CIS NIIJB-POLIGON» (LLC) (download

advertisement

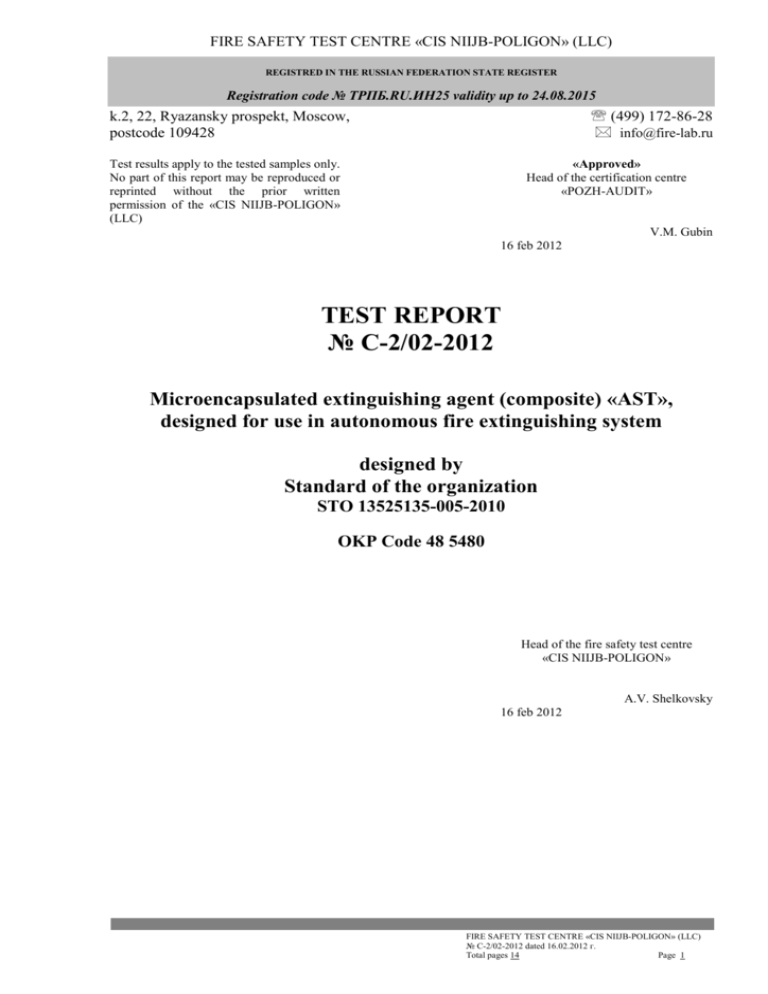

FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) REGISTRED IN THE RUSSIAN FEDERATION STATE REGISTER Registration code № ТРПБ.RU.ИН25 validity up to 24.08.2015 (499) 172-86-28 info@fire-lab.ru k.2, 22, Ryazansky prospekt, Moscow, postcode 109428 Test results apply to the tested samples only. No part of this report may be reproduced or reprinted without the prior written permission of the «CIS NIIJB-POLIGON» (LLC) «Approved» Head of the certification centre «POZH-AUDIT» V.M. Gubin 16 feb 2012 TEST REPORT № C-2/02-2012 Microencapsulated extinguishing agent (composite) «AST», designed for use in autonomous fire extinguishing system designed by Standard of the organization STO 13525135-005-2010 OKP Code 48 5480 Head of the fire safety test centre «CIS NIIJB-POLIGON» A.V. Shelkovsky 16 feb 2012 FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 1 CONTENTS 1. The name and the address of the applicant, manufacturer. ................................... 3 2. The specification of the test subject. ..................................................................... 3 3. Official reason for testing. ..................................................................................... 3 4. Description of the service being ordered. ............................................................. 3 5. Test methods. ......................................................................................................... 3 6. Sampling procedure............................................................................................... 3 7. Test procedure. ...................................................................................................... 3 8. Test equipment. ..................................................................................................... 6 9. Measuring means................................................................................................... 7 10. Test results........................................................................................................... 8 11. Executors. ............................................................................................................ 9 SUPPLEMENTARY INFORMATION ................................................................... 10 Appendix 1. ............................................................................................................. 11 Appendix 2. ............................................................................................................. 13 FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 2 1. The name and the address of the applicant, manufacturer. Applicant: Manufacturer: Certification Centre «POZH-AUDIT». Address: k.1, h.5, 1st Vyazovsky proezd, Moscow, Russia, post code 109428. Telephone: +7 (495) 740-43-61. Closed Joint Stock Company «Pirohimika». Address: h.4, Pokrovka street, Moscow, Russia, post code 101000. Telephone: +7 (495) 933-53-13. 2. The specification of the test subject. Microencapsulated extinguishing agent (composite) «AST», designed for use in autonomous fire extinguishing system (hereinafter - the composite). The composite is designed for extinguishing fire (classes A, B, C, E according to the GOST 27331-87) in small volumes (switchboards, electrical cabinets, control cabinets, storage values, small vaults, located in areas with operating temperature range from − 40 °C to + 40 °C) without human intervention. The thickness of the specimen made of a composite — 3,0 mm. Color of the sample — white, with a slight yellow tinge, not transparent, with visible reinforcing fibers. 3. Official reason for testing. Tests were conducted on the basis of an internal purchase order for works № 01A/VZN-12 dated 31.01.2012 from the certification centre «POZH-AUDIT» and the contract № 01-01/I-12 dated 26.01.2012 between FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) and Closed Joint Stock Company «Pirohimika». 