Paper vocabulary

advertisement

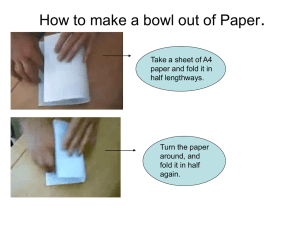

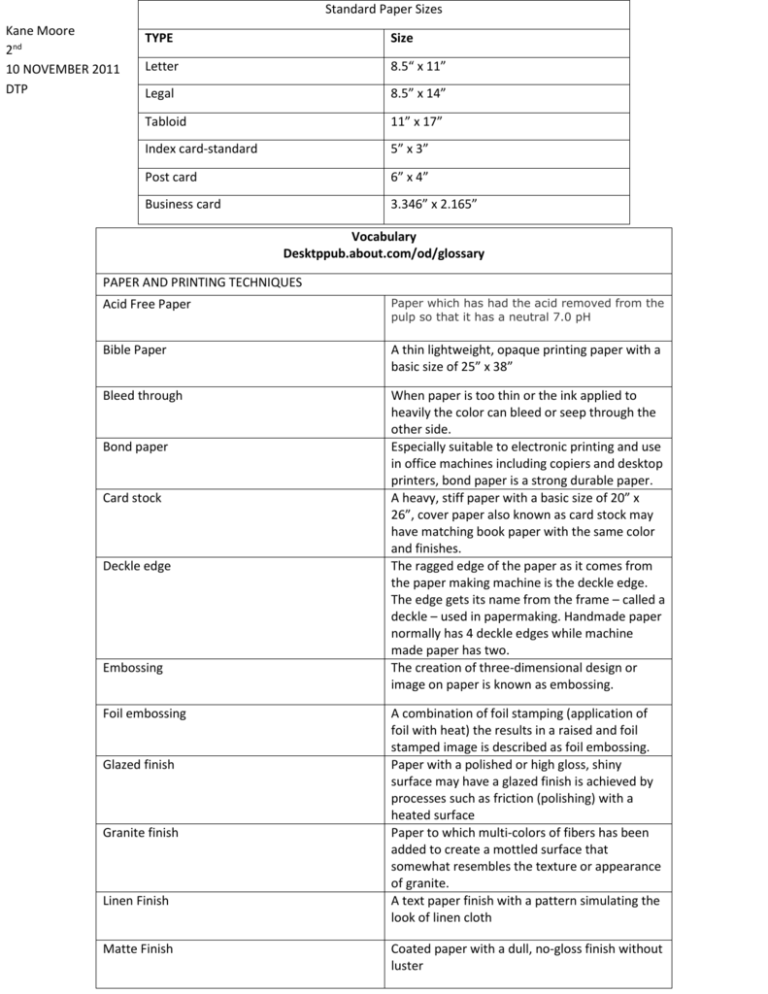

Standard Paper Sizes Kane Moore 2nd 10 NOVEMBER 2011 DTP TYPE Size Letter 8.5“ x 11” Legal 8.5” x 14” Tabloid 11” x 17” Index card-standard 5” x 3” Post card 6” x 4” Business card 3.346” x 2.165” Vocabulary Desktppub.about.com/od/glossary PAPER AND PRINTING TECHNIQUES Acid Free Paper Paper which has had the acid removed from the pulp so that it has a neutral 7.0 pH Bible Paper A thin lightweight, opaque printing paper with a basic size of 25” x 38” Bleed through When paper is too thin or the ink applied to heavily the color can bleed or seep through the other side. Especially suitable to electronic printing and use in office machines including copiers and desktop printers, bond paper is a strong durable paper. A heavy, stiff paper with a basic size of 20” x 26”, cover paper also known as card stock may have matching book paper with the same color and finishes. The ragged edge of the paper as it comes from the paper making machine is the deckle edge. The edge gets its name from the frame – called a deckle – used in papermaking. Handmade paper normally has 4 deckle edges while machine made paper has two. The creation of three-dimensional design or image on paper is known as embossing. Bond paper Card stock Deckle edge Embossing Foil embossing Glazed finish Granite finish Linen Finish Matte Finish A combination of foil stamping (application of foil with heat) the results in a raised and foil stamped image is described as foil embossing. Paper with a polished or high gloss, shiny surface may have a glazed finish is achieved by processes such as friction (polishing) with a heated surface Paper to which multi-colors of fibers has been added to create a mottled surface that somewhat resembles the texture or appearance of granite. A text paper finish with a pattern simulating the look of linen cloth Coated paper with a dull, no-gloss finish without luster Newsprint Parchment paper Safety paper Vellum Ream Ream weight (or paper weight) Inexpensive paper made primarily of mechanically ground wood pulp rather than chemical pulp Once made from the skin of animals such as goats, sheep, or calves, the parchment paper is now achieved by treating paper from cellulose fibers with sulfuric acid. Specially treated, calendared bond paper that readily reveals attempts to alter it trough erasures or printing An absorbent finish of paper, vellum finish is a very slightly rough or “tooth” texture intended to mimic natural vellum. 500 sheets of printing paper The actual weight in pounds of 500 sheets of paper (a ream) PAPER FOLDS Accordion fold Crossfold Zigzag folds with 6 –panels and two parallel folds that go in opposite directions. Each panel of the accordion fold is about the same size. Two or more folds going in different directions, typically at right angles. Double parallel fold Paper is folded in half and then folded in half again with a fold parallel to the first fold. Spiral Fold A piece of paper folded in spiral folds has two or more parallel folds that fold in on each other. C-fold (or trifold) When folding paper into three parts, c folds have 6 panels (counting both sides of the paper) with two parallel folds in a spiral fold configuration To bend a paper to meet its other side once on one paper in any direction Half-fold BINDING Binding Spiral binding Saddle stitch Perfect binding A general term for any of various methods of securing the loose pages or sections of a book or booklet One of several ways of securing loose printed pages using single or double loop wire of plastic that fit into round or rectangular holes in the pages Securing loose printed, folded, and nested pages with stitches or staples down the middle of the fold (the spine) A method of bookbinding where a flexible adhesive attaches a paper cover to the spine of the assembled signatures