2011-06-13 Risk_Assessment_template_DCL

advertisement

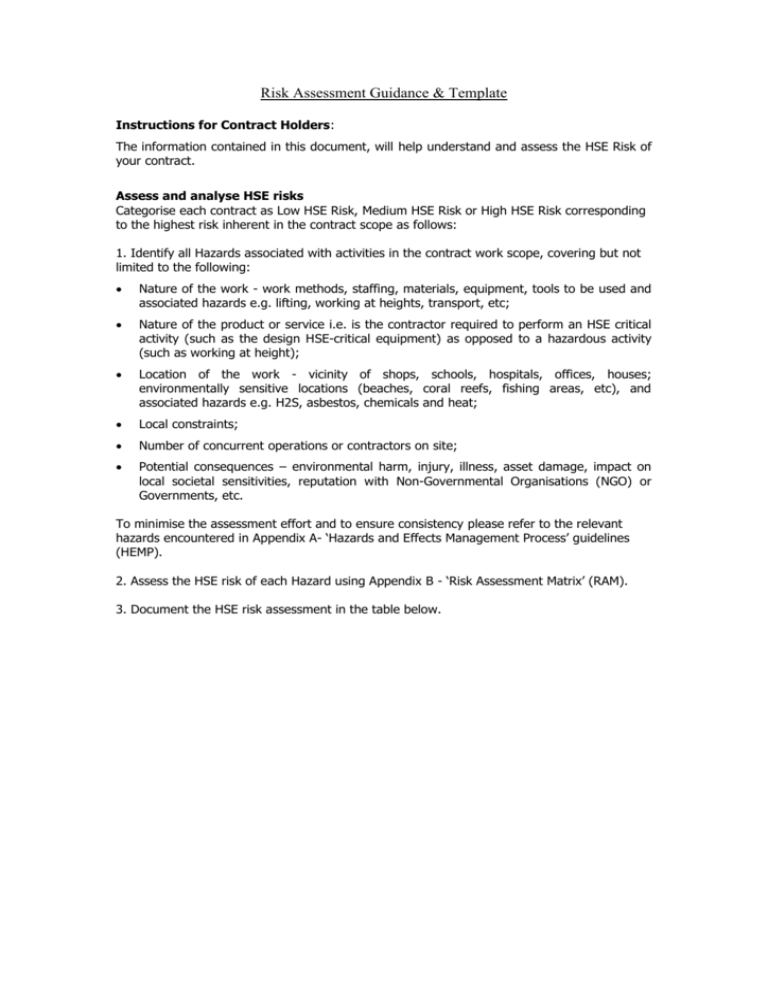

Risk Assessment Guidance & Template Instructions for Contract Holders: The information contained in this document, will help understand and assess the HSE Risk of your contract. Assess and analyse HSE risks Categorise each contract as Low HSE Risk, Medium HSE Risk or High HSE Risk corresponding to the highest risk inherent in the contract scope as follows: 1. Identify all Hazards associated with activities in the contract work scope, covering but not limited to the following: Nature of the work - work methods, staffing, materials, equipment, tools to be used and associated hazards e.g. lifting, working at heights, transport, etc; Nature of the product or service i.e. is the contractor required to perform an HSE critical activity (such as the design HSE-critical equipment) as opposed to a hazardous activity (such as working at height); Location of the work - vicinity of shops, schools, hospitals, offices, houses; environmentally sensitive locations (beaches, coral reefs, fishing areas, etc), and associated hazards e.g. H2S, asbestos, chemicals and heat; Local constraints; Number of concurrent operations or contractors on site; Potential consequences – environmental harm, injury, illness, asset damage, impact on local societal sensitivities, reputation with Non-Governmental Organisations (NGO) or Governments, etc. To minimise the assessment effort and to ensure consistency please refer to the relevant hazards encountered in Appendix A- ‘Hazards and Effects Management Process’ guidelines (HEMP). 2. Assess the HSE risk of each Hazard using Appendix B - ‘Risk Assessment Matrix’ (RAM). 3. Document the HSE risk assessment in the table below. Contract Risk Assessment: (HEMP study) Please complete the template to help you perform a contract risk assessment. This exercise is not supposed to be an exhaustive or comprehensive assessment as such effort should be directed towards identifying the higher risk activities and their more Contract Name Contract Work Scope Assessed* Risk (High / Medium/ Low) Activity Hazard Effect Consequence Likelihood Risk *Ranking (If hazard was to be realised / released) (Severity rating number ) (Frequency letter) (letter & Number) N.B. For guidance please refer to Appendix A“Hazard and Effects Management Process (HEMP)” and B “Guidance for Using the RAM” Appendix ‘A’ Hazards and Effects Management Process (HEMP) To help guide you, we have listed some activities and hazards that, can be considered when determining the contracts risk. This list should only be used as a guide, as it does not include all hazardous activities. Activity Hazard Driving/ Transport Dust, road condition, weather, 3rd parties, animals/camels, vehicle maintenance/condition, driver competence & fitness, load restraining, driving permit, driving hours, speed, mobile phone use Manual handling, spills, fall of load, crane/ forklift failure, sling failure, air winch failure Home made, wrong for the job, wrong size or type Tool racks, stoppers, conditions, securing mechanisms Unsecured objects, earthing, un-authorized personnel, moving/ rotating parts, noise, vibration, hot surface (high operating temperature), slippery surface/ trips, compressed air failure, hydraulic power failure Domestic, medical, batteries, drilling, exhaust fumes Equipment failure, lockout failure, overloading circuit/ cables, incorrect voltage/ frequency, high voltage. Slips/ trips/ falls, falling objects, condition of ladders, condition and presence of railings, loose gratings Release of pressure, release of test fluid, not following manufacturer guidelines, excessive pressure, stored energy, material failure, connection failure, calibration failure No gas flash back arrester, gas leaks, unsecured cylinders, welding or cutting near flammable fluids, fumes, open flame, arcing, UV light, heat stress, electrical failure Exposure to paint, painting at height Lack of Air, H2S Crude oil & diesel, paints & coatings, oils & greases, solvents, acids, mud chemicals, completion chemicals, cement, cement