Draft Chapter 1 – General Second Draft June 13, 2013 CEMA

advertisement

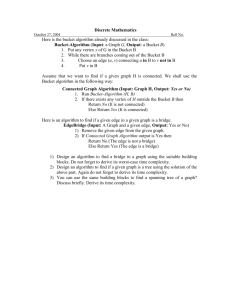

CEMA Bucket Elevator Book Chapter 1 General Chapter Lead: D. Warren Knapp Contacts and References Name Company E-Mail D. Warren Knapp Screw Conveyor Corp wknapp@screwconveyor.com Chris Tarver Maxi Lift ctarver@maxilift.com Jeff Gerhart Martin Sprocket & Gear jgerhart@martinsprocket.com DRAFT HISTORY Draft Number 1 2 Date September 3, 2012 June 13, 2013 Draft Chapter 1 – General Second Draft June 13, 2013 GENERAL DESCRIPTION Bucket elevators (legs) are the most efficient means of elevating free flowing material such as grain, pelleted and soft ingredients, finished feeds, coal, aggregate. Except for sticky materials which will not discharge completely from buckets. There are two major types of bucket elevators; centrifugal discharge and gravity discharge (continuous elevators). Both types use buckets or cup mounted on belt or chain. Bucket elevators of the centrifugal discharge are normally used in the feed industry and most are of belt type. However pellets and other friable materials may be best handled in continuous bucket elevators that operate at low speeds. The continuous buckets are discharged by gravity on the back of the preceding bucket while passing over the head pulley, thus reducing breakage caused by the centrifugal force discharge of a centrifugal elevator. Bucket elevators usually require the least amount of horsepower for vertical conveying of any conveying system. The bucket elevator has been in existence for many centuries. The ancestors of the modern day bucket elevator first appeared at about 230 BC. These devices were predominantly used for elevating water by the use of pots attached to an endless rope. It is believed that the water used for the famous Hanging Gardens of Semiramus was brought up to a height of 300 feet by this means. A remarkable achievement, having regard to the fact, that modern elevators rarely work to heights greater than 150 - 200 feet. Since inception in 230 BC, the bucket elevator has gone through a period of evolution. There was a flourish of activity in elevator design and patents between 1850 and 1930. Since that time there has been very little new work or mathematically supported designs developed. There are few in depth texts on bucket elevator design and/or proper application. This is true for all bucket elevators, not only the feed and grain legs. Draft Chapter 1 – General Second Draft June 13, 2013 As referenced above, there are two major types. The centrifugal and the continuous with about 15 sub-types and numerous variations of each subtypes. The centrifugal type bucket elevator is by far the most dominant in the feed industry. This machine is the heart of most feed mills. It is rare to find a feedmill which has any fewer than five bucket elevators (legs). The statement that the bucket elevator is the heart of most feed production facilities may seem prejudiced, in light of the fact this document is generated by the manufactures of bucket elevators. It is not in way prejudice, just enthusiastic about the proper design of bucket elevators. As an example of the importance of the bucket elevator in the movement of materials the following is offered for consideration. Commonly, at least one bucket elevator is employed in each of the following areas: receiving, grinding, mixing, pelleting, storage and load out. Commonly feedmill designers and operators give a large amount of consideration to the selection of hammer mills, mixers, pellet mills, liquid additions, and baggers. But, how much consideration is given to the bucket elevator, the device supplying each of these machines with the required material for continuous production or how they effect the material being elevated? The most plant manager or owner is responsible for six basic areas: production, quality, cost, safety, housekeeping, and employee relations. The bucket elevator is a key function in each one of these areas. You will have poor production, low quality, increased cost, safety problems, bad housekeeping, and unhappy employees if you have an improperly designed or misapplied bucket elevator. Your production costs increases if the bucket elevator continually requires maintenance or constantly causes damage to your finished goods. You will have safety problems if your bucket elevator does not comply with all of Draft Chapter 1 – General Second Draft June 13, 2013 the state, federal, and insurance safety requirements. You will have housekeeping problems if your bucket elevator has improper connections and joints allow dusting which is not only a safety but also a housekeeping problem. You may agree that the bucket elevator influences these areas; but you may not believe a bucket elevator affects employee relations. How many have seen a happy employee after they have just finished digging out a plugged elevator? It is a common belief that a bucket elevator (leg) is a simple machine. It is nothing more than sheet metal housing with two pulleys and a piece of belt with some attached buckets. This is not the true. The bucket elevator though simple in appearance is quite complex if properly designed. There are a number of old “rules of thumb” and common beliefs in designing a bucket elevator. Some are correct and some are incorrect. For the most part the basic mathematics for these rules of thumb have been forgotten over the years. Though these rules of thumb are considered to be proper for finial design they are not, at best they are guidelines to start the design. Some of the more popular these rules of thumb or opinion are: 1. A slow belt speed means less damage and a better discharge. Not true belt speed alone is not a controlling factor. It is relevant factor only when considered in conjunction with pulley diameter, bucket projection, bucket angle and the properties of the material being conveyed. 