4. Description of the service being ordered. Testing to determine the next indicators of fire danger: - a group of smoke-forming ability according to the GOST 12.1.044-89*; - an indicator of toxicity according to the GOST 12.1.044-89*; - group of combustibility according to the GOST 30244-94 5. Test methods. Determination of a group of smoke-forming ability (test method according to the GOST 12.1.044-89*). Determination of a toxicity (test method according to the GOST 12.1.044-89*). Determination of a group of combustibility (test method according to the GOST 3024494). 6. Sampling procedure. The sampling was made using the technique of random selection by the expert of the certification centre «POZH-AUDIT» from the manufacturer’s store as provided by the sampling act № 01/AO-12 dated 30.01.2012 (Appendix 1). 7. Test procedure. The test was performed at «CIS NIIJB-POLIGON» from 30.01.2012 to 16.02.2012. FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 3 7.1. Environmental conditions during the testing. Name of condition Ambient temperature Barometric absolute pressure Relative humidity Speed of the wind Value 17-20 °С 745-757 mm Hg 50-66 % < 0,5 м/сек 7.2. The order of testing procedure. 7.2.1. Determination of a smoke-forming ability. Test. 10-15 samples of invistigated material sized 40x40 mm of actual thickness were prepared for the test. Before the test prepared samples were kept at temperature 20 ± 2 °С not less than 48 hours, than were weighed with not more than 0,01 g. The testing of the samples was performed in two modes: smouldering mode and burning mode (with gas burner with the length of the flame from 10 to 15 mm). The sample was chambered in a combustor, that was equipped with a heat-radiating panel, which made 35 kW/m2 density of the heat flow, falling on the sample. Smoke-forming ability is an indicator, that defines optical density of smoke, that is produced in a smouldering mode or in a burning mode in a standard volume. Classification. According to the point 9 article 13 of the federal law № 123 «Technical regulations of the fire safety requirements» dated 22.07.2008 the following groups of smoke-forming ability are destinguished: 1) with low smoke-forming ability (group «D1»), with a smoke generation factor less than 50 m /kg 2 2) with moderate smoke-forming ability (group «D2»), with a smoke generation factor not less than 50 m2/kg, but not more than 500 m2/kg; 3) with high smoke-forming ability (group «D3»), with a smoke generation factor more than 500 m2/kg; 7.2.2. Determination of a group of combustibility. Test 4 vertically oriented samples sized 1000x190 mm were fixed in a holder and exposured to 88 MJ/h gas burner output during 10 minutes. Emitted gases temperature and the time of self burning were registred. After carrying out the test of the samples’ weight loss and the extent of damage to the length were estimated. Classification According to the point 5 article 13 of the federal law № 123 «Technical regulations of the fire safety requirements» dated 22.07.2008 the following groups combustibility are destinguished: 1) low-combustible (group «G1») with the smoke temperature not more than 135 °С, extent of damage to the length of a sample not more than 65 %, extent of damage to the sample’s weight not more than 20%, 0 sec self burning time; 2) moderately-combustible (group «G2») with the smoke temperature not more than FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 4 235 °С, extent of damage to the length of a sample not more than 85 %, extent of damage to the sample’s weight not more than 50%, self burning time not more than 30 seconds; 3) normally-combustible (group «G3») with the smoke temperature not more than 450 °С, extent of damage to the length of a sample not more than 85 %, extent of damage to the sample’s weight not more than 50%, self burning time not more than 300 seconds; 4) high-combustible (group «G4») with the smoke temperature more than 450 °С, extent of damage to the length of a sample more than 85 %, extent of damage to the sample’s weight more than 50%, self burning more than 300 seconds. According to the point 6 article 13 of the federal law № 123 «Technical regulations of the fire safety requirements» dated 22.07.2008 the formation of burning melt drops during the test is not allowed for the G1-G3 combustibility group materials (for the G1-G2 combustibility group materials isn’t allowed the formation of melt drops). 