pola27261-sup-0003-suppinfo

advertisement

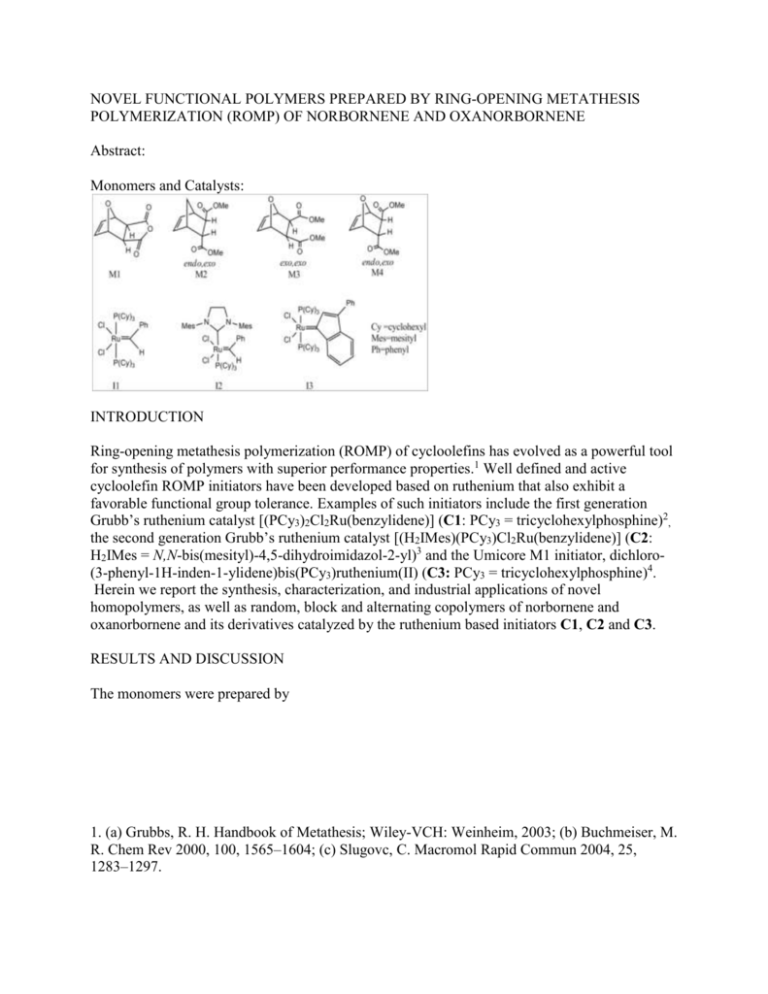

NOVEL FUNCTIONAL POLYMERS PREPARED BY RING-OPENING METATHESIS POLYMERIZATION (ROMP) OF NORBORNENE AND OXANORBORNENE Abstract: Monomers and Catalysts: INTRODUCTION Ring-opening metathesis polymerization (ROMP) of cycloolefins has evolved as a powerful tool for synthesis of polymers with superior performance properties.1 Well defined and active cycloolefin ROMP initiators have been developed based on ruthenium that also exhibit a favorable functional group tolerance. Examples of such initiators include the first generation Grubb’s ruthenium catalyst [(PCy3)2Cl2Ru(benzylidene)] (C1: PCy3 = tricyclohexylphosphine)2, the second generation Grubb’s ruthenium catalyst [(H2IMes)(PCy3)Cl2Ru(benzylidene)] (C2: H2IMes = N,N-bis(mesityl)-4,5-dihydroimidazol-2-yl)3 and the Umicore M1 initiator, dichloro(3-phenyl-1H-inden-1-ylidene)bis(PCy3)ruthenium(II) (C3: PCy3 = tricyclohexylphosphine)4. Herein we report the synthesis, characterization, and industrial applications of novel homopolymers, as well as random, block and alternating copolymers of norbornene and oxanorbornene and its derivatives catalyzed by the ruthenium based initiators C1, C2 and C3. RESULTS AND DISCUSSION The monomers were prepared by 1. (a) Grubbs, R. H. Handbook of Metathesis; Wiley-VCH: Weinheim, 2003; (b) Buchmeiser, M. R. Chem Rev 2000, 100, 1565–1604; (c) Slugovc, C. Macromol Rapid Commun 2004, 25, 1283–1297. 2. (a) Schwab, P.; France, M. B.; Ziller, J. W.; Grubbs, R. H. Angew Chem Int Ed 1995, 34, 2039–2041; (b) Sanford, M. S.; Love, J. A.; Grubbs, R. H. J Am Chem Soc 2001, 123, 6543– 6554. 3. Scholl, M.; Trnka, T. M.; Morgan, J. P.; Grubbs, R. H. Tetrahedron Lett 1999, 40, 2247–2250. 4. Ana M. Lozano Vila, Stijn Monsaert, Renata Drozdzak, Stanislaw Wolowiec, Francis Verpoort; Advanced Synthesis & Catalysis 2009, Volume 351 Issue 16, Pages 2689 - 2701 Materials and methods: Synthesis of monomers: Monomer M1: Materials: Furan (Aldrich) and maleic anhydride (Aldrich) were used as purchased. Dry Et2O was supplied through Department. The reaction was carried out in a nitrogen atmosphere. Procedure: Maleic anhydride (98g, 1mol) was weighed in a three-necked 1L round-bottom flask, equipped with a magnetic stirrer, a dropping funnel and a reflux condenser. The system was kept under a N2 atmosphere. Et2O (~350 ml) was added through the septum by a syringe. The mixture was heated to 35°C to dissolve maleic anhydride. When maleic anhydride was completely dissolved in Et2O, 10% excess of furan (80ml, 1.1mol) was added. The reaction mixture was stirred at 35°C for 48h until white solid appeared in the flask. The solid was filtered and washed with copious amounts of Et2O. The product was dried under reduced pressure for 12h at room temperature and then 12h at 33oC (yield 80%). The product was found to be pure and was used for future reactions without any purification. However, the product can be recrystallized from Et2O or THF. Product specification: white solid powder, - soluble in THF, acetone, DMSO and water melting point is 110.4 C - decomposition temperature (retro Diels-Alder reaction) is 150 C Monomer M2: Materials: Dicyclopentadiene (Aldrich), dimethyl fumarate (Aldrich) and THF (Fisher) were used as purchased. The synthesis was carried out in a nitrogen atmosphere. Procedure: Cracking of dicyclopentadiene (DCPD). Two necked round bottom flask (250ml) fitted with stirrer bar, an air condenser and a distillation head was filled with DCPD and heated to 185oC. DCPD cracked at 160oC to produce cyclopentadiene (CPD, b.p.= 40oC). CPD was collected in a pre-weighed Shlenk immersed in dry ice to prevent fast dimerisation of CPD. Diels-Alder reaction between CPD and dimethyl fumarate (DMFum). [0061] Dimethyl fumarate (200.43g, 1.4 mol) was dissolved in THF (1.2L) at 60oC in a round-bottomed flask (2L) fitted with a dry ice/acetone dropping funnel, condenser, thermometer, and stirrer bar. Freshly cracked CPD (92.4g, 1.4 mol) was added dropwise with intensive stirring. During the addition of CPD temperature rose from 60oC up to 70oC. The reaction proceeded for 24hrs at 60oC. The reaction was stopped and half of the solvent was removed on a rotary evaporator. Then the reaction mixture was placed in the freezer. White solid product was recovered and dried under reduced pressure for 24h at 28oC (yield 90%). Note: CPD should be weighed accurately. Excess of CPD in reaction mixture is dimerised during the reaction to DCPD, which cannot be separated from product. Product specification: - white solid powder, - soluble in THF, acetone, CHCl3, hexane and toluene - melting point is 34.6-35.8 oC - decomposition temperature (retro Diels-Alder reaction) is 151oC Monomer M3: Materials: p-toluenesulphonic acid (Aldrich) and diethyl ether (Fisher) were used as received. Dry methanol was supplied through Department. Monomer 1 (synthesized as described above). The reaction was carried out in a nitrogen atmosphere. Procedure: Monomer 1 (50.46g, 0.3 mol) was placed in two-necked round bottom flask (500ml) equipped with a condenser and a stirrer bar and dissolved in dry methanol (300 ml) at 90oC for 1h. Then a solution of p-toluenesulphonic acid (0.72g, 3.8·10-3 mol) in dry methanol (5ml) was added. The reaction mixture was heated at 90oC for 12h. The bulk of solvent was removed on a rotary evaporator and Et2O was added to precipitate the product. The product was recovered and dried under reduced pressure for 24h at 40oC (yield 25%). Product specification: - white solid powder, - soluble in THF, acetone, CHCl3 and water Monomer M4: Materials: Fumaryl chloride (Aldrich) and diethyl ether (Fisher) were used as received. Furan was shaken with NaOH, dried (MgSO4) and distilled under N2. Dry methanol was supplied through Department. Triethylamine (Fluka) was dried with CaH2, then distilled and collected over 4 Å molecular sieves. The reaction was carried out in a nitrogen atmosphere. Procedure: (1.5 ml, 13 mmol) was added dropwise to pre-cooled (0 °C, ice bath) furan (1 ml, 13 mmol). After stirring at 0 °C for 30 min, the solution entirely solidified to give a pale yellow solid. Anhydrous methanol (5 ml, 0.1 mol) and distilled triethylamine (4.2 ml, 30 mmol) were dissolved in ether (50 ml) at 10 °C. To this solution, the solid obtained as described above was added cautiously in small portions and the resulting suspension was stirred for 30 min. Then cold water (40 ml) was added to give a solution that was extracted with ether (2 x 20 ml). The organic extracts were combined, washed with water (40 ml) and brine solution (20 ml), dried (MgSO4) and concentrated in vacuo to give a fluffy solid (pale yellow). It was recrystallized as white needles from ether in 72% yield. Product specification: - white solid crystals, - soluble in THF, acetone, CHCl3 and ether Ring-opening metathesis polymerization (ROMP) \ and copolymerization (ROMCP) in the presence of Umicore ruthenium initiator (UM) Materials: Dichloro-(3-phenyl-1H-inden-1-ylidene)bis(tricyclohexylphosphine) ruthenium(II) (Umicore catalyst (UM), Strem), hydroquinone (Aldrich) and hexane (Fisher) were used as received. THF (Fisher) was deoxygenated before use. Monomer 1, Monomer 2 and Monomer 3 were obtained as described above. The reactions were carried out under a nitrogen atmosphere. ROMP of Monomer 1 (M1) Procedure: M1 (1g, 0.006mol) was dissolved in deoxygenated THF (~10ml) and then the solution of UM (0.056g, 6.02·10-5mol) in THF (2 ml) was added to the solution of M1 (mole ratio [M]/[Ru] = 100) with constant stirring. The gel was formed during the reaction. