Project 4 Final

advertisement

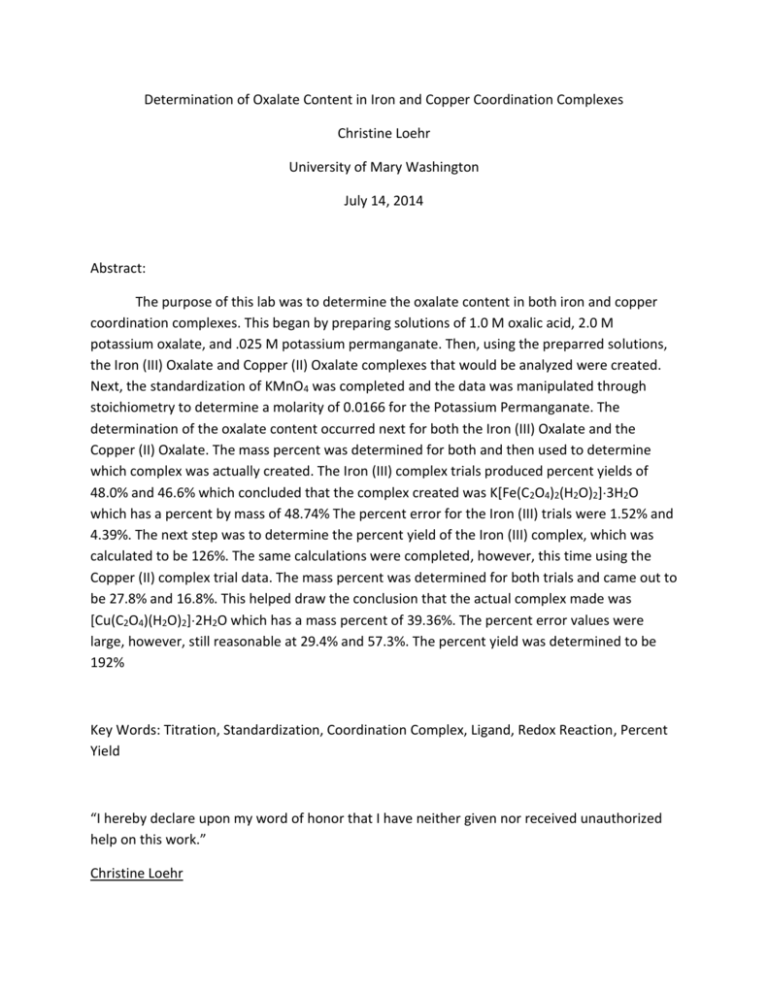

Determination of Oxalate Content in Iron and Copper Coordination Complexes Christine Loehr University of Mary Washington July 14, 2014 Abstract: The purpose of this lab was to determine the oxalate content in both iron and copper coordination complexes. This began by preparing solutions of 1.0 M oxalic acid, 2.0 M potassium oxalate, and .025 M potassium permanganate. Then, using the preparred solutions, the Iron (III) Oxalate and Copper (II) Oxalate complexes that would be analyzed were created. Next, the standardization of KMnO4 was completed and the data was manipulated through stoichiometry to determine a molarity of 0.0166 for the Potassium Permanganate. The determination of the oxalate content occurred next for both the Iron (III) Oxalate and the Copper (II) Oxalate. The mass percent was determined for both and then used to determine which complex was actually created. The Iron (III) complex trials produced percent yields of 48.0% and 46.6% which concluded that the complex created was K[Fe(C2O4)2(H2O)2]3H2O which has a percent by mass of 48.74% The percent error for the Iron (III) trials were 1.52% and 4.39%. The next step was to determine the percent yield of the Iron (III) complex, which was calculated to be 126%. The same calculations were completed, however, this time using the Copper (II) complex trial data. The mass percent was determined for both trials and came out to be 27.8% and 16.8%. This helped draw the conclusion that the actual complex made was [Cu(C2O4)(H2O)2]2H2O which has a mass percent of 39.36%. The percent error values were large, however, still reasonable at 29.4% and 57.3%. The percent yield was determined to be 192% Key Words: Titration, Standardization, Coordination Complex, Ligand, Redox Reaction, Percent Yield “I hereby declare upon my word of honor that I have neither given nor received unauthorized help on this work.” Christine Loehr I: Introduction Inorganic chemistry is a division of chemistry that studies metals, their compounds, and their reactivity. It discusses coordination compounds, solid state chemistry, and inorganic acids and bases. 1 Coordination compounds are used in this lab. They are based on a type of bond called dative bonding. Dative bonding is when both electrons in the bond come from one species. This incorporates a ligand bonded to a metal. A ligand is another ion or small molecule that surrounds the central atom or ion in a molecule which is the metal. The purpose of this lab was to determine the oxalate content in both iron and copper coordination complexes. The content of oxalate is measured in terms of the amount of oxalate ligands that are bound to each of the metal centers. This occurs though a redox titration with the potassium permanganate. A redox titration utilizes redox reactions to determine the amount of oxidizing or reducing agent in a sample.2 The redox titration specifically used for this lab is as followed when balanced in acidic conditions: MnO4- + 5C2O42- + 16H+ → 2Mn2+ + 10CO2 + 8H2O This is the redox reaction that occurs when the oxalate is added with the permanganate in an acidic condition. Redox (reduction-oxidation) reactions are chemical reactions in which the oxidation states of the reactants are changed. Reduction is the gain of electrons or a decrease in oxidation state by a molecule, atom or ion. Oxidation is the loss of electrons or an increase in oxidation state by a molecule, atom or ion. If one species is oxidized then the other must be reduced because apart, the reduction and oxidation are each called a half-reaction. They must be together to create the whole redox reaction. The first step of the experiment was to prepare the