7.2.3. Determination of a toxicity. Preliminary test In process of preliminary test the temperature of self burning and the temperature of smouldering is being determined. 10 samples sized 40x40 mm of actual thickness were used for the test. The samples were kept under laboratory conditions not less than 48 hours and were weighed with not more than 0,01 g error. Preliminarily the samples were exposured to heat flow of various density, providing the rise of sample’s temperature on 50 °С in each following test. At the time the temperature of the smouldering mode test of material was found (it must be 50 °С lower than the sample’s self ignition temperature). Primary test. Materials are tested in one of two modes – smouldering mode or burning mode, specifically in the mode, that promotes release of more toxic volatile substances composites. Burning mode is provided with 750 °С test temperature (density of falling heat flow is 65 kW×m-2). Primary test mode selection criterion is the greatest number of fatal outcomes in comparison groups of experimental animals. During the primary test in a chosen mode a range of values of combustion product toxic action to the value of sample weight to installation cubature ratio relation is found. To get the toxic effect below and above 50% fatal rate, the exhibition chamber cubature is changed while the materials’ sizes remain the same. 8 white mice of 20 ± 2g weight were used in each test. The exposition time was 30 minutes. During exhibition time the air temperature in the prechamber didn’t exceed 30 °C, and the oxygen concentration was not less than 16 % (volume). Derived range of lethality to material relative weight relation values is used to calculate toxicity indicator 𝐻𝐶𝐿50 (g × m-3). The calculation is made by the means of probit analysis and other methods of average lethal doses and concentrations calculation. In the case the value of 𝐻𝐶𝐿50 that was derived during the material test is close to the two classes limit value, the test mode, sample decomposition time, combustion product composition facts, information about detected compounds toxicity are considered when the material risk class is being determined. FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 5 Classification. According to the GOST 12.1.044-89* chart, the following toxicity groups are discriminated: 𝑯𝑪𝑳𝟓𝟎 , g Danger class Extremely dangerous Highly dangerous Moderately dangerous Low dangerous 5 Under 25 25-70 70-210 Above 210 m-3, at exhibition time, min 15 Under 17 17-50 50-150 Above 150 30 Under 13 13-40 40-120 Above 120 60 Under 10 10-30 30-90 Above 90 According to point 10 article 13 of the federal law № 123 «Technical regulations of the fire safety requirements» dated 22.07.2008 and chart 2 of the appendix to this federal law the following toxicity groups are destinguished: 1) Low dangerous (group «T1»); 2) Moderately dangerous (group «T2»); 3) Highly dangerous (group «T3»); 4) Extremely dangerous (group «T4») 8. Test equipment. Chart № 1 Serial number Equipment name Installation for determination of solid substances and materials smoke generation factor, “Smoke” Installation for determination of polymeric materials combustion products toxicity, “Toxicity” Installation for determination of construction materials combustibility group, “Shaft-furnace” 03 02 05 Certificate № 33-12 till 25.01.2013 № 54-12 till 25.01.2013 № 42-12 till 25.01.2013 FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 6 9. Measuring means. Chart № 2 № Name of production characteristic (parameter) being determined (measured) Measuring tool name, type (model), works number, year of production 1 2 Transformation of subject’s physical parameters (temperature) into electric signals 3 1 2 3 4 5 6 7 8 9 10 11 12 Thermocouples ТТ 41 ХА Work number № 1-20, 2003 Electronic balance ВР-04 МС 2/5-1БР № 6873 , 2003 Rotameter with local Volume gas consumption indications РТКА-0,25 ГУЗ measurement № 03350, 2005 Rotameter with local Volume gas consumption indications РТКА-0,63 ГУЗ measurement №6123119, 2005 Electronic anemometer ЭА-70 Speed of the wind model ЭА-70(1) Works measurement number №20, 2010 Mechanical