pubdoc_2_26576_1589

advertisement

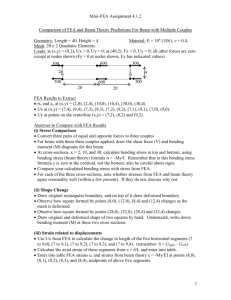

Selection of material and shape Shape factors The loads on a component can be decomposed into those that are axial, those that exert bending moments and those that exert torques. One of these usuallydominates to such an extent that structural elements are specially designed to carry it, and these have common names. Thus ties carry tensile loads; beams carry bending moments; shafts carry torques; columns carry compressive axial loads. Figure 11.3 shows these modes of loading applied to shapes that resist them well. The point it makes is that the best material-and-shape combination depends on the mode of loading. In what follows, we separate the modes, dealing with each separately. In axial tension, the area of the cross-section is important but its shape is not: all sections with the same area will carry the same load. Not so in bending: beams with hollow-box or I-sections are better than solid sections of the same cross-sectional area. Torsion too, has its efficient shapes: circular tubes, for instance, are more efficient than either solid sections or I-sections. To characterize this we need a metric—a way of measuring the structural efficiency of a section shape, independent of the material of which it is made. An obvious one is that given by the ratio of _ the stiffness or strength of the shaped sectionsection with the same cross-sectional area, and thus the same mass per unit length, as the shaped section.1 to that of a ‘neutral’ reference shape, which we take to be that of a solid square Elastic bending of beams and twisting of shafts (Figure 11.3b and c) The bending stiffness S of a beam is proportional to the product EI Here E is Young’s modulus and I is the second moment of area of the beam about the axis of bending (the x axis): where y is measured normal to the bending axis and dA is the differential element of area at y (Figure 11.3). Values of the moment I and of the area A for common sections are listed in the first two columns of Table 11.2. Those for the more complex shapes are approximate, but completely adequate for present needs. The second moment of area, Io, for a reference beam of square section with edge-length bo and section-area is simply (Here and elsewhere the subscript ‘o’ refers to the solid square section.) The bending stiffness of the shaped section differs from that of a square one with the same area A by the factor We call where the shape factor for elastic bending. Note that it is dimensionless— I has dimensions of (length)4 and so does A2. It depends only on shape, not on scale: big and small beams have the same value of if their section shapes are the same.2 This is shown in Figure 11.4. The three members of each group differ in scale but have the same shape factor—each member is a magnified or shrunken version of its neighbors. Shape-efficiency factors for common shapes, calculated from the expressions for A and I in Table 11.2, are listed in the first column of Table 11.3. Solid equiaxed sections (circles, squares, hexagons, octagons) all have values very close to 1—for practical purposes they can be set equal to 1. But if the section is elongated, or hollow, or of I-section, things change; a thin-walled tube or a slender I-beam can have a value of of 50 or more. A beam with beam of the same weight. =50 is 50 times stiffer than a solid Shapes that resist bending well may not be so good when twisted. The stiffness of a shaft—the torque T divided by the angle of twist, (Figure 11.3c)—is proportional to GK, where G is its shear modulus and K its torsional moment of area. For circular sections K is identical with the polar moment of area, J: where dA is the differential element of area at the radial distance r, measured from the center of the section. For non-circular sections, K is less than J; it is defined such that the angle of twist is related to the torque T by where L is length of the shaft and G the shear modulus of the material of which it is made. Approximate expressions for K are listed in Table 11.2. The shape factor for elastic twisting is defined, as before, by the ratio of the torsional stiffness of the shaped section, ST, to that, STo, of a solid square shaft of the same length L and cross-section A, which, using equation (11.5), is: The torsional constant Ko for a solid square section (Table 11.1, top row with b=h) is It, too, has the value 1 for a solid circular square section, and values near 1 for any solid, equiaxed section; but for thin-walled shapes, particularly tubes, it can be large. As before, sections with the same value of differ in size but not shape. Values derived from the expressions for K and A in Table 11.2 are listed in Table 11.3. Onset of failure in bending and twisting Plasticity starts when the stress, somewhere, first reaches the yield strength, ; fracture occurs when this stress first exceeds the fracture strength, ; fatigue failure if it exceeds the endurance limit we use the symbol for the failure stress, meaning ‘‘the local stress that will first cause yielding or fracture or fatigue failure’’. In bending, the stress is largest at the point ym in the surface of the beam that lies furthest from the neutral axis; it