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. More THF was added and then the polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Polymer 1 was dried under reduced pressure for 40h at 35°C (yield 98%). Product specification: [0068] Brown colored gel is not soluble in THF, DMF, hexane, and water. ROMP of Monomer 2 (M2) Procedure: M2 (0.57g, 0.0027 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0126g, 1.36·10-5mol) in THF (1 ml) was added to the solution of M2 (mole ratio [M]/[Ru] = 200) with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Polymer 2 was dried under reduced pressure for 40h at 35°C (yield 90%). Product specification: Polymer is quit rubbery and has pale pink color. Soluble in THF, acetone, CHCl3. Example 7 ROMP of Monomer 3 (M3) Procedure: M3 (0.48g, 0.0022 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0104g, 1.12·10-5mol) in THF (1 ml) was added to the solution of M3 (mole ratio [M]/[Ru] = 200) with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Polymer 3 was dried under reduced pressure for 40h at 35°C (yield 98%). Product specification: Polymer is quit rubbery and has pale pink color. Soluble in THF, acetone, CHCl3. ROMP of Monomer 4 (M4) Procedure: M3 (0.28g, 0.00123 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0057g, 6.17·10-6mol) in THF (1 ml) was added to the solution of M4 (mole ratio [M]/[Ru] = 200) with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10fold excess) containing hydroquinone (around 0.05g as an inhibitor). The product Polymer 4 was dried under reduced pressure for 40h at 35°C (yield 85%). Ring-opening metathesis random copolymerization of M2 and M1 [M2]/[M1]/[UM] = 150/50/1. Procedure: Mixture of M1 (0.039g, 2.38·10-4 mol) and M2 (0.15g, 7.14·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 1 was dried under reduced pressure for 40h at 35°C (yield 89% after second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 1 23% and 77%, respectively. Product specification: Copolymer 1 has pale yellow color. Soluble in THF, acetone, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. Ring-opening metathesis random copolymerization of M2 and M1, [M2]/[M1]/[UM] = 100/100/1 Procedure: Mixture of M1 (0.079g, 4.76·10-4 mol) and M2 (0.1g, 4.76·10-4 mol) was dissolved in deoxygenated THF (~6ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 2 was dried under reduced pressure for 40h at 35°C (yield 85% after second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 2 43% and 57%, respectively. 32 Product specification: Copolymer 2 has pale yellow color. Soluble in THF, acetone and DMF, soluble in ethanol or methanol if left for a long time. Ring-opening metathesis random copolymerization of M2 and M1, [M2]/[M1]/[UM] = 50/150/1. Procedure: Mixture of M1 (0.12g, 7.14·10-4 mol) and M2 (0.05g, 2.38·10-4 mol) was dissolved in deoxygenated THF (~10ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). Received Copolymer 3 is not soluble completely in THF after reprecipitation in to hexane. The product Copolymer 3 was dried under reduced pressure for 40h at 35°C (yield 86% after second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 3 66% and 34%, respectively. Product specification: Copolymer 3 has pale yellow color. Ring-opening metathesis random copolymerization of M3 and M1, [M3]/[M1]/[UM] = 150/50/1. Procedure: Mixture of M1 (0.039g, 2.38·10-4 mol) and M3 (0.15g, 7.14·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 4 was dried under reduced pressure for 40h at 35°C (yield 90% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification: Copolymer 4 has pale yellow color. Soluble in THF, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. Ring-opening metathesis random copolymerization of M3 and M1, [M3]/[M1]/[UM] = 100/100/1 Procedure: Mixture of M1 (0.079g, 4.76·10-4 mol) and M3 (0.1g, 4.76·10-4 mol) was dissolved in deoxygenated THF (~6ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 5 was dried under reduced pressure for 40h at 35°C (yield 93% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification: Copolymer 5 has pale yellow color. Soluble in THF, acetone and DMF, soluble in ethanol or methanol if left for a long time. Ring-opening metathesis random copolymerization of M3 and M1, [M3]/[M1]/[UM]= 50/150/1 Procedure: Mixture of M1 (0.12g, 7.14·10-4 mol) and M3 (0.05g, 2.38·10-4 mol) was dissolved in deoxygenated THF (~10ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). Received Copolymer 6 is not soluble completely in THF after reprecipitation in to hexane. The product Copolymer 6 was dried under reduced pressure for 40h at 35°C (yield 86% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification: Copolymer 6 has pale yellow color. Ring-opening metathesis random copolymerization of M4 and M1, [M4]/[M1]/[UM] = 150/50/1 Procedure: Mixture of M1 (0.076g, 3.09·10-4 mol) and M4 (0.196g, 9.26·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0057g, 6.17·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.05g as an inhibitor). The product Copolymer 7 was dried under reduced pressure for 40h at 35°C (yield 90% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification: Copolymer 7 has pale yellow color. Soluble in THF, DMF, DCM and chloroform. Ring-opening metathesis random copolymerization of M4 and M1, [M4]/[M1]/[UM] = 100/100/1 Procedure: Mixture of M1 (0.138g, 8.34·10-4 mol) and M4 (0.18g, 8.34·10-4 mol) was dissolved in deoxygenated THF (~6ml) and then the solution of UM (0.0077g, 8.34·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.05g as an inhibitor). The product Copolymer 8 was dried under reduced pressure for 40h at 35°C (yield 93% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification: Copolymer 8 has pale yellow color. Soluble in THF, acetone and DMF. 38 Ring-opening metathesis random copolymerization of M4 and M1, [M4]/[M1]/[UM]= 50/150/1 Procedure: Mixture of M1 (0.264g, 0.0016 mol) and M4 (0.112g, 5.3·10-4 mol) was dissolved in deoxygenated THF (~10ml) and then the solution of UM (0.0098g, 1.06·10-5 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). Received Copolymer 9 is not soluble completely in THF after reprecipitation in to hexane. The product Copolymer 9 was dried under reduced pressure for 40h at 35°C (yield 86% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification: Copolymer 9 has pale yellow color. Soluble in THF, acetone and DMF. Example 18 Ring-opening metathesis block copolymerization of M2 and M1, [M2]/[M1]/[UM] = 75/25/1. Procedure: M2 (0.075g, 3.57·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of M2 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.02g, 1.19·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 10 was dried under reduced pressure for 40h at 35°C (yield 98% after the second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 10 18% and 