2. A bucket elevator will operate the same for all grain and or products. 3. If you want more capacity just speed the leg up. Designing a bucket elevator for application requires the following information: a. Type of material handled b. Capacity Draft Chapter 1 – General Second Draft June 13, 2013 c. Particle size (nominal) Max & Min & % d. Moisture content e. Hydroscopic f. Free flowing or abrasive g. Friable h. Fibrous i. Will it compact j. Temperature of the material k. Density and pounds per cubic foot 1. Corrosive m. High fat or oil content n. Does the boot need to be self-cleaning o. How is the elevator being fed p. To what does the elevator feed q. What are the surrounding environmental conditions r. s. Federal and local codes and regulations Is there any special federal regulation such as FDA, which must be satisfied Possibly, the best way to explain designing for applications is by example. Selection of a Receiving Leg for an Up Grade or New Mill First, the type of material to be elevated. It is common for this machine to encounter corn, milo, barley, oats, wheat, corn screenings, pellets, dust, brewer's grain, malt hulls, alfalfa pellets, wheat mids, bakery by-products, cottonseed hulls, beet pulp, soybean meal, cottonseed meal, meat meal, corn and wheat meal, limestone, phosphates, salt, and urea. In answering the above questions for the receiving leg, it becomes quite obvious the particle sizes are all over the board. So is the moisture content, and some are hydroscopic, free flowing, abrasive, fibrous, and some will compact. Most of the Draft Chapter 1 – General Second Draft June 13, 2013 materials in will be at ambient temperatures. Density or pounds per cubic foot will vary anywhere from 12 to 100 PCF. Corrosive? Yes. High fat and oil content? Yes. How is the material being fed? Generally controlled by gravity and gate or conveyor. How is it discharging? Usually to a spout or a series of spouts. Whole grains are the predominant material handled, and should be the base for the capacity. However, the leg should be reviewed for the capacity requirements of each of the products it will be expected to handle. Since the bucket elevator is a volumetric device, and elevates material based on cubic feet per hour, it cannot discriminate between one hundred (100) pound material per cubic foot and 15 pounds per cubic foot material. The product weight variation will effect the selection of the receiving bucket elevator. If a 50 TPH, full line feed plant, has a daily requirement for 325 tons of whole grains consisting of corn, milo, barley, oats, and wheat, and a requirement for 24 tons per day of cottonseed hulls, with the whole grain requirement being 38% of the total daily requirements, and cottonseed hulls 3%. 325 tons of whole grain is equal to 14,444 cubic feet. 38% of 8 operating hours is 3, divide the 14,444 by 3, the minimum capacity is 4,751 cubic feet per hour. Considering the cottonseed hulls, at 12 pounds per cubic foot, a 24 ton per day requirement equals 4,000 cubic feet, 3% of 8 operating hours is .24 hour. To elevate 4,000 cubic feet of cottonseed hulls in .24 hour the capacity is 16,000 cubic feet per hour. I have stated these two examples to show the extremes of variation. As we all know, in any operation regardless of the duration of operating hours, 100% efficiency is not achieved. Of course, it is possible to extend the elevating and receiving hours to have minimum quantity of ingredients in overhead storage. However, to maintain this quantity you must at least replenish it at the rate it is being consumed. To make a true and exact determination of the capacity required for a receiving unit, you must take into additional considerations Draft Chapter 1 – General Second Draft June 13, 2013 such as percentage of ingredients that will be transferred through this unit, other uses for this particular bucket elevator, and allotted time for the receiving operation. Over the years, some general rules of thumb have been developed in sizing the receiving system for feed mills. These are merely rules of thumb and should be used as guidelines. The receiving elevator should have an average handle rate equal to 3 to 4 times your average production rate. If you have 50 TPH production rate, the minimum size receiving unit should have a nominal capacity of 150 to 200 tons per hour based on 40 cubic foot material. Additionally, the nominal capacity of a bucket elevator should be considered to be 75% of its theoretical maximum volume, which would equal a 13,333 CFH. As you see this rule of thumb gets you close, but if our requirement for cottonseed hulls is correct and receiving is limited to 8 hours then the capacity should be 16,000 CFH. If the feed rate to the elevator does not