Standard Operating Procedures for the Kazlauskas Lab

advertisement

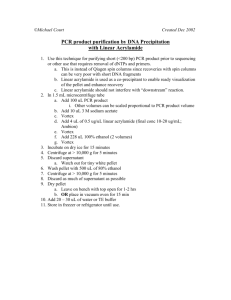

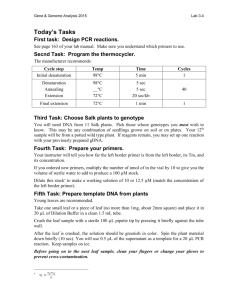

Standard Operating Procedures for the Kazlauskas Lab (Updated 23 Nov 2015) 1. Preparation of sterile LB media 2. Electroporation of DNA into E. coli 3. Preparation of Pseudomonas fluorescens esterase 4. A pHstat experiment 5. Startup and shutdown of Agilent 6890N gas chromatograph 6. Startup and shutdown of Agilent HPLC 7. Measuring esterase activity by hydrolysis of p-nitrophenyl acetate (microplate reader) 8. Measuring perhydrolase activity by bromination of monochlorodimedone 9. Random mutagenesis/saturation mutagenesis including gel electrophoresis 10. Site-directed mutagenesis by QuickChange dsDNA PCR and Dpn I digest 11. Expression of lipase B from Candida antarctica in Pichia pastoris (electroporation of DNA into P. pastoris) 1. Preparation of sterile LB media (last update: August 2012) 1. Add 25 g/L of LB broth to a glass media bottle, and 15 g/L of agar if making plates (500 mL is enough to make 25 plates). Fill up to rim with MilliQ ddH2O. Important: Loosen lid before autoclaving to prevent explosion. If making LB broth yourself, consult the standard microbiology recipes in Current Protocols in Molecular Biology, or similar books. Recipe for the LB broth can be found on the container. 2. Add distilled water (from the distilled water tap, by the sink) to the autoclave (second floor of Gortner Labs) until the water level reaches the bottom plate of the chamber. Place the media bottle in a rack and put in the chamber. Make sure to securely tighten the autoclave lid. 3. Press “power” and then “run” on control panel. The default program has already been set at 121 °C for 35 min, which is suitable for autoclaving LB medium. Operating the autoclave: The autoclave will raise the temperature in the chamber to 100 °C, then raise the pressure. Once the operating pressure is reached the timer will start. When 35 minutes are up the autoclave beeps once. When the temperature and pressure is reduced to allow the autoclave from being opened, the autoclave will make a series of beeps (approximately 2 hours, the indicator will point to “0” and the temperature indicator will show less than 100 °C). Carefully and slowly open the lid and take out the medium. Use an oven mitt; it is still hot! Switch the bottle lid tight and shake it for few seconds (if the bottle is opened after shaking when it is too hot, media might leak out). In an emergency: the autoclave can be evacuated by pressing the power button twice (shut off, then turn on). The autoclave should be cleaned every other month by removing residual water and washing a couple of times with distilled water. 4. If antibiotic is high-temperature resistant, such as chloramphenicol, add it before autoclaving. If the antibiotic is not stable, such as ampicillin, make a stock solution (see details below) and add it when the media is cooled down enough so that you can touch it against your face (alternatively, can hold the bottle for more than 10 seconds without gloves). 5. If agar has been added to the media, pour the medium on plates, before the temperature goes down to about 50 °C. If the media has not been used up, save remaining LB agar media and use the 80 °C oven to melt it and pour plates later. To make a stock of ampicillin: Add 100 mg/mL (enough with 10 mL volume) ampicillin in MilliQ ddH2O. Filter sterilize through a 0.22 um MillexGP filter unit into a red conical tube. Aliquot 1-mL fractions into microcentrifuge tubes using sterile technique. Store at –20 °C. Add 1/1000~1/2000 volume of ampicillin stock solution to LB media to reach the final concentration from 50 ug/ml to 100 ug/ml. 2. Electroporation of DNA into E. coli (last update: August 2012) Use Escherichia coli BL21 for protein expression experiments or Escherichia coli DH5alpha for plasmid isolation. A. Preparation of electrocompetent cells Before you start, prepare 250 mL of sterile LB medium (no antibiotic added) and 500 mL of sterile 10% (v/v) glycerol solution in water. 1. Inoculate 250 mL of LB medium with 2.5 mL of a fresh overnight E. coli culture. 2. Grow the cells at 37 °C shaking at 300 rpm to an OD600 of approximately 0.5–0.7. (Measure using microplate reader.) 