Civil Works Specification - Construction for road and drainage works

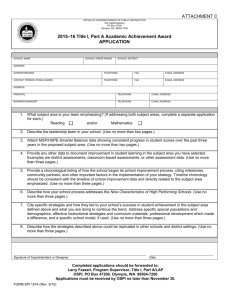

advertisement