Fulltext

advertisement

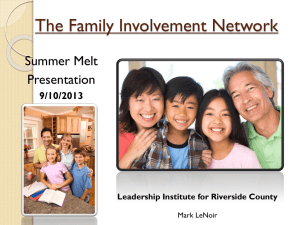

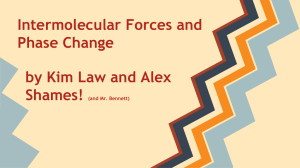

IMPROVEMENT OF MECHANICAL PROPERTIES OF HPDC A356 ALLOY THROUGH MELT QUENCHING PROCESS Shouxun Ji, Wenchao Yang, Bo Jiang and Z. Fan Brunel Centre for Advanced Solidification Technology (BCAST), Brunel University, Uxbridge, Middlesex UB8 3PH, United Kingdom Keywords: High pressure die casting, melt quenching, nucleation, microstructural evolution Abstract Melt quenched high pressure die casting (MQ-HPDC) is a new die casting process developed recently for improving the casting quality of the conventional high pressure die casting (HPDC) process. In the MQ-HPDC process, an alloy melt with a specified dose and superheat is quenched by directly pouring the alloy melt into a preheated metallic container. The thermal mass and preheating temperature of the container is selected so that the alloy melt is quenched just below the alloy liquidus and heterogeneous nucleation takes place during the melt quenching. The quenched alloy melt is then fed immediately into the shot sleeve for component casting. In this paper we present the MQHPDC process and the resultant microstructures and mechanical properties of a MQ-HPDC A356 alloy. Introduction The cold chamber high pressure die casting (HPDC) process has been widely used for manufacturing shaped castings of light alloys due to its high efficiency, high consistency and low further machining, low cost and versatility in component shapes. However, this process still faces several technological challenges. For example, die castings have relatively poor mechanical performance due to porosity and other casting defects and the formation of a large solid lump in the shot sleeve before die filling. Major effort has been made over many years to overcome these challenges, using semisolid metal (SSM) processing [1,2], vacuum die casting [3,4] and squeeze casting [5,6]. Recently, we have developed a melt quenched high pressure die casting (MQ-HPDC) process to overcome the problems associated with conventional HPDC process, in particular, to reduce the casting defects and the formation of the large solid lump in the shot sleeve. This paper presents the MQ-HPDC process and the microstructure and mechanical properties of A356 aluminum alloy processed with the MQ-HPDC process. The MQ-HPDC process The MQ-HPDC process (Figure. 1) consists of three sequential steps: melt quenching, melt dosing and high pressure die casting. This process originated from the concept that large dendrites and solidification in the shot sleeve could be reduced by quenching the melt in a metallic container before being transferred into the shot sleeve. For a given alloy melt with a specified superheat and dose, the thermal mass and the preheating temperature of the metallic container can be selected so that the alloy melt can be quenched to a temperature close to the alloy liquidus for enhancing heterogeneous nucleation without significant crystal growth. The quenched alloy melt has the following characteristics: (a) a temperature just a few degree below the alloy liquidus; (b) an almost isothermal temperature due to the severe convection caused by melt pouring; (c) copious nuclei due to significantly enhanced heterogeneous nucleation during melt quenching. If the nuclei are uniformly distributed throughout the entire volume of the melt, the growth of such nuclei ensures a relatively uniform melt temperature in the shot sleeve before filling the die cavity. This will prevent the formation of the large dendrites and the solidification in the shot sleeve will facilitate die filling and will promote a more uniform solidification after die filling, and therefore reduce the formation of casting defects. The MQ-HPDC process requires the use of a number of metallic containers. The number required for processing is determined by the specified melt dose, cycle time and container thermal mass. The container will be cooled naturally to the temperature which equals the preheating temperature described previously for a single container. Step I: Quenching ladler Step II: Dosing die Step III: Shaping container Piston container Shot sleeve die Shot sleeve Figure 1. Schematic illustration of the melt quenched high pressure die casting (MQ-HPDC) process. Experimental Commercial grade ingots of A356 alloy were used to demonstrate the MQ-HPDC process. The A356 ingots were melted at 710°C in a clay-graphite crucible using an electric resistance furnace. The container used was made of stainless steel with dimensions (in mm) as shown in the inset in Figure 2. The container was preheated to the specified temperature in the furnace. The die casting was carried out using a 4500kN cold chamber die casting machine. The melt was manually dosed into the shot sleeve followed by the standard HPDC process. In the MQ-HPDC process, the melt was poured at 710°C