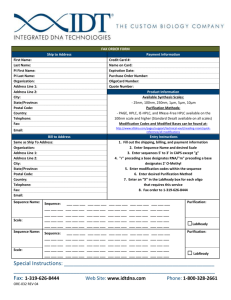

full press release

advertisement

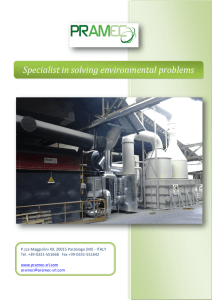

Press release March 2015 KBA-CleanAir – Converting Exhaust Air to Energy Efficient solutions for air purification and heat storage KBA-MetalPrint, a subsidiary of Koenig & Bauer, the world's second largest printing press manufacturer, is the market leader in metal decorating. The product range includes printing and coating lines, drying technology and air purification systems. KBA-CleanAir, the environmental division of KBA, offers efficient solutions for the purification of solvent-polluted or odour intensive exhaust air. Steadily increasing legal demands call for the development of new solutions, in particular for industries with aggressive exhaust air streams or strong odour problems. The KBA-CleanAir portfolio includes thermal recuperative, thermal regenerative and catalytic air purification systems. The ZEROClean concept deploys a combination of concentration and thermal post treatment. Typical areas of applications are all solvent-processing or odour-producing industries, such as the printing industry, surface finishing, metal packaging industry, coating, dye and paint manufacture, chemical industry and plastics manufacture. Air purification systems are also increasingly applied in industries associated with offensive odours, such as the animal meal industry, the fish industry, coffee roasting plants or breweries. By numerous innovations KBA-CleanAir demonstrates their competence. XtraActiveTM, the new and innovative ceramic heat exchanger material based on nanoparticle technology significantly reduces the energy consumption of air purification systems. Sophisticated energy management systems drive down the operational costs to an absolute minimum and optimize the system availability. Yet another example of this innovative strength is its high-temperature heat storage system. KBA-CleanAir has developed a worldwide brand-new solution for the storage and deferred use of thermal energy/surplus energy and successfully piloted at the solar tower power plant in Jülich, Germany. This technology enables the storage of solar energy or waste process heat at temperatures of up to 1000° C for use at a later, user- defined, date. Areas of application are energy-intensive industries, such as iron, steel and aluminium production, glass, brick and ceramic manufacture, chemical industries and solar tower power plants. Regenerative thermal oxidisers (RTOs) for example are suitable for operation as heat storage systems. KBA-CleanAir is constantly working to improve these concepts and, in this context, is currently working together with the Deutsches Zentrum für Luft- und Raumfahrt (DLR German Aerospace Center) on a research project for high-temperature solid media storage systems. The results and insights from this project will be incorporated in the technical design of standard products, thus ensuring the highest product standards. RTO in 3-canister design in the automotive industry for an exhaust air volume of 100,000 m³/h For more details please contact: KBA-MetalPrint GmbH KBA-CleanAir Division Dietmar Decker Wernerstr. 119-129 D-70597 Stuttgart Tel: +49-711-69971-0 Fax: +49-711-69971-670 cleanair@kba-metalprint.de www.kba-cleanair.de Your contact at ICE: Dietmar Decker Mobile: +49-172 7103565 dietmar.decker@kba-metalprint.de