3. Chill cells on ice for ~20 min For all subsequent steps, keep the cells as close to 0 °C as possible and chill all containers in ice before adding cells. To harvest, transfer the cells to a cold centrifuge bottle and spin at 4200 rpm for 15 min at 4 °C. 4. Carefully pour off and discard the supernatant. It is better to sacrifice the yield by pouring off a few cells than to leave any supernatant behind. 5. Gently resuspend the pellet in 250 mL of ice-cold 10% glycerol. Centrifuge at 4200 rpm for 15 min at 4 °C; carefully pour off and discard the supernatant. 6. Resuspend the pellet in 125 mL of ice-cold 10% glycerol. Centrifuge at 4200 rpm for 15 min at 4 °C; carefully pour off and discard the supernatant. 6a. To have extra pure electrocompetent cells repeat step #6. 7. Resuspend the pellet in 10 mL of ice-cold 10% glycerol and centrifuge at 4200 rpm for 15 min at 4 °C; carefully pour off and discard the supernatant. 8. Resuspend the cell pellet in a final volume of 0.75 mL of ice-cold 10% glycerol. 9. Aliquot 50 μl of the suspension to sterile 1.5 mL Ependorf tubes, freeze aliquots in liquid nitrogen and store at -80 °C. The cells should be stable for several months. B. Electroporation 1. Thaw the electrocompetent cells on ice. For each sample to be electroporated, place either a 0.1 or 0.2 cm electroporation cuvette on ice. 2. Mix 50 μl of the cell suspension with 1 to 5 μl of DNA. Mix well but gently and incubate on ice for ~1 min. 3. Set the MicroPulser to “Ec1” when using the 0.1 cm cuvettes or to "Ec2" when using the 0.2 cm cuvettes. 4. Transfer the mixture of cells and DNA to a cold electroporation cuvette and tap the suspension to the bottom. Place the cuvette in the chamber slide. Push the slide into the chamber until the cuvette is seated between the contacts in the base of the chamber. Pulse once. 5. Remove the cuvette from the chamber and immediately (less than 20s) add 1 mL of SOC medium to the cuvette. Quickly but gently resuspend the cells with a pipette. THE PERIOD BETWEEN APPLYING THE PULSE AND TRANSFERRING THE CELLS TO OUTGROWTH MEDIUM IS CRUCIAL FOR RECOVERING E. COLI TRANSFORMANTS. 6. Transfer the cell suspension to sterile Ependorf tube and incubate at 37 °C for 1 hour, shaking at 225 rpm and plate desired volume on selective medium (with antibiotic added). Check and record the pulse parameters. The time constant should be close to 5 milliseconds. IF THE RECORDED TIME CONSTANT WAS LOWER THAN 4 MS OR YOU SAW SPARK DURING ELECTROPORATION, YOU CAN BE SURE THE TRANSFORMATION WAS UNSUCCESSFUL. Bio-rad MicroPulser Electroporation Apparatus Responsible Person: Zhi-Jun Zhang Maintenance: No need for routine maintenance. Keep it clean and do not spill liquids on it. Repairs: 3. Expressing Pseudomonas fluorescens esterase (from E. coli BL21 pJOE2792) (last update: August 2012) with plasmid Using a bacterial stock from someone else: *thaw one of the tubes from the -80 freezer *make serial dilutions... 100x and 1000x in autoclaved water and spread out 100 μl on agar plates containing 100 ug/mL ampicillin *pick only a single colony from one of these plates and streak it out on a new plate using a sterile loop *inoculate a single colony in approx. 20 mL LB broth containing 100 ug/ml Amp *save 5 mL of overnight culture to make your own stocks and use the rest for isolating plasmid DNA *make sure to verify that all bases from sequencing correspond to the gene of PFE *FOLLOW THE APPROPRIATE STEPS BELOW TO EXPRESS PFE Using your own stocks to make PFE *add 1% (v/v) of overnight culture to LB broth (liquid media) containing 100 ug/mL Amp and grow to an OD(600nm) of 0.5 in the case of Rhamnose induction and 0.7 in the case of IPTG induction. Rhamnose is added from a 20% (w/v) stock (2.5 ml to 250 mL liquid media); IPTG is normally added from 100 mM stock to a final concentration of 0.2 mM. *express PFE for no more than 20 h, proceed with purification as described in (Cheeseman et al., 2004) with the following modifications: buffer exchange can be done quicker using a size-exclusion chromatography column, desalting column, or similar, or the ultraconcentrator in the bioprocess lab. The eluted fraction may need to be concentrated using a centricon tube, before desalted. *Protein concentration can be estimated using OD(280nm) or Bradford’s method. Imidazole in the purification buffers must be thoroughly removed before using OD(280nm) measurements 4. A Radiometer pH-stat procedure (last update: May 2006) 1. Turn on & calibrate the pH electrode - Go to Electrodes window and go to “run calibration “ with < >, press “√”, or press” ”; - It will automatically calibrate at pH 7. Change to a pH 7 buffer under the electrode and press ” ” to confirm; - Repeat with pH 4 and pH 10; - When finished, choose “ save and continue” by pressing ” ”; choose “end of analysis” by pressing “ ”; press “√” to end the calibration. 2. Set up base for the titration - Go to Reagent window. Change reagent bottle to the one you want to use, e.g.,1 N NaOH or 0.1 N NaOH. - Put a bottle under the reagent tip; press” ” to use Burette functions; press “ ” to use “flush”; when it finishes, press “√” to end. 3. Run your enzyme-catalyzed ester hydrolysis Go to Working Mode to start reaction; Current method “PM” will keep a reaction that generates acid at pH at 7.2. (To adjust the pH set point: Method Library, go to Edit Method, select Method Parameters, and change the Set Point to your desired pH.) Put the pH electrode and reagent electrode in reaction solvent. Run ”PM” by pressing ” ”; Confirm by pressing ” ”; Press” ” to begin calibrate the reaction pH; When the reaction finishes, press “stop” to stop your reaction. (Before adding enzyme, start the method. This will adjust the pH to 7.2. Then stop the method to reset the volume to zero. Then restart the method and add the enzyme to start the reaction.) 4. After reaction Use bleach to wash the two electrodes for about 10 min (removes protein), then rinse with distilled water. Put the pH electrode in the electrode storage solution; leave reagent electrode in the air. Turn off the machine. Maintenance: - The electrode must be filled with saturated KCl with a needle and syringe. Cover the filling hole with Parafilm when not in use to prevent evaporation. - Do not leave NaOH in the burette for extended periods of time. Replace with water using the flush control. Example reaction: BES buffer 5 mM, pH 7.2, acetonitrile ~8 vol%, (S,R)-MBMP 100 mM PFE ~100 μl from 2 mL protein from 100 mL E.coli culture Total volume = 10 mL. The reaction will be kept at pH7.2 One molecule of MBMP hydrolyzed will generate one H+ and we will need one molecule of NaOH to neutralize it. For 40% conversion, we will need 40%*100 mM*10 mL/0.1 M = 4 mL 0.1N NaOH. So when ~4 mL NaOH is added, we can stop our reaction. 5. Startup and Shutdown of Agilent 6890N Gas Chromatograph (last update: September 2005) A. Start up 1. Turn on all gas tanks (H2, He, N2, Air). 2. Turn on Instrument (switch on bottom right). 3. Log in to Windows XP. 4. Start GC program: Start All Programs ChemStations GC (inst 2) Online. 5. Initialization will turn on gases and ignite FID at >150 °C (check panel on GC to confirm carrier, make-up, H2 and air flow rate). 6. Instrument is “ready” when injector, oven and detector are at set temperature. Note: Maximum oven temperature for chiral column is 200 °C B. Shut down 1. Set injector temperature to 50 °C (manually or via computer). 2. Set oven temperature to 50 °C (manually or via computer). 3. Set detector temperature 50 °C (manually or via computer). 4. Close program. 5. FID can be turned off, but it will automatically shut down when <150 °C. 6. When injector, oven and detector are 50 °C or below, turn off GC and close the tank valves (H2, He, N2, Air). UHP Gas Product Numbers (Ustores) Air CX77020 He CX77059 H2 CX77069 N2 CX77086 Manuals are installed on PC. Contact: Agilent Tech Support 1-800-227-9770 Maintenance ...In progress... Columns: CP7502 CP-Chirasil-Dex CB 25 m X 0.25 mm (Varian, Tel: +1 800 421 2825) HP-5 J&W Scientific 30 m X 0.32 mm (Agilent) 6. Agilent 1100 Series high performance liquid chromatograph (last update: Oct 2012) A. Start up 1. Set solvents in the top cabinet. If you use normal phase solvents (for example, hexane), change the standard pump seals (Agilent 5603-6589) to those for normal phase (Agilent 0905-1420). See page 120 of Binary Pump manual. To switch between immiscible solvents (e.g., hexane and water), wash the lines first with a solvent miscible with both (e.g., isopropanol). 2. Check the waste bottle is not full. 3. Turn on all the instruments (degasser, binary pump, injector, column thermostat, diode array detector (DAD)). Wait at least 30 min. 4. Log in to Windows XP. Start HPLC program (instrument 1 online) on Windows. If Chemstation does not recognize the instruments, shut down Chemstation, wait for a while, and then restart it. 5. Select “Method Run Control” on Chemstation to show system diagrams. Click the pump diagram. Set an appropriate flow rate, typically 0.5 to 1.0 mL/min, and turn it on. Open the front cover of the binary pump, and check the solvent lines are filled with solvents. If the lines are empty, loosen the purge valve and pump the solvent with a flow rate of 5 mL/min until they are filled. 