into the preheated container, and then transferred immediately to the shot sleeve followed by a full automatic HPDC cycle. The HPDC die produced three 6.35mm diameter tensile test bars and three square bars (2x6.3mm2, 3x6.3mm2, 5x6.3mm2) in each shot. The die was heated by the circulation of mineral oil at 250°C. Tensile tests were conducted following ASTM standard B557, using an Instron 5500 Universal Electromechanical Testing Systems with a ±50kN load cell. All tensile tests were carried out at ambient temperature with a 2mm/min crosshead speed. The specimen for microstructural examination was cut from the middle of the tensile test bar. Each specimen was examined using a Zeiss optical microscope with quantitative metallography using an AxioVision 4.3 Quantimet digital image analysis system. 700 Temperature (oC) 600 500 temperature between 200°C and 400oC. Formation of a solid lump at the bottom of the shot sleeve prior to die filling is inevitable. Such a solid piece is pushed and deformed by the moving piston during the die filling, resulting in severe cracking in the solid. Such cracked solid is usually found at the bottom of the biscuit (Figure 3c) and occasionally also found at the top of the biscuit. Except the cracked solid in the biscuit, the rest of the biscuits (middle and the top section) exhibit a coarse dendrite structure as shown in Figure 3a&b). 400 a 300 T1(ºC) 200 T2(ºC) 100 T3(ºC) 0 0 1 2 3 4 5 6 Time (s) Figure 2. Temperature recorded by three thermo-couples in the stainless steel container during quenching of the A356 melt. The insert shows the dimensions of the container in mm and the positions of the thermo-couples in the container. The temperature of A356 melt was 650°C. The initial container temperature was 200°C.The liquidus temperature of A356 is 615ºC. b Results Experiments were carried out to understand the thermal history of the melt during melt quenching. Three thermocouples were fixed in the metallic container at different locations prior to melt pouring as shown in the insert in Figure. 2. The recorded temperatures against the time during one of the quenching experiments are shown in Figure. 2. At all the three locations the temperature increased in a fraction of second to a maximum and then leveled off to a temperature just below the alloy liquidus (615°C). The slightly slower reaction of the thermal couple T2 is mainly caused by the delayed emersion of T2 in the alloy melt. In consideration of the above time delay, it should be noted that the recorded temperatures reached the maximum value within 1s and achieved an almost isothermal temperature within 2s. It needs to emphasis that the initial temperature includes the responding time of the thermocouple. However, from the time to reach the maximum temperature and the pouring temperature, it is possible to estimate the average cooling rate of the melt during melt quenching. The results showed that the cooling rate during the melt quenching was in the order of 102K/s, which is comparable with that achieved in the shot sleeve during HPDC process. As discussed in ref. [7], the cooling rate in the shot sleeve of die caster is at a level of 100 K/s. The similar level of cooling rate will provide similar undercooling for microstructural evolution. It needs to emphasis that the operation from pouring liquid into the container and then to the shot sleeve can results in the temperature variation because of the heat loss and the multiple process steps. However, the process time of melt quenching is very short and the whole process can be automatically achieved during production. Therefore, the benefits are obvious. The microstructure of the biscuits (the material solidified in the shot sleeve) was examined to understand the primary phase formation in the shot sleeve prior to die filling. During the conventional HPDC process, superheated alloy melt (about 700°C) is directly poured into the shot sleeve that is at a c 200μm Figure 3. Optical micrographs showing the microstructure of A356 alloy biscuit (70mm) after HPDC process on a cross section 15mm from the surface in touch with the piston, (a) top of the section, (b) middle of the section, and (c) bottom of the section. a a b b c Figure 5. Optical micrographs showing the microstructure of A356 alloy (6.35mm bar) produced by HPDC process showing (a) the overall microstructure and (b) the morphology of primary α-Al phase. 200μm Figure 4. Optical micrographs showing the microstructure of A356 alloy biscuit (70mm) after MQ-HPDC process on a cross section 15mm from the surface in touch with the piston, (a) top of the section, (b) middle of the section and (c) bottom of the section. However, although with the same condition, the biscuit produced by the MQ-HPDC process has a different microstructure: (1) the cracked solid region (Figure. 