Additional File 1

advertisement

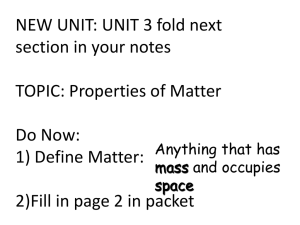

Additional File 1: Network Diagrams Civic Chicken Producer 1: production of 1 kg of chicken meat and CO2 equiv emissions 1 kg Chicken meat, CivicP1 7.66 kg CO2 229 bird.days Growing birds, CivicP1 7.66 kg CO2 1.66 kg Layer mix, feed for chickens 0.589 kg CO2 0.554 kg Grain maize IP, at farm/CH U 0.301 kg CO2 1.11 kg Scratch mix for chickens, at regional store 0.563 kg CO2 5.83E-5 m3 Tractor use, per litre diesel consumed/AU U 0.192 kg CO2 3.5 MJ Tractor engine, low population area/AU U 0.299 kg CO2 12.1 kg Lucerne, at regional store 1.15E4 m Car, average, per km travelled/AU U 0.934 kg CO2 0.225 kg Lime, calcined, at regional store/AU U 0.268 kg CO2 4.33 kg CO2 2.79 tkm Transport, articulated truck, >20t, fleet 0.29 kg CO2 1.04E4 m Car, petrol, per km travelled/AU U 3.93 kg CO2 0.898 kg Petrol, unleaded, at consumer/AU U 0.599 kg CO2 0.00125 m3 Refining petrol, unleaded/AU U 0.303 kg CO2 3.57 MJ Energy, from fuel oil, just fuel, CO2,CH4, & 0.277 kg CO2 229 bird.days Manure managment, backyard 1.27 kg CO2 -0.812 kg Urea, at regional storehouse/RER U/Adapted/AU U -1.25 kg CO2 -0.419 kg Ammonia, steam reforming, liquid, at plant/RER -0.796 kg CO2 1.19 kg Crude oil, australian average, at 0.352 kg CO2 0.00101 m3 Crude oil, imported/GLO U 0.259 kg CO2 0.00148 m3 Crude oil exploration and extraction/AU U 0.297 kg CO2 In this model about 7.7kg CO2 equivalent emissions are produced for one kg of cooked chicken meat on the consumer’s table. The main contributors are the feed- the layer and scratch mixes together account for about 2kg –and car travel by Civic Chicken Producer 1 to collect feed contributes about 4 kg, assuming that only feed is collected during the trip. If other items shared the fuel usage, this contribution would be diminished. (Aim to check this later by re-doing model accordingly). Manure management contributes an offset by reducing the need for synthetic fertiliser production. Civic Chicken Producer 1 and production of 1 kg of chicken meat: land use (hectareyrs) 1 kg Chicken meat, CivicP1 0.00514 Ha a 229 bird.days Growing birds, CivicP1 0.00514 Ha a 12.1 kg Lucerne, at regional store 1.11 kg Scratch mix for chickens, at regional store 1.66 kg Layer mix, feed for chickens 0.000815 Ha a 0.000493 Ha a 0.000666 Ha a 0.332 kg Lupins, at farm/AU U 0.332 kg Soybean, at farm/AU U 0.775 kg Wheat, at farm/AU U 0.000228 Ha a 0.000166 Ha a 0.000476 Ha a 0.221 kg Canola seed, at farm/AU U 0.000176 Ha a 8.1 m2 Land occupation including background N2O emissions 0.00081 Ha a In this model 0.005 hectare-years (50 sq metres over one year) are used to provide for 1kg of chicken meat. Wheat is the major contributor to land use accounting for the largest component. The space required by the birds themselves was about 6 sqm for 4 meat (weight 800 grams) chickens for 5 months. This is approximately 1.2 square metres per kilogram of chicken meat per year. Civic Chicken Producer 1 and production of 1 kg of chicken meat water use cubic metres 1 kg Chicken meat, CivicP1 0.173 M3 H2O 229 bird.days Growing birds, CivicP1 0.173 M3 H2O 1.66 kg Layer mix, feed for chickens 0.00269 M3 