6. Click the column diagram. Click “set column thermostat method”. Click “temperature (left)”. These steps are necessary anytime to activate the system, even if you don’t use the thermostat. You can turn off the temperature control right away if you don’t use it. 7. Click the DAD diagram. Set its parameters and turn it on. 8. Set your samples and start. B. Shut down 1. Click the DAD diagram and turn off the UV/vis lamp. Turn off the application and log off Windows. 2. Wash the lines with isopropanol if you have used strong acid, strong alkali, salt or buffer in your solvents. 3. If you don’t use HPLC for more than a week, wash the lines with an appropriate solvent and switch off all the instruments. www.chem.agilent.com Tech Support 1-800-227-9770 Have called them a couple of times, are helpful Columns in the lab - CHECK COMPATIBLE SOLVENTS BEFORE USING COLUMN Reversed Phase: Agilent Zorbax SB-C18 and Zorbax Eclipse XDB-C8 Reverse/normal phase achiral: Suppleco Discovery Cyano (CN derivatized silica) Chiral columns Daicel Chiralpak AD Daicel Chiralcel OD (2) Daicel Chiralcel OJ-R (reverse phase) Also have CR(+), OT, OB (old) Common Parts and Procedures: Pump head seals for switching between reverse and normal phase: procedure on page 120 of Binary Pump manual along with part numbers Seals are ~$80-100 Consumables: Vials (2 mL) - U-store 51820714 (100 vials / 1 pk), 5183-2067 (10 pks) Inserts - U-store HP51811270N Caps - U-store 51820717 (blue), 5182-0718 (green), 5182-0719 (red) (100 vials) Microplates -Agilent 5042-1386 (0.5mL, polypropylene, 10/sleeve) Microplate covers - Nalge Nunk International 276011 (10/sleeve) Filter unit for HPLC (0.45 μm) - U-store CX18095 Maintance done/Parts replaced: 04/2004 - Paul - Changed active inlet valve on channel A (we have several (3) extra acive inlet valves in the HPLC drawer) 03/2006 - Ryota - Changed active inlet valve on channel B 7. Measuring esterase activity by hydrolysis of p-nitrophenyl acetate (last update: March 2006) Stock solutions *make a 200 mM pNPAc solution in acetonitrile (give amounts), and a 5 mM BES buffer at pH 7.2 (give amounts, how to check pH) Assay procedure *mix 20 μl of 200 mM pNPAc solution, 11.11 mL BES buffer, and 870 μl MeCN (= 12 mL assay solution) *add 90 μl of assay solution to 10 μl of protein [0.30 mM pNPAc, 7.4 vol% MeCN, and 4.2 mM BES as final concentrations] *read slope at 404 nm, the slope 'mAbs/min' should be read between 10 and 100 for at least 100 s Calculations mAbs/min to U/mg protein (c = A/εl). 1. Divide mAbs/min by 1000 to get Abs/min then divide by ( *0.29 cm), where is the extinction coefficient and 0.29 cm corresponds to the path length for 100 μl. This gives molar/min. 2. Multiply that number by 100 to get μmoles/min. (molar/min = μmoles/μl/min; thus, multiplying by the assay volume of 100 μl gives μmoles/min) 3. Divide μmoles/min by the mg of enzyme used to get U/mg. Notes: 1. The light path length varies with the amount of solution in the well. However, the microplate reader can measure the amount of water in the well and adjust the readings to a 1 cm path length. Check your software settings to see how it reports your absorbance. 2. The extinction coefficient for p-nitrophenoxide is xx,xxxx M-1cm-1, but at pH 7.2 part of it is protonated, so the extinction coefficient for the p-nitrophenoxide/p-nitrophenol mixture present at pH 7.2 is 16,600 M-1cm-1. Reference: Bernhardt et al. (2005) Molecular basis of perhydrolase activity in serine hydrolases. Angew. Chem. Intl. Ed. 44, 2742 Maintenance: Contact: Molecular Devices Corporation 1311 Orleans Drive Sunnyvale California 94089 tel: +1 800 635 5577 fax: +1 408 548 6435 8. Measuring perhydrolase activity by bromination of monochlorodimedone (last update: March 2006) Stock solutions Monochlordimedone, 10 mM in 2 M sodium acetate: A 10 ml Stock of MCD Assay solution is to be made a few minutes prior to the assay. Typically, a 10 mM MCD stock solution is made for the assay. This can be kept for 2 weeks at 4 oC. MCD is light sensitive and can also precipitate into crystal shards at 4 over time. MCD is difficult to dissolve in pure water over most concentrations. However, MCD can be dissolved in 2 M NaAcetate pH 5.5 at