82%, respectively. Product specification Copolymer 10 has pale yellow color. Soluble in THF, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. Example 19 Ring-opening metathesis block copolymerization of M2 and M1, [M2]/[M1]/[UM] = 50/50/1 Procedure: M2 (0.05g, 4.76·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of M2 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.04g, 4.76·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 11 was dried under reduced pressure for 40h at 35°C (yield 92% after the second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 11 18% and 82%, respectively. Product specification Copolymer 11 has pale yellow color. Soluble in THF, DMF and acetone. Soluble in ethanol or methanol if left for a long time. Ring-opening metathesis block copolymerization of M2 and M1, [M2]/[M1]/[UM]= 25/75/1. Procedure: M2 (0.025g, 1.19·10-4 mol) was dissolved in deoxygenated THF (~10ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of M2 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.06g, 3.57·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h. The gel was formed during the reaction. The reaction was stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 12 was dried under reduced pressure for 40h at 35°C (yield 89%). 1H NMR shows the content of M1 and M2 in the Copolymer 12 75% and 23%, respectively. Product specification Copolymer 12 has pale yellow color. Insoluble in THF, DMF, DCM and chloroform Ring-opening metathesis block copolymerization of M3 and M1, [M3]/[M1]/[UM] = 75/25/1. Procedure: M3 (0.075g, 3.57·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of M3 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.02g, 1.19·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 13 was dried under reduced pressure for 40h at 35°C (yield 92% after the second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification Copolymer 13 has pale yellow color. Soluble in THF, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. Ring-opening metathesis block copolymerization of M3 and M1, [M3]/[M1]/[UM] = 50/50/1. Procedure: M3 (0.05g, 4.76·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of M3 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.04g, 4.76·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 14 was dried under reduced pressure for 40h at 35°C (yield 96% after the second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification Copolymer 14 has pale yellow color. Soluble in THF, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. Ring-opening metathesis block copolymerization of M3 and M1, [M3]/[M1]/[UM]= 25/75/1. Procedure: M3 (0.025g, 1.19·10-4 mol) was dissolved in deoxygenated THF (~10ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of M3 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.06g, 3.57·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h. The gel was formed during the reaction. The reaction was stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 15 was dried under reduced pressure for 40h at 35°C (yield 89%). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification Copolymer 15 has pale yellow color. Insoluble in THF, DMF, DCM and chloroform. Ring-opening metathesis block copolymerization of M2 and M3, [M2]/[M3]/[UM] = 50/50/1. Procedure: M2 (0.05g, 4.76·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of M2 with constant stirring. The reaction mixture was stirred for 4h and then solution of M3 (0.05g, 4.76·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 16 was dried under reduced pressure for 40h at 35°C (yield 88% after the second precipitation). 1H NMR shows the content of M2 and M3 in the Copolymer 13 58% and 42%, respectively. Product specification Copolymer 16 has pale yellow color. Soluble in THF, DMF, DCM and chloroform. Ring-opening metathesis block copolymerization of M4 and M1, [M3]/[M1]/[UM] = 100/100/1. Procedure: M4 (0.220g, 1.04·10-3 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0096g, 1.04·10-5 mol) in THF (0.7 ml) was added to the solution of M4 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.172g, 1.04·10-3 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 17 was dried under reduced pressure for 40h at 35°C (yield 92% after the second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification Copolymer 17 has pale yellow color. Soluble in THF, DMF, DCM and chloroform. Ring-opening metathesis block copolymerization of M4 and M1, [M4]/[M1]/[UM] = 50/150/1. Procedure: M4 (0.083g, 3.95·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of UM (0.0073g, 7.9·10-6 mol) in THF (0.7 ml) was added to the solution of M4 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.197g, 0.0012 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.05g as an inhibitor). The product Copolymer 18 was dried under reduced pressure for 40h at 35°C (yield 91% after the second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification Copolymer 18 has pale yellow color. Soluble in THF, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. Ring-opening metathesis polymerization (ROMP) and copolymerization (ROMCP) in the presence of Grubbs ruthenium initiator 1st generation (G1) Materials for all ROMP and ROMCP reactions in the presence of G1 initiator: Grubbs ruthenium initiator 1st generation (G1, Aldrich), hydroquinone (Aldrich) and hexane (Fisher) were used as received. THF (Fisher) was deoxygenated before use. Monomer 1, Monomer 2 and Monomer 3 were obtained as described above. The reactions were carried out under a nitrogen atmosphere. ROMP of Monomer 1 (M1). OOOOOOOOG1, G2 or G2m THF, RT m G1, THF, RT Polymer 5 Monomer 1 Scheme 27 Procedure: [0091] M1 (2g, 0.012mol) was dissolved in deoxygenated THF (~20ml) and then the solution of G1 (0.05g, 6.07·10-5mol) in THF (1 ml) was added to the solution of M1 (mole ratio [M]/[Ru] = 200) with constant stirring. The gel was formed during the reaction. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. More THF was added and then the polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Polymer 5 was dried under reduced pressure for 40h at 35°C (yield 95%). Product specification: Brown colored gel is not soluble in THF, DMF, hexane, and water. 49 Example 28 ROMP of Monomer 2 (M2). COOMe CO OM e G1, THF , RT MeO OC COOMe G1, THF, RT Scheme 28 Polymer 6 Monomer 2 Procedure: [0092] M2 (0.64g, 0.0031 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G1 (0.0126g, 1.53·10-5mol) in THF (1 ml) was added to the solution of M2 (mole ratio [M]/[Ru] = 200) with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Polymer 6 was dried under reduced pressure for 40h at 35°C (yield 95%). Product specification: Polymer is quit rubbery and has pale pink color. Soluble in THF, acetone, CHCl3. Example 29 ROMP of Monomer 3 (M3). COOMe COOMe UM, THF, RT O COOMe COOMe G1, THF, RT Scheme 29 OMonomer 3 Polymer 7 Procedure: [0093] M3 (0.53g, 0.0025 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G1 (0.0104g, 1.26·10-5mol) in THF (1 ml) was added to the solution of M3 (mole ratio [M]/[Ru] = 200) with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and 50 stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Polymer 7 was dried under reduced pressure for 40h at 35°C (yield 94%). Product specification: Polymer is quit rubbery and has pale pink color. Soluble in THF, acetone, CHCl3. Example 30 Ring-opening metathesis random copolymerization of M2 and M1 [M2]/[M1]/[G1] = 150/50/1. COOMeCOOMeCOOMeMeOOCOOOOOOOOG2Monomer 1 Monomer 2 Copolymer 19 ,THF, RT, 15h nm+ G1, THF, RT Scheme 30 Procedure: [0094] Mixture of M1 (0.044g, 2.67·10-4 mol) and M2 (0.17g, 8.02·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G1 (0.0044g, 5.34·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 19 was dried under reduced pressure for 40h at 35°C (yield 92% after second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 19 21% and 79%, respectively. Product specification: Copolymer 19 has pale yellow color. Soluble in THF, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. 