seconds counter Test time lags measurement СОПпр-2а-3-000 Works number № 4200, 2010 Calipers External and internal ШЦЦ-I-150 0,01 measurements № 105021 Metal measuring rule Linear dimension measurement 0-1000 mm Works number № 2, 2010 Metal tape measure 0-5 m Linear dimension measurement Works number № without number , 2010 Registration device Physical parameters recording «ТЕРЕМ 4.1» Works number № 154, 2008 Portable device for absolute Barometric absolute pressure pressure measurement Testomeasurement 622 №39500351/911 Measurement of relative air Combined device Testo-622 humidity indoors. Temperature №39500351/911 measurement Weight measurement Gas analyzer ИНФРАКАР М1.01, Works number № 92, 2003 13 Measurement of СО, СО2, О2, СН content in gas environment 14 Gas analyzer KANE 940 Measurement of СО, СО2, О2 , Works number № 23607026, NO content in gas environment 2008 Metrological parameters of measuring tools Class of Measuring accuracy, range measurement error 4 5 Certificate of measuring tools verification, number, duration 6 0 … +600 ºС 2 № 25/29/2/11 till 1.02.2013 Up to 15 kg (2-5) g. № 25/14/2/13 till 1.02.2013 Qmax (m3/hour) 2,5; ± 2,5 % № 25/10/2/23 till 1.02.2014 Qmax (m3/hour) 6,3; ± 2,5 % № 25/34/2/19 till 1.02.2014 0,2-30 m/sec 0,1 m/sec № 207/11 - 0658п (0,2 – 5 m/sec) till 14.04.2012 0 sec…60 min Scale factor 0,2 sec Certificate №4282А/001000 till 20.01.2012 0-125 mm ±0,02 mm № 203-4107 till 14.12.2012 0 … 1000 mm Scale factor 1 mm № 08-12 till 17.01.2013 0…5000 mm Scale factor 1 mm № 09-12 till 17.01.2013 -50-1250 ºС 0,1 % № 25/29/2/37 till 1.03.2012 (300-1200) gPa ±3 gPa+1 № 191508 till 16.12.2012 (10-98)%; (0-50) ºС ±3 % ± 0,5 К +1. № 191508 till 16.12.2012 2% till 12.04.2012 1% till 14.04.2012 0 – 10 % СО; 0-5000 СН; 0-20 СО2; 0-25 О2 (0-25)% О2; (0-10000) СО; (0-5000) NO; (0-5000) CO2; FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 7 10. Test results. Chart № 3. Smoke generation factor determination. Test results. Weight of Transparency Test mode the reference, % finally, % sample 1 3,71 100 68,8 2 3,72 100 67,3 Smouldering 3 3,77 100 67,5 4 3,80 100 66,8 5 3,83 100 66,5 Medium value in the smouldering mode Dm(av) = 68 1 3,63 100 75,0 2 3,74 100 75,4 Burning 3 3,79 100 75,7 4 3,85 100 70,2 5 3,91 100 71,1 Medium value in the burning mode Dm(av) = 53 Sample’s number Smoke generation factor, m2/kg 66 69 68 69 69 m2/kg 52 49 48 60 57 m2/kg Chart № 4. Toxicity determination. Test results. Testing temperature (most dangerous), ºС Time of decomposition, min 750 15 The loss of mass of the sample (converted to CO), g 6,05 the percentage of gaseous substances, % НСL50 g/m3 65,6 92,9 Chart № 5. 0 16 0 15 0 16 Simple average 112 0 2 3 4 16 16 15 15 16 15 15 16 16 16 16 16 Damage to the length, sm 16 Samples’ weight, g (simple average ) Before the After the test test 748 704 750 712 744 710 The extent of damage to the weight, % 112 114 111 1 The extent of damage to the length, % Smoke temperature, ОС 1 2 3 Self burning time, sec Test number Combustibility group determination. Test results. 6 5 5 5 FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 8 Thereby the test results established that samples of the microencapsulated extinguishing agent (composite) «AST» (designed by the standard of the organization STO 13525135-0052010, manufacturer — Closed Joint Stock Company «Pirohimika») belong to the following groups: - moderately smoke generation ability according to the GOST 12.1.044-89* (group «D2» according to the clause 13 of the federal law № 123 «Technical regulations of the fire safety requirements»); - moderately dangerous materials by combustion products toxicity factor, according to the GOST 12.1.044-89* (group «T2» according to the clause 13 of the federal law № 123 «Technical regulations of the fire safety requirements»); - low-combustible materials according to the GOST 30244-94 (group «G1» according to the clause 13 of the federal law № 123 «Technical regulations of the fire safety requirements») 11. Executors. Test engineer ________ N.Afonin Quality deputy administrator of the FIRE SECURITY TEST CENTRE ________ D.Borisov FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 9 SUPPLEMENTARY INFORMATION 1. This report is neither a fire safety certificate nor a conformance certificate. 