H2O 1.11 kg Scratch mix for chickens, at regional store 12.1 kg Lucerne, at regional store 1.15E4 m Car, average, per km travelled/AU U 229 bird.days Manure managment, backyard 0.0144 M3 H2O -0.00335 M3 H2O 0.0396 M3 H2O 0.00885 M3 H2O 0.221 kg Sweet sorghum grains, at farm/CN U 0.105 kg DAP, production & application, including N2O emission 0.0376 M3 H2O 0.00611 M3 H2O 0.0131 M3 H2O 0.145 kg Diammonium phosphate, at regional store/RER U/Adapted/AU U 0.00842 M3 H2O 4.83E-5 p Passenger car/RER/I S 0.306 m2 Irrigating/ha/CH U 0.0371 M3 H2O 1.04E4 m Car, petrol, per km travelled/AU U 0.00658 M3 H2O -0.812 kg Urea, at regional storehouse/RER U/Adapted/AU U -0.00325 M3 H2O 0.00882 my Operation, maintenance, road/CH/I S 0.00407 M3 H2O 0.0924 kg Phosphoric acid, fertiliser grade, 70% in H2O, at plant/US U/Adapted/AU U 0.00793 M3 H2O 0.141 kg Sulphuric acid, liquid, at plant/RER U/Adapted/AU U 0.00762 M3 H2O In this model 0.17 cubic metres of water are used, primarily in production of feed. This model includes rain water used on site for the 4 chickens to drink. Note that a big impact seems to be from irrigated sorghum based on CH (Swiss) data. (Aim to re-do the model with Australian data if possible). Manure management contributes an offset by reducing the need for synthetic fertiliser. Civic Chicken Producer 2 and production of 1 kg of chicken meat: CO2 equivalent emissions version 1 kg Chicken meat, CivicP2 3.97 kg CO2 28.1 bird.days Growing birds, CivicP2 3.94 kg CO2 6.32 kg Grower 1, feed for industrial chickens, at farm 0.312 p Hatched eggs,CivicP2 2.47 kg CO2 1.69 kg Sweet sorghum grains, at farm/CN U 0.492 kg CO2 1.85 kg Wheat, at farm/AU U 0.546 kg CO2 5.71 MJ Tractor engine, low population area/AU U 0.487 kg CO2 0.858 kg Soybean, at farm/AU U 0.215 kg CO2 1.25 kg CO2 0.556 kg Canola seed, at farm/AU U 0.376 kg CO2 7.08E-5 m3 Tractor use, per litre diesel consumed/AU U 0.234 kg CO2 1.24 MJ Electricity, low voltage, Eastern Australia/AU U 0.375 kg CO2 1.32 MJ Electricity, high voltage, Eastern Australian/AU U 0.38 kg CO2 3.92 MJ Electricity,lLow voltage, Australian/AU U 1.15 kg CO2 4.02 MJ Electricity, high voltage, Australian/AU U 1.11 kg CO2 0.357 p Eggs delivery,CivicP2 0.182 kg CO2 3.31 bird.days Breeding birds, industrial chicken production 0.182 kg CO2 4.14 MJ Electricity, high voltage, New South Wales/AU U 1.11 kg CO2 4.52 MJ Electricity, black coal NSW, sent out /AU U 1.23 kg CO2 In this model it is estimated that production of 1 kg of chicken meat leads to 3.97 kg of CO2 equivalent. The major contributor is production of feed for the chickens. More detail about the production of wheat as part of this process is shown in the next diagram. Electricity used to hatch the eggs also has some impact on CO2 emissions. The cooking process of one hour in a gas oven is not included here, but would only contribute a small component (0.21 kg CO2 equivalent emissions). Civic Chicken Producer 2 and production of 1 kg of chicken meat: land use. Hectareyears 1 kg Chicken meat, CivicP2 0.00257 Ha a 28.1 bird.days Growing birds, CivicP2 0.00257 Ha a 6.32 kg Grower 1, feed for industrial chickens, at farm 0.312 p Hatched eggs,CivicP2 0.00237 Ha a 1.85 kg