a concentration of at least 10mM. Hydrogen peroxide, 1 M: Dilute 1.14 ml of 30% H2O2 with 8.86 ml of di H20. Make fresh each day. Store at 4o C. Sodium bromide: A 2 M stock solution of NaBr in di H20 may be kept at 4° C as long as there are no visible signs of precipitation. Sodium acetate: A 2 M stock solution of of NaAcetate pH 5.5 can be made prior to the assay and stored at 4 o C for >6 months. Assay procedure In a 15 ml Falcon tube (or similar) combine: 4.375 ml of 2 M NaAcetate pH 5.5 0.830 ml of 2 M NaBr 0.110 ml of 1 M H2O2 0.220 ml of 10 mM MCD in 2 M sodium acetate 4.465 ml of diH20 Total volume: 10 ml Add 90 μl of assay solution above to 10 μl of protein [0.20 mM MCD, 9.9 mM H2O2, 149 mM NaBr and 788 mM acetate as final concentrations] *read absolute values at 290nm in flat bottom plates (UV transparent), the slope 'mAbs/min' should be between -10 and -30 and linear for at least 3 min *under the conditions above, L29P give a slope of -25 with good reproducibility Calculations: Divide mAbs/min by 1000 to get Abs/min Divide Abs/min by (ε*0.29 cm), where ε is the extinction coefficient. Multiply by 100 μl to get μmoles/min Divide μmoles/min by mg of enzyme used to get U/mg. Notes 1. For explanation of the calculations see above in the p-nitrophenyl aceate section. 2. The extinction coefficient for MCD in the assay conditions is 19,900 M-1cm-1. This extinction coefficient does not vary much in a different buffer, but this should be checked. Modifications: For substrates other than acetate, use 650 mM MES buffer at a pH of 5.5. 9. Random mutagenesis/saturation mutagenesis with QuickChange Multi site-directed mutagenesis kit (Stratagene, cat# 200515) (last update: April 2006) Part 1. PCR 1. Create 50 L of 48 ng/L plasmid cells, by diluting plasmid from the given concentration. 2. Choose a primer that has 15 base pairs on either side of the amino acid being mutated and NNK at site of the amino acid being mutated. 3. Program the PCR machine to: 1.1. Step 1: 95 °C for 1minute 1.2. Step 2: 95 °C for 1 minute 1.3. Step 3: 55 °C for 1 minute 1.4. Step 4: 65°C for # minutes (2 minutes for every 1 kb of plasmid) 1.5. Step 5: go to step 2, repeat 29 times 1.6. Step 6: 4°C for 0 minutes (Machine will read as forever) 1.7. Step 7: end. 4. In a PCR tube place: 1.8. 1 L of 50 ng/L plasmid 1.9. 1 L of primer (100 ng) 1.10. 1 L of dNTP Mix 1.11. 2.5 L of 10x reaction buffer 1.12. 18.6 L of ddH2O Add 1 L of QuickChange Multi enzyme blend remembering to keep it in the cold box. Place PCR tubes in machine in shut lid. Allow reaction to run. When machine is constant at 4 °C and you are ready for PCR products click "proceed" button and choose to go to next step (which is End). Store PCR product on ice. Digestion of Parent DNA 1. Add 1 L of DPN I to each PCR product tube. 2. Centrifuge for 1 minute. 3. Incubate at 37 °C for 3 h. DNA Agarose Gel Electrophoresis (last updated: Oct 2016) 1. In a PCR tube place: 1 µL of 1 kb ladder, 7 µL of ddH2O, and 2 µL of loading dye. 2. In other PCR tubes place: 8 µL of PCR product and 2 µL of loading dye. 3. In a glass bottle place 0.5 g of agarose and 50 mL of lx TBE buffer. 4. Heat bottle in microwave for 1 min with loosened cap. (bottle and cap will be too hot to handle without gloves, use heat resistant oven gloves to handle) 5. Tighten cap and swirl mixture. 6. Heat bottle for small increments of time (10 or 15 s) in microwave with loosened cap until all agarose is dissolved. (Typically takes 2 or 3 times) 7. Let bottle stand on bench until it can be touched to your wrist comfortably. (Typically at least 10 min.) (EtBr is not stable at high temperature, this step is important for proper observation of DNA) 8. Add 1 µ of ethidium bromide (EtBr) for every 50 mL of agarose solution. [Invitrogen, 10 mg/mL] 9. Store bottle in 60 °C incubator until ready for use. 10. Place gel box in casting tray and turn knob until the gel box is held tightly. 11. Pour agarose mixture into gel box being careful not to overfill box. Box should be half to three-quarters full. 12. PLACE COMB in top slots. (Don’t forget this step! If you do, you will be sad ) 13. Allow to set until hardened. 14. Place gel box and gel into electrophoresis box and remove comb. 15. Add 1x TBE buffer to box until gel is covered. 16. Load samples into wells. 