have a variable control to limit the flow of material the horsepower would be based on 16,000 CFH @ 100 PCF. On a 150’ discharge height elevator this would mean a 200 HP drive. If you restrict the flow rate on minerals to 50% of the grain products, it would require a 100 HP drive. The capacity requirement for the mash elevator, since in the United States, most feed mills operate with a batch mixer, is not always obvious. If in a production facility using a single 5-ton horizontal ribbon mixer with drop bottom, having established a 5 minutes cycle time, which provides 1/2 minute for scale discharge, 31/2 minutes for mixing, 1/4 of a minute mixer discharge, and 3/4 of a minute contingency, with a surge beneath the mixer having a capacity equal to one batch. The mash elevator must empty the surge prior to the next discharge of the batch mixer. The minimum capacity for this machine would be cycles per hour X tons per cycle or 60 tons, based on 35 #/cuft material. or 3500 cubic feet per hour. It is generally considered prudent to be able to empty the lower surge in a time frame equal to the mixing cycle, or 3 1/2 minutes in this case. The bucket elevator would have a minimum requirement of 4,900 cubic feet per hour. Thus, in selecting a machine for this area, I would recommend a unit, which has a nominal Draft Chapter 1 – General Second Draft June 13, 2013 operating capacity of 5,000 cubic feet per hour. The same logic should be applied to all elevators through out the mill. Thus far we have only determined that the operating capacity of the bucket elevator. We have not defined any of the functional requirements of this machine. Each one of the three areas, which we have discussed, has a different functional requirement. The receiving leg, although quite cumbersome in sizing for capacity, can be designed similar to that of a standard grain leg. This machine usually falls into the category of a high-speed centrifugal discharge. At this point one should discuss some of the design requirements which is often overlooked by the user, and is not governed by any regulatory agency, and often not considered by manufacturers. The centrifugal bucket elevator has a minimum operating speed and a maximum operating speed. The optimum operating speed will vary with respect to the variation in product or commodity being handled. Basically the principal criteria of bucket unloading or discharge is on the up leg side of a vertical bucket elevator, the load is in a straight uniform motion and acted upon by a constant gravity force. This force is equal to mass times gravity. As the bucket begins to move around the head pulley an additional centrifugal force appears which is represented by the equation F=MVo2/R or CF=WV2/qR. Where M is the mass of load in the bucket in kilograms, Vo is the velocity of the center of gravity of the bucket load in meters per second, and R is the radius of rotation (distance from the center of gravity of the bucket to the center of the pulley). As a bucket revolves on the pulley, the resultant of the force of gravity and the centrifugal force varies in magnitude and direction. When the resultant force has rotated out of the bucket plane the sheer plane lies wholly inside the bucket indicating all remaining material in the bucket is now subjected to a force that in time will eject it. The optimum speed for discharge is affected by the weight of the material, the angle repose of the material, the Draft Chapter 1 – General Second Draft June 13, 2013 coefficient of friction between the material and the bucket or cup, and the actual shape of the bucket. The grain and feed organizations have for the most part, adopted a standard bucket configuration originally introduced by B.I. Willer “Calumet” and K.I. Willis Style “CC” The acceptance of this style bucket has established in the industry an average angle between the base of the cup and the lip for a high speed grain or feed bucket of 30°. Using the 30° average for a metal cup, the average angle repose of 28° 22 minutes, (Department of Agriculture average for the angle repose (emptying) for various grains), and a simplified formula, it is relatively easy to determine reasonable belt speeds for grain bucket elevators. This formula is velocity in feet per minutes equals 88.56 times the simplification and results in an answer near to the optimum operating speed obtained from more rigorous calculations. In addition to designing a bucket elevator to operate at the proper speed for the buckets (cups) being used and the material handled, it is also necessary to take into consideration the shape of the discharge hood or bonnet, and the discharge opening. All of these items are crucial factors in the design of a bucket elevator. Proper consideration of all of these items will result in a machine which operates efficiently, with little or no down legging or back-legging, and minimal damage to the material. Loading of the buckets is equally important as unloading. The loading of the buckets is affected as greatly by the belt speed as the discharge. In the true interpretation of the formulas and what effects the discharge is speed, it is not belt speed but angular velocity of the centroid at the cup. The angular velocity is greater than the belt speed. Practices employed earlier in the United States, used boot pulleys