Fume cupboards - University Wiki

advertisement

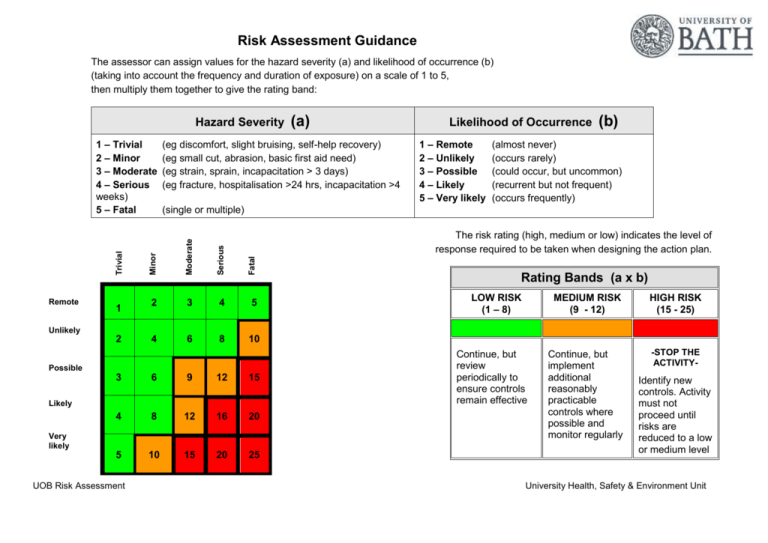

Risk Assessment Guidance The assessor can assign values for the hazard severity (a) and likelihood of occurrence (b) (taking into account the frequency and duration of exposure) on a scale of 1 to 5, then multiply them together to give the rating band: Hazard Severity 1 – Remote 2 – Unlikely 3 – Possible 4 – Likely 5 – Very likely (b) (almost never) (occurs rarely) (could occur, but uncommon) (recurrent but not frequent) (occurs frequently) Fatal The risk rating (high, medium or low) indicates the level of response required to be taken when designing the action plan. Serious 1 Likelihood of Occurrence (single or multiple) Moderate Remote (eg discomfort, slight bruising, self-help recovery) (eg small cut, abrasion, basic first aid need) (eg strain, sprain, incapacitation > 3 days) (eg fracture, hospitalisation >24 hrs, incapacitation >4 Minor Trivial 1 – Trivial 2 – Minor 3 – Moderate 4 – Serious weeks) 5 – Fatal (a) 2 3 4 5 4 6 8 10 Rating Bands (a x b) LOW RISK (1 – 8) MEDIUM RISK (9 - 12) HIGH RISK (15 - 25) Continue, but implement additional reasonably practicable controls where possible and monitor regularly -STOP THE ACTIVITY- Unlikely 2 Possible 3 6 9 12 15 4 8 12 16 20 5 10 15 20 25 Likely Very likely UOB Risk Assessment Continue, but review periodically to ensure controls remain effective Identify new controls. Activity must not proceed until risks are reduced to a low or medium level University Health, Safety & Environment Unit Risk Assessment Record Risk Assessment of: Assessor(s): Overview of activity / location / equipment / conditions being assessed: Use of fume cupboards This assessment does not include recirculating fume cupboards that return clean air back into the workroom or other local exhaust ventilation systems This assessment does not include biological safety cabinets used to control exposure to hazardous microorganisms. Context of assessment (delete as appropriate): planning stage / ‘desk-top’ exercise / site visit / in consultation with Generic or specific assessment? Generic risk assessment # Hazard(s) identified UOB Risk Assessment Date: employees / in consultation with managers / other (please describe) Persons affected Existing controls & measures A B A x B Additional controls required University Health, Safety & Environment Unit # Hazard(s) identified Persons affected Existing controls & measures FUME CUPBOARD USE – GENERAL Fume cupboards may not provide sufficient reduction in hazardous chemical exposure. Poorly designed, constructed, installed or commissioned; Performance deteriorates after installation; and Performance less than expected as not used properly Exposure during monitoring, inspection, testing or maintenance operations Users may be exposed to hazardous chemical residues during decommissioning, removal or disposal UOB Risk Assessment A B A x B Additional controls required General precautions: o Fume cupboards designed, constructed, installed and commissioned to a recognised standard; o Fume cupboard subject to a regime of performance monitoring, inspection, testing and maintenance; o Fume cupboard users follow manufacturer’s instructions and other authoritive guidance; o Exposure to hazardous chemicals to be prevent or reduced during inspection, testing or maintenance operations; and o Fume cupboard subject to any necessary decontamination prior to decommissioning, removal and disposal University Health, Safety & Environment Unit # Hazard(s) identified Persons affected Existing controls & measures FUME HOOD POORLY DESIGNED OR CONSTRUCTED Fume cupboard hood may not provide sufficient reduction in hazardous chemical exposure due to poor cupboard design or construction UOB Risk Assessment Fume cupboard hood requirements to be clearly defined prior to selection o Fume hood cupboard construction materials to be resistant to the chemicals to be used; o