Wheat, at farm/AU U 0.00113 Ha a 0.858 kg Soybean, at farm/AU U 0.00043 Ha a 0.485 kg Oats 0.000298 Ha a 0.000151 Ha a 0.556 kg Canola seed, at farm/AU U 0.000442 Ha a 0.275 kg Blood and bone meal 0.000314 Ha a 0.459 kg Lupins, at farm/AU U 0.000314 Ha a 0.357 p Eggs delivery,CivicP2 0.000145 Ha a 3.31 bird.days Breeding birds, industrial chicken production 0.000145 Ha a In this model, 0.003 hectare-years (30 sq metres over one year) are used to produce 1kg meat. Growing the feed produces the greatest impact on land use, especially wheat. To produce 1kg of chicken meat requires 0.003 hectare-years (note: one hectare is 10,000 sq metres or 2.45 acres) The space taken by the birds themselves is about 0.25 acre (approx 1000 sq m ) to raise approximately 490 kg (140 chickens of size 3.5kg) in one year or about 2sq m per kg meat produced in one year. Civic Chicken Producer 2 and production of 1 kg of chicken meat: water use in cubic metre (5% cutoff) 1 kg Chicken meat, CivicP2 0.315 M3 H2O 28.1 bird.days Growing birds, CivicP2 0.313 M3 H2O 6.32 kg Grower 1, feed for industrial chickens, at farm 0.281 M3 H2O 1.69 kg Sweet sorghum grains, at farm/CN U 0.286 M3 H2O 2.33 m2 Irrigating/ha/CH U 0.283 M3 H2O 0.312 p Hatched eggs,CivicP2 0.022 M3 H2O 0.357 p Eggs delivery,CivicP2 0.0199 M3 H2O 3.31 bird.days Breeding birds, industrial chicken production 0.0199 M3 H2O In this model, 0.32 cubic metre of water is used, primarily in production of feed. Note that the big impact seems to be from irrigated sorghum based on CH (Switzerland) data which may not be representative for Australia. In the final papers, models will incorporate Australian data. Dam water for drinking and heated Sydney water used in the harvesting process contributes only minimally to the overall usage of water in this model. Local industrial production of 1 kg of chicken meat and CO2 equivalent emissions 1 kg Chicken meat, industrial production, on table 2.58 kg CO2 1 kg Harvested chicken, industrial production, at plant 2.48 kg CO2 20.4 bird.days Growing birds, industrial chicken production 2.21 kg CO2 0.725 p Hatched eggs, industrial chicken production at plant 0.43 kg CO2 0.943 p Eggs delivery, industrial chicken production, at plant 0.37 kg CO2 6.6 bird.days Breeding birds, industrial chicken production 0.363 kg CO2 0.551 kg Grower 1, feed for industrial chickens, at farm 0.215 kg CO2 0.246 kg Grower 2, feed for industrial chickens, at farm 0.125 kg CO2 0.922 kg Sweet sorghum grains, at farm/CN U 0.269 kg CO2 1.06 kg Finisher, feed for industrial chickens, at farm 0.331 kg CO2 1.04 kg Wheat, at farm/AU U 0.307 kg CO2 0.83 MJ Electricity, low voltage, New South Wales/AU U 0.234 kg CO2 0.733 kg Withdrawal, feed for industrial chickens, at farm 0.305 kg CO2 0.198 kg Canola seed, at farm/AU U 0.134 kg CO2 2.76 MJ Electricity,lLow voltage, Australian/AU U 0.807 kg CO2 2.9 MJ Electricity, high voltage, Australian/AU U 0.804 kg CO2 1.9 MJ Tractor engine, low population area/AU U 3.86 MJ Electricity, high voltage, New South Wales/AU U 0.162 kg CO2 1.04 kg CO2 27.9 bird.days Manure managment 0.151 kg CO2 -0.0795 kg Urea, at regional storehouse/RER U/Adapted/AU U -0.123 kg CO2 3.88 MJ Electricity, black coal NSW, sent out /AU U 1.06 kg CO2 *(10% contribution cut off used as model has so many components) In this model 2.58 kg CO2 equivalent emissions are produced for one kg chicken meat on the consumer’s table; a further 0.21kg would be produced to cook the chicken in a gas oven for one hour. The main contributor is the feed; there is a small offset due to the use of chicken manure as a fertilizer which offsets the need to use synthetic fertilizers. Car travel by the consumer 5km to buy the chicken from the supermarket accounted for about 5% of the total CO2 equivalent emissions, assuming that the chicken was about 5% of groceries bought at the same time (based on monetary value). If other items were not bought in conjunction with the chicken, this contribution would be considerably increased. Local industrial production of 1 kg of chicken meat: land use Hectare-years 1 kg Chicken meat, industrial production, on table 0.000905 Ha a 1 kg Harvested chicken, industrial production, at plant 0.000904 Ha a 20.4 bird.days Growing birds, industrial chicken production 0.2 kg Disposal of chicken inerds. 0.00122 Ha a 0.725 p Hatched eggs, industrial chicken production at plant 0.000312 Ha a 0.943 p Eggs delivery, industrial chicken production, at plant 0.00029 Ha a 0.346 kg Starter, feed for industrial chickens, at farm 0.000151 Ha a 0.551 kg Grower 1, feed for industrial chickens, at farm -0.000228 Ha a 0.246 kg Grower 2, feed for industrial chickens, at farm 0.000207 Ha a 0.000106 Ha a 0.216 kg Soybean, at farm/AU U 1.04 kg Wheat, at farm/AU U 0.000108 Ha a 0.000637 Ha a 1.06 kg Finisher, feed for industrial chickens, at farm 0.000407 Ha a 0.137 kg Oats 8.4E-5 Ha a 0.733 kg Withdrawal, feed for industrial chickens, at farm -0.286 kg Lupins, at farm/AU U 0.000259 Ha a -0.000196 Ha a 0.198 kg Canola seed, at farm/AU U 0.000158 Ha a 0.05 kg Disposal of feather meal -8.56E-5 Ha a 0.104 kg Blood and bone meal 0.000118 Ha a 6.6 bird.days Breeding birds, industrial chicken production 0.00029 Ha a In this model 0.0009 hectare-years are used to produce 1 kg of chicken meat. The feed production dominates the land use pattern. In terms of land actually occupied by chickens at the grower farms in one year, 1 m2 at grower farm can grow 223.2kg chicken meat (16.9chickens x 5.5 batches=93 chickens @ 2.4 kg each). Land used at breeder farm, hatchery, processing plant, retail store is not included in the model. Industrial local production of 1 kg of chicken meat water use cubic metres 1 kg Chicken meat, industrial production, on table 0.177 M3 H2O 1 kg Harvested chicken, industrial production, at plant 0.176 M3 H2O 20.4 bird.days Growing birds, industrial chicken production 0.167 M3 H2O 0.725 p Hatched eggs, industrial chicken production at plant 0.0414 M3 H2O 0.943 p Eggs delivery, industrial chicken production, at plant 0.0403 M3 H2O 6.6 bird.days Breeding birds, industrial chicken production 0.0403 M3 H2O 0.346 kg Starter, feed for industrial chickens, at farm 0.0167 M3 H2O 0.551 kg Grower 1, feed for industrial chickens, at farm 0.0245 M3 H2O 0.0137 m3 Water, drinking, Sydney, reticulated/AU U 0.0138 M3 H2O 0.246 kg Grower 2, feed for industrial