51 Example 31 Ring-opening metathesis random copolymerization of M2 and M1, [M2]/[M1]/[G1] = 100/100/1. COOMeCOOMeCOOMeMeOOCOOOOOOOOG2,THF, RT, 15h nm+ Procedure: [0095] Mixture of M1 (0.088g, 5.34·10-4 mol) and M2 (0.11g, 5.34·10-4 mol) was dissolved in deoxygenated THF (~3ml) and then the solution of G1 (0.0044g, 5.34·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 20 was dried under reduced pressure for 40h at 35°C (yield 95% after second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 20 26% and 74%, respectively. Product specification: Copolymer 20 has pale yellow color. Soluble in THF, acetone and DMF, soluble in ethanol or methanol if left for a long time. 52 Example 32 Ring-opening metathesis random copolymerization of M2 and M1, [M2]/[M1]/[G1] = 50/150/1. COOMeCOOMeCOOMeMeOOCOOOOOOOOG2Monomer 1 Monomer 2 G1, THF, RT Monomer 1 Monomer 2 Copolymer 20 Scheme 31 Copolymer 21 ,THF, RT, 15h nm+ G1, THF, RT Scheme 32 Procedure: [0096] Mixture of M1 (0.13g, 8.00·10-4 mol) and M2 (0.056g, 2.67·10-4 mol) was dissolved in deoxygenated THF (~3ml) and then the solution of G1 (0.0044g, 5.34·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). Received Copolymer 21 is not soluble completely in THF after reprecipitation in to hexane. The product Copolymer 21 was dried under reduced pressure for 40h at 35°C (yield 94% after second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 21 51% and 49%, respectively. Product specification: Copolymer 21 has pale yellow color. Soluble in THF, acetone and DMF, soluble in ethanol or methanol if left for a long time. 53 Example 33 Ring-opening metathesis block copolymerization of M2 and M1, [M2]/[M1]/[G1] = 75/25/1. COOMeCOOMeCOOMeMeOOCOOOOCOOMeMeOOCOOOOG1,THF, RT, 4h n nm Block 10h G1, THF, RT, 4h Monomer 1 Monomer 2 Copolymer 22 Scheme 33 Procedure: [0097] M2 (0.084g, 4.01·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G1 (0.0044g, 5.34·10-6 mol) in THF (0.7 ml) was added to the solution of M2 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.022g, 1.34·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 22 was dried under reduced pressure for 40h at 35°C (yield 70% after the second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 22 18% and 82%, respectively. Product specification Copolymer 22 has pale yellow color. Soluble in THF, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. 54 Example 34 Ring-opening metathesis block copolymerization of M2 and M1, [M2]/[M1]/[G1] = 50/50/1. COOMeCOOMeCOOMeMeOOCOOOOCOOMeMeOOCOOOOG1,THF, RT, 4h n nm Block 10h G1, THF, RT, 4h Monomer 1 Monomer 2 Copolymer 23 Scheme 34 Procedure: [0098] M2 (0.11g, 5.34·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G1 (0.0044g, 5.34·10-6 mol) in THF (0.7 ml) was added to the solution of M2 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.088g, 5.34·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 23 was dried under reduced pressure for 40h at 35°C (yield 86% after the second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 23 41% and 59%, respectively. Product specification Copolymer 23 has pale yellow color. Soluble in THF, DMF and acetone. Soluble in ethanol or methanol if left for a long time. 55 Example 35 Ring-opening metathesis block copolymerization of M2 and M1, [M2]/[M1]/[G1]= 25/75/1. COOMeCOOMeCOOMeMeOOCOOOOCOOMeMeOOCOOOOG1,THF, RT, 4h n nm Block 10h G1, THF, RT, 4h Monomer 1 Monomer 2 Copolymer 24 Scheme 35 Procedure: [0099] M2 (0.028g, 1.34·10-4 mol) was dissolved in deoxygenated THF (~10ml) and then the solution of G1 (0.0044g, 5.34·10-6 mol) in THF (0.7 ml) was added to the solution of M2 with constant stirring. The reaction mixture was stirred for 4h and then solution of M1 (0.066g, 4.01·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h. The gel was formed during the reaction. The reaction was stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 24 was dried under reduced pressure for 40h at 35°C (yield 92%). 1H NMR shows the content of M1 and M2 in the Copolymer 24 66% and 34%, respectively. Product specification Copolymer 24 has pale yellow color. Insoluble in THF, DMF, DCM and chloroform 56 Example 36 Ring-opening metathesis block copolymerization of M2 and M3, [M2]/[M3]/[G1] = 50/50/1. COOMeCOOMeG1,THF,RT MeOOC COOMe O COOMe COOMe n 4h MeOOC COOMe O COOMe COOMe nm Monomer 3 10h G1, THF, Monomer 2 Copolymer 25 Scheme 36 Procedure: [00100] M2 (0.056g, 2.67·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G1 (0.0044g, 5.34·10-6 mol) in THF (0.7 ml) was added to the solution of M2 with constant stirring. The reaction mixture was stirred for 4h and then solution of M3 (0.056g, 2.67·10-4 mol) in THF was added dropwise. The reaction mixture was stirred during for 10h and then stopped by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 25 was dried under reduced pressure for 40h at 35°C (yield 96% after the second precipitation). 1H NMR shows the content of M2 and M3 in the Copolymer 25 53% and 47%, respectively. Product specification Copolymer 25 has pale yellow color. Soluble in THF, DMF, DCM and chloroform. 57 Example 37 Ring-opening metathesis polymerization (ROMP) and copolymerization (ROMCP) in the presence of Grubbs ruthenium initiator 2nd generation (G2) Materials for all ROMP and ROMCP reactions in the presence of G2 initiator: [00101] Grubbs ruthenium initiator 2nd generation (G2, Aldrich), hydroquinone (Aldrich) and hexane (Fisher) were used as received. THF (Fisher) was deoxygenated before use. Monomer 1, Monomer 2 and Monomer 3 were obtained as described above. The reactions were carried out under a nitrogen atmosphere. ROMP of Monomer 1 (M1). OOOOOOOOG1, G2 or G2m THF, RT m G2, THF, RT Polymer 8 Monomer 1 Scheme 37 Procedure: [00102] M1 (1g, 0.006mol) was dissolved in deoxygenated THF (~10ml) and then the solution of G2 (0.051g, 6.02·10-5mol) in THF (1 ml) was added to the solution of M1 (mole ratio [M]/[Ru] = 100) with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. Polymer 8 was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Polymer 8 was dried under reduced pressure for 40h at 35°C (yield 97% after the second re-precipitation). Product specification: Polymer 8 has pale yellow color. Soluble in THF, DMF and ethanol if left for a long time. 58 Example 38 ROMP of Monomer 2 (M2). COOMeCOOMeG2,THF,RTMeOOCCOOMeScheme 38 Polymer 9 Monomer 2 Procedure: [00103] M2 (0.64g, 0.003 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G2 (0.025g, 3.0·10-5mol) in THF (1 ml) was added to the solution of M2 (mole ratio [M]/[Ru] = 100) with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Polymer 9 was dried under reduced pressure for 40h at 35°C (yield 92%). Product specification: Polymer 9 is quit rubbery and has pale pink color. Soluble in THF, acetone, CHCl3. 