4a) is very much reduced or perhaps even eliminated; (2) no cracked solid was found at the top of the biscuit; (3) the dendrite size was considerably smaller (Figure. 4a&b). This demonstrates that melt quenching can significantly enhance heterogeneous nucleation (smaller dendrite size) and reduce/eliminate solid formation in the shot sleeve. The microstructures of A356 Al-alloy processed by the conventional HPDC process the MQ-HPDC and are shown in Figures 5 and 6, respectively. The HPDC sample shows fragmented dendrites with an elongated morphology and up to 100µm in size (Figure. 5a), fine spheroids of 8µm in average size (Figure. 5b) and substantial amount of irregular shaped cracks resultant from hot tearing during the final solidification in the die cavity (Figures 5a&b). However, the microstructure of the MQHPDC sample is considerably different from that of the HPDC sample. Figure 6 shows that the primary α-Al phase was characterised by the co-existence of two types of globular particles. The relatively large primary α-Al globules (Figure. 6a) with an average size of 35µm were fragmented from the rosettes formed in the shot sleeve, while the fine α-Al globules (Figure. 6b) with an average size of 7.5µm were formed in the die cavity. The MQ-HPDC samples were much less cracked than the HPDC samples, suggesting that there was much less hot tearing in the MQ-HPDC process. For A356 alloy, the measured average porosity level was 0.95% for the HPDC castings and 0.27% for the MQ-HPDC samples. This indicates that MQ-HPDC could produce castings with lower porosity and higher integration. a Discussion The unique feature of the MQ-HPDC process is melt quenching prior to conventional HPDC process. The high cooling rate achieved by pouring superheated alloy melt into a relatively cold metallic container results in a large thermal undercooling, which allows an increased number of existing solid particles in the melt to nucleate. However, the growth of such nuclei will be restricted in the container due to lack of time and cooling capacity. The fast growth of the nuclei in the alloy melt in the shot sleeve can generate latent heat, which acts as a temperature regulator to ensure a relatively uniform temperature field in the alloy melt, in comparison of the situation in conventional HPDC process. The simultaneous growth of increased number of primary grains results in a relatively small growth of each primary grain and therefore large dendrites are eliminated, which improve the die filling and result in a reduction of casting defects and improve the mechanical properties. b Summary A melt quenched high pressure die casting (MQ-HPDC) process has been developed to improve casting quality. In this process, melt quenching by purpose designed metallic container is used to enhance heterogeneous nucleation; and the latent heat released by the growth of the increased number of nuclei in the shot sleeve is used to achieve a relatively uniform melt temperature. This helps to reduce the formation of large dendrites and solidification in the shot sleeve, produces slurry with fine globules, and facilitates the die filling process, reduces casting defects and improves casting quality. References Figure. 6 Optical micrographs showing the microstructure of A356 alloy (6.35mm bar) produced by MQ-HPDC process showing (a) the overall microstructure and (b) the morphology of primary α-Al phase. The mechanical properties of A356 alloy processed by both MQHPDC and HPDC processes are shown in Table 1. Although both yield strength and ultimate tensile strength (UTS) show little difference between the two groups of samples, elongation of the MQ-HPDC samples was significantly improved. The average elongation was increased from 10.1% for HPDC samples to 12.6% for MQ-HPDC samples, a 25% increase. Table 1. Tensile properties of A356 alloy produced by HPDC and MQ-HPDC processes. Yield strength (MPa) Ultimate tensile strength (MPa) Elongation (%) HPDC 120.2±3.97 262.1±2.66 10.1±1.05 MQ-HPDC 120.6±3.56 262.3±2.93 12.6±1.16 [1] M. C. Flemings, Behavior of metal alloys in the semi-solid state, Metall. Mater. Trans. A 22A (1991) 957-81. [2] Z. Fan, Semisolid Metal Processing, Inter. Mater. Review, 47(2002) 49-85. [3] X.P. Niua, B.H. Hua, I. Pinwilla, H. Lib, Vacuum assisted high pressure die casting of aluminum alloys, J. Mater. Proc. Tech. 105(2000)119–127. [4] E.S Kim, K.H Lee, Y.H Moon, A feasibility study of the partial squeeze and vacuum die casting process, J. Mater. Proc. Tech. 105 (2000) 42–48. [5] A. Maleki, B. Niroumand, A. Shafyei, Effects of squeeze casting parameters on density, macrostructure and hardness of LM13 alloy, Mater. Sci. Eng. A, 428 (2006) 135–140. [6] M.R. Ghomashchi, A Vikhrov, Squeeze casting-an overview, J. Mater. Proc. Tech., 101 (2000) 1–9. [7] S.Ji, Y. Wang, D. Watson, Z. Fan, Microstructural Evolution and Solidification Behavior of Al-Mg-Si Alloy in High-Pressure Die Casting. Metall. Mater. Trans. A 44A (2013)3185-97.