chickens, at farm 0.0139 M3 H2O 1.06 kg Finisher, feed for industrial chickens, at farm 0.0643 M3 H2O 0.733 kg Withdrawal, feed for industrial chickens, at farm 0.0416 M3 H2O 0.922 kg Sweet sorghum grains, at farm/CN U 0.156 M3 H2O 1.27 m2 Irrigating/ha/CH U 0.155 M3 H2O In this model 0.18 cubic metres of water are used, primarily in production of feed. This model includes drinking water used on farms for the chickens to drink, modelled as Sydney drinking water- this component is very small compared to water for feed production, but Sydney water is likely to be more contested. Not all farms use Sydney water and other sources would have less impact. Note that the big impact seems to be from irrigated sorghum based on CH (Swiss) data. (Aim to reassess using Aust data if possible) Civic Lettuce Producer 1 and production of 1 kg lettuce: CO2 equivalent emissions 1 kg Harvested lettuce, Civic LP1, at table 0.253 kg CO2 e 0.00339 m3 Water, drinking, Sydney, reticulated/AU U 1.67 p Lettuce growing in garden bed, Civic LP1,, at backyard 0.00369 kg CO2 e 0.0308 MJ Electricity, high voltage, Eastern Australian/AU U 0.00891 kg CO2 e 0.0334 MJ Electricity brown coal VIC, sent out/AU U 0.0124 kg CO2 e 0.249 kg CO2 e 1.67 p Seedling growth, Civic LP1, at backyard 1.03 kg Cow manure, baged at regional store. 0.08 kg CO2 e 202 m Car, average, per km travelled/AU U 0.0763 kg CO2 e 182 m Car, petrol, per km travelled/AU U 0.0692 kg CO2 e 0.0157 kg Petrol, unleaded, at consumer/AU U 0.0114 tkm Transport, Lucerne, 3.5-16t, customisable/AU U 0.0997 kg CO2 e 0.34 tkm Transport, articulated truck, >20t, fleet 0.0501 kg Urea, at regional storehouse/RER U/Adapted/AU U 0.0355 kg CO2 e 0.308 MJ Articulated truck engine operation/AU U 0.028 kg CO2 e 0.0138 kg CO2 e 0.0777 kg CO2 e 0.216 MJ Energy, from natural gas/AU U 0.0125 kg CO2 e 0.0419 MJ Electricity,lLow voltage, Australian/AU U 0.0123 kg CO2 e 9.16E-6 m3 Mulcher, per litre fuel without catalytic 0.0147 kg CO2 e 0.139 MJ Rigid truck operation, diesel/AU U 0.0127 kg CO2 e 0.0278 kg Ammonia, steam reforming, liquid, at plant/RER 0.0531 kg CO2 e 0.0441 MJ Electricity, high voltage, Australian/AU U 0.0106 kg CO2 e 0.0123 kg CO2 e 0.0381 kg Crude oil, australian average, at refinery/AU U 0.0455 MJ Electricity, high voltage, New South Wales/AU U 0.0114 kg CO2 e 0.0123 kg CO2 e 0.0556 MJ Electricity, black coal NSW, sent out /AU U 0.0152 kg CO2 e The model shows production of 1kg of lettuce producing 0.25kg CO2 equivalent emissions. Production of own or industrially produced seeds is quite influential on total CO2 equivalent emissions. Use of seed from industrial production involves tractor use, fertilizers and transport- production of own seed greatly reduces this impact. Likewise, production of own compost and reduction of use of industrial fertilizers is influential. Civic Lettuce Producer 1 and production of 1 kg of lettuce: land use Hectare-years 1 kg Harvested lettuce, Civic LP1, at table 3.96E-6 Ha a 0.00339 m3 Water, drinking, Sydney, reticulated/AU U 1.7E-8 Ha a 0.0308 MJ Electricity, high voltage, Eastern Australian/AU U 4.15E-8 Ha a 1.67 p Lettuce growing in garden bed, Civic LP1,, at backyard 3.94E-6 Ha a 1.67 p Seedling growth, Civic LP1, at backyard 1.89E-6 Ha a 1.03 kg Cow manure, baged at regional store. 