considerably smaller than the head pulley, this has an adverse effect on the loading. If you have a belt speed of 573 FPM a 42" diameter head pulley, and a 24" diameter boot pulley, the angular velocity of the boot pulley will be considerably larger than that of the head pulley. If 8" projected buckets were used the velocity of the centroid at the head pulley would be 682 FPM, Draft Chapter 1 – General Second Draft June 13, 2013 conversely, the velocity at the tail pulley would be 764 FPM. This differential in velocity of the centroid has a drastic effect upon the loading of the buckets in the boot section. In order for material to enter the cup while the buckets are in angular contact with the pulley, it is important that the same consideration be given to the boot design as that of the head. As should be obvious by now, the design of a bucket elevator is far from a simple procedure and best left to companies or individuals who are well experienced in this area and have a proven track record. All of the information I have reviewed thus far can easily be altered by changing cups to a European design, such as the low profile, or going to the continuous which I mentioned earlier. The continuous bucket elevator is designed to handle friable material like pellets. This unit uses a bucket with a V configuration, having a front lip angle of 40° nominal. These buckets on close centers and the discharge is affected by the material sliding in a trough created by the bucket proceeding. These machines generally operate at a belt speed of approximately 200 FPM. There are no adverse centrifugal forces as required in the discharging of a centrifugal elevator. The continuous bucket elevator allows a gentle filling and discharge. It does require a greater distance between pulley centerline and the throat of the discharge. The advantage of using a continuous discharge bucket elevator versus the centrifugal is a decrease in breakage. The centrifugal elevator generates velocities at discharge point of cup 42% greater than the belt speed. USDA research data indicates that high-speed centrifugal elevator damage as much as 3.5% per handling with an average of 1.1%. Friable pellets are subject to 1.1% to 3.5% breakage as a result of handling in a centrifugal bucket elevator. In a 5O TPH facility, this is the equivalent to .6 to 1.8 tons per hour. If this can be reduced by the proper selection of a bucket elevator by 50%, a savings of 600 to 1750 tons per year based on 8 hour a day operation, 5 days a week, 50 weeks a year. Over 10 years this becomes a large cost of production. Draft Chapter 1 – General Second Draft June 13, 2013 The continuous bucket elevator offers possibilities of greatly reducing the breakage that would be normally encountered with a centrifugal elevator normally used as a pellet leg. The advantage of a continuous leg is slower belt speed; it does not discharge by the centrifugal force and therefore, applies less damage to the product being handled. The disadvantage is higher initial cost. This design has been used for many years in industrial application handling materials considered to be friable and require extreme delicate handling. You may want to consider this type of elevator in the future. Today everyone is aware of the state, federal, and insurance requirements for safety in the work place. These regulatory agencies have established safety requirements of bucket elevators used in the feed and grain industry. Two of these agencies are OSHA and NFPA. In reading documents from these agencies you will encounter to phrases “it shall be” and “should be”. “It shall be” is telling you to do it that way. “It should be” is tell you that it is highly recommended that you do it that way. There is a fine line difference between these two agencies. If you state or local codes has adopted the OSHA codes then it is a law to which you must comply. NFPA makes recommendations only and have no bearing as to enforcement or law unless the NFPA standard has been adopted by reference or by transcription. Since most states have adopted the federal OSHA codes I will address this topic for that position and limited to bucket elevators in grain handling facilities. This is covered in OSHA Standards for General Industry (29 CFR PART 1910) section 1910.272 1. Elevator legs must be of dust tight construction of noncombustible material. 2. Exterior legs when used shall be provided with an explosion relieve panel constructed in the vertical casing where maximum possible explosion relieve area in the head. 3. Elevator legs or portions of elevator legs which are located inside shall have the maximal practical explosion relieve area through the roof directly to the outside. (Small exterior legs that are used as part of the processing equipment are exempt). Draft Chapter 1 – General Second Draft 4. June 13, 2013 Boot section shall be provided with adequate doors for clean out of the entire boot and for inspection of the boot pulley and leg belt. 5. The use of plastic as lining material shall be limited to impact points and wear surfaces only. 6. Inspection doors shall be provided in the head section to allow complete inspection of head pulley, lagging, the leg belt, and a discharge throat of the bucket elevator. 7. Leg head section between the upper and down casings shall be hoppered at an angle of not less than 45°. 