17. Place on top and close the lid of the electrophoresis box. 18. Turn on power supply, set voltage to 100 V & press run. 19. When dye has migrated a sufficient amount press stop, open electrophoresis box, and remove gel. 20. Take a UV picture of the gel in the Imaging Center. If the gel needs to be paused for any reason, the run/pause button can be pressed. This procedure does not generate any material with ethidium bromide concentrations above 10 mg/L. All the materials (agarose gels, gloves and pipette tips) should be disposed in the trash under the 37°C incubator. They should be put in a double lined trash bag and labeled as “nonhazardous”. Spills of Ethidium Bromide Small spills (less than 0.5 L) of aqueous solutions of more than 10 mg/L EtBr and the resulting contaminated lab equipment can be decontaminated using the Lunn and Sansone method for decontamination of equipment contaminated with EtBr. The EtBr is degraded by wiping the surface with paper towels soaked in a freshly prepared decontamination solution (an aqueous solution of sodium nitrite and hypophosphorous acid) while wearing the proper protective equipment. All spills containing Ethidium Bromide should be reported to EHS at (612) 626-6002. Lunn and Sansone Ethidium Bromide Destruction Method (Lunn, George, and Sansone, Eric B. 1994. Destruction of Hazardous Chemicals in the Laboratory. John Wiley and Sons, Inc. pp. 185.) 1. Carry out the following steps in a fume hood and follow all laboratory safety precautions, including proper protective clothing. 2. Dilute solutions containing EtBr to concentration <0.05% w/v (50 mg/100 mL). 3. For each 100 mL of EtBr solution add 20 mL of fresh 5% hypophosphorous acid and 12 mL of fresh 0.5 M sodium nitrite solution. Check that the pH of the solution is <3.0. Stir briefly. 4. After reacting for at least 20 h, neutralize with sodium bicarbonate, then rinse the solution down the sanitary sewer with water. Armour Ethidium Bromide Destruction Method (Armour, Margaret-Ann. 1994. Personal communication.) (Kaufman, James A. ed. 1990. Waste Disposal in Academic Institutions. Lewis Publishers. pp. 127-8) 1. Carry out the following steps in a fume hood and follow all laboratory safety precautions, including proper protective clothing. 2. Dilute solutions containing EtBr to concentration <0.034% w/v (34 mg/100 mL). 3. Add 10 mL of fresh bleach for every 1 mg EtBr. 4. Stir at room temperature for at least 4 hours. 5. The EtBr is converted to the physiologically inactive product 2-carboxybenzophenone, and the solution should then be rinsed down the sanitary sewer with water. Lunn and Sansone Method for the Decontamination of Equipment Contaminated with Ethidium Bromide (Lunn, George, and Sansone, Eric B. 1994. Destruction of Hazardous Chemicals in the Laboratory. John Wiley and Sons, Inc. pp. 186.) 1. Before decontamination, deenergize all electrical equipment and wear the appropriate protective equipment. 2. The decontamination solution is prepared by adding 20mL of 50% hypophosphorous acid to a solution of 2g of sodium nitrite in 300mL of water. 3. Scrub the contaminated surface or equipment with a paper towel soaked in the freshly prepared decontamination solution. Scrub another five times with paper towels soaked in the freshly prepared decontamination solution, using a fresh towel each time. 4. Place all the used towels in a large container and soak them in fresh decontamination solution for at least one hour. 5. Neutralize used decontamination solution and towels with sodium bicarbonate. The towels can then be discarded in the trash, and the solution may be rinsed down the sanitary sewer with water. Note: A small amount of nitrogen dioxide may be given off when the decontamination solution is initially mixed, so the procedure should be carried out in a chemical fume hood. 10. Site-directed mutagenesis by QuickChange PCR and Dpn I digest (last update: Oct 2015) References: QuickChange II Site-Directed Mutagenesis Kit (Agilent Technologies, Catalog# 200523) http://www.agilent.com/cs/library/usermanuals/Public/200523.pdf Sambrook, J., and D. W. Russel. "Molecular Cloning, a labortory manual third edition." (2001). (Volume 2 Chapter 13 Protocol 3 (13.19)) Zheng, Lei, Ulrich Baumann, and Jean-Louis Reymond. "An efficient one-step site-directed and site-saturation mutagenesis protocol." Nucleic acids research 32.14 (2004): e115-e115. Northwestern University Biotools Oligo Calculator: website http://www.basic.northwestern.edu/biotools/oligocalc.html Reagents and Equipment: 1.5 mL microcentrifuge tubes 0.5 mL microcentrifuge tubes (PCR