solutions of oxalic acid, potassium oxalate, and potassium permanganate. The standardization that needed to occur for this experiment is of the potassium permanganate solution. Standardization is using a known concentration to determine an unknown concentration. Potassium Permanganate was titrated into a solution containing potassium oxalate, DI water, and H2So4. The Permanganate was slowly added to the beaker containing the solution until it maintained a slight pink color for 1-2 minutes. This experiment required multiple equations. The first was the equation that is used to find the mass percent of the oxalates. It is as followed: Mass of the oxalate Mass of the sample titrated (100%) = Mass percent oxalate (1) Once the mass percent was determined for both trials, they were compared to the actual mass percent that was previously determined in a pre-lab question. They were compared by using the percent error formula: Percent Error = |Approximate Value − Exact Value| |Exact Value| × 100% (2) Once the values were compared and the error was observed, the next step was to calculate the percent yield. The percent yield indicates the percent of theoretical yield that was obtained from the final product in an experiment. The formula to calculate the percent yield is as followed: Percent Yield = (Mass of actual yield) (Mass of theoretical yield) x100% (3) II: Experimental This experiment began by making 25.0 mL of a 1.0 M oxalic acid solution, 50.0 mL of a 2.0 M potassium oxalate solution, and 200. mL of a 0.025 M potassium permanganate solution. The solid mass needed to be added to DI water to make each solution was determined using the volume needed and the molecular weight of the solids through simple stoichiometry. The next step to occur was the preparation of the iron (III) oxalate complex. This began by dissolving 1.0 grams of ferrous ammonium sulfate hexahydrate in 3.0 mL of DI water in a flask. Then, about 10 drops of 3 M sulfuric acid was added along with a stir bar. While the components were stirring, 5.0 mL of the previously prepared 1.0 M oxalic acid solution was added. The solution was then brought to a boil. Once boiling, the solution was removed from the hot plate and the solid was allowed to settle to the bottom. The liquid was removed using a pipet while being careful not to disturb the solid on the bottom. Once all of the liquid was removed, the solid was washed with 3.0 mL of hot water and then allowed to settle to the bottom once again. The water was removed and then the washing process was repeated. All of the liquid layers that were removed were collected and then disposed of in the designated waste beaker. Next, 2.0 mL of a 2 M solution of potassium oxalate was added to the wet solid. This was put back on the stirring hot plate and then 2.0 mL of 6% hydrogen peroxide was added. Next, 2.0 mL of the 1.0 M oxalic acid solution was added and then brought to a boil and kept there for 1 minute. The solution was removed from the heat and then allowed to cool to room temperature. Once at room temperature, the solid was removed by gravity filtration. The filtrate was then cooled in an ice water bath. Once cooled, the product was precipitated from the solution by adding 10.0 mL of ethanol to the filtrate and swirling it. The solid product was collected by vacuum filtration. The mass of the dry product was then recorded. The preparation of the copper (II) oxalate complex was the next step. First, 4.1 grams of copper (II) sulfate hexahydrate was dissolved in 10.0 mL of DI water in a flask. The solution was then heated to a boil. Then, 35.0 mL of potassium oxalate was heated separately and brought to a boil as well. The copper solution was then gradually added to the potassium