Ca hardness = 100 mg/L as CaCO 3

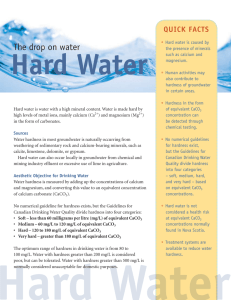

advertisement

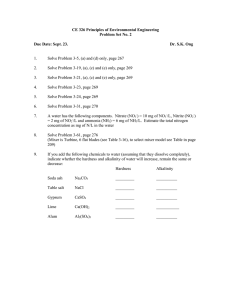

AWPPCE HW 9 Problem 1 From diagram you can see that Total hardness = 200 mg/L as CaCO3 Ca hardness = 100 mg/L as CaCO3 Mg hardness = 100 mg/L as CaCO3 Total alkalinity = bicarbonate alkalinity = 50 mg/L as CaCO3 So carbonate hardness = 50 mg/L as CaCO3 non-carb. hardness = 150 mg/L as CaCO3 The purpose is to help see the chemical composition. Increasing Ca hardness alkalinity and pH increase scaling and decrease corrosion. Increasing temp increases scaling and corrosion. This aids in deciding how much lime or soda ash to add to soften the water. Other methods are ion exchange, zeolite, or other chemical processes. Problem 2 There are many common methods for cyanide removal from water: Chlorination: HCl will break the bonds in HCN. Add chlorine gas and sodium dioxide to water Iron Salts: Ferrocyancide is less toxic because it does not release as much cyanide into solution. Ferrous sulfates with cyanide can be oxidized to ferrous complexes which may still be toxic but precipitate and can be removed in sedimentation Ozone: Using an ozone generator to dissolve ozone into water stream. Ozone will not combine with organics to create any toxic compounds. Increasing temperature of water stream will induce detoxification Also EPA recommends granular activated carbon in combination with packed tower aeration/ mixing the air in will absorb CO2 into the water and formation of carbonic acid will break the HCN bond creating HOCN Problem 3 Cr(VI) is a result of metal working a plating. Being a toxic pollutant that is easily transported through water, it deserves a great deal of attention. Remediation methods include: Chemical reduction- direct introduction of a reducing chemical agent like zero valent iron or sulfite to reduce to Cr(III) Chemical precipitation- atomized slag and liquid hydroxyapatite Bioreduction- yeast, bacteria, fungi and algae for anaerobic and aerobic reduction