59 Example 39 ROMP of Monomer 3 (M3). OCOOMeCOOMeG2,THF,RTOCOOMeCOOMeMonomer 3 Scheme 39 Polymer 10 Procedure: [00104] M3 (0.53g, 0.0025 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G2 (0.021g, 2.5·10-5mol) in THF (1 ml) was added to the solution of M3 (mole ratio [M]/[Ru] = 100) with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Polymer 10 was dried under reduced pressure for 40h at 35°C (yield 97%). Product specification: Polymer 10 is quit rubbery and has pale pink color. Soluble in THF, acetone, CHCl3. 60 Example 40 Ring-opening metathesis random copolymerization of M2 and M1 [M2]/[M1]/[G2] = 75/25/1. COOMeCOOMeCOOMeMeOOCOOOOOOOOG2Monomer 1 Monomer 2 Copolymer 25 ,THF, RT, 15h nm+ G2, THF, RT Scheme 40 Procedure: [00105] Mixture of M1 (0.07g, 4.5·10-4 mol) and M2 (0.19g, 8.85·10-4 mol) was dissolved in deoxygenated THF (~10ml) and then the solution of G2 (0.01g, 1.18·10-5 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The copolymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 25 was dried under reduced pressure for 40h at 35°C (yield 94% after second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 25 44% and 56%, respectively. Product specification: Copolymer 25 has pale yellow color. Soluble in THF, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. 61 Example 41 Ring-opening metathesis random copolymerization of M2 and M1, [M2]/[M1]/[G2] = 50/50/1. COOMeCOOMeCOOMeMeOOCOOOOOOOOG2,THF, RT, 15h nm+ Procedure: [00106] Mixture of M1 (0.098g, 5.9·10-4 mol) and M2 (0.125g, 5.9·10-4 mol) was dissolved in deoxygenated THF (~10ml) and then the solution of G2 (0.01g, 1.18·10-5 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The copolymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 26 was dried under reduced pressure for 40h at 35°C (yield 95% after second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 26 42% and 58%, respectively. Product specification: Copolymer 26 has pale yellow color. Soluble in THF, acetone and DMF, soluble in ethanol or methanol if left for a long time. 62 Example 42 Ring-opening metathesis random copolymerization of M2 and M1, [M2]/[M1]/[G2] = 25/75/1. COOMeCOOMeCOOMeMeOOCOOOOOOOOG2Monomer 1 Monomer 2 G2, THF, RT Monomer 1 Monomer 2 Copolymer 26 Scheme 41 Copolymer 27 ,THF, RT, 15h nm+ G2, THF, RT Scheme 42 Procedure: [00107] Mixture of M1 (0.147g, 8.85·10-4 mol) and M2 (0.062g, 2.95·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G2 (0.01g, 1.18·10-5 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). Received Copolymer 27 is not soluble completely in THF after reprecipitation in to hexane. The product Copolymer 27 was dried under reduced pressure for 40h at 35°C (yield 98% after second precipitation). 1H NMR shows the content of M1 and M2 in the Copolymer 27 82% and 18%, respectively. Product specification: Copolymer 27 has pale yellow color. Soluble in THF, acetone and DMF, soluble in ethanol or methanol if left for a long time. 63 Example 43 Ring-opening metathesis random copolymerization of M3 and M1, [M3]/[M1]/[G2] = 75/25/1. Copolymer 28 Monomer 3 OCOOMeCOOMeG2,THF,RTOCOOMeCOOMeOOOO+OOOOnmMonomer 1 Scheme 43 Procedure: [00108] Mixture of M1 (0.07g, 4.5·10-4 mol) and M3 (0.19g, 8.85·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G2 (0.01g, 1.18·10-5 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 28 was dried under reduced pressure for 40h at 35°C (yield 95% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR Product specification: Copolymer 28 has pale yellow color. Soluble in THF, DMF, DCM and chloroform, soluble in ethanol or methanol if left for a long time. 64 Example 44 Ring-opening metathesis random copolymerization of M3 and M1, [M3]/[M1]/[G2] = 50/50/1. Copolymer 29 Monomer 3 OCOOMeCOOMeG2,THF,RTOCOOMeCOOMeOOOO+OOOOnmMonomer 1 Scheme 44 Procedure: [00109] Mixture of M1 (0.098g, 5.88·10-4 mol) and M3 (0.124g, 5.88·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G2 (0.01g, 1.17·10-5 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 29 was dried under reduced pressure for 40h at 35°C (yield 93% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification: Copolymer 29 has pale yellow color. Soluble in THF, acetone and DMF, soluble in ethanol or methanol if left for a long time. 65 Example 45 Ring-opening metathesis random copolymerization of M3 and M1, [M3]/[M1]/[G2]= 25/75/1. Copolymer 30 Monomer 3 OCOOMeCOOMeG2,THF,RTOCOOMeCOOMeOOOO+OOOOnmMonomer 1 Scheme 45 Procedure: [00110] Mixture of M1 (0.147g, 8.85·10-4 mol) and M3 (0.062g, 2.95·10-4 mol) was dissolved in deoxygenated THF (~5ml) and then the solution of G2 (0.01g, 1.18·10-5 mol)in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The polymer was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). Received Copolymer 30 is not soluble completely in THF after reprecipitation in to hexane. The product Copolymer 30 was dried under reduced pressure for 40h at 35°C (yield 97% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification: Copolymer 30 has pale yellow color. 66 Example 46 Ring-opening metathesis random copolymerization of M3 and M2, [M3]/[M2]/[G2] = 50/50/1. OCOOMeCOOMeCOOMeCOOMeOOMeOOMeOCOOMeMeOOC+Monomer 2 Monomer 3 Scheme 46 G2,THF, RT, 15h nm G2, THF, RTCopolymer 31 Procedure: [00111] Mixture of M2 (0.123g, 5.9·10-4 mol) and M3 (0.125g, 5.9·10-4 mol) was dissolved in deoxygenated THF (~6ml) and then the solution of G2 (0.0044g, 4.76·10-6 mol) in THF (0.7 ml) was added to the solution of monomers mixture with constant stirring. The reaction was stopped after 12h by adding of vinylethyl ether (0.1 ml) and stirring for 30 min. The Copolymer 31 was precipitated into hexane (10-fold excess) containing hydroquinone (around 0.1g as an inhibitor). The product Copolymer 31 was dried under reduced pressure for 40h at 35°C (yield 98% after second precipitation). The chemical shifts of two monomer units are overlapping and hence difficult to define the composition by 1H NMR. Product specification: Copolymer 31 has pale yellow color. Soluble in THF, acetone, CHCl3, CH2Cl2 and DMF. Example 47 Hydrogenation of synthesized homo- and copolymers. Materials for all hydrogenation reactions: [00112] Polymers and copolymers were synthesized as described above, p-toluene sulphonylhydrazide (p-TSH, Aldrich), DMF (Aldrich). 