Rotary Encoders: Incremental vs. Absolute Explained

advertisement

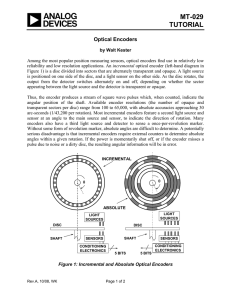

Encoder Concepts: A position encoder is a device that provides a digital output as a result of a linear or angular displacement. It converts motion into a sequence of digital pulses. By counting a single bit or by decoding a set of bits, the pulses can be converted to relative or absolute position measurements. Encoders have both linear and rotary configurations, but the most common type is rotary. The following diagram shows fundamental principle of optical encoder construction. A beam of light passes through slots in a disc and is detected by a suitable light sensor. When the disc is rotated, a pulsed output is produced by the sensor with number of pulses being proportional to the angle through which the disc rotates. Rotary encoders are manufactured in two basic forms: a) Incremental encoders b) Absolute encoder Incremental encoders, that gives changes in rotation from a reference or datum position. An incremental encoders have three concentric tracks with three sensors. The inner most track has one hole that is used to locate the home position of the disc. The other two tracks have a series of equally spaced holes that go completely round the disc but holes in the middle track offset from the holes in the outer track by one-half the width of a hole. This offset enables the direction of rotation to be determined. In case of clockwise rotation of the shaft the pulses generated by the outer tracks holes leads those in the inner track; whereas in case of anti-clockwise direction pulses generated by the outer track lags that of the inner track. The resolution is determined by the number of slots (opening) in the disc. There can be an optional third output: reference, which happens once every turn. This is used when there is the need of an absolute reference, such as positioning systems. Example: With 60 slots disc, resolution will be 360/60 = 6º. This means position of the shaft could be determined as small as 6º movement. The incremental can be either mechanical or optical. In the optical type there are two gray coded tracks. The incremental rotary encoder is the most widely used of all rotary encoders due to its low cost: only two sensors are required. The fact that incremental encoders use only two sensors does not compromise their accuracy. One can find in the market incremental encoders with up to 10,000 counts per revolution, or more. The optical type is used when higher RPMs are encountered or a higher degree of precision is required. Absolute encoders, that produce a unique digital word corresponds to each rotational position of the shaft. Absolute encoders have three or more concentric circles having slot-patterns that generate unique binary code based on the position of the shaft. Number of concentric tracks determines the number of binary bits. The optical disc of the absolute encoder is designed to produce a digital word that distinguishes N distinct positions of the shaft. Typically, encoders have 10 or 12 tracks. Thus a 10 track encoder has 10 bit binary word and that will produce 1024 (210 =1024) unique position code. This means resolution of detection of position will be 360/1024 = 0.35º. This also means that the shaft movement can be determined as accurate as 0.35º. Figure 1 Side-view of the Absolute Encoder disk The normal form of binary code is not used as the position distinguishing position code because changing from one binary number to the next can result in more than one bit changing. For example: change from 001 (001 = binary 1) to 010 (010 = binary 2) are two adjacent number but two binary bits (bit 0 changes from 1 to 0 and bit 1 changes from 0 to 1) need to change during the transition. Thus to overcome the problem another type of code called Gray code is used. Standard Binary Code Disc: Gray Code Disc Output from a three concentric circle Binary Coded Disc Sector Circle#1 Circle#2 Circle#3 Position in Degree 1 OFF OFF OFF 0° to 45° 2 OFF OFF ON 45° to 90° 3 OFF ON OFF 90° to 135° 4 OFF ON ON 135° to 180° 5 ON OFF OFF 180° to 225° 6 ON OFF ON 225° to 270° 7 ON ON OFF 270° to 315° 8 ON ON ON 315° to 360° Output from three concentric circle Gray Coded Disc Position in Degree Sector Circle#1 Circle#2 Circle#3 1 OFF OFF OFF 0° to 45° 2 OFF OFF ON 45° to 90° 3 OFF ON ON 90° to 135° 4 OFF ON OFF 135° to 180° 5 ON ON OFF 180° to 225° 6 ON ON ON 225° to 270° 7 ON OFF ON 270° to 315° 8 ON OFF OFF 315° to 360°