2.48E-7 Ha a 202 m Car, average, per km travelled/AU U 9.5E-7 Ha a 182 m Car, petrol, per km travelled/AU U 8.58E-7 Ha a 0.000197 my Operation, maintenance, road/CH/I S 1.6E-7 Ha a 12.5 m Car, LGG, per km travelled/AU U 5.88E-8 Ha a 0.34 tkm Transport, articulated truck, >20t, fleet 5.03E-8 Ha a 0.0501 kg Urea, at regional storehouse/RER U/Adapted/AU U 1.63E-7 Ha a 0.0419 MJ Electricity,lLow voltage, Australian/AU U 6.59E-8 Ha a 0.0278 kg Ammonia, steam reforming, liquid, at plant/RER 5.15E-8 Ha a 0.000236 m3 Manure collection, Civic LP1 5.19E-8 Ha a 0.0563 kg Triple superphosphate, at regional 5.24E-8 Ha a 3.31E-11 p Chemical plant, organics/RER/I S 1.11E-7 Ha a 0.0014 kg Phosphoric acid, fertiliser grade, 70% in H2O, at 5.25E-8 Ha a 0.0441 MJ Electricity, high voltage, Australian/AU U 6.59E-8 Ha a 0.0455 MJ Electricity, high voltage, New South Wales/AU U 6.59E-8 Ha a The model shows production of 1kg of lettuce takes 3.96 x 10-6 hectare years. Civic Lettuce Producer 1and production of 1 kg of lettuce: water use in cubic metres 1 kg Harvested lettuce, Civic LP1, at table 0.00439 M3 H2O 0.00339 m3 Water, drinking, Sydney, reticulated/AU U 0.00339 M3 H2O 1.67 p Lettuce growing in garden bed, Civic LP1,, at backyard 0.00105 M3 H2O 1.67 p Seedling growth, Civic LP1, at backyard 0.000321 M3 H2O 1.03 kg Cow manure, baged at regional store. 0.000452 M3 H2O 0.0437 kg Sand, at mine/CH U/Adapted/AU U 202 m Car, average, per km travelled/AU U 6.17E-5 M3 H2O 0.000253 M3 H2O 0.34 tkm Transport, articulated truck, >20t, fleet 0.000223 M3 H2O 182 m Car, petrol, per km travelled/AU U 5.42E-8 p Lorry 40t/RER/I S 0.000229 M3 H2O 5.28E-5 M3 H2O 8.46E-7 p Passenger car/RER/I S 0.000197 my Operation, maintenance, road/CH/I S 9.11E-5 M3 H2O 0.000115 M3 H2O 0.000236 m3 Manure collection, Civic LP1 5.05E-5 M3 H2O 0.0501 kg Urea, at regional storehouse/RER U/Adapted/AU U 0.000201 M3 H2O 0.000532 my Road/CH/I S 0.000146 M3 H2O 0.0278 kg Ammonia, steam reforming, liquid, at plant/RER 8.87E-5 M3 H2O 9.16E-6 m3 Mulcher, per litre fuel without catalytic 9.12E-5 M3 H2O 3.31E-11 p Chemical plant, organics/RER/I S 0.000132 M3 H2O 0.0563 kg Triple superphosphate, at regional 0.000107 M3 H2O 0.00678 kg Petrol, two-stroke blend, at regional storage/RER U 9.12E-5 M3 H2O 0.0014 kg Phosphoric acid, fertiliser grade, 70% in H2O, at 0.000121 M3 H2O 0.00664 kg Petrol, unleaded, at regional storage/RER U 8.79E-5 M3 H2O 0.00216 kg Sulphuric acid, liquid, at plant/RER U/Adapted/AU U 0.000117 M3 H2O 0.00664 kg Petrol, unleaded, at refinery/RER U 8.39E-5 M3 H2O The model shows production of 1kg of lettuce takes 0.004 cu m water. If industrial seeds are used this becomes a major contributor to water use. Home production of seed reduces this impact. Civic Lettuce Producer 2 and production of 1 kg lettuce: CO2 equivalent emissions 1 kg Harvested lettuce, Civic LP2, at table 0.0807 kg CO2 1.67 p Lettuce growing in garden bed, Civic LP2, at backyard 0.00335 m3 Water, drinking, Sydney, reticulated/AU U 0.0771 kg CO2 0.00363 kg CO2 0.18 kg Lucerne or legume, NE NSW 120 m Car, average, per km