oxalate solution while simultaneously heating and stirring. Once combined, the solution was removed from the heat and allowed to cool to room temperature. It was then transferred to an ice water bath to cool even more. Once cooled, the solid product was collected using vacuum filtration. Small portions of ice cold water were used to ensure all of the product was able to be filtrated. Once all of the product was extracted, it was rinsed with ethanol while still under the vacuum filtration system. The dry product was collected and then the mass of it was recorded. The next step in this experiment was the standardization of the potassium permanganate solution. First, between 0.15 and 0.20 grams of the previously prepared potassium oxalate was measured out and put into a flask. Then, 20.0 mL of Di water, 20.0 mL of sulfuric acid, and a stir bar was added to the potassium oxalate. A hot water bath was then set up on top of the hot plate using a beaker. The water was maintained at a temperature between 80 and 100°C. Then, a buret was conditioned with DI water and small portions of the potassium permanganate solution. The buret was then filled to the 0.00mL line with the potassium permanganate solution. The flask containing the potassium oxalate was placed in the hot water bath and a stir bar was added. The titration then began by adding the titrant in small increments to the flask. Once the solution maintained a faint pink color for 1-2 minutes, the titration was complete. The final volume on the buret was read and recorded. This titration was repeated two times for a total of three trials. Once the potassium permanganate was standardized, it would be possible to determine the oxalate content in the two complexes previously created. The only changes made for the titrations that needed to occur for the two complexes were the components put into the flask. First, the iron (III) oxalate was titrated. Between 0.15 and 0.20 grams of the oxalate was added to a flask. Then, 20.0 mL of DI water, 20.0 mL of 3 M sulfuric acid, and a stir bar was added to the flask. Then, all of the steps that were previously taken in the standardization of potassium permanganate after the point of adding all the components to the flask were replicated. For the determination of the oxalate content in the copper (II) oxalate complex, the same exact procedure was added. The only difference was using between 0.15 and 0.20 grams of the copper (II) oxalate instead of the iron (III) oxalate. Each of the two solutions had two trials completed and all of the results recorded. III: Results and Discussion Once all of the data was collected, it was possible to begin the analysis. The first calculation was finding the molarity of the potassium permanganate. The following table contains the results of all three trials of the standardization of the potassium permanganate: Trial 1 2 3 Mass of KMnO4 used .197 g .198 g .199 g Total volume of titrant used 23.70 mL 24.30 mL 24.20 mL Molarity of KMnO4 .0167 M .0164 M .0166 M .0166 M An example of the stoichiometry used to solve for the molarity of KMnO4 is shown below using the first trials data: 0.197 g K2C2O4•H2O 1 mol K2C2O4•H2O 2 mol KMnO4 198.676 g K2C2O4•H2O 5 mol K2C2O4•H2O 0.0237 L KMnO4 The next step in the analysis was determining the percent oxalate in the iron (III) oxalate complex based on the redox titration data that was recorded. The results for the two trials are as followed: Trial 1 2 Mass of iron (III) oxalate used 0.177 grams 0.178 grams Total volume of titrant used 23.25 mL 22.70 mL The percent by mass is calculated using stoichiometry and the mass percent formula. The below calculations are examples using the first trials data: 0.02325 L KMnO4 0.0166 mol KMnO4 1 L KMnO4 