67 Hydrogenation of Copolymer 2 MeOOCCOOMeOOOOnmRandompTSHMeOOCCOOMeOOOOnmRandomDMFCopolymer 2 Copolymer 2.1. Scheme 47 Procedure: [00113] Copolymer 2 (0.2g, 9.52·10-4 mol), p-TSH (0.02g, 1.19·10-4 mol) and DMF (5ml) were placed in a one necked, round bottomed flask (50ml) fitted with a condenser and stirrer bar and then heated with stirring to 140oC for 12h. The hot solution was added dropwise to vigorously stirring methanol (150ml) to give a precipitate, which was isolated by filtration. The resulting polymer (yield 96%) was a yellowish powder insoluble in DMF. Example 48 Hydrogenation of Copolymer 5 O COOMe COOMe O O OO nm Random p-TSH O COOMe COOMe O O OO nm Random DMF Copolymer 5 Copolymer 5.1. Scheme 48 Procedure: [00114] Copolymer 5 (0.2g, 9.52·10-4 mol), pTSH (0.02g, 1.19·10-4 mol) and DMF (5ml) were placed in a one necked, round bottomed flask (50ml) fitted with a condenser and stirrer bar and then heated with stirring to 140oC for 12h. The hot solution was added dropwise to vigorously stirring 68 methanol (150ml) to give a precipitate, which was isolated by filtration. The resulting polymer (yield 93%) was a yellowish powder insoluble in DMF. Example 49 Hydrogenation of Copolymer 8 OOOOCOOMeMeOOCOOOOOOCOOMeMeOOCnmp-TSH, DMF RandomScheme 49 Copolymer 8 Copolymer 8.1. Procedure: [00115] Copolymer 8 (0.2g, 9.52·10-4 mol), p-TSH (0.02g, 1.19·10-4 mol) and DMF (5ml) were placed in a one necked, round bottomed flask (50ml) fitted with a condenser and stirrer bar and then heated with stirring to 140oC for 12h. The hot solution was added dropwise to vigorously stirring methanol (150ml) to give a precipitate, which was isolated by filtration. The resulting polymer (yield 93%) was a yellowish powder insoluble in DMF. 69 Example 50 Hydrogenation of Copolymer 11 MeOOCCOOMeOOOOnmBlockpTSHMeOOCCOOMeOOOOnmBlockDMFCopolymer 11 Copolymer 11.1. Scheme 50 Procedure: [00116] Copolymer 11 (0.2g, 9.52·10-4 mol), p-TSH (0.02g, 1.19·10-4 mol) and DMF (5ml) were placed in a one necked, round bottomed flask (50ml) fitted with a condenser and stirrer bar and then heated with stirring to 140oC for 12h. The hot solution was added dropwise to vigorously stirring methanol (150ml) to give a precipitate, which was isolated by filtration. The resulting polymer (yield 97%) was a yellowish powder insoluble in DMF. Example 51 Hydrogenation of Copolymer 14 O COOMe COOMe O O OO nm Block p-TSH O COOMe COOMe O O OO nm Block DMF Copolymer 14 Copolymer 14.1. Scheme 51 Procedure: [00117] Copolymer 14 (0.2g, 9.52·10-4 mol), p-TSH (0.02g, 1.19·10-4 mol) and DMF (5ml) were placed in a one necked, round bottomed flask 70 (50ml) fitted with a condenser and stirrer bar and then heated with stirring to 140oC for 12h. The hot solution was added dropwise to vigorously stirring methanol (150ml) to give a precipitate, which was isolated by filtration. The resulting polymer (yield 93%) was a yellowish powder insoluble in DMF. Example 52 Hydrogenation of Copolymer 17 OOOOCOOMeMeOOCOOOOOOCOOMeMeOOCnmp-TSH, DMF RandomScheme 52 Copolymer 17 Copolymer 17.1. Procedure: [00118] Copolymer 17 (0.2g, 9.52·10-4 mol), p-TSH (0.02g, 1.19·10-4 mol) and DMF (5ml) were placed in a one necked, round bottomed flask (50ml) fitted with a condenser and stirrer bar and then heated with stirring to 140oC for 12h. The hot solution was added dropwise to vigorously stirring methanol (150ml) to give a precipitate, which was isolated by filtration. The resulting polymer (yield 93%) was a yellowish powder insoluble in DMF. 71 Example 53 Hydrogenation of Polymer 8 Polymer 8.1. Scheme 53 OOOOOOOOmptoluenesulfonylhydrazideDMF, 1400CmPolymer 8 Procedure: [00119] Polymer 8 (0.2g, 1.2·10-3 mol), p-TSH (1.12g, 6.02·10-3 mol) and DMF (5ml) were placed in a one necked, round bottomed flask (50ml) fitted with a condenser and stirrer bar and then heated with stirring to 140oC for 12h. The hot solution was added dropwise to vigorously stirring methanol (150ml) to give a precipitate, which was isolated by filtration. The resulting polymer (yield 96%) was a yellowish powder insoluble in DMF. Example 54 Hydrogenation of Copolymer 26 RandomRandom MeOOC COOMe O O OO n m p-TSH MeOOC COOMe O O OO nm DMF Copolymer 26 Copolymer 26.1. Scheme 54 Procedure: [00120] Copolymer 26 (0.2g, 9.52·10-4 mol), p-TSH (0.89g, 4.76·10-3 mol) and DMF (5ml) were placed in a one necked, round bottomed flask (50ml) fitted with a condenser and stirrer bar and then heated with stirring to 72 140oC for 12h. The hot solution was added dropwise to vigorously stirring methanol (150ml) to give a precipitate, which was isolated by filtration. The resulting polymer (yield 96%) was a yellowish powder insoluble in DMF. Example 55 Hydrogenation of Copolymer 29 OCOOMeCOOMeOOOOnmRandomp-TSHOCOOMeCOOMeOOOOnmRandomDMFCopolymer 29 Copolymer 29.1. Scheme 55 Procedure: [00121] Copolymer 29 (0.2g, 9.52·10-4 mol), p-TSH (0.89g, 4.76·10-3 mol) and DMF (5ml) were placed in a one necked, round bottomed flask (50ml) fitted with a condenser and stirrer bar and then heated with stirring to 140oC for 12h. The hot solution was added dropwise to vigorously stirring methanol (150ml) to give a precipitate, which was isolated by filtration. The resulting polymer (yield 96%) was a yellowish powder insoluble in DMF. Example 56 Base hydrolysis of synthesized polymers and copolymers Materials for all base hydrolysis reactions: [00122] NaOH (Aldrich) was used as received. Demineralised water was supplied from the Department. Copolymer 1 – Copolymer 13 were obtained as described above. The reactions were carried out on the air. 73 Base hydrolysis of Polymer 4. **On COONaNaOOC**On COOMeMeOOCNaOH, waterPolymer 4.2 Polymer 4 Scheme 56 Procedure: [00123] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Polymer 4 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Polymer 4 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to white. Polymer 4.2. was kept in the solution. However, Polymer 4.2 can be precipitated in ethanol and dried under reduced pressure. Example 57 Base hydrolysis of Copolymer 1. RandomRandom MeOOC COOMe O O OO n m NaOH, water NaOOC COONa O NaOOC COONa nm Copolymer 1 Copolymer 1.2. Scheme 57 Procedure: [00124] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 1 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 1 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The 74 color of the solution during the reaction changed from colorless to greenish. Copolymer 1.2. was kept in the solution. However, Copolymer 1.2. can be precipitated in ethanol and dried under reduced pressure. Example 58 Base hydrolysis of Copolymer 2. MeOOCCOOMeOOOOnmRandomNaOH,waterNaOOCCOONaONaOOCCOONanmRandomCopolymer 2 Copolymer 2.2. Scheme 58 Procedure: [00125] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 2 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 2 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 2.2. was kept in the solution. However, Copolymer 2.2. can be precipitated in ethanol and dried under reduced pressure. 75 Example 59 Base hydrolysis of Copolymer 3. MeOOCCOOMeOOOOnmRandomNaOH,waterNaOOCCOONaONaOOCCOONanmRandomCopolymer 3 Copolymer 3.2. Scheme 59 Procedure: [00126] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 3 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 3 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 3.2. was kept in the solution. However, Copolymer 3.2. can be precipitated in ethanol and dried under reduced pressure (yield 98% after precipitation). Example 60 Base hydrolysis of Copolymer 4. Copolymer 4 Copolymer 4.2. O COOMe COOMe O O OO nm Random NaOH, water O COONa COONa O NaOOC COONa nm Random Scheme 60 Procedure: [00127] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 4 (0.17g, 8.09·10-4 mol) and 76 stirred 2h. At the start the Copolymer 4 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 4.2. was kept in the solution. However, Copolymer 4.2. can be precipitated in ethanol and dried under reduced pressure. Example 61 Base hydrolysis of Copolymer 5. OCOOMeCOOMeOOOOnmRandomNaOH,waterOCOONaCOONaONaOOCCOONanmRandomCopolymer 5 Copolymer 5.2. Scheme 61 Procedure: [00128] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 5 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 5 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 5.2. was kept in the solution. However, Copolymer 5.2. can be precipitated in ethanol and dried under reduced pressure. 