reaction tubes) Automatic micropipettes (P1000, P200, P10, P2 or as needed) Pipet tips Dpn I restriction endonuclease (digests methylated DNA) dNTP’s 10mM mix (Do not repeatedly freeze thaw, store small aliquots frozen and thaw once) Thermostable High-fidelity Polymerase: Q5 (recommended) or Pfu Polymerase Buffer: Q5 5X (recommended) or Pfu 5 or 10 X (X is relative to volume of polymerase used, e.g. 1 µL Q5 polymerase, use 5 µL 5X buffer) ddH2O: double distilled H2O (preferably sterilized) Programable PCR thermal cycler Procedures: 1. Thaw 5X Q5 / Pfu polymerase on ice and 5X Q5 / Pfu Buffer at ambient 2. Re-suspend primers to 100 µM by diluting with ddH2O in primer delivered tube for primer stock (e.g. 25 nmoles of primer delivered in tube – add 250 µL ddH2O) 2.1. Always spin down delivered primer tubes prior to opening them to re-suspend 2.2. TE buffer can also be used if maintaining constant pH is important 2.3. Store in fridge (Can also be stored in aliquots at -20°C) 3. Dilute Primer stocks 5X to 20 µM in ddH2O (e.g. 10 µL primer stock + 40 µL ddH2O) 4. Mix the following in order listed in 0.5 mL microcentrifuge PCR reaction tubes: 1. 5 µL 5X Q5 / Pfu Buffer 5. 6. 7. 8. 9. 2. 1 µL ~20 ng/µL template DNA 3. 1 µL 20 µM Primer A 4. 1 µL 20 µM Primer B 5. 1 µL 10 mM dNTP mix 6. 30 µL ddH2O 7. 1 µL Q5 / Pfu Polymerase 4.1 Polymerase (7) must always be added last and should be added immediately prior to thermal cycling. Pipet up and down and swirl pipet tip thoroughly to mix 4.2 Master mix of solutions 1 - 2 and 5 – 6 may be mixed in an appropriate volume microcentrifuge tube and subsequently mixed with different primer pairs in separate reaction tubes for the generation of multiple mutants 4.3 Template concentration is important for success of the reaction. 5 – 50 ng template load is recommended. Obtain template concentration using UV absorbance at 260 nm and estimate DNA load and increase volume of template in place of ddH20 accordingly. 4.4 1 µL DMSO or 1 µL glycerol may be added to mix to facilitate primer-template interaction and is recommended as a troubleshooting measure following a reaction failure Amplify tubes in a programmable thermal cycler using Denaturation, Annealing, Polymerization times below (All temperatures in °C): 1. 95 for 2 min (Initial Denaturation) 2. 95 for 30 s (Denaturation) 3. 55 for 30 s (Annealing) (55-65 typical annealing temperatures) 4. 72 for 15 min (Polymerization) 5. Go to 2, 25X (Cycle) 6. 72 for 10 min (Final Polymerization) 7. 10 hold (Storage) 5.1 55°C is a good starting point to set annealing temperatures but optimal results may vary depending on primer-template characteristics. Gradient run experiment of subaliquoted tubes from 55 – 65°C ran across a thermal cycler heat block recommended as troubleshooting measure in event of reaction failure. PCR product(s) may be ran on agarose gel with ethidium bromide (See Wiki section 12) along with template and 1-kb DNA ladder to confirm product. Dpn I digestion and transformation often successful even if PCR product band is not observed. Thaw Dpn I restriction enzyme on ice. Add 1 µL (10U, 10 U/µL) to each PCR reaction tube, mix thoroughly by slowly pipetting up and down and swirling pipet tip, spin down briefly in centrifuge Incubate at 37°C for ~1 hour to digest methylated parental DNA, only mutated PCR product should remain Store refrigerated until transformation procedure if not performed on same day (See wiki SOP section 10) 11. Expression of lipase B from Candida antarctica in Pichia pastoris (last update: February 2006) Preparation of media 10x D: Autoclave 20% dextrose in 1 L water. YPD medium: Autoclave 10 g of yeast extract and 20 g of peptone in 900 mL of water and add 100 mL of 10x D. YPDS medium: Autoclave 10 g of yeast extract and 20 g of peptone, 182.2 g of sorbitol in 900 mL of water and add 100 mL of 10x D. 1/2 YPDS - tributyrin plate 1. Dissolve 10 g of yeast extract, 20 g of peptone and 182.2 g of sorbitol in 900 mL of water in 2 L beaker. 2. Add 20 g of agar. 3. Autoclave for 20 min on liquid cycle. 4. Add 100 mL of 10x D. 5. Add 10 mL of tributyrin (Sigma). 6. Emulsify the liquid with Branson digital sonifer model 250 with 70% amplitude for 3 min. If you find drop of tributyrin on the bottom of the beaker, you should continue the sonification until the drop disappears. 7. Add 1 mL of zeocin. 