slides

advertisement

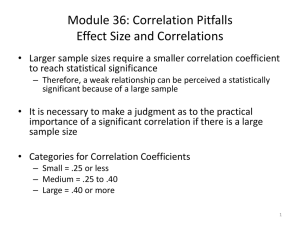

Fabrication of nanostructures by means of Block Copolymer based lithography Monica Ceresoli Supervisor: Prof. Paolo Milani Co-Supervisor: Dr. Michele Perego Introduction 2003 2005 2007 2009 2011 2013 2015 90 nm 65 nm 45 nm 32nm 22 nm 14 nm 10 nm Manifacturing Development Research Fabrication issue: sub 20 nm structures • • • Requirements: High density Long range order Simple and short process Implementation of self-assembling materials in Microelectronics lithography. ITRS 2011 Edition: “Emerging Research Materials” Introduction BLOCK COPOLYMERS (BCP): class of macromolecules produced by covalently bonding two or more chemically distinct polymer blocks. Thermodynamic Incompatibility + Covalent Bond Lamellae Thermal treatment Phase separation in ordered nano-domains I.Botiz et al., Materials Today 13, 42-51 (2010), F. S. Bates et al., Physics Today 52, 32-38 (1999) Introduction Lithographic application of Lamellar thin films. Problems: Furnace 100 minutes Annealing temperature (°C) Correlation length ξ (nm) Correlation length ξ (nm) • Long time process. • Weak dependence on Temperature and time of annealing. • Small dimension of ordered domains (correlation length ξ) Requirements: • High density • Long range order • Simple and short process Annealing time (min) R. Ruiz et al., Adv. Mater. 2007, 19, 2157–2162, R. Ruiz et al., Adv. Mater. 19, 587–591 (2007) Introduction Lithographic application of Lamellar thin films. Problems: • Long time process. • Weak dependence on Temperature and time of annealing. • Small dimension of ordered domains (correlation length ξ) Requirements: • High density • Long range order • Simple and short process New study: Thermodynamics on short time-scale R. Ruiz et al., Adv. Mater. 2007, 19, 2157–2162, R. Ruiz et al., Adv. Mater. 19, 587–591 (2007) Materials and Techniques Preparation of lamellar thin films. • Neutralization of the substrate. Random Copolymer SiO2 Si Materials and Techniques Preparation of lamellar thin films. • Neutralization of the substrate. • Block Copolymer deposition. Block Copolymer Random Copolymer SiO2 Si Poly (Styrene-block-Methyl Methacrylate) 50% PS 50% PMMA Materials and Techniques Preparation of lamellar thin films. • Neutralization of the substrate. • Block Copolymer deposition. • Thermal treatment. Block Copolymer Random Copolymer SiO2 Si Materials and Techniques Standard thermal process in furnace : Hours! • Slow heating and cooling ramp. • Impossibility to fine-tuning the rate of thermal energy transferred to the sample. Novel approach with Rapid Thermal Processing: • Fast heating and cooling ramp. • Real time –control of sample temperature. Seconds! • Temperatures up above 300°C. Steady state 260 Temperature (°C) 240 220 200 180 160 140 120 100 80 60 40 20 0 Samples are heated by halogen lamps irradiation. F. Ferrarese Lupi et al., Nanotechnology, 24 (2013) 315601 80 100 120 Time (s) 140 160 Experimental Results 60s of annealing Increasing the annealing temperature more and more ordered films get formed. Temperature M. Ceresoli et al., 2013, submitted. Experimental Results Significant variations of the correlation length (ξ) have been observed. 60s treatment 10s treatment Temperature (°C) M. Ceresoli et al., 2013, submitted. Experimental Results Two times higher ξ in respect to literature results. 60s treatment 10s treatment 100 minutes conventional furnace 1minute in RTP time of process reduced by two orders of magnitude ? Temperature (°C) R. Ruiz et al., Adv. Mater. 