77 Example 62 Base hydrolysis of Copolymer 6. OCOOMeCOOMeOOOOnmRandomNaOH,waterOCOONaCOONaONaOOCCOONanmRandomCopolymer 6 Copolymer 6.2. Scheme 62 Procedure: [00129] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 6 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 6 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 6.2. was kept in the solution. However, Copolymer 6.2. can be precipitated in ethanol and dried under reduced pressure. Example 63 Base hydrolysis of Copolymer 7. OO OO COOMe MeOOC O OO COONa NaOOC COONa NaOOC nm Random NaOH, water nm Random Copolymer 7 Scheme 63 Copolymer 7.2. Procedure: [00130] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 7 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 7 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The 78 color of the solution during the reaction changed from colorless to greenish. Copolymer 7.2. was kept in the solution. However, Copolymer 7.2. can be precipitated in ethanol and dried under reduced pressure. Example 64 Base hydrolysis of Copolymer 8. OOOOCOOMeMeOOCOOOCOONaNaOOCCOONaNaOOCnmRandomNaOH, waternmRandom Copolymer 8 Scheme 64 Copolymer 8.2. Procedure: [00131] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 8 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 8 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 8.2. was kept in the solution. However, Copolymer 8.2. can be precipitated in ethanol and dried under reduced pressure. 79 Base hydrolysis of Copolymer 9. Example 65 OOOOCOOMeMeOOCOOOCOONaNaOOCCOONaNaOOCnmRandomNaOH, waternmRandomCopolymer 9 Scheme 65 Copolymer 9.2. Procedure: [00132] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 9 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 9 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 9.2. was kept in the solution. However, Copolymer 9.2. can be precipitated in ethanol and dried under reduced pressure. Example 66 Base hydrolysis of Copolymer 10. Procedure: [00133] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 10 (0.17g, 8.09·10-4 mol) and stirred 10h. At the start the Copolymer 10 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded BlockBlock NaOH, water NaOOC COONa O NaOOC COONa nm MeOOC COOMe O O OO nm Copolymer 10 Scheme 66 Copolymer 10.2. 80 with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 10.2. was kept in the solution. However, Copolymer 10.2. can be precipitated in ethanol and dried under reduced pressure. Example 67 Base hydrolysis of Copolymer 11. MeOOCCOOMeOOOOnmBlockNaOH,waterNaOOCCOONaONaOOCCOONanmBlockCopolymer 11 Scheme 67 Copolymer 11.2. Procedure: [00134] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 11 (0.17g, 8.09·10-4 mol) and stirred 10h. At the start the Copolymer 11 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 11.2 was kept in the solution. However, Copolymer 11.2. can be precipitated in ethanol and dried under reduced pressure. 81 O Example 68 Base hydrolysis of Copolymer 12. MeOOCCOOMeOOOOnmBlockNaOH,waterNaOOCCOONaONaOOCCOONanmBlockCopolymer 12 Scheme 68 Copolymer 12.2. Procedure: [00135] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 12 (0.17g, 8.09·10-4 mol) and stirred 10h. At the start the Copolymer 12 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 12.2. was kept in the solution. However, Copolymer 12.2. can be precipitated in ethanol and dried under reduced pressure. Example 69 Base hydrolysis of Copolymer 13. Copolymer 13 Copolymer 13.2. Scheme 69 Procedure: [00136] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 13 (0.17g, 8.09·10-4 mol) and 82 stirred 10h. At the start the Copolymer 13 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 13.2. was kept in the solution. However, Copolymer 13.2. can be precipitated in ethanol and dried under reduced pressure. Example 70 Base hydrolysis of Copolymer 14. OCOOMeCOOMeOOOOnmBlockNaOH,waterOCOONaCOONaONaOOCCOONanmBlockCopolymer Scheme 70 Procedure: 14 Copolymer 14.2. [00137] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 14 (0.17g, 8.09·10-4 mol) and stirred 10h. At the start the Copolymer 14 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 14.2. was kept in the solution. However, Copolymer 14.2. can be precipitated in ethanol and dried under reduced pressure. 83 Example 71 Base hydrolysis of Copolymer 15. OCOOMeCOOMeOOOOnmBlockNaOH,waterOCOONaCOONaONaOOCCOONanmBlockCopolymer 15 Copolymer 15.2. Scheme 71 Procedure: [00138] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 15 (0.17g, 8.09·10-4 mol) and stirred 10h. At the start the Copolymer 15 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 15.2. was kept in the solution. However, Copolymer 15.2. can be precipitated in ethanol and dried under reduced pressure. Example 72 Base hydrolysis of Copolymer 17. Copolymer 16 Scheme 72 Copolymer 16.2. Procedure: [00139] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 16 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 16 was floated on the surface but 84 eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 16.2. was kept in the solution. However, Copolymer 16.2. can be precipitated in ethanol and dried under reduced pressure. Example 73 Base hydrolysis of Copolymer 18. OOOOCOOMeMeOOCOOOCOONaNaOOCCOONaNaOOCnmBlockNaOH, waternmBlock Copolymer 17 Scheme 73 Copolymer 17.2. Procedure: [00140] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 17 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 17 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 17.2. was kept in the solution. However, Copolymer 17.2. can be precipitated in ethanol and dried under reduced pressure. 85 Example 74 Base hydrolysis of Copolymer 19. MeOOCCOOMeOOOOnmRandomNaOH,waterNaOOCCOONaONaOOCCOONanmRandomCopolymer 19 Copolymer 19.2. Scheme 74 Procedure: [00141] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 19 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 19 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 19.2. was kept in the solution. However, Copolymer 19.2. can be precipitated in ethanol and dried under reduced pressure. Example 75 Base hydrolysis of Copolymer 20. MeOOC COOMe O O OO nm Random NaOH, water NaOOC COONa O NaOOC COONa nm Random Copolymer 20 Copolymer 20.2. Scheme 75 Procedure: [00142] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 20 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 20 was floated on the surface but 86 eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 20.2. was kept in the solution. However, Copolymer 20.2. could be precipitated in ethanol and dried under reduced pressure. Example 76 Base hydrolysis of Copolymer 21. MeOOCCOOMeOOOOnmRandomNaOH,waterNaOOCCOONaONaOOCCOONanmRandomCopolymer 21 Copolymer 21.2. Scheme 76 Procedure: [00143] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 21 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 21 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 21.2. was kept in the solution. However, Copolymer 21.2. can be precipitated in ethanol and dried under reduced pressure (yield 98% after precipitation). 