chemicals, shock cards, storage, shading Sharp objects, manual handling, steam, smoke, boiling water, boiling oil, hot surface, slippery surface/ trips, chemicals, electrical appliances, food contamination, water contamination, flies/ insects, rodents Fire, smoking, slippery surface, tripping, electrical appliances, flies/insects, spiders, rodents, snakes, scorpions, heat, cold, winds, dust Hydrogen sulphide, hydrocarbons Storage (Security, non–segregation of explosives, premature detonation) and transportation (compatibility, shock/stress loading, non–segregation of explosives, premature detonation), gun loading & laying down (e.g. trapped pressure), gun misfire. Radioactive sources, storage and transportation Hydrocarbons at surface, high pressure, hydrogen sulphide, ionising radiation, naturally occurring radioactive materials, ignition sources, tubular, drill pipe and BHA handling, elevated objects, working out of direct sight (e.g. in the cellar) Lack of air, H2S Incorrect voltage /frequency, sparking/ earthing Material handling, Lifting, loading, unloading Use of hand tools Storage of tools Use of machines & Equipment Waste Electrical work Working at heights Pressure testing Welding, cutting, grinding Painting Confined spaces Dealing with chemicals Cooking Accommodation/ desert environment Gases at surface Explosives Radioactive sources Well intervention (in addition to above activities) Entry into Confined Spaces Moving Equipment under Power Lines Etc. “” “” Etc. “” “” Appendix ‘B’ Guidance for Use of the RAM The starting point for a RAM assessment is an understanding of the Hazard in its context (activity, location etc.), or an understanding of the particular incident being considered. HSE Risk Assessment Matrix An assessment consists of the following steps. Step 1 Identify potential consequences Identify the consequences that could develop from a release of the Hazard under the prevailing conditions. Ask the question: ‘What could happen if the controls don’t work or they fail?’ For example, the operation of a pump in crude oil service involves the potential for a release of crude oil in the event of a pump seal failure. Some of the consequences that could result are: a) Leak of crude oil into the drain system and then into the sea. b) Ignition of the crude oil resulting in a small fire around the pump. c) Inadequate fire fighting and escalation of the fire to the point where other process equipment fails and a major fire and explosion occurs. Step 2 Estimate the Severity of each potential Consequence For each of the identified consequences assess the Severity (0 - 5) in the four Consequence categories people, assets, environment and reputation (PAER). In the crude oil pump example above, for the consequence in which crude oil leaks from the pump seal and flows through the drain system into the sea, there could be impacts in 3 Consequence categories asset, environment and reputation. Step 3 Estimate the Likelihood For each of the potential consequences make an estimate of the Likelihood of the Consequence in terms of the Likelihood levels A to E. The Likelihood level should be judged from past experience, by asking the question: ‘How often in the past has a hazard release resulted in a Consequence similar to the one that we are considering?’ The approach is one of applying history to predict the future. The estimate of Likelihood should be based on the Likelihood of the particular Consequence under consideration, not on the Likelihood of the Hazard being realised or incident occurring. In the example above an estimate should be made of the likelihood of the crude oil pump seal leak resulting in oil into the sea, not the likelihood that the pump seal will leak. Step 4 Estimate the risk rating For each potential Consequence determine the risk rating for each of the applicable PAER categories in terms of the product of the Consequence Severity and the Likelihood. The risk ratings (up to 4 for each potential Consequence) can be plotted on the matrix to provide a visual representation of the risk profile of the hazard release scenario under consideration.