2. The report is valid during the period of time when no changes are made (not more than 3 years): - to the production or test method normative documents; - to organization and (or) methods of production. 3. In case aforementioned occurs, the Customer must send a message about it to the laboratory, which performed a test. On the ground of these changes effect analysis, the laboratory decides about the test report duration. 4. The information contained in the test report as well as the name of the test center and its emblem may not be used for public advertising purposes or in any other way without the written permission of the test center. 5. Pages with the test results statement may not be used separately without the full test report. 6. The obtained results and conclusions contained in the report apply only to the tested sample(s) and don’t reflect the quality of the production-run where this sample was taken from as well as the quality of all the output of this type. 7. If not specifically mentioned, this report is intended only for the Customer’s use. 8. Tested samples that were not destroyed during the test as well as unused remains of samples are returned to the Customer within 30 days from the moment of the report’s issuance. FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 10 Appendix 1. Sampling report. FIRE SAFETY SERTIFICATION SYSTEM CERTIFICATION centre «POZH-AUDIT» REGISTRED IN THE RUSSIAN FEDERATION STATE REGISTER REGISTRATION CODE № ТРПБ.RU.ПБ34 DATED 24.08.2010 109428, Moscow, 1 Vyazovskiy pass., 5, 1 +7(495)7404361, 7404362 Sampling report №01/AO-12 dated 30.01.2012 For certification testing Product name: Microencapsulated extinguishing agent (composite) «AST», made in accordance with STO 13525135-005-2010 For the compliance with the requirements of: Technical Regulations of fire security requirements (State Law №123-ФЗ dated 22.07.2008) In the store of “Pirohimika” CJSC, 101000, Moscow, Pokrovka st., 4, We, an CC «POZH-AUDIT» expert In the presence of “Pirohimika” representative Were sampled the production, made in accordance with the technical documentation, approved by Technical Control Department. Samples construct, composition and production technology are identical to the ones of the products, supplied to the customer. Number (weight) Scope of of the samples Name of the tested Production № Measure Supply № supply sample date (units) Tested control 1. Microencapsulated extinguishing agent (composite) «AST», made in accordance with STO 13525135005-2010 M2 - 100 12.2011 10 0.5 Sampling made in accordance to the contract Samples are packing in tare Marked with CC «POZH-AUDIT» label Completed with documentation ___________ Given to the CC in accordance with contract Storage conditions store Tested samples are to be destroyed Control samples are to be responsible storage by Client FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 11 Conclusion to the product identification 1. Product name Microencapsulated extinguishing agent (composite) «AST», made in accordance with STO 13525135-005-2010 2. Production country Russian Federation 3. Manufacturer name and address Pirohimika CJSC, Russia, 101000, Moscow, Pokrovka st., 4 4. Additional information Conclusion: tested production is identificated/can’t be identificated with the sample and/or its description. Appendix: Documents, approving product acceptance by manufacturer/buyer and its compliance with the regulatory document under which production (or it’s copies) is manufacturing. Signs of the sampling members Acquainted with report: Chief director of “Pirohimika” CJSC CC expert: ______________ Bliznec I.V. ___________ Poedincev I.A. January, 30, 2012 FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 12 Appendix 2. Photos. Photo. The samples before testing. FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 13 Photo. The samples after testing. FIRE SAFETY TEST CENTRE «CIS NIIJB-POLIGON» (LLC) № C-2/02-2012 dated 16.02.2012 г. Total pages 14 Page 14

![Your_Solutions_LLC_-_New_Business3[1]](http://s2.studylib.net/store/data/005544494_1-444a738d95c4d66d28ef7ef4e25c86f0-300x300.png)