Fume hood containment to be sufficient for the planned activities; and o Fume hood size to be sufficient for the planned activities Fume cupboard hoods designed and constructed to a recognised standard: o Fume cupboard hoods manufactured prior to XXXX – BS 7258: 1994 o Fume cupboard hoods manufactured from XXXX onwards – BS EN 14175 Fume cupboard hoods services, such as gas and electricity, designed and constructed to relevant British Standards. Newly purchased equipment to conform with EU essential health and safety requirements – manufacturer / supply to CE mark and issue a certificate of conformity A B A x B Additional controls required Fume cupboard hood requirements to be recorded prior to selection Manufactures / suppliers / designers / installers claims regarding design, construction and performance to be recorded – used to inform subsequent acceptance and operations Manufactures / suppliers / designers / installers instructions for operation and maintenance to be recorded – used to inform subsequent operations University Health, Safety & Environment Unit # Hazard(s) identified Persons affected Existing controls & measures FUME SYSTEM POORLY DESIGNED OR CONSTRUCTED Fume cupboard hood may not provide sufficient reduction in hazardous chemical exposure due to poor system design or construction Fume cupboard system may not provide sufficient reduction in hazardous chemical exposure due to poor system design or construction UOB Risk Assessment Generally, the average face velocity needs to be: o For vapours and the like 0.5 m/s o For dusts and the like 1.0 m/s Fume cupboard system requirements to be clearly defined prior to selection o Fume cupboard system construction materials to be resistant to the chemicals to be used; and o Fume system containment to be sufficient for the planned activities; and Fume cupboard systems designed and constructed to a recognised standard: o Fume cupboard systems manufactured prior to XXXX – BS 7258: 1994 o Fume cupboard systems manufactured from XXXX onwards – BS EN 14175 Fume cupboard hoods services, such as gas and electricity, designed and constructed to relevant British Standards Newly purchased equipment to conform with EU essential health and safety requirements – manufacturer / supply to CE mark and issue a certificate of conformity Design and installation to take account of factors that might disrupt airflow such as: o Need for source of make-up air; o Presence of disruptive airflows from doors, windows, other A B A x B Additional controls required Fume cupboard system requirements to be recorded prior to selection Manufactures / suppliers / designers / installer claims regarding design, construction and performance to be recorded – used to inform subsequent acceptance and operations Manufactures / suppliers / designers / installers instructions for operation and maintenance to be recorded – used to inform subsequent operations Fume cupboard system performance to be determined once in situ – follow standard in BS EN 14175-4: 2004 on site test methods University Health, Safety & Environment Unit # Hazard(s) identified Persons affected Existing controls & measures FUME SYSTEM PERFORMANCE DETERIORATES Fume system performance may deteriorate with time as components suffer wear or damage FUME CUPBOARD PERFORMANCE MAY BE LESS THAN EXPECTED DURING OPERATION A fume cupboard may give less than the expected performance due to users not following good practice whilst operating the cupboard. UOB Risk Assessment Proactive actions to prevent deterioration o Maintain as per manufacturers / suppliers instructions and other authoritive guidance Monitoring to detect deterioration in performance – activities to stop and fault reported o Visual check and air flow check before use – fitted with a means to check air flow (eg manometer) o Periodical visual checks and air flow checks by Department o Full examination and testing at least every 14 months by Estates