View

advertisement

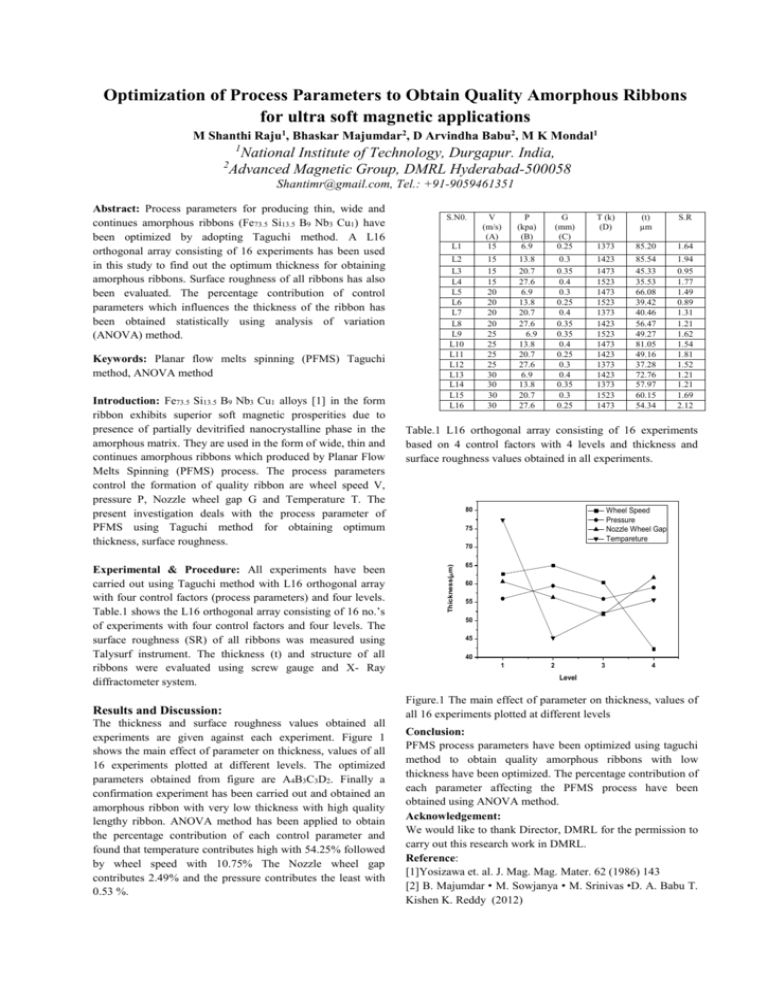

Optimization of Process Parameters to Obtain Quality Amorphous Ribbons for ultra soft magnetic applications M Shanthi Raju1, Bhaskar Majumdar2, D Arvindha Babu2, M K Mondal1 1 2 National Institute of Technology, Durgapur. India, Advanced Magnetic Group, DMRL Hyderabad-500058 Shantimr@gmail.com, Tel.: +91-9059461351 Keywords: Planar flow melts spinning (PFMS) Taguchi method, ANOVA method Introduction: Fe73.5 Si13.5 B9 Nb3 Cu1 alloys [1] in the form ribbon exhibits superior soft magnetic prosperities due to presence of partially devitrified nanocrystalline phase in the amorphous matrix. They are used in the form of wide, thin and continues amorphous ribbons which produced by Planar Flow Melts Spinning (PFMS) process. The process parameters control the formation of quality ribbon are wheel speed V, pressure P, Nozzle wheel gap G and Temperature T. The present investigation deals with the process parameter of PFMS using Taguchi method for obtaining optimum thickness, surface roughness. Experimental & Procedure: All experiments have been carried out using Taguchi method with L16 orthogonal array with four control factors (process parameters) and four levels. Table.1 shows the L16 orthogonal array consisting of 16 no.’s of experiments with four control factors and four levels. The surface roughness (SR) of all ribbons was measured using Talysurf instrument. The thickness (t) and structure of all ribbons were evaluated using screw gauge and X- Ray diffractometer system. Results and Discussion: The thickness and surface roughness values obtained all experiments are given against each experiment. Figure 1 shows the main effect of parameter on thickness, values of all 16 experiments plotted at different levels. The optimized parameters obtained from figure are A4B3C3D2. Finally a confirmation experiment has been carried out and obtained an amorphous ribbon with very low thickness with high quality lengthy ribbon. ANOVA method has been applied to obtain the percentage contribution of each control parameter and found that temperature contributes high with 54.25% followed by wheel speed with 10.75% The Nozzle wheel gap contributes 2.49% and the pressure contributes the least with 0.53 %. S.N0. P (kpa) (B) 6.9 G (mm) (C) 0.25 T (k) (D) (t) µm S.R L1 V (m/s) (A) 15 1373 85.20 1.64 L2 L3 L4 L5 L6 L7 L8 L9 L10 L11 L12 L13 L14 L15 L16 15 15 15 20 20 20 20 25 25 25 25 30 30 30 30 13.8 20.7 27.6 6.9 13.8 20.7 27.6 6.9 13.8 20.7 27.6 6.9 13.8 20.7 27.6 0.3 0.35 0.4 0.3 0.25 0.4 0.35 0.35 0.4 0.25 0.3 0.4 0.35 0.3 0.25 1423 1473 1523 1473 1523 1373 1423 1523 1473 1423 1373 1423 1373 1523 1473 85.54 45.33 35.53 66.08 39.42 40.46 56.47 49.27 81.05 49.16 37.28 72.76 57.97 60.15 54.34 1.94 0.95 1.77 1.49 0.89 1.31 1.21 1.62 1.54 1.81 1.52 1.21 1.21 1.69 2.12 Table.1 L16 orthogonal array consisting of 16 experiments based on 4 control factors with 4 levels and thickness and surface roughness values obtained in all experiments. 80 Wheel Speed Pressure Nozzle Wheel Gap Tempareture 75 70 Thickness(m) Abstract: Process parameters for producing thin, wide and continues amorphous ribbons (Fe73.5 Si13.5 B9 Nb3 Cu1) have been optimized by adopting Taguchi method. A L16 orthogonal array consisting of 16 experiments has been used in this study to find out the optimum thickness for obtaining amorphous ribbons. Surface roughness of all ribbons has also been evaluated. The percentage contribution of control parameters which influences the thickness of the ribbon has been obtained statistically using analysis of variation (ANOVA) method. 65 60 55 50 45 40 1 2 3 4 Level Figure.1 The main effect of parameter on thickness, values of all 16 experiments plotted at different levels Conclusion: PFMS process parameters have been optimized using taguchi method to obtain quality amorphous ribbons with low thickness have been optimized. The percentage contribution of each parameter affecting the PFMS process have been obtained using ANOVA method. Acknowledgement: We would like to thank Director, DMRL for the permission to carry out this research work in DMRL. Reference: [1]Yosizawa et. al. J. Mag. Mag. Mater. 62 (1986) 143 [2] B. Majumdar • M. Sowjanya • M. Srinivas •D. A. Babu T. Kishen K. Reddy (2012)