Lesson 6: Lesson Extensions Manufacture It! Things you will need

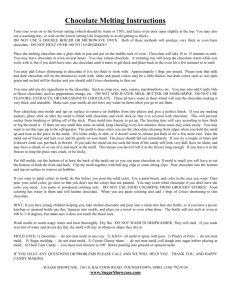

advertisement

Lesson 6: Lesson Extensions Manufacture It! Things you will need: • Two blocks of polymer Clay – this will be the mold • Chocolate (melted) • Cooking oil or petroleum jelly • Carving knives • Syringes When you need to manufacture a design on a large scale, this too has to be factored into the design process. When Dyson engineers finish working on the models and prototypes of their designs, they transfer their projects to engineers in Malaysia to get it ready for manufacture. There, engineers take the design through two production runs—engineering build 1 (EB01) and engineering build 2 (EB02). EB01 is the first time that the design is made using mass production techniques. The EB01 machines are advanced prototypes (using production intent components) —it’s the last chance for engineers to fix any small problems, like rough edges on the molded plastic components. Any necessary changes are then made and then EB02 machines are produced to make sure. This is the last stage before the design goes into mass production and onto shop shelves all over the world. The DC39 has hundreds of components, from screws and springs to electrical wires, electronics, plastic moldings and a motors. Dyson buys a few of the components, like the cable rewind mechanism, from specialist suppliers. Others are made especially for Dyson—for example, the 110 plastic molded parts. Pictured here is the inside of the DC39 cone pack tool, the most important part of the vacuum cleaner—the cones that separate the dust from the air. A plastic injection molding tool comes in two or more parts that fit together to form a space which is the shape of the finished component. To start off with you have a cavity half and a core half. On this cone pack, there are no less than 7 injector points to make sure the plastic flows around the mold evenly. This tool weighs 3,000 lbs (the weight of an average car!). A tool like this will cost tens of thousands of dollars to make, but can make up to a million plastic parts! After the hot plastic is injected into the mold, it’s left to set for a few seconds. Then the mold tool opens up and the parts are ejected by moving metal pins. Students can easily, and relatively inexpensively, experience injection molding for themselves. Working in small groups, give student groups some polymer clay to kneed thoroughly into two thick slabs, (one cavity slab, one core slab) thick enough to accommodate the part of their classroom product they hope to create from the mold. These slabs will go together later – ensure the two mating faces are flat and sit together nicely. Next, students can use carving tools to carve half of the shape of their product out of the Cavity slab block press and the other half of the piece of the product on the lower Core slab half. They could also use other items that have similar shapes into the clay to create impressions (i.e. a chocolate egg profile). On one slab, you will need to carve out a feed system connecting to the shape and to the edge of the block you have carved or pressed into the slab, which you can use to inject the chocolate through later. It should be about 3/5 mm deep (or deeper, if you feel it needs to be). The chocolate will flow under pressure from the syringe. Treat the mold first by spraying it with water, then a release agent, such as cornstarch. Once the mold shape and feed system is complete, bake the clay according to the manufacturer’s instructions. Once the molds have been baked, students can put the cavity and the core slab halves of their product’s component together. Before they do, have the students discuss ways to connect the two halves together in the correct orientation. 1. 2. 3. 4. Have them treat the molds with a release agent (again, water and cornstarch will do). Then Put them together and hold using your chosen method Melt the chocolate Use syringes to inject the liquid chocolate through the feed system into their mold. Allow the chocolate to cool. 5. Ask students to create several ‘prototypes’ of their part. Taking what they have learnt, they should write instructions on how to use each mold. This could include how fast to squirt the chocolate, how to hold the syringe, or how to combine the two halves to make a whole component. The instructions should then be rotated to the next group who will try and create the perfect part. Discuss as a class which methods the students would use to manufacture their chocolate parts on a mass scale. How would they put them together? And how would they get them into the right packaging and onto the shelves? 2