o Alarms fitted to warn of sudden performance loss Fume cupboard users must be competent to use them o Sufficient understanding of how the cupboards work; o Sufficient understanding of the limitations of cupboards; and o Sufficient understanding of how their actions may impact on cupboard performance A B A x B Additional controls required Proactive actions to prevent deterioration o Increase the frequency of maintenance actions if monitoring shows this to be necessary o Increase the frequency of maintenance if the activities are likely to cause a deterioration in performance Reactive actions to detection of deterioration o Increase the frequency of monitoring actions if results show this to be necessary Fume cupboards reduce exposure to airborne chemicals. However, users hands and arms may still be exposed and this needs to be considered in the COSHH assessment. University Health, Safety & Environment Unit # Hazard(s) identified Persons affected Existing controls & measures Sash opening too wide, reducing face velocity and containment Material drawn into ducting (eg paper sheet, plastic bags, etc), disruption air flow and reducing containment Equipment or material in fume cupboard blocks airflow / creates air flow eddies reducing containment Running equipment may create air flows that disrupt the fume cupboard air flow (eg centrifuge, power tools, etc) UOB Risk Assessment Loose material that might be drawn into the ducting to be excluded from the fume cupboard Large items of equipment that are likely to disrupt air flow to be excluded from the cupboard – test air flow if there are any doubts Smaller items of equipment can be raised slight (eg on small wooden blocks) to allow air flow all around the equipment B A x B Additional controls required Mark maximum sash height that still allows the face velocity to be maintained on the fume cupboard As a general rule, keep sash down as far as possible whilst still allowing access, but not above maximum A If loose material is drawn into the ducting, then use of the cupboard must cease until the material has been recovered Large items of equipment that generate air flows that might reduce face velocity to be assessed separately. Examples might be: o Centrifuges o Cooling fans o Power tools o etc University Health, Safety & Environment Unit # 5 6 Hazard(s) identified Raid or violent movements across the face of the fume cupboard may disrupt air flows, reducing face velocity and containment Air flows from open doors / windows may disrupt fume cupboard air flow, reducing face velocity and containment FUME CUPBOARD IMPACTS UPON ACTIVITIES WITHIN THE CUPBOARD The condition of the fume cupboard may make some activities more difficult to perform, increasing the risk of a failure Level of illumination insufficient View of work obscured by fume cupboard Persons affected Existing controls & measures Insufficient space to perform tasks safely UOB Risk Assessment B A x B Additional controls required Doors and windows to be kept shut Fans are not to be run whilst fume cupbaords are being used 7 A Provide good lighting Suitable for chemicals used eg dust proof, flameproof Sash viewing screen to be kept clean and clear Cupboard housekeeping to remove uneccessary materials, leaving as much free space as possible See also seleting a fume cupboard above University Health, Safety & Environment Unit # Hazard(s) identified Existing controls & measures A B A x B Additional controls required 8 9 Persons affected FUME CUPBOARD 10 11 Assessor signature: UOB Risk Assessment Print name: Review date: University Health, Safety & Environment Unit Risk Assessment Action Plan Action Plan in respect of: Ref no. Prepared by: Action to be taken, incl. Cost Responsible manager’s signature: Print name: UOB Risk Assessment By whom Target date Review date Outcome at review date Responsible manager’s signature: Date: Print name: Date University Health, Safety & Environment Unit