5 mol C2O4 88.02 g C2O4 2 mol KMnO4 1 mol C2O4 The stoichiometry was used to get the value of the mass of the oxalate. The next step was to use the mass percent formula to solve. The mass of the oxalate calculated by the stoichiometry and the mass of the sample that was titrated was used. It looks as followed: Mass of the oxalate Mass of the sample titrated 0.0849 grams 0.177 grams (100%) = Mass percent oxalate (100%) = 48.0% (1) These calculations were completed for both trials of the iron (III) oxalate complex. The second trial was calculated to have a mass percent oxalate of 46.6%. Therefore, when referencing prelab assignments from previous weeks, it can be concluded that the complex that was actually made was K[Fe(C2O4)(H2O)4]∙2H2O. This is possible to conclude because the percent mass of oxalate was found for the possible complex. The percent by mass of oxalate in K[Fe(C2O4)(H2O)4]∙2H2O was calculated by dividing the mass of oxalate (C2O4) by the molecular weight of the possible complex. It came out to be 48.74 % oxalate in this specific complex. When these trials are compared to the actual results for percent error, the following equation is used: Percent Error = |Approximate Value − Exact Value| |Exact Value| Percent Error = (48.00 – 48.74) x 100% (48.74) Percent Error = 1.52% × 100% (2) The percent error of 1.52% was determined using the data from the first trial of the Iron (III) oxalate. The percent error done for the second trial was determined to be 4.39%. The next step of analysis was to find the percent yield. Using the amounts from when the oxalate was first created, an example of how to calculate percent yield is given below. Percent Yield = (Mass of actual yield) (Mass of theoretical yield) Percent Yield = .998 g x100% .792 g Percent Yield = 126% x100% (3) This was the percent yield calculated according to the starting amount of (NH 4)2Fe(SO4)2⋅ 6H2O that was used which was 1.012 grams. Next, was to repeat all of the previous calculations that were done for the Iron (III) Oxalate with the data from the Copper (II) Oxalate results. The results for the two titration trials of the Copper (II) Oxalate are as followed: Trial Mass of Copper (II) Oxalate used Total volume of titrant used 1 0.187 grams 14.20 mL 2 0.180 grams 8.30 mL The percent by mass was then calculated using stoichiometry. The first trial’s percent by mass was calculated to be 27.8% and the second trial was calculated to be 16.8%. When referencing pre-lab assignments from previous weeks, it can be concluded that the complex that was actually made was [Cu (C2O4)(H2O)2] 2H2O. The percent by mass for this complex was determined to be 39.36%. The percent error for the first trial was calculated to be 29.4% and was 57.3% for the second trial. Although these percent errors are slightly higher than desirable, they were the lowest between the two options of possible Copper (II) complexes. The next step was to calculate the percent yield of the Copper (II) Oxalate complex. The percent yield was determined by using the mass of the actual yield, 7.030 grams, and the mass of the theoretical yield, 3.67%. These values were manipulated to get a percent yield of 192%. The large sources of error in the Copper (II) Oxalate trials could be attributed to many different factors. These factors include inconsistent stirring while creating each complex, not including the entire created complex during vacuum filtration, and less than ideal environmental surroundings for the experiment. References: 1. Inorganic Chemistry, http://www.saylor.org/courses/chem107/ [accessed: July 10,2014] 2. Redox Titrations, https://www.boundless.com/chemistry/aqueous-reactions/oxidationreduction-reactions/redox-titrations/ [accessed: July 10, 2014]