is: where M is the bending moment. Failure occurs when this stress first exceeds . Thus, in problems of failure of beams, shape enters through the sectionmodulus, Z=I/ym. The strength-efficiency of the shaped beam, , is measured by the ratio Z/Zo, where Zo is the section modulus of a reference beam of square section with the same cross-sectional area, A: Like the other shape-efficiency factor, it is dimensionless and therefore independent of scale, and its value for a beam with a solid square section is unity. Table 11.3 gives expressions for other shapes derived from the values of the section modulus Z, which can be found in Table 11.2. A beam with an failure shape-efficiency factor of 10 is 10 times stronger in bending than a solid square section of the same weight. In torsion the problem is more complicated. For circular rods or tubes subjected to a torque T (as in Figure 11.3c) the shear stress is a maximum at the outer surface, at the radial distance rm from the axis of bending: The quantity in J/rm twisting has the same character as I/ym in bending. For non-circular sections with ends that are free to warp, the maximum surface stress is given instead by where Q, with units of m3 now plays the role of J/rm or Z. This allows the definition of a shape factor, , for failure in torsion, following the same pattern as before: Values of Q and are listed in Tables 11.2 and 11.3. Shafts with a solid equiaxed sections all have values of close to 1. Axial loading and column buckling A column of length L, loaded in compression, buckles elastically when the load exceeds the Euler load where n is a constant that depends on the end-constraints. The resistance to buckling, then, depends on the smallest second moment of area, I min, and the appropriate shape factor is the same as that for elastic bending (equation (11.4)) with I replaced by Imin. Elastic bending of beams and twisting of shafts. Consider the selection of a material for a beam of specified bending stiffness SB and length L (the constraints), to have minimum mass, m (the objective). The mass m of a beam of length L and section area A is given, as before, by Its bending stiffness is where C1 is a constant that depends only on the way the loads are distributed on the beam. Replacing I by using equation (11.3) gives Using this to eliminate A in equation (11.24) gives the mass of the beam. For beams with the same shape (for which is constant) the best choice is the material with the greatest value o _—the result derived in Chapter 5. But if we want the lightest material-shape combination, it is the one with the greatest value of the index The procedure for elastic twisting of shafts is similar. A shaft of section A and length L is subjected to a torque T. It twists through an angle required that the torsional stiffness, . It is , meet a specified target, ST, at minimum mass. Its torsional stiffness is where G is the shear modulus. Replacing K by gives Using this to eliminate A in equation (11.24) gives using equation (11.7) The best material-and-shape combination is that with the greatest value of 1=2. The shear modulus, G, is closely related to Young’s modulus E. For the practical purposes we approximate G by 3/8E; when the index becomes Failure of beams and shafts. The procedure is the same. A beam of length L, loaded in bending, must support a specified load F without failing and be as light as possible. When section-shape is a variable the best choice is found as follows. Failure occurs if the load exceeds the moment where Z is the section modulus and is the stress at which failure occurs. Replacing Z by the shape-factor B of equation (11.10) gives Substituting this into equation (11.24) for the mass of the beam gives The best material-and-shape combination is that with the greatest value of the index A similar analysis for torsional failure gives: Co-selecting material and shape The indices allow comparison and selection of material-shape combinations. shape combinations. Co-selection by calculation. Consider as an example the selection of a material for a stiff shaped beam of minimum mass. Four materials are available, listed in Table 11.5, each with their properties and typical (modest) values for shapes, characterized by . We seek the combination with the largest value of the index M1 of equation (11.28) which, repeated, is It identifies the material-shape combinations with the lowest mass for a given stiffness. The second last column of the table shows the simple ‘‘fixed shape’’ index : wood has the greatest value, more than twice as great as steel. But when each material is shaped efficiently (last column) wood has the lowest value ofM1—even steel is better; the aluminum alloy wins, surpassing steel and GFRP. Selection for strength follows a similar routine, using the index M3 of equation (11.35). Graphical co-selection. The material index for elastic bending (equation (11.28)) can be rewritten as The equation says: a material with modulus E and density , when structured, can be thought of as a new material with a modulus and density of The chart is shown schematically in Figure 11.16. The ‘‘new’’ material properties and can be plotted onto it. Introducing shape moves the materialMto the lower left