2007, 19, 2157–2162 Experimental Results 5s 10s 60s RTP 290°C 1s Correlation length ξ (nm) Time of annealing 290°C 270°C 250°C time (s) R. Ruiz et al., Adv.Mater. 2007,19, 587-591, S. Ji, P.F. Nealey et al., Macrom. (2011) 44.4291. 5m 15m Experimental Results A double phase appears! Selective remotion of PMMA phase 100 nm Residual solvent at the interface with the substrate 100 nm F. Ferrarese Lupi et al., Nanotechnology, 24 (2013) 315601 Experimental Results 5s 10s 60s 15m 5m RTP 290°C 1s Correlation length ξ (nm) Time of annealing Solvent content cylinders drive order 290°C Time (s) On courtesy of Prof. M. Laus, Università del Piemonte Orientale 1 10 100 Time (s) 1000 Perspectives and Open Points Morphology investigation with Grazing Incident Small Angle X-ray Scattering. Analysis in progress… Perspectives and Open Points Boiling Temperature of solvent The presence of a double phase is affected by solvent choise… ? Toluene PS selective PMMA selective 20 nm Acetone 20 nm Chloroform 1min, 250°C, RTP THF Perspectives and Open Points In very fast thermal treatment, heating and cooling ramps become relevant… length Correlation Correlation lenght (nm)(nm) Temperature (°C) 70 Steady state 260 240 220 200 180 160 140 120 100 80 60 40 20 65 60 55 50 45 40 0 80 100 120 140 160 0 Time (s) • No significant variation for steady state as long as 30 s. • What about 5 s or 1 s of steady state? 10 20 30 Heating rate (°C/s) Heating rate (°C/s) 40 50 Pubblications Rapid Thermal Processing of self-assembling block copolymer thin films F. Ferrarese Lupi, T.J. Giammaria, M. Ceresoli, G. Seguini, K. Sparnacci, D. Antonioli, V. Gianotti, M. Laus and M. Perego. Nanotechnology, 24 (2013) 315601. Higly ordered lamellar patterns in symmetric block copolymer thin films M.Ceresoli, F.Ferrarese Lupi, G.Seguini, K. Sparnacci, V. Gianotti, D. Antonioli, M. Laus, L. Boarino and M. Perego. submitted. Flash Grafting of Functional Random Copolymers for surface neutralization F. Ferrarese Lupi, T.J. Giammaria, G. Seguini, M. Ceresoli, M. Perego, D. Antonioli, V. Gianotti, K. Sparnacci and M. Laus. submitted. Conferences EPF2013 European Congress of Polymers, Pisa, June16th-21th 2013. Stabilization of mixed morphology in Block Copolymer thin films by solvent assisted thermal processing. Poster presentation Fabrication of nanostructures by means of block copolymer based lithography Thank you for your attention. Monica Ceresoli 15/10/2013 Technologies under study Residual solvent Residual solvent locally trapped at the interface between random and block copolymer. "local" toluene rich interphase. Toluene amount in the block layer in the absence of random is 0,083 ng mm-2nm-1. Correlation length SEM images are mapped through a intensity gradient function. Gradient vector of intensity correlation function Extraction of correlation length ξ C. Harrison et al, ,Macromolecules 33, 857-65 Optimization of RTP 260 260 240 240 220 220 200 200 Temperature (°C) Temperature (°C) How to get an effective plateau … setting an overheating in the nominal temperature, the radiative power of infrared lamps can keep the temperature costant. 180 160 140 120 100 180 160 140 120 100 80 80 60 60 40 40 20 20 0 0 80 100 120 Time (s) 140 160 80 100 120 140 160 Time (s) This assures control on very short thermal treatments too (from minutes to seconds). Study of the Early stages of self-assembling evolution in symmetric PS-b-PMMA thin films Materials and Techniques Samples preparation • • • • • Neutralization of the substrate. Block Copolymer deposition. Thermal treatment for self-assembling. Remotion of PMMA Acquisition of images by SEM Block Copolymer Random Copolymer SiO2 Si