8. Pour the liquid onto plastic plates and fix them at room temperature. Electroporation of Pichia pastoris See also the manual of BioRad MicroPulser system, Section 11. Additional information is described in Cregg, J.M. and Russell, K.A., Transformation, in Methods in Molecular Biology, 103, Higgins,D.R. and Cregg, J.M. (eds.), Humana Press, Totowa, NJ, 27 (1998). A. Preparation of Electrocompetent Cells 1. Inoculate 200 ml of YPD in a 500 mL Fernbach flask with an aliquot from a fresh overnight culture of Pichia pastoris GS115 (or X-33) 2. Incubate at 30°C overnight, shaking at 300 rpm, to a density of 5–7 of OD600. 3. Decant the cells into two sterile 200 ml centrifuge bottles and pellet the cells by centrifugation at 3000 x g for 5 min at 4°C. 4. Carefully pour off and discard the supernatant. 5. Add 50 ml of sterile YPD/HEPES to each of the bottles and vortex to resuspend the cell pellets; add 1.25 ml of 1M DTT to each bottle; mix gently. Incubate the cells for 15 min at 30°C. 6. Add 200 ml of sterile, ice-cold 1 M sorbitol to each centrifuge bottle. Pellet the cells by centrifugation at 3000 x g for 5 min at 4°C; pour off and discard the supernatant. 7. Add ~50 ml of sterile, ice-cold 1 M sorbitol to each of the bottles and vortex to resuspend the cell pellets; bring the volume in each of the centrifuge bottles to 250 ml with sterile, ice-cold 1 M sorbitol. Pellet the cells by centrifugation at 3000 g for 5 min at 4°C; pour off and discard the supernatant. 8. Resuspend each cell pellet in 10 ml of sterile, ice-cold 1 M sorbitol and pool in a chilled 50 ml Corning tube. Pellet the cells by centrifugation at 3000 g for 5 min at 4°C; pour off and discard the supernatant. 9. Resuspend the cell pellet in 0.5 ml of sterile, ice-cold 1 M sorbitol; the final cell volume should be ~1.3 ml and the cell concentration should be ~1 x 109 cells/ml. Keep the cells on ice and use as soon as possible for electroporation. B. Electroporation 1. Pipette the DNA samples (up to 10 µg) to be electroporated into sterile 1.5 ml microfuge tubes. Place tubes on ice. 2. Add 40 µl of the competent cells to each DNA sample and mix gently. 3. Set the MicroPulser to "Pic". 4. Transfer the DNA–cell samples to 0.2 cm electroporation cuvettes that have been chilled in ice and tap the suspension to the bottom of the tube. Place the cuvette in the chamber and pulse once. The time constant should be close to 5 milliseconds. 5. Remove the cuvette from the chamber and immediately add 1.0 ml of ice cold YPDS or YPD medium. Gently transfer the diluted cells to a sterile tube. 6. Incubate the cells at 30°C for 1–2 h without shaking; plate aliquots of the electroporated cells on a 1/2 YPDS–tributyrin plate. Incubate the plate for 2-3 days at 30 °C. If colony has lipase activity, halo will be formed around it. Expression of lipase 1. Transform P. pastoris with pBGPCalB, which is pBGP1 vector carrying CAL-B gene. 2. The colonies forming halo were inoculated into 200 μL of YPD medium containing 100 μg/mL zeocin in a 96 deep well plate. The deep well plate should be square and flat-bottom because growing speed of cells is faster. 3. Add 5 mm sterilized glass beads into each well. 4. The plate was incubated at 30°C for 2 days at 800 rpm. 5. Add 400 μL of YPD medium containing 100 μg/mL zeocin. 6. Incubate at 20°C for 7 days at 800 rpm to express of CAL-B. Purification of lipase Wash buffer: 50 mM HEPES pH 7.0, 20 mM imidazole, 300 mM NaCl, 0.05% Triton X-100 Elution buffer: 50 mM HEPES pH 7.0, 250 mM imidazole, 300 mM NaCl, 0.05% Triton X-100 1. Centrifuge 500 µL of culture medium with expressed lipase at 4000 g for 5 min and decant supernatant. 2. Add 5 µl of 1 M imidazole. 3. Suspend the Ni-NTA Magnetic agarose beads (QIAGEN) by vortexing for 2 s and then immediately add 50 µL of the suspension of the culture medium. 4. Mix the suspension gently on a shaker for 30 min to 1 h at room temperature. Centrifuge tubes shortly and place the tube on a magnetic separator (QIAGEN) for 1 min and remove supernatant with a pipet. 5. Remove tube from the magnet, add 500 µl of Wash Buffer, mix the suspension, place the tube on a magnetic separator for 1 min, and remove Wash Buffer. 6. Repeat step 5 another 1–2 times. 7. If you use the Ni-NTA beads adsorbing lipase for assay directly, wash them with 200 µl of buffer or water 1–2 times, as well as step 5. If you recover lipase from the beads, add 100 µl of elution buffer, mix the suspension, incubate the tube for 1 min, place for 1 min on magnetic separator, and collect the eluate.