along a line of slope 1, from the position E, to the position E/10, /10 as shown in the figure. it is shown, for one value of as a broken line. The introduction of shape has moved the material from a position below this line to one above; its performance has improved. Elastic twisting of shafts is treated in the same way. Materials selection based on strength (rather than stiffness) at a minimum weight uses a similar procedure. The material index for failure in bending (equation (11.35)), can be rewritten as follows The material with strength and density , when shaped, behaves in bending like a new material of strength and density Introducing shape moves material M along a line of slope 1, taking it, in the schematic, from a position , below the material index line (the broken line) to the position /10, /10 that lies above it. The performance has again improved. Torsional failure is analyzed by using T in place of Forks for a racing bicycle The first consideration in bicycle design (Figure 12.4) is strength (Table 12.6). Stiffness matters, of course, but the initial design criterion is that the frame and forks should not yield or fracture in normal use. The loading on the forks is predominantly bending. If the bicycle is for racing, then the mass is a primary consideration: the forks should be as light as possible. What is the best choice of material and shape? The model and the selection. We model the forks as beams of length L that must carry a maximum load P (both fixed by the design) without plastic collapse or fracture. The forks are tubular, of radius r and fixed wall-thickness, t. The mass is to be minimized. The fork is a light, strong beam. Further details of load and geometry are unnecessary: the best material and shape, read from Table 12.1, is that with the greatest value of Table 12.7 lists seven candidate materials with their properties. If the forks were solid, meaning that , spruce wins (see the second last column of the table). Bamboo is special because it grows as a hollow tube with a macroscopic shape factor of about 2.2, giving it a bending strength that is much higher than solid spruce (last column). When shape is added to the other materials, however, the ranking changes. The shape factors listed in the table are achievable using normal production methods. Steel is good; CFRP is better; Titanium 6-4 is better still. In strength-limited applications magnesium is poor despite its low density. Postscript. Bicycles have been made of all seven of the materials listed in the table—you can still buy bicycles made of six of them. Early bicycles were made of wood; present-day racing bicycles of steel, aluminum or CFRP, sometimes interleaving the carbon fibers with layers of glass or Kevlar to improve the fracture-resistance. Mountain bicycles, for which strength and impact resistance are particularly important, have steel or titanium forks. Ultra-efficient springs Springs, we deduced in Section 6.7, store energy. They are best made of a material with a high value of volume, then of , or, if mass is more important than . Springs can be made more efficient still by shaping their section. We take as a measure of performance the energy stored per unit volume of solid of which the spring is made; we wish to maximize this energy. Energy per unit weight and per unit cost are maximized by similar procedures (Table 12.4). The model and the selection. Consider a leaf spring first (Figure 12.3a). A leaf spring is an elastically bent beam. The energy stored in a bent beam, loaded by a force F, is where SB, the bending stiffness of the spring, is given by equation (11.25), or, after replacing I by , by equation (11.26), which, repeated, is: The force F in equation (12.2) is limited by the onset of yield; its maximum value is (The constants C1 and C2 are tabulated in Appendix A, Sections A.3 and A.4). Assembling these gives the maximum energy the spring can store: where V=AL is the volume of solid in the spring. The best material and shapefor the spring—the one that uses the least material—is that with the greatestvalue of the quantity For a fixed section shape, the ratio involving the two is a constant: then the best choice of material is that with the greatest value —the same result as before. When shape is a variable, the most efficient shapes are those with large Values for these ratios are tabulated for common section shapes in Table 12.5; hollow box and elliptical sections are up to three times more efficient than solid shapes. Torsion bars and helical springs are loaded in torsion (Figure 12.3b). A similar calculation gives The most efficient material and shape for a torsional spring is that with the largest value of (where G has been replaced by 3E/8). The criteria are the same: when shape is not a variable, the best torsion-bar materials are those with high values of with a ratio of . Table 12.5 shows that the best shapes are hollow tubes, that is twice that of a solid cylinder; all other shapes are less efficient. Springs that store the maximum energy per unit weight (instead of unit volume) are selected with indices given by replacing E by in equations (12.6) and (12.8). For maximum energy per unit cost, replace E by where Cm is the material cost per kg.