travelled/AU U 0.00848 kg CO2 0.00156 kg DAP, production & application, including N2O emission 0.0123 MJ Electricity, high voltage, Eastern Australian/AU U 0.0452 kg CO2 0.00302 kg Lime, calcined, at regional store/AU U 0.00355 kg CO2 0.0036 kg CO2 0.00156 kg Diammonium phosphate, at regional store/RER U/Adapted/AU U 0.0019 kg CO2 3.52E-6 kg Nitrogen Volatilisation from Fertiliser Application/AU U 0.00164 kg CO2 109 m Car, petrol, per km travelled/AU U 0.041 kg CO2 0.00939 kg Petrol, unleaded, at consumer/AU U 0.00626 kg CO2 1.3E-5 m3 Refining petrol, unleaded/AU U 0.00317 kg CO2 0.0368 MJ Energy, from fuel oil, just fuel, CO2,CH4, & N2O/AU U 0.00285 kg CO2 4.22 m Car, diesel, per km travelled/AU U 0.00166 kg CO2 0.00353 kg CO2 7.47 m Car, LGG, per km travelled/AU U 0.00254 kg CO2 0.00768 MJ Electricity, black coal NSW, sent out /AU U 0.0021 kg CO2 5.05E-7 p Passenger car/RER/I S 0.00212 kg CO2 0.0122 kg Crude oil, australian average, at refinery/AU U 0.00362 kg CO2 1.05E-5 m3 Crude oil, imported/GLO U 0.00267 kg CO2 1.53E-5 m3 Crude oil exploration and extraction/AU U 0.00306 kg CO2 The model shows production of 1kg of lettuce produces 0.08kg CO2 equivalent emissions. This current model does not take account of chickens to provide manure- they produce a by product of eggs (avoiding industrial production) and the manure avoids use of synthetic fertilisers. They also require input of feed. Civic Lettuce Producer 2 and production of 1 kg of lettuce: land use Hectares per year 1 kg Harvested lettuce, Civic LP2, at table 1.35E-5 Ha a 1.67 p Lettuce growing in garden bed, Civic LP2, at backyard 1.35E-5 Ha a 120 m Car, average, per km travelled/AU U 5.67E-7 Ha a 109 m Car, petrol, per km travelled/AU U 5.12E-7 Ha a The model shows production of 1kg of lettuce uses 1.35 x 1 -5 hectare yrs. Civic Lettuce Producer 2 and production of 1 kg of lettuce: water use in cubic metres 1 kg Harvested lettuce, Civic LP2, at table 0.0036 M3 H2O 1.67 p Lettuce growing in garden bed, Civic LP2, at backyard 0.00026 M3 H2O 0.18 kg Lucerne or legume, NE NSW 0.000108 M3 H2O 0.00156 kg DAP, production & application, including N2O 9.08E-5 M3 H2O 0.00335 m3 Water, drinking, Sydney, reticulated/AU U 0.00335 M3 H2O 120 m Car, average, per km travelled/AU U 0.000151 M3 H2O 109 m Car, petrol, per km travelled/AU U 0.000136 M3 H2O 0.00156 kg Diammonium phosphate, at regional store/RER 9.08E-5 M3 H2O 0.000994 kg Phosphoric acid, fertiliser grade, 70% in H2O, at plant/US 8.53E-5 M3 H2O 0.00152 kg Sulphuric acid, liquid, at plant/RER U/Adapted/AU U 8.23E-5 M3 H2O The model shows production of 1kg of lettuce accounts for 0.004 cu m water. Local Industrial lettuce Producer 1 and production of 1 kg of lettuce: CO2 equivalent emissions (5% cutoff) The model shows production of 1kg of lettuce produces 0.32kg CO2 equivalent emissions. Local Industrial lettuce Producer 1 and production of 1 kg of lettuce: land use in hectares. (0.6% cutoff) The model shows production of 1kg of lettuce uses 2.0 x 10-5 hectares per year. Local Industrial lettuce Producer 1 and production of 1 kg of lettuce: water use. (0.6% cutoff) The model shows production of 1kg of lettuce uses 0.072 cubic metres of water.