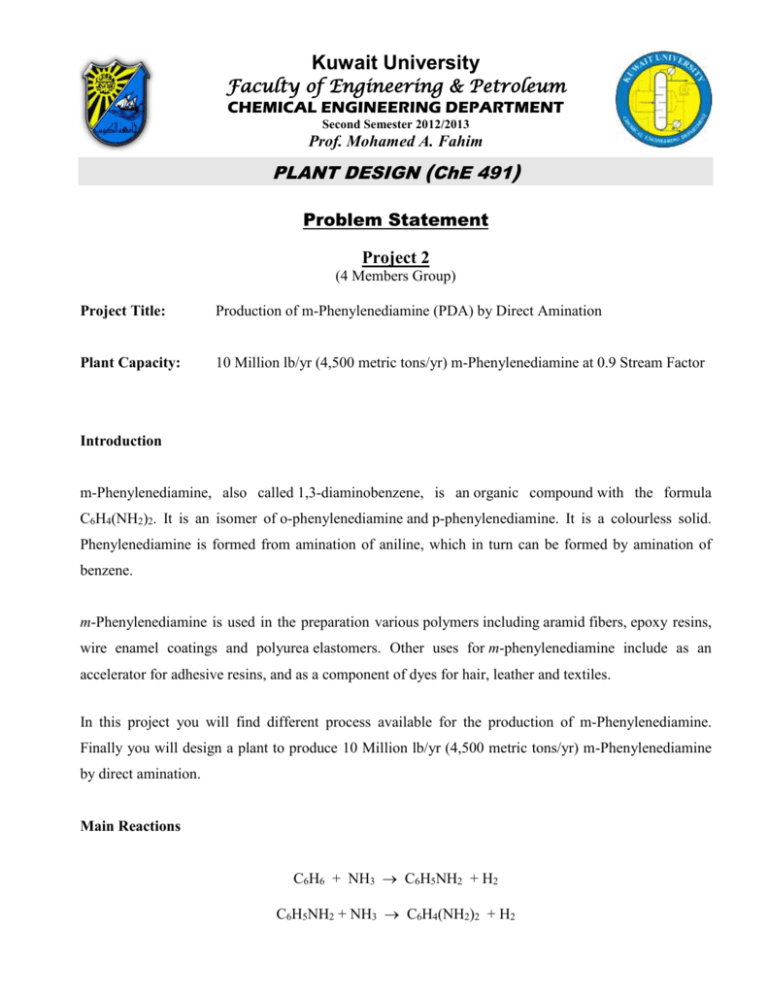

Kuwait University Faculty of Engineering & Petroleum CHEMICAL ENGINEERING DEPARTMENT Second Semester 2012/2013 Prof. Mohamed A. Fahim PLANT DESIGN (ChE 491) Problem Statement Project 2 (4 Members Group) Project Title: Production of m-Phenylenediamine (PDA) by Direct Amination Plant Capacity: 10 Million lb/yr (4,500 metric tons/yr) m-Phenylenediamine at 0.9 Stream Factor Introduction m-Phenylenediamine, also called 1,3-diaminobenzene, is an organic compound with the formula C6H4(NH2)2. It is an isomer of o-phenylenediamine and p-phenylenediamine. It is a colourless solid. Phenylenediamine is formed from amination of aniline, which in turn can be formed by amination of benzene. m-Phenylenediamine is used in the preparation various polymers including aramid fibers, epoxy resins, wire enamel coatings and polyurea elastomers. Other uses for m-phenylenediamine include as an accelerator for adhesive resins, and as a component of dyes for hair, leather and textiles. In this project you will find different process available for the production of m-Phenylenediamine. Finally you will design a plant to produce 10 Million lb/yr (4,500 metric tons/yr) m-Phenylenediamine by direct amination. Main Reactions C6H6 + NH3 C6H5NH2 + H2 C6H5NH2 + NH3 C6H4(NH2)2 + H2 Design Bases and Assumptions Reaction conditions 4500 psia, 660oF Catalyst Ni/Mg/Zr Space velocity in catalyst 14.5 lb/lb-hr Per pass yield (mol) Benzene to aniline, 7.3% Aniline to Phenylenediamines, 8.3% Excess ammonia in feed 39 times stoichiometric Selectivity 95% on benzene and aniline 98% on ammonia Phenylenediamines 74% meta isomer Ammonia loss 0.9% of circulation Feeds Pure Benzene 678 lb/hr Pure Ammonia 556 lb/hr Pure Aniline 923 lb/hr Final Product Pure m-Phenylenediamine 1,268 lb/yr The process should be designed to produce to produce 10 Million lb/yr (4,500 metric tons/yr) m-Phenylenediamine by direct amination. You are required to carry out the project by completing the following tasks and submit a formal report on each task: TASK LIST Task 1: Literature Survey (Report submission date: 17/02/2013) 1. Various process routes for the production of m-Phenylenediamine 2. Properties of raw materials and final products. 3. Uses of m-Phenylenediamine. Task 2: HYSYS Simulation (Report submission date: 17/03/2013) Simulation of m-Phenylenediamine production process by direct amination using one selected process flow-sheet. Task 3: Equipment Design (Report submission date: 14/04/2013) Perform detailed design calculations of all the major and minor equipments in your plant and report its size, construction details, material of construction and instrumentation & control. Task 4: Environmental Effects, Safety and Health Hazard (Report submission date: 28/04/2013) Assessment of environmental and safety features taken in the plant design and report health hazards. Task 5: Economic evaluation (Report submission date: 28/04/2013) Perform economic study and project evolution for the selected plant. Task 6: Final Report (Report submission date: 5/5/2013) Submit final report for whole project.