8. The leg shall be driven by an individual motor and drive train capable of handling the full rated capacity of the elevator without overloading. (Multiple legs on a line shaft are exempt). 9. Elevator legs shall be provided with an automatic mechanical or electro mechanical device which cuts off the power to the motor and activates an alarm in the event the belt slows down. Feed to the elevator leg shall be stopped or diverted. (Again small auxiliary legs are exempt). 10. The elevator leg shall be designed to maximize traction between pulleys and the belt. 11. All spouts intended to receive grain or dry ingredients discharge directly from the elevator shell, be designed and installed to handle the full rated elevating capacity of the largest elevator leg feeding such spout. 12. All bins or other receptacles which are fed by the elevator leg which are not designed with automatic overflow systems, shall be equipped with devices to shut down equipment or with high level indication devices with visual or audible alarms. 13. Where drive assemblies involve the use of drives, they shall be static conducting. 14. Where drive belt is used, the drive train shall use the design with sufficient service factor to stall the drive without slipping. Draft Chapter 1 – General Second Draft 15. June 13, 2013 Roller or ball bearings shall be used and they shall be located outside of the machinery enclosures where bearings will be less exposed to dust and where they are more accessible for inspection. 16. Engines, motors, driven equipment used in confined Class II Group G Division 2 Operating areas shall be equipped with safety devices to reduce potential fire and electrical shock hazard. Federal Register December 1987 Rules and Regulations 49625 Section 4910.272 Grain Handling Facilities. 17. Inside bucket elevators means an elevator that has more than 20% of the total leg height above grade or ground level inside a grain elevator structure. 18. Bucket elevators with casings that have an outside and pass through the roof of rail or truck dump sheds with remainder of the leg outside the grain are not considered inside legs. 19. Bucket elevators shall not be jogged to free a choked leg. 20. All belts purchased after March 30, 1988 shall be conductive; such belts shall have a surface electrical resistance not to exceed 300 Megaohms. 21. Not later than April 1, 1991 all bucket elevators shall be equipped with means of access to the head pulley section to allow inspection of the head pulley, belt, legging, discharge throat. 22. The boot section shall be provided with a means of access for clean out of the boot, for inspection of pulley and belts. 23. Not later than April 1, 1991 the employer shall mount bearings externally to leg casings or provide vibration monitoring temperature monitoring or other means to monitor the conditions of bearings mounted inside or practically inside the leg casing. 24. Not later than April 1, 1991 the employer shall equip bucket elevators with a motion detection device which will shut down the bucket elevator when the belt speed is reduced by no more than 20% of the normal operating speed. 25. Not later than April 1, 1991 the employer shall equip the bucket elevators with a belt alignment monitoring device which will initiate an alarm to employees when the belt is not tracking, provide a means to keep the belt tracking properly such as a system that Draft Chapter 1 – General Second Draft June 13, 2013 provides constant alignment adjustment and the above information does not relate to facilities having a permanent storage capacity of less than 1 million bushels provide the daily visual inspection is made and the bucket movement and tracking of the belt. 26. The above applicable requirements are not enforced on operational fire and explosion suppression systems capable of protecting at least the head and boot section of the bucket elevator or the bucket elevators which are equipped with pneumatic or other dust control methods that keep dust contamination in the elevator at least 25% below the lower explosion limit at all times during operation. In case you are considering the installation of dust control systems to avoid any of these particular safety requirements, testing has indicated that 55 grams per cubic meter or .055 ounces per cubic foot is the minimum concentration required for an explosion of mixed grain dust. If the conditions are ideal, it could be as low as 20 grams per cubic meter or .02 ounces per cubic foot. The interpretation of the new regulation would be the dust must be less than .75 x .02 oz. per cubic foot or .015 oz/cuft. The application of dust control to a bucket elevator must conform to the American Standards of Industrial Ventilation and should be in compliance with such publications as Dust Control for Grain Elevators, National Grain and Feed Association, as well as several other applicable references. The above information will be defined in greater detail in the following chaprers. Reference Text NFPA 61B NFPA 61C NFPA 61D Draft Chapter 1 – General Second Draft June 13, 2013 NFPA 69 Prevention of Grain Elevator and Mill Explosions (NRC) Feed Manufacturing Technology I, II, III Conveying Machines, MIR Publishers Moscow ASAE Paper No. 69-840, 69-853 GEAPS, March 11, 1980 Link Belt W. D. Sweet