87 Example 77 Base hydrolysis of Copolymer 22. MeOOCCOOMeOOOOnmBlockNaOH,waterNaOOCCOONaONaOOCCOONanmBlockCopolymer 22 Scheme 77 Copolymer 22.2. Procedure: [00144] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 22 (0.17g, 8.09·10-4 mol) and stirred 10h. At the start the Copolymer 22 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 22.1. was kept in the solution. However, Copolymer 22.1. can be precipitated in ethanol and dried under reduced pressure. Example 78 Base hydrolysis of Copolymer 23. MeOOC COOMe O O OO nm Block NaOH, water NaOOC COONa O NaOOC COONa nm Block Copolymer 23 Scheme 78 Copolymer 23.2. Procedure: [00145] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 23 (0.17g, 8.09·10-4 mol) and 88 stirred 10h. At the start the Copolymer 23 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 23.2. was kept in the solution. However, Copolymer 23.2. can be precipitated in ethanol and dried under reduced pressure. Example 79 Base hydrolysis of Copolymer 24. MeOOCCOOMeOOOOnmBlockNaOH,waterNaOOCCOONaONaOOCCOONanmBlockCopolymer 24 Scheme 79 Copolymer 24.2. Procedure: [00146] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 24 (0.17g, 8.09·10-4 mol) and stirred 10h. At the start the Copolymer 24 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 24.2. was kept in the solution. However, Copolymer 24.2. can be precipitated in ethanol and dried under reduced pressure. 89 Example 80 Base hydrolysis of Polymer 8. OOOOOOOONaNaOmm-+-+Scheme 80 Polymer 8 Polymer 8.2. Procedure: [00147] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Polymer 8 (0.17g, 8.09·10-4 mol) and stirred 10h. At the start the Polymer 8 was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Polymer 8.2. was kept in the solution. However, Copolymer 8.2. can be precipitated in ethanol and dried under reduced pressure. Example 81 Base hydrolysis of Copolymer 25. RandomRandom MeOOC COOMe O O OO n m NaOH, water NaOOC COONa O NaOOC COONa nm Copolymer 215 Copolymer 25.2. Scheme 81 Procedure: [00148] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 25 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 25 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The 90 color of the solution during the reaction changed from colorless to greenish. Copolymer 25.2. was kept in the solution. However, Copolymer 25.2. can be precipitated in ethanol and dried under reduced pressure. Example 82 Base hydrolysis of Copolymer 26. MeOOCCOOMeOOOOnmRandomNaOH,waterNaOOCCOONaONaOOCCOONanmRandomCopolymer 26 Copolymer 26.2. Scheme 82 Procedure: [00149] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 26 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 26 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 26.2. was kept in the solution. However, Copolymer 26.2. can be precipitated in ethanol and dried under reduced pressure. 91 Example 83 Base hydrolysis of Copolymer 27. MeOOCCOOMeOOOOnmRandomNaOH,waterNaOOCCOONaONaOOCCOONanmRandomCopolymer 27 Copolymer 27.2. Scheme 83 Procedure: [00150] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 27 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 27 was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 27.2. was kept in the solution. However, Copolymer 27.2. can be precipitated in ethanol and dried under reduced pressure (yield 98% after precipitation). Example 84 Base hydrolysis of Copolymer 29. O O O COOMe MeOOC O O COONa NaOOC COONa NaOOC nm Random NaOH, water nm Random Copolymer 29 Scheme 84 Copolymer 29.2. Procedure: [00151] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 29 (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 29 was floated on the surface but 92 eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 29.2. was kept in the solution. However, Copolymer 29.2. can be precipitated in ethanol and dried under reduced pressure (yield 98% after precipitation). Example 85 Base hydrolysis of Copolymer 2.1. MeOOCCOOMeOOOOnmRandomNaOH,waterNaOOCCOONaONaOOCCOONanmRandomCopolymer 2.1. Copolymer 2.3. Scheme 85 Procedure: [00152] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 2.1. (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 2.1. was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 2.3. was kept in the solution. However, Copolymer 2.3. can be precipitated in ethanol and dried under reduced pressure. 93 Example 86 Base hydrolysis of Copolymer 5.1. OCOOMeCOOMeOOOOnmRandomNaOH,waterOCOONaCOONaONaOOCCOONanmRandomCopolymer 5.1. Copolymer 5.3. Scheme 86 Procedure: [00153] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 5.1. (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 5.1. was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 5.3. was kept in the solution. However, Copolymer 5.3. can be precipitated in ethanol and dried under reduced pressure. Example 87 Base hydrolysis of Copolymer 11.1. Procedure: MeOOC COOMe O O OO nm Block NaOH, water NaOOC COONa O NaOOC COONa nm Block Copolymer 11.1. Copolymer 11.3. Scheme 87 [00154] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 11.1. (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 11.1. was floated on the surface 94 but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 11.3. was kept in the solution. However, Copolymer 11.3. can be precipitated in ethanol and dried under reduced pressure. Example 88 Base hydrolysis of Copolymer 14.1. OCOOMeCOOMeOOOOnmBlockNaOH,waterOCOONaCOONaONaOOCCOONanmBlockCopolymer 14.1 Copolymer 14.3. Scheme 88 Procedure: [00155] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Copolymer 14.1. (0.17g, 8.09·10-4 mol) and stirred 2h. At the start the Copolymer 14.1. was floated on the surface but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Copolymer 14.3. was kept in the solution. However, Copolymer 14.3. can be precipitated in ethanol and dried under reduced pressure. 95 Example 89 Base hydrolysis of Polymer 7.1. Scheme 89 OOOOOOOONaNaOmm-+-+Polymer 8.1. Polymer 8.3. Procedure: [00156] NaOH (0.065g, 1.61·10-3 mol) was dissolved in water (5ml) and added to a flask containing solid Polymer 8.1. (0.17g, 8.09·10-4 mol) and stirred 10h. At the start the Polymer 8.1. was floated on the surface, then formed a gel but eventually dissolved in the water as the reaction proceeded with time. The color of the solution during the reaction changed from colorless to greenish. Polymer 8.3. was kept in the solution. However, Polymer 8.3. can be precipitated in ethanol and dried under reduced pressure. [00157] While a number of embodiments of this invention have been represented, it is apparent that the basic construction can be altered to provide other embodiments that utilize the invention without departing from the spirit and scope of the invention. All such modifications and variations are intended to be included